Aliphatic polyester resin composition

A technology of polyester resin and aliphatic polyester is applied to an aliphatic polyester resin composition with excellent flexibility and high heat resistance, and the field of aliphatic polyester resin composition can solve the problem of low crystallization rate. , for a long time, it is difficult to make molded products with flexibility and heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

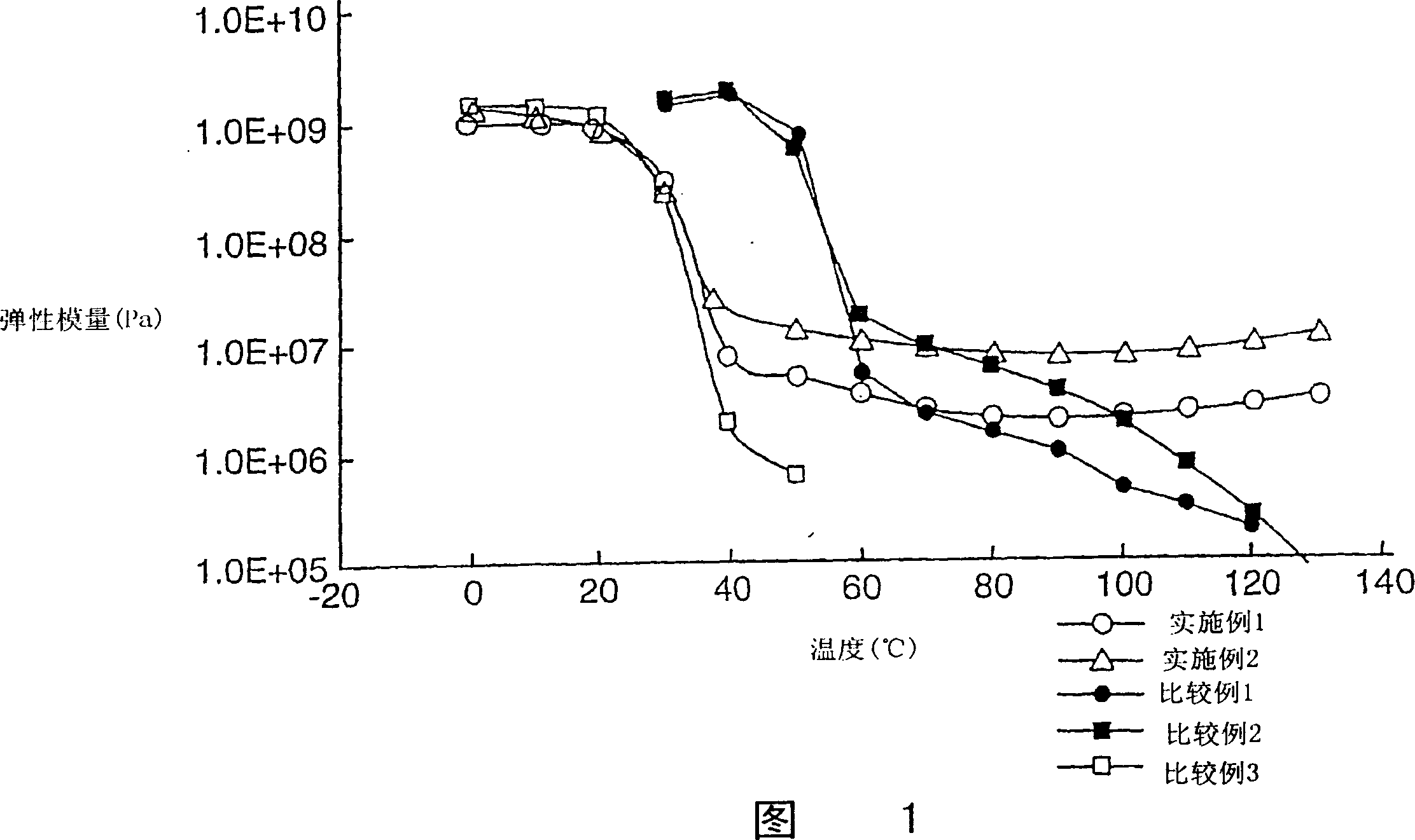

Embodiment 1

[0052] To 100 parts by weight of polylactic acid (LACTY9800, manufactured by Shimadzu Corp.) with a weight average molecular weight of 120,000 was added 30 parts by weight of polyethylene glycol with a weight average molecular weight of 200, and the mixture was heated at 150° C. at 30 rpm using a Brabender mixer. Knead. To 100 parts by weight of this mixed resin was added 20 parts by weight of hydrophilic amorphous silica particles ("AEROSIL 200", with an average primary particle diameter of 12 nm, manufactured by Japan Aerosil Ltd.), and the mixture was kneaded again. The composition thus obtained was formed into a film at 150°C, the elastic modulus was measured, and the temperature dependence of the elastic modulus was measured. Using Rheometric RSAII (manufactured by RheometricScience Inc.), the elastic modulus was measured in the tension mode at a frequency of 1 Hz in the range of -50°C to 130°C.

Embodiment 2

[0054] The composition was prepared and the modulus of elasticity was measured according to Example 1, but the amount of the hydrophilic amorphous silica particles was changed to 40 parts by weight.

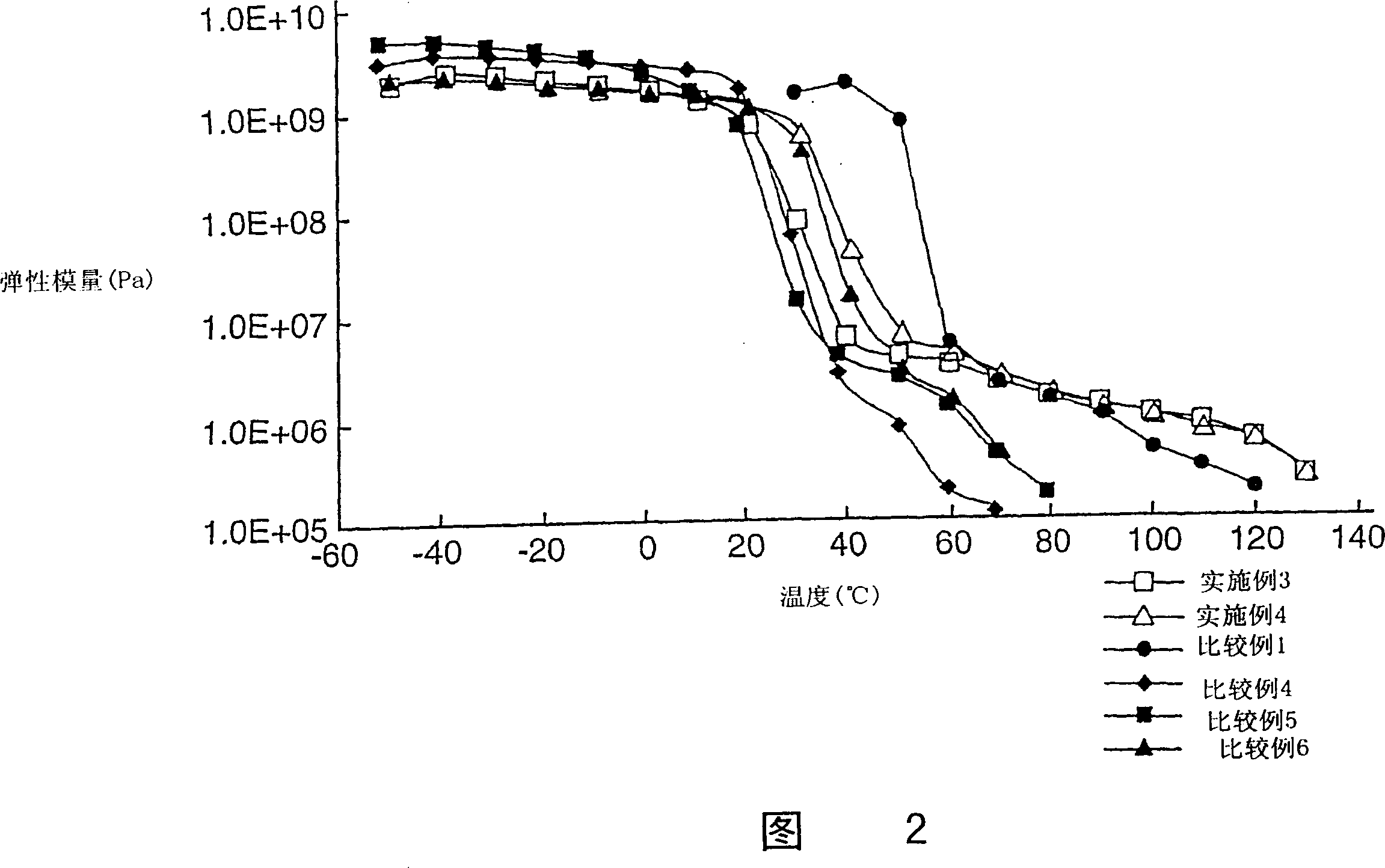

Embodiment 3

[0063] The composition was prepared according to Example 1, formed into a film, and the elastic modulus was measured, but the polyethylene glycol with a weight average molecular weight of 200 was changed to polyethylene glycol with a weight average molecular weight of 1000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com