Stator structure for reciprocating motor

A technology of stator structure and reciprocating motion, applied in the field of mechanical engineering, can solve the problems of general products without structure, and achieve the effects of reducing manufacturing costs, preventing channel blockage, and preventing abnormal compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation, structure, features and functions of the stator structure of the reciprocating motor according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

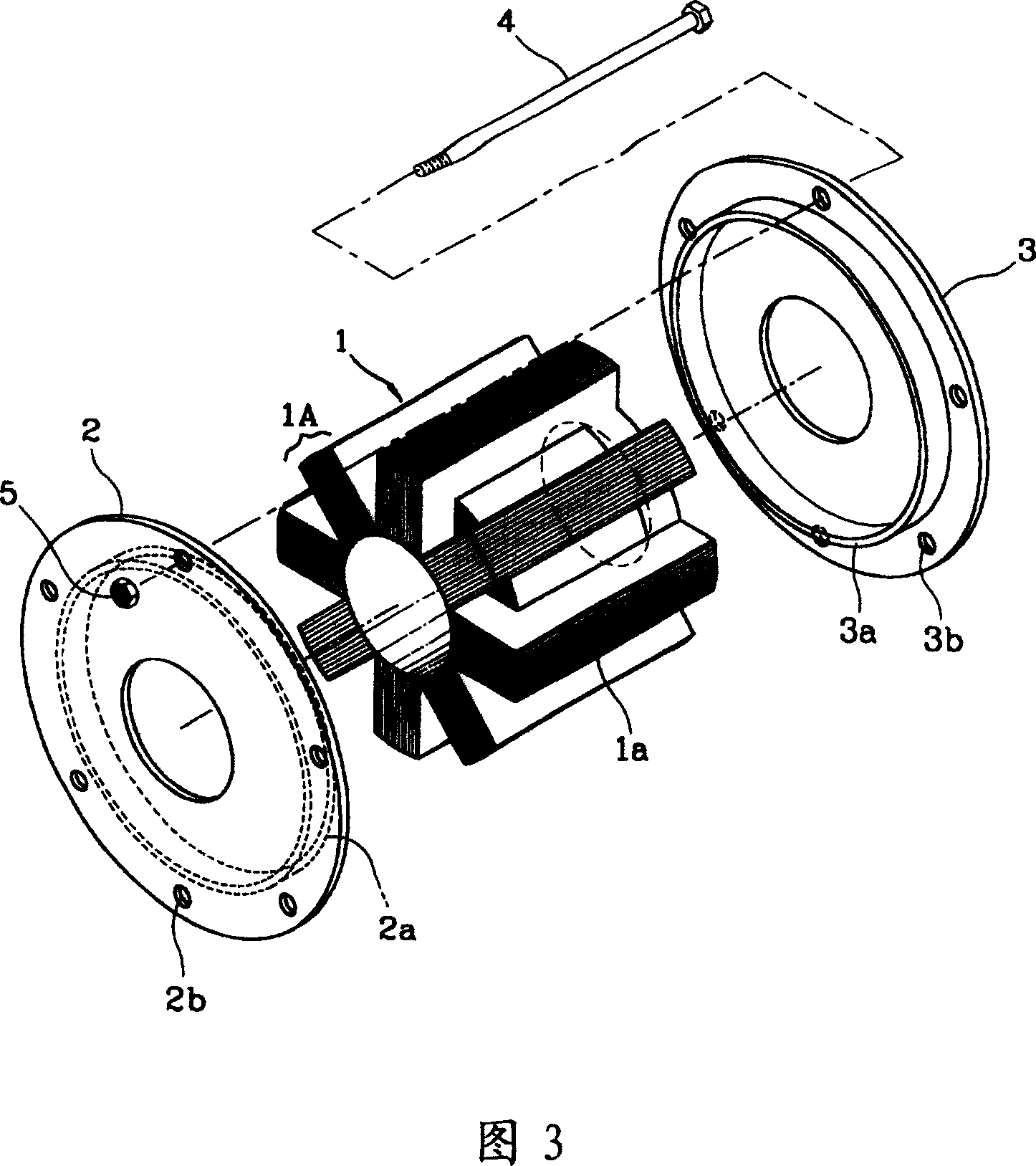

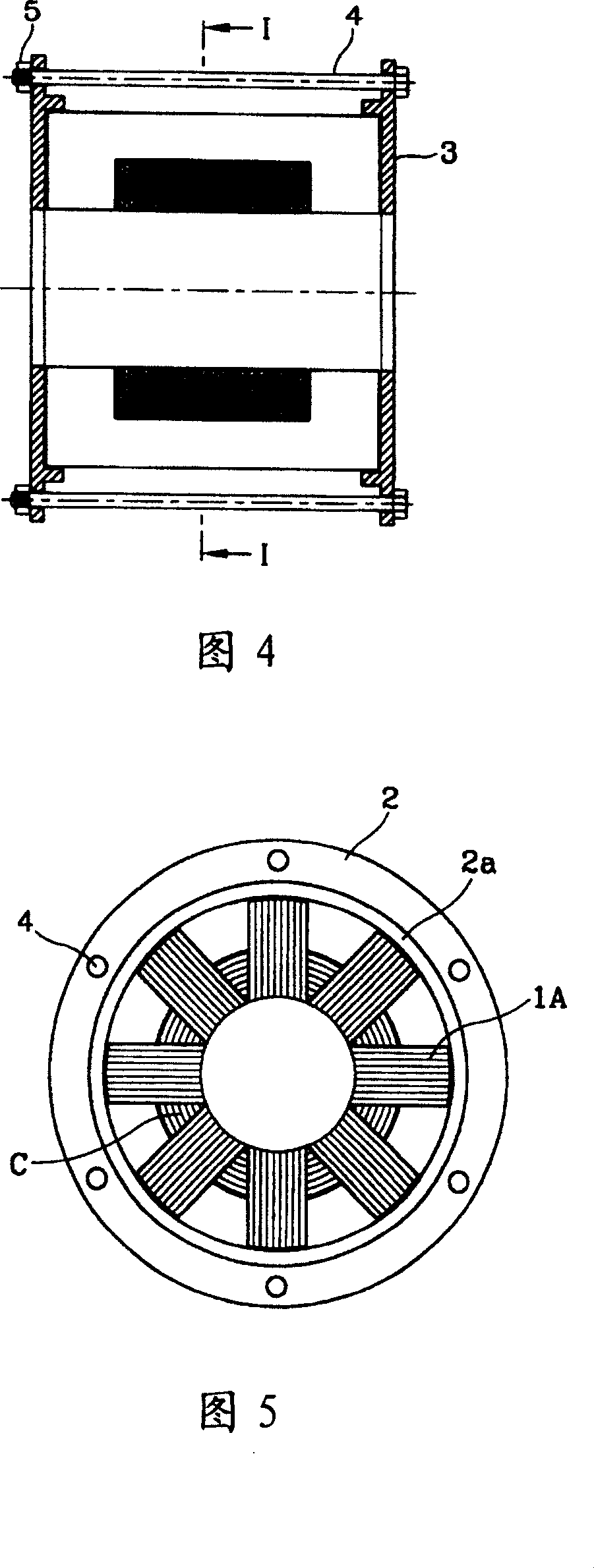

[0047] Please refer to Fig. 3, Fig. 4, shown in Fig. 5, Fig. 3 is the schematic diagram of the outer stator on the reciprocating motor of the present invention, Fig. 4 is the sectional view of the outer stator on the reciprocating motor of the present invention, shown in Fig. 5 It is a sectional view along line "I-I" in Fig. 4 .

[0048] Please refer to shown in Fig. 3, according to the outer stator of the reciprocating motor proposed by the present invention, it comprises: several stator iron cores 1a layer upon layer put into the stator core group 1A of substantially regular hexahedron shape, this stator core group 1A A laminated body 1 stacked radially in a cylindrical shape, several plates 2, 3 supporting it on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com