System and method for steam turbine backpressure control using dynamic pressure sensors

A technology of steam turbine and control system, which is applied in the direction of steam engine device, engine components, starting of engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following detailed description uses examples to explain the present invention, but these examples do not limit the present invention. This description clearly enables one skilled in the art to make and use the invention, and it describes several embodiments of the invention, several improvements, variations, substitutions and uses, including the invention of the best mode for carrying out the invention.

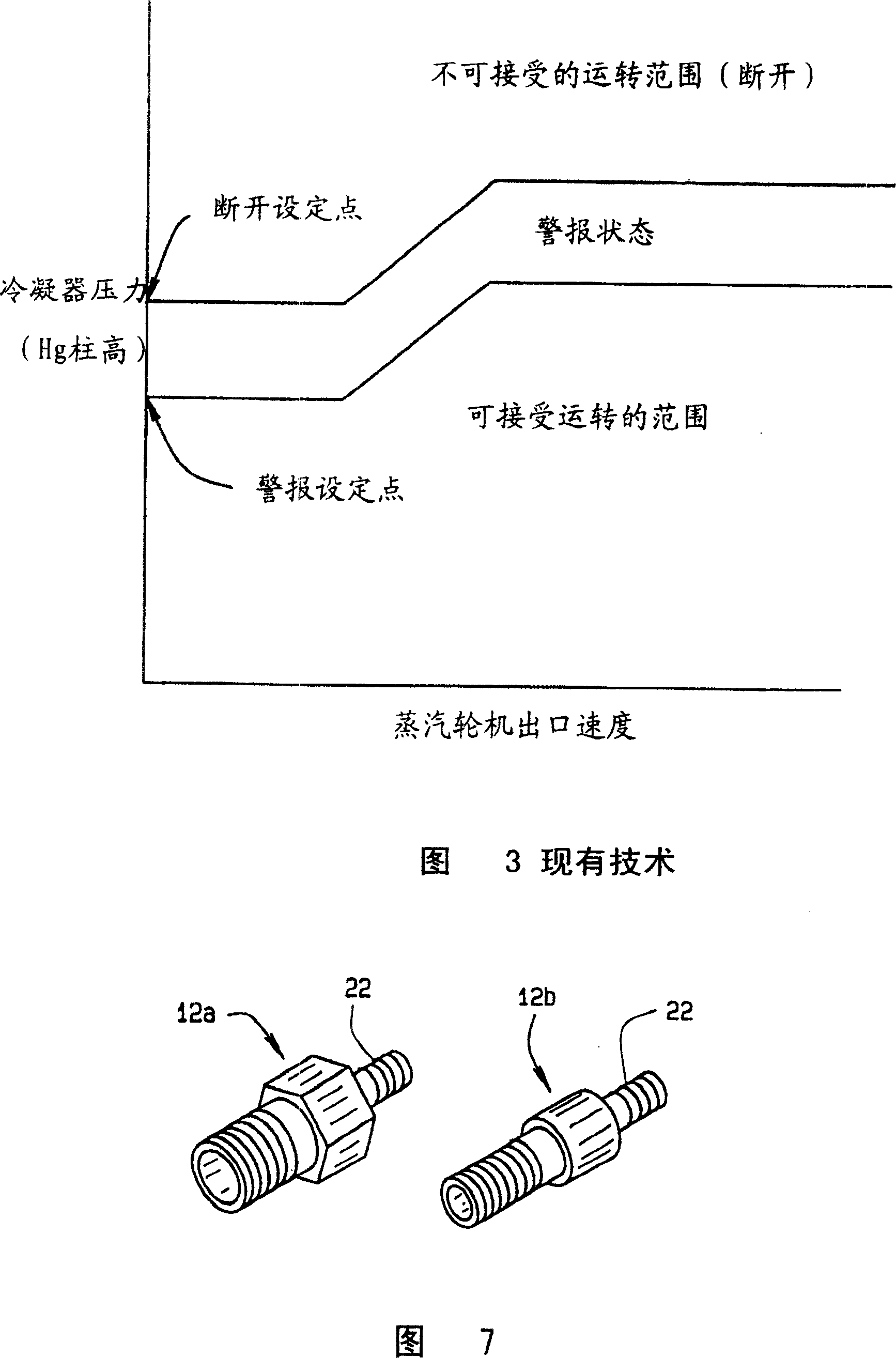

[0021] According to the present invention and as shown in FIG. 4 , the steam turbine control system of the present invention is indicated by reference numeral 10 . According to the invention, one or more dynamic pressure sensors or probes 12 are positioned around the periphery of the blades B comprising the last stage Sn of the turbine T. Such as indicated at 12a and 12b of Figure 7, the sensor detects the pressure value or magnitude in this region of the turbine during operation of the turbine. Because the sensors are dynamic pressure sensors, they detect instabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com