Low temp air separation system adopting integrated pressurizing compression and multiple group sub-refrigerating compression

A low-temperature air separation, booster compressor technology, applied to the compression of fluids. field, which can solve the problems of expensive compressor installation, maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

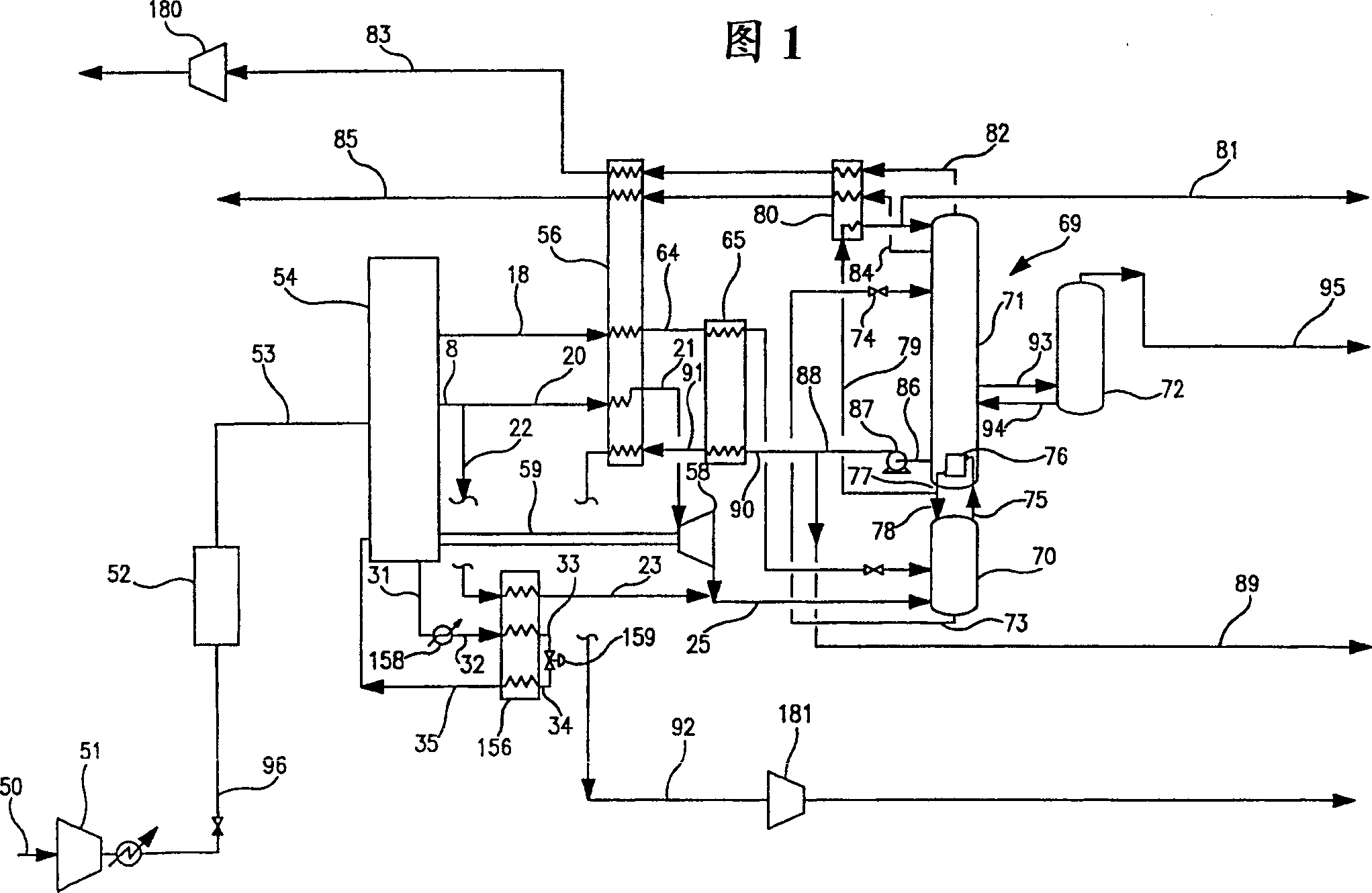

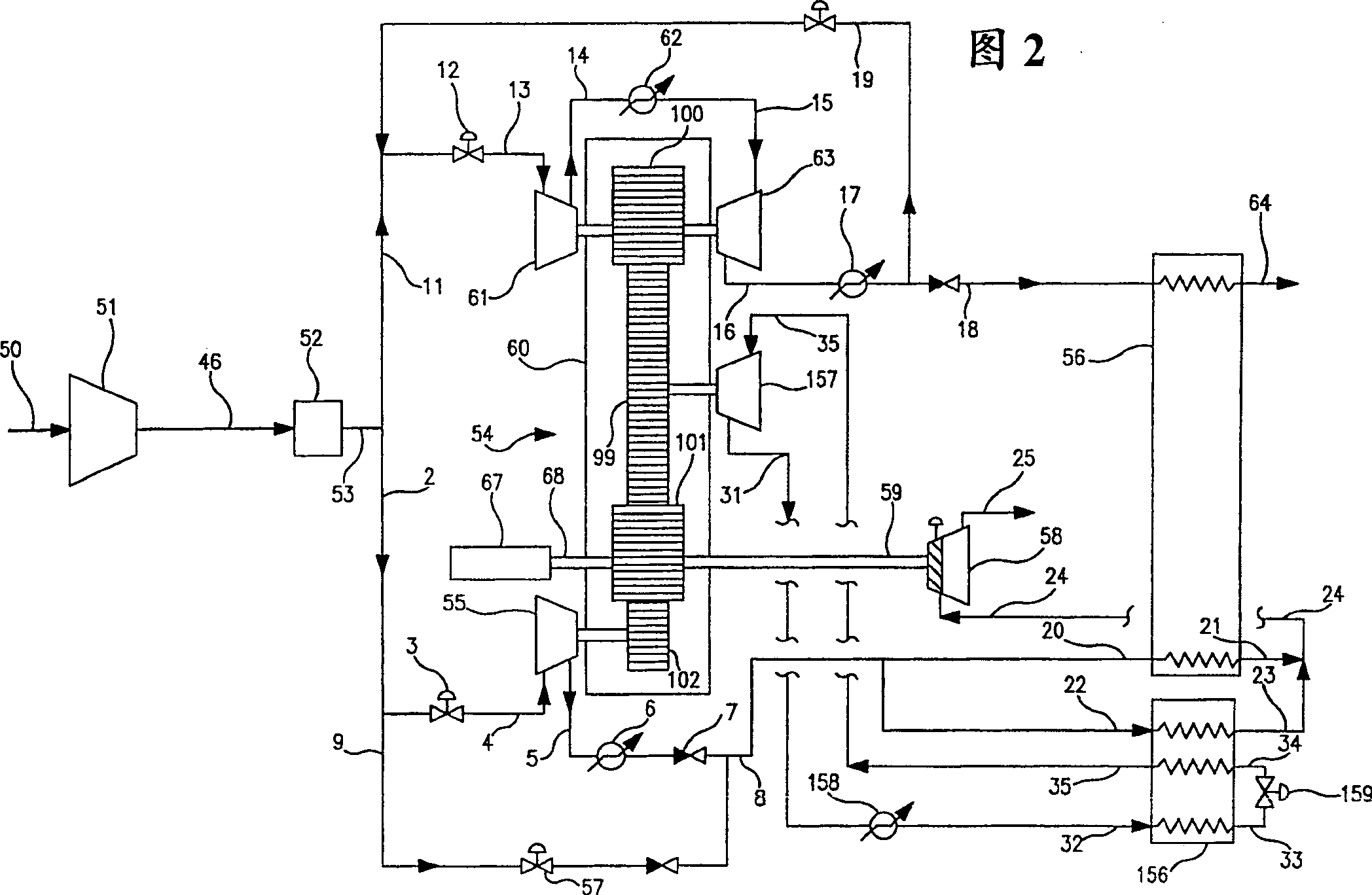

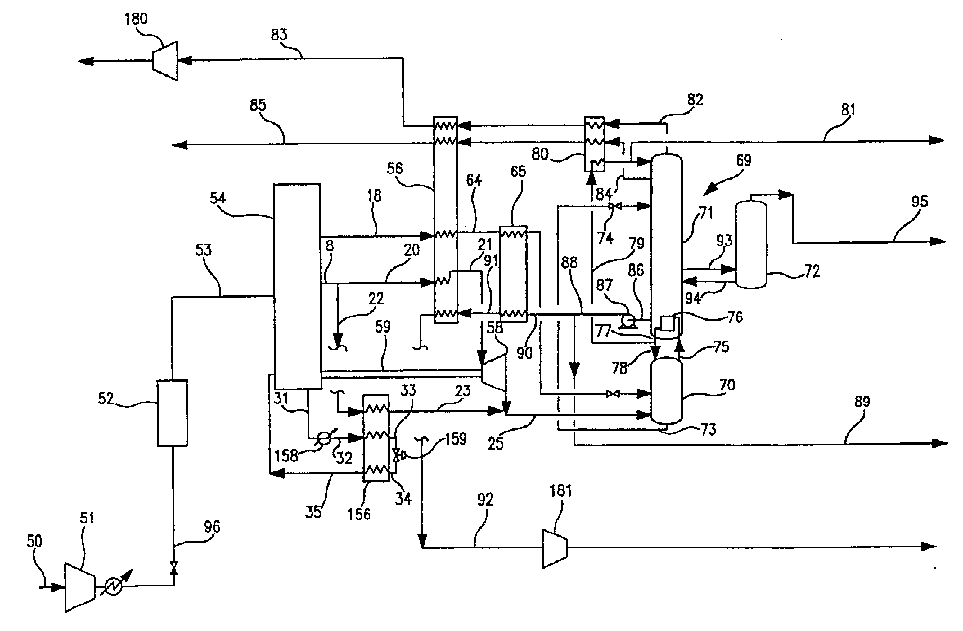

[0043] The present invention will be described in detail with reference to the accompanying drawings. Referring now to Figures 1 and 2, the feed air provided to the cryogenic air separation plant, represented by feed air stream 50, is passed into a base load air compressor 51 wherein the air stream is compressed to a base load pressure (absolute pressure Typically in the range of 80-110 pounds per square inch (psia)). The base load pressure provides sufficient energy to the cryogenic air separation plant to separate the feed air into one or more of the product oxygen, product nitrogen and product argon, and obtain a nominal pressure gaseous product and a nominal amount of liquid product (usually about 2% of the feed air). Then the feed air 96 of the base load pressure is passed through the pre-purifier 52 to remove various high-boiling impurities (such as water vapor, carbon dioxide and hydrocarbons), and then the feed air 53 of the clean base load pressure is provided to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com