Method for producing electric circuit device

A technology of circuit device and manufacturing method, applied in the direction of printed circuit manufacturing, circuit, printed circuit, etc., can solve the problems of lack of flatness, inability to use metal mold molding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

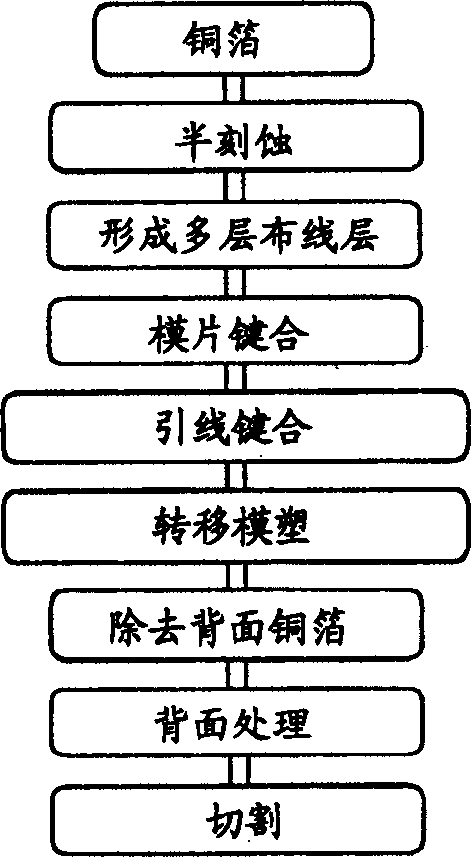

[0052] First, while referring to figure 1 , while explaining the manufacturing method of the circuit device of the present invention.

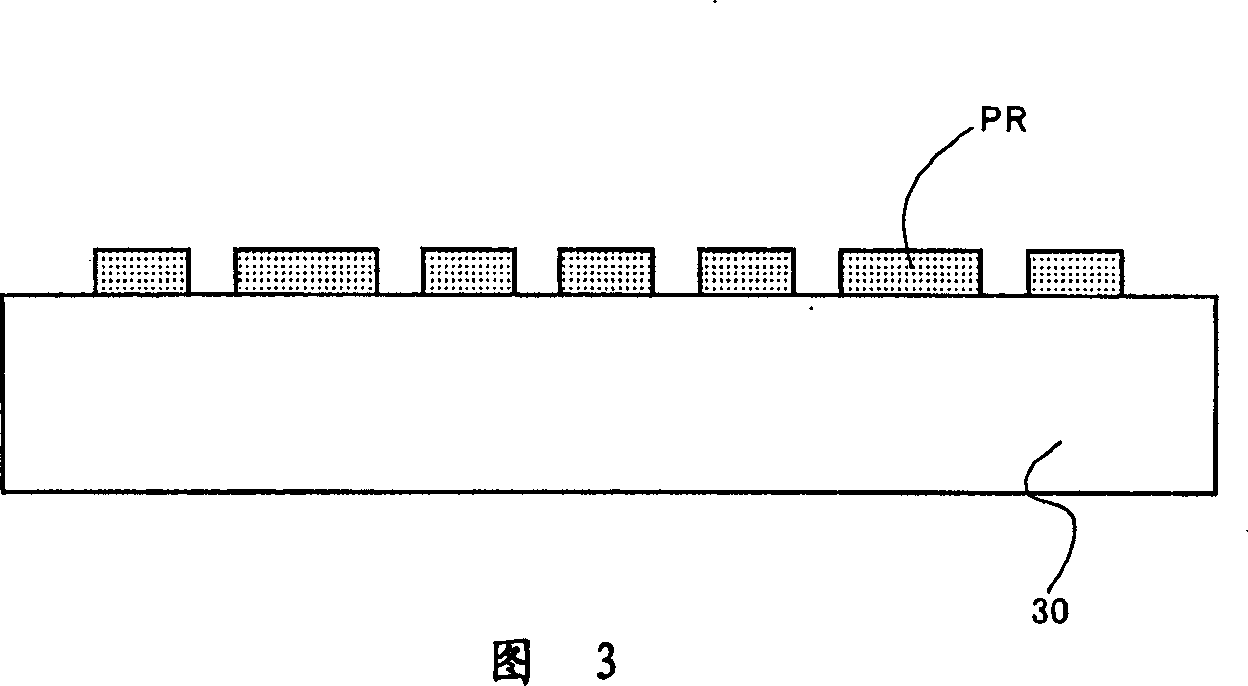

[0053] The present invention consists of the following steps: preparing a conductive foil, forming a separation groove shallower than the thickness of the conductive foil on the above-mentioned conductive foil in a region other than the first-layer conductive pattern to form a first-layer conductive pattern; The process of forming a multilayer conductive pattern through an interlayer insulating film on the first layer of conductive pattern; the process of assembling circuit components on the desired conductive pattern; covering the above circuit components with insulating resin and molding the whole Steps; a step of removing the conductive foil in the thickness portion where the separation groove is not provided; and a step of separating the insulating resin into the individual circuit elements by dicing.

[0054] figure 1 The flow shown i...

no. 2 Embodiment

[0091] First, while referring to Figure 11 , while explaining the manufacturing method of the circuit device of the present invention.

[0092] The present invention consists of the following steps: a step of preparing a conductive foil and forming a multilayer conductive pattern through an interlayer insulating film; a step of assembling a circuit element on the desired conductive pattern; covering the above-mentioned circuit element with an insulating resin, a step of molding the whole; a step of removing the conductive foil; and a step of separating the insulating resin into individual circuit devices including the respective circuit elements by dicing.

[0093] Figure 11 The flow shown in is different from the above-mentioned steps, but the conductive foil supporting the multilayer wiring layer formed thereon is prepared in two flows of Cu foil and Ag plating. A multilayer conductive pattern is formed on the conductive foil in the process of forming the multilayer wiri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com