Fabric component detecting ultraviolet laser method

A UV laser and fabric technology, applied in the measurement of color/spectral properties, material inspection products, textile testing, etc., can solve problems such as inability to distinguish between chemical fiber fabrics and blended fabrics, damage to finished fabrics, and inability to judge the percentage of cotton and chemical fibers. To achieve the effect of accurate judgment and intuitive phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

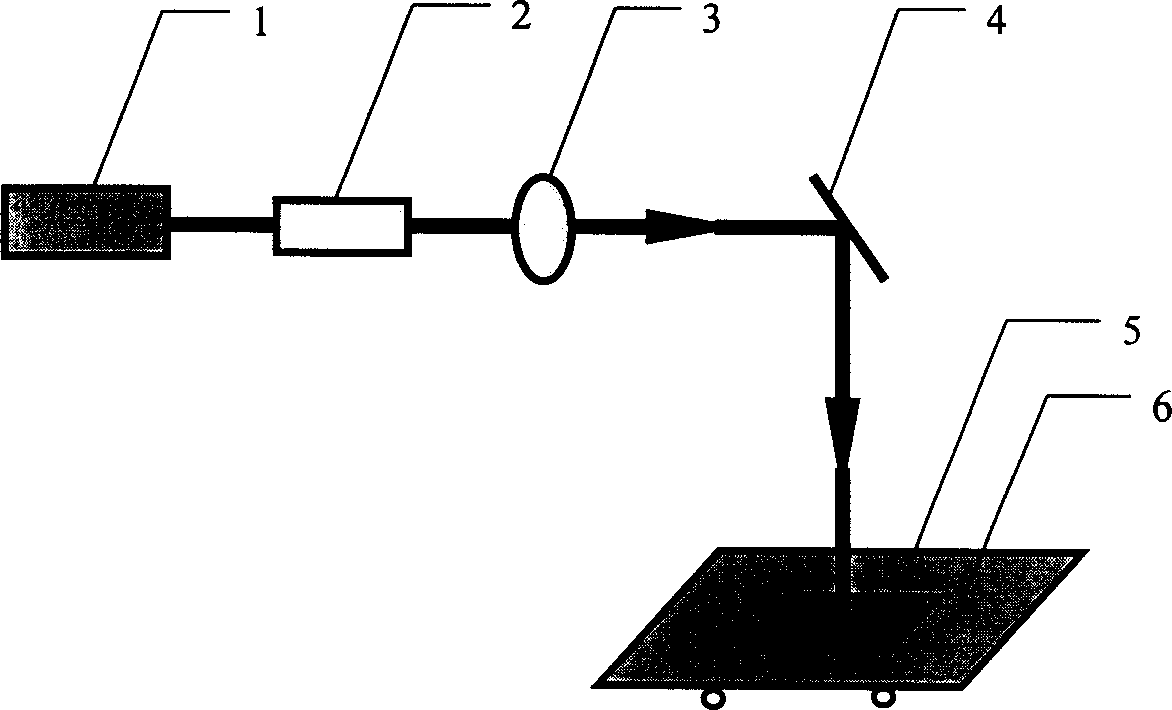

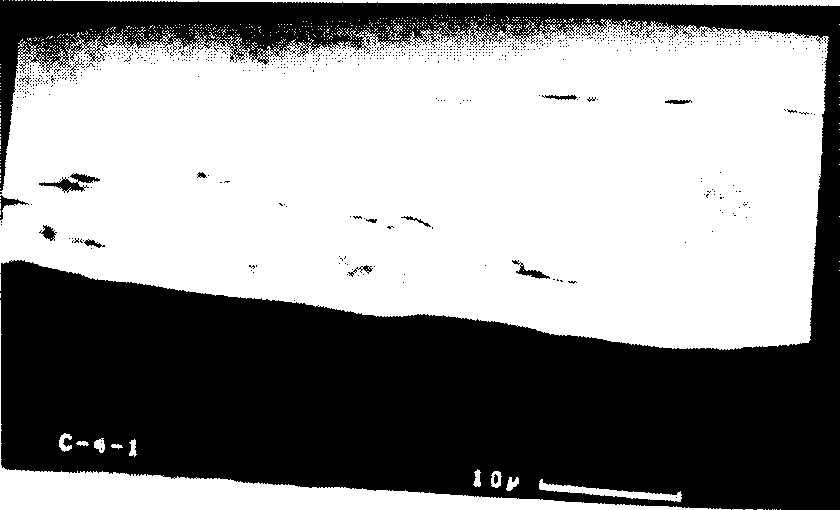

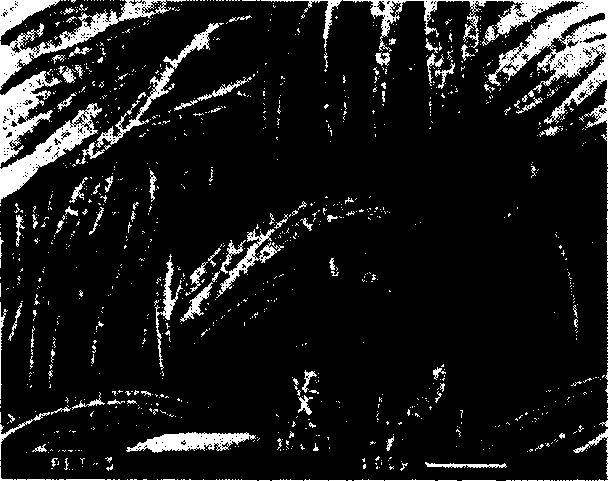

[0014] As above-mentioned method and specific steps of the present invention, the processing device of the ultraviolet laser that adopts is as figure 1 shown. The ultraviolet laser is an excimer laser 1, and the laser beam emitted by the excimer laser 1 passes through a tunable attenuator 2 and a lens 3 on the same horizontal axis as the excimer laser 1, and through a reflection placed at an angle of 45° to the horizontal line The mirror 4 irradiates onto the two-dimensional platform 5 placed horizontally directly under the mirror 4 , and the fabric 6 to be tested is placed flat on the platform 5 . The laser energy output by the excimer laser 1 is controlled by the tunable attenuator 2 , focused by the lens 3 , and then reflected by the mirror 4 to the surface of the fabric 6 to be tested placed on the two-dimensional platform 5 . After the fabric to be tested is treated, it is observed and photographed under an electron microscope, and a micrograph of the fabric to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com