A battery, process for producing battery, process for producing battery case and battery pack

A technology for battery packs and casings, which is applied in the direction of primary batteries to battery packs, battery pack components, dry batteries, etc., which can solve problems such as poor sealing, achieve improved sealing, increase productivity, and avoid strain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

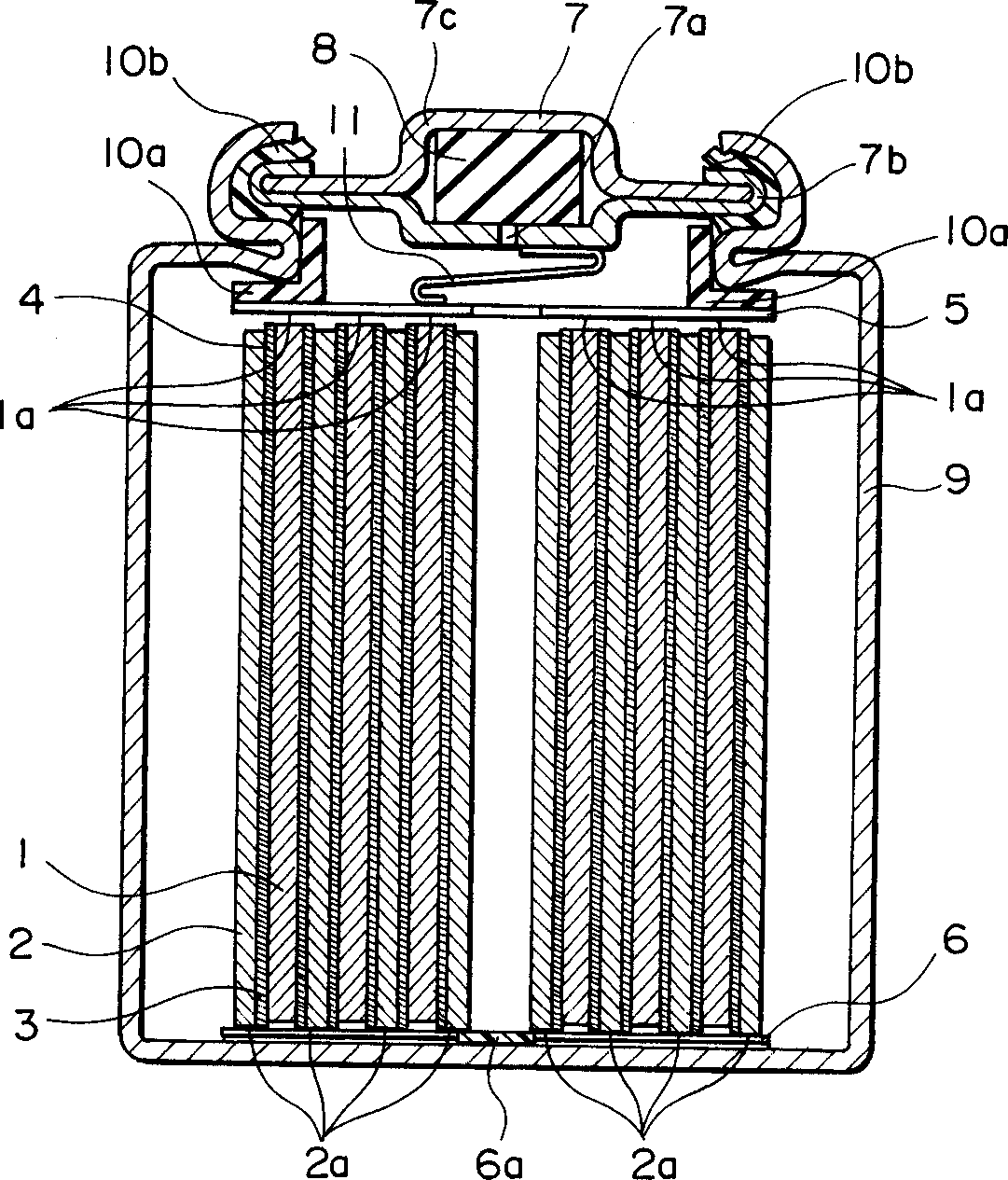

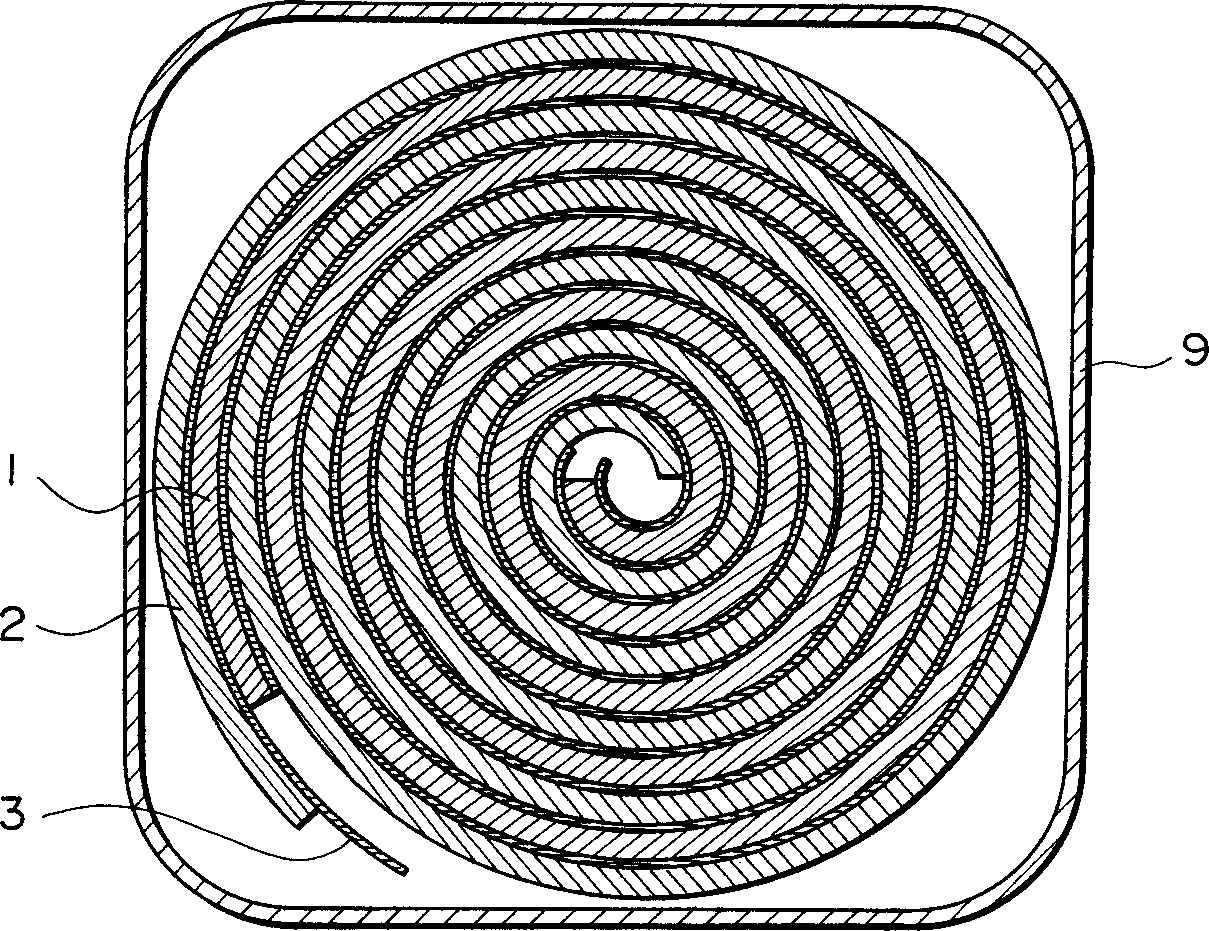

[0049] The electrical unit 4 is constructed by inserting a separator 3 between the strip-shaped positive electrode 1 and the strip-shaped negative electrode 2 and spirally winding the upwardly protruding end surface 1a of the positive electrode 1 and the downwardly protruding end surface 2a of the negative electrode 2.

[0050] The upper current collector 5 with a hole in the center is welded to the end face 1a of the positive electrode 1 of the electric unit 4 by resistance welding, and the lower current collector 6 with the tongue 6a is welded to the end face 2a of the negative electrode 2 by resistance welding.

[0051] The sealing plate 7 is constructed by arranging a filter 7b having a valve port 7a and a rubber valve body 8, and placing a cap end 7c thereon, and then welding the filter 7b and the cap end 7c by resistance welding.

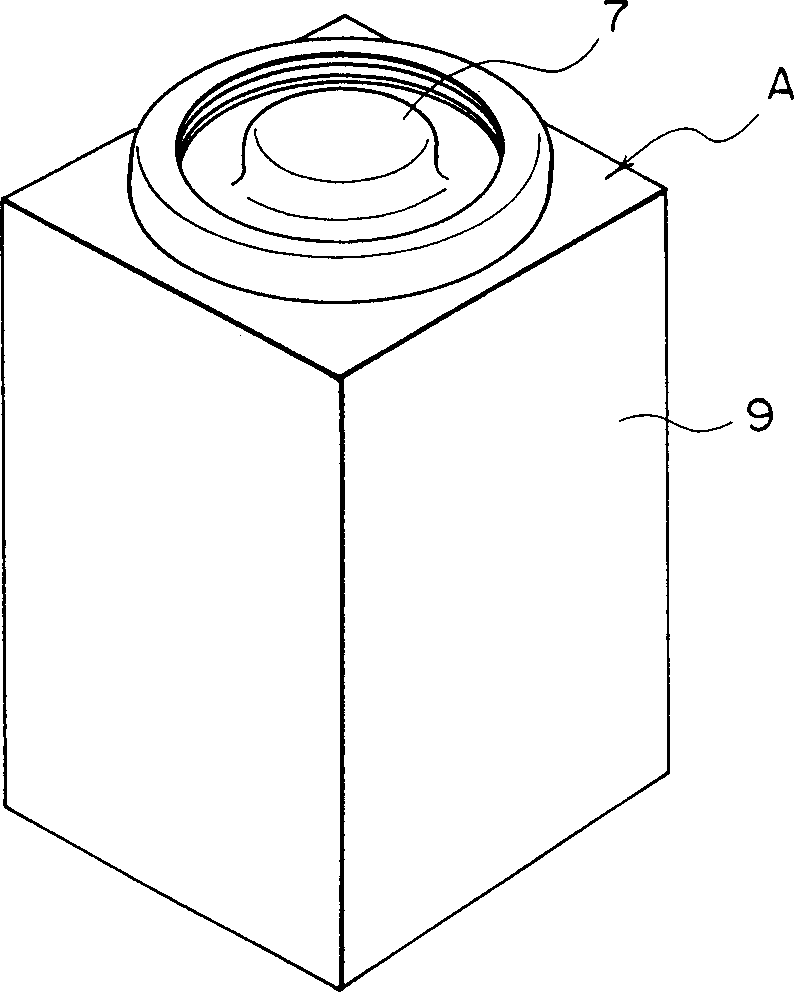

[0052] The metal battery casing 9 is made as follows: rotate the square barrel-shaped casing while pushing it from bottom to top; place its openi...

example 2

[0060] In Example 1, the described example is to insert the electrical unit only when the shape of the upper part of the battery has been formed. In this example, the battery production steps that will be described are to first insert the electrical unit and then refer to Figure 5 The schematic diagram shown forms a shell shape. In the following description, some of the reference numbers used are in Figure 5 Not shown in.

[0061] Reference Figure 5 . The electrical unit 4 is constructed by inserting a separator 3 between the strip-shaped positive electrode 1 and the strip-shaped negative electrode 2 and spirally winding the end surface of the positive electrode 1 projecting upward and the end surface of the negative electrode 2 projecting downward. The end face 1a of the positive electrode 1 of the electric unit 4 constructed as described above is welded to the upper current collector 5 having a hole in the center and the conductive sheet 11 by resistance welding. The lower cu...

example 3

[0066] Battery C was fabricated in the same manner as in Example 2, but using a hexagonal barrel-shaped casing. Figure 6 A perspective view of battery C is shown. Figure 7 A plan view of a battery pack for a power tool constructed by tightly assembling batteries C is shown. As a comparative example, a battery pack using the cylindrical battery B of the above comparative example is also Figure 7 Shown in.

[0067] It can be seen that the space utilization rate in the battery pack using the battery of the present invention is higher than that in the battery pack using the comparative example battery B, where the upper part of the battery of the present invention is circular and the lower part is hexagonal. In addition, The battery of the present invention thus makes it possible to use the space in the battery pack with higher efficiency. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com