Automatic sintered material controlling method

An automatic determination and automatic detection technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of large particle changes, unstable operation, and large changes in time parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

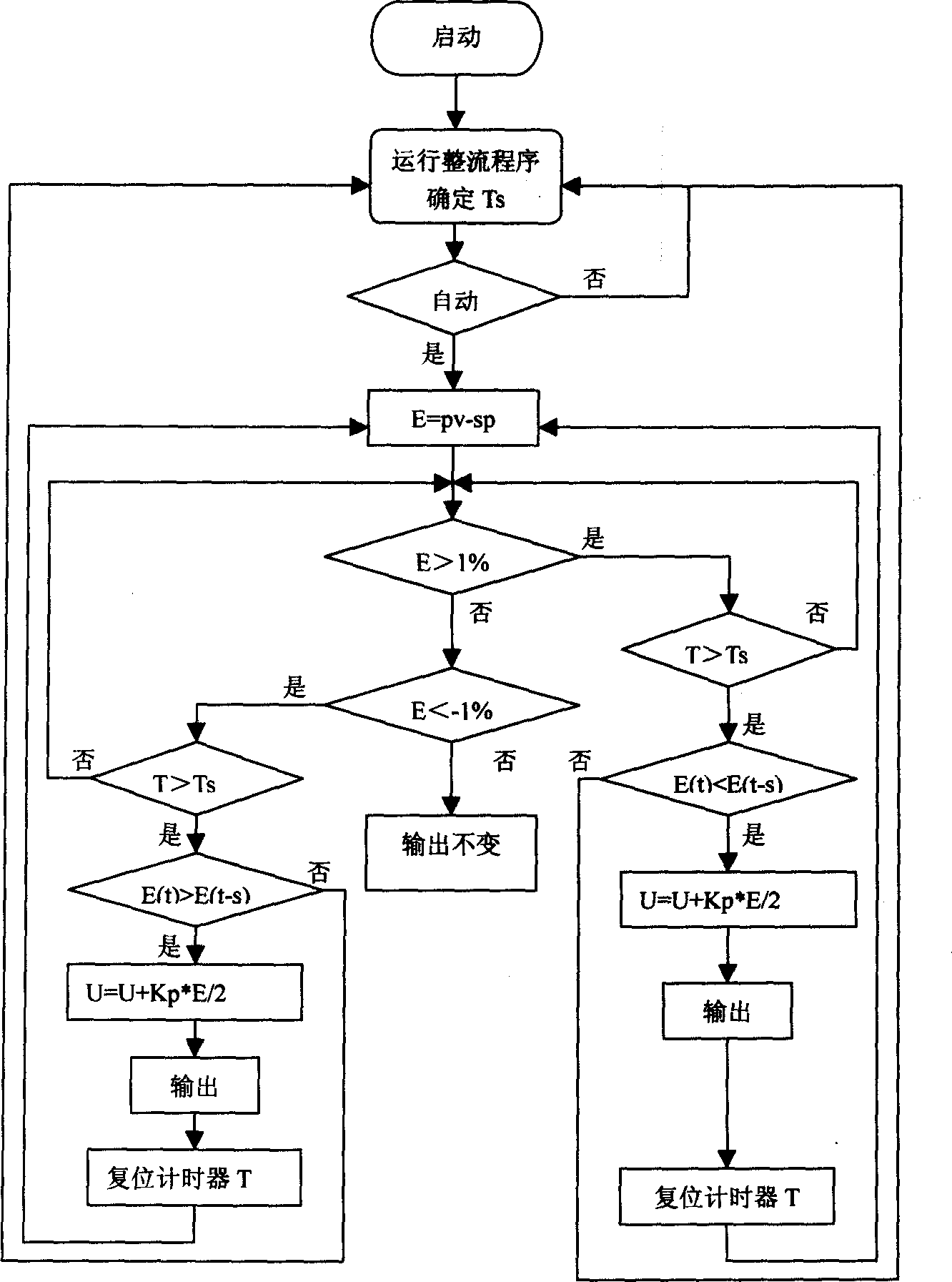

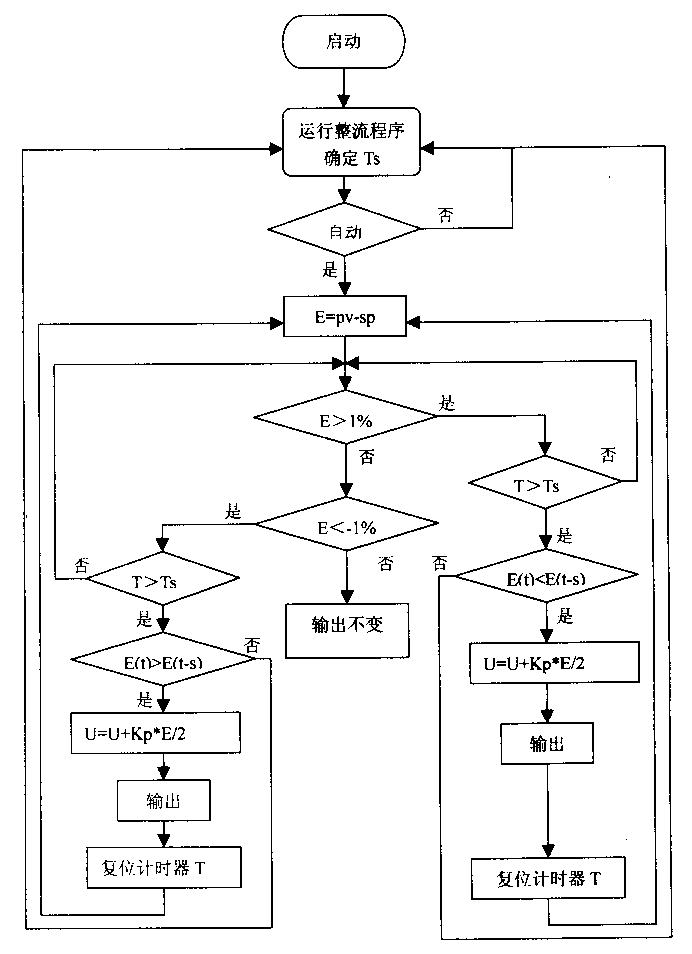

[0015] As shown in the figure, the automatic control method of sintering ingredients,

[0016] 1) After the system is started, it automatically detects the parameter change period of the object under constant excitation or the time period when it reaches stability, runs the rectification program to automatically rectify the process value, and calculates the control output period Ts;

[0017] 2) After automatic input, according to the deviation value E between the process value pv and the system value sp within the control area, if it is less than or equal to the preset positive deviation +1%, and greater than or equal to the preset negative deviation -1%, the control output will not be adjusted , the output remains unchanged;

[0018] 3) The deviation value E between the process value pv and the system value sp When the deviation value exceeds the range, the control output of the system is automatically determined according to the approximation method.

[0019] 4) When the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com