Low-torque swivel connector

A technology for connecting connectors and connectors, applied in the directions of circuit/collector parts, connections, connecting end caps, etc., can solve problems such as reducing contact area, increasing resistance, and reducing screw connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

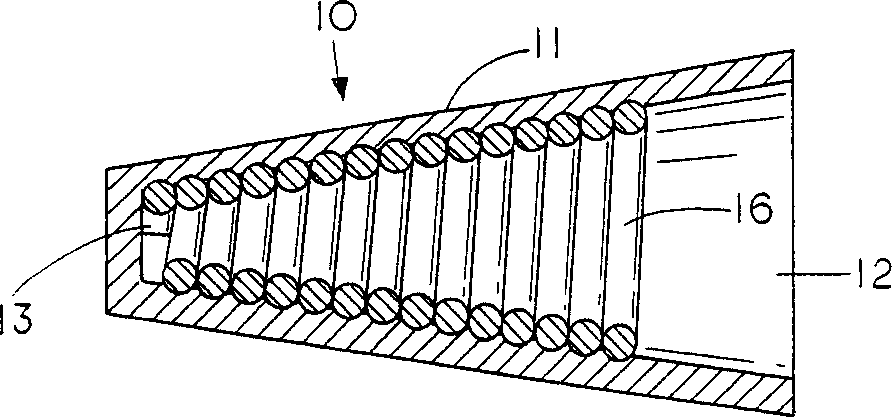

[0017] refer to figure 1 , reference numeral 10 represents an existing rotary connector. The connector 10 includes an electrically insulating housing 11 having an open end 12 and a closed end 13 , wherein the diameter of the open end 12 is greater than the diameter of the closed end 13 . The helical wire 16 extends axially inwardly within the housing 11 . The diameter of the helical wire 16 near the open end 12 of the housing 11 is larger than the diameter of the helical wire 16 near the closed end 13 of the housing 11 so that the wires are squeezed into tight contact with each other when they are threaded into the helical wire. Although this embodiment shows the helical wire as a metal spring, it is conceivable that the helical wire could be integrally formed in the housing of the rotary connector.

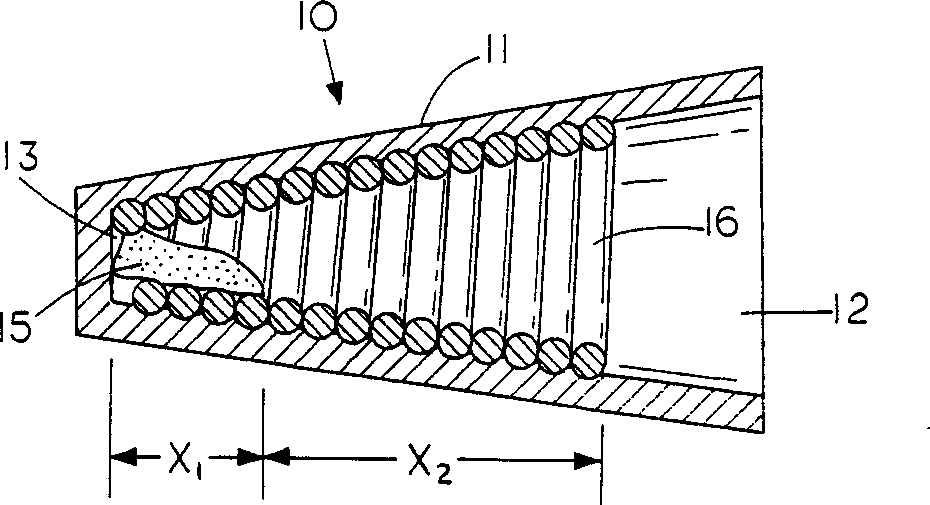

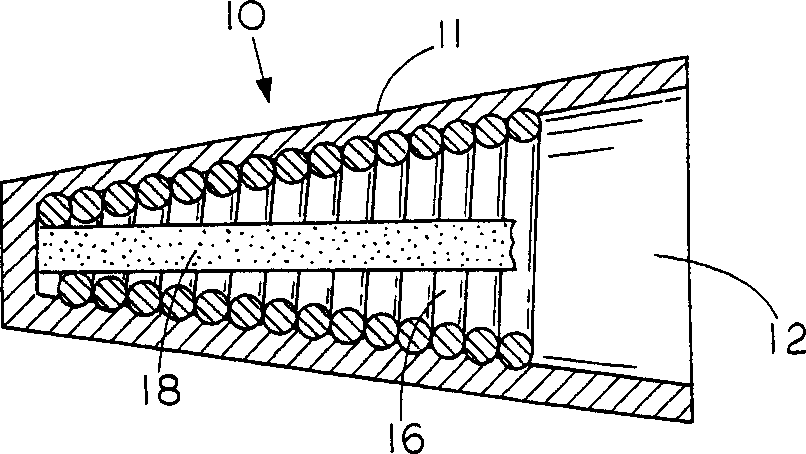

[0018] figure 2 One embodiment of the invention is shown having a self-adhesive lubricant 15 located at the closed end 13 of the connector 10 . The self-adhesive lubricant 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com