Patents

Literature

32 results about "Twist-on wire connector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Twist-on wire connectors are a type of electrical connector used to fasten two or more low-voltage (or extra-low-voltage) electrical conductors. They are widely used in North America in residential, commercial and industrial building power wiring.

Twist-on connector

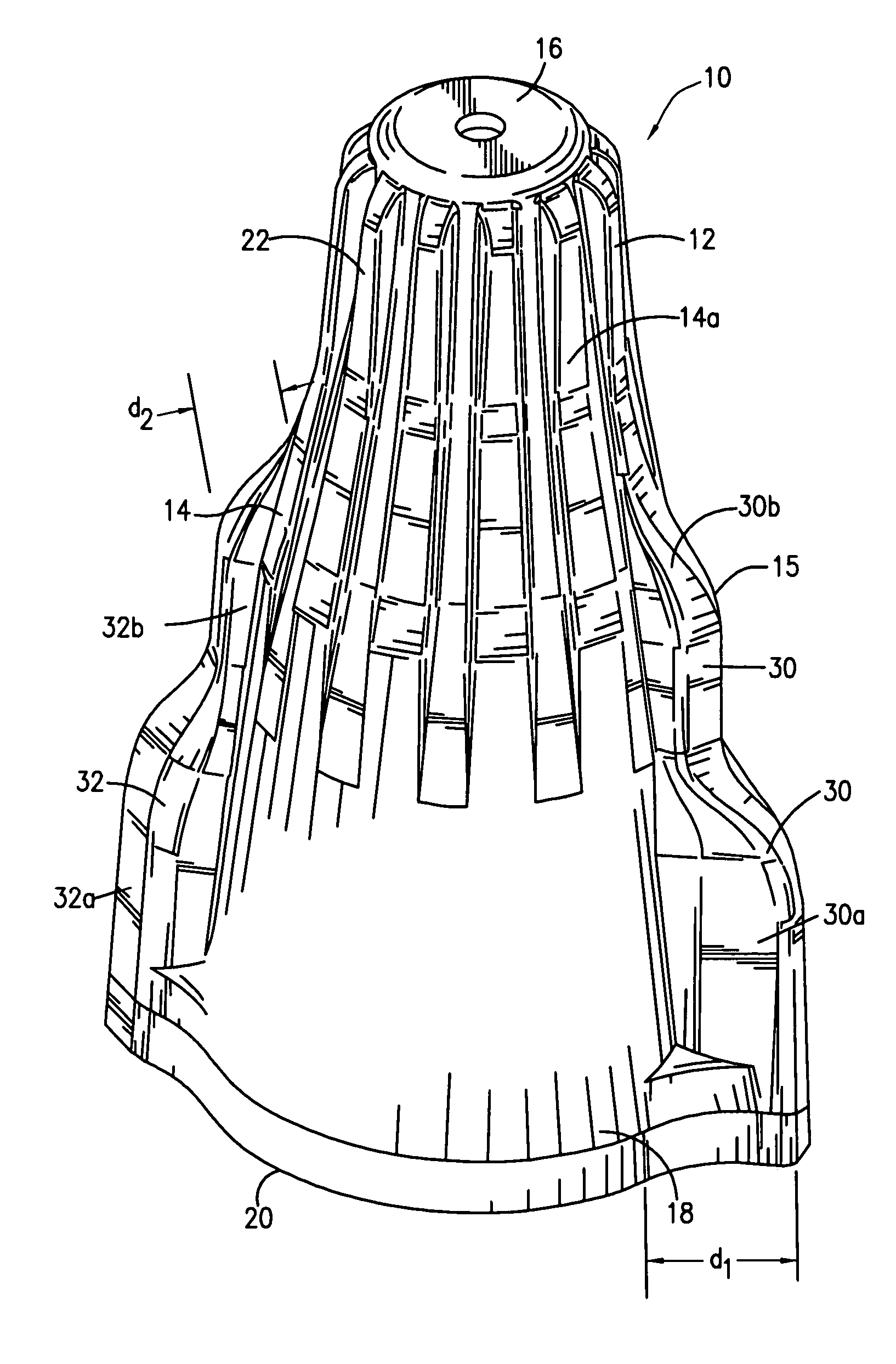

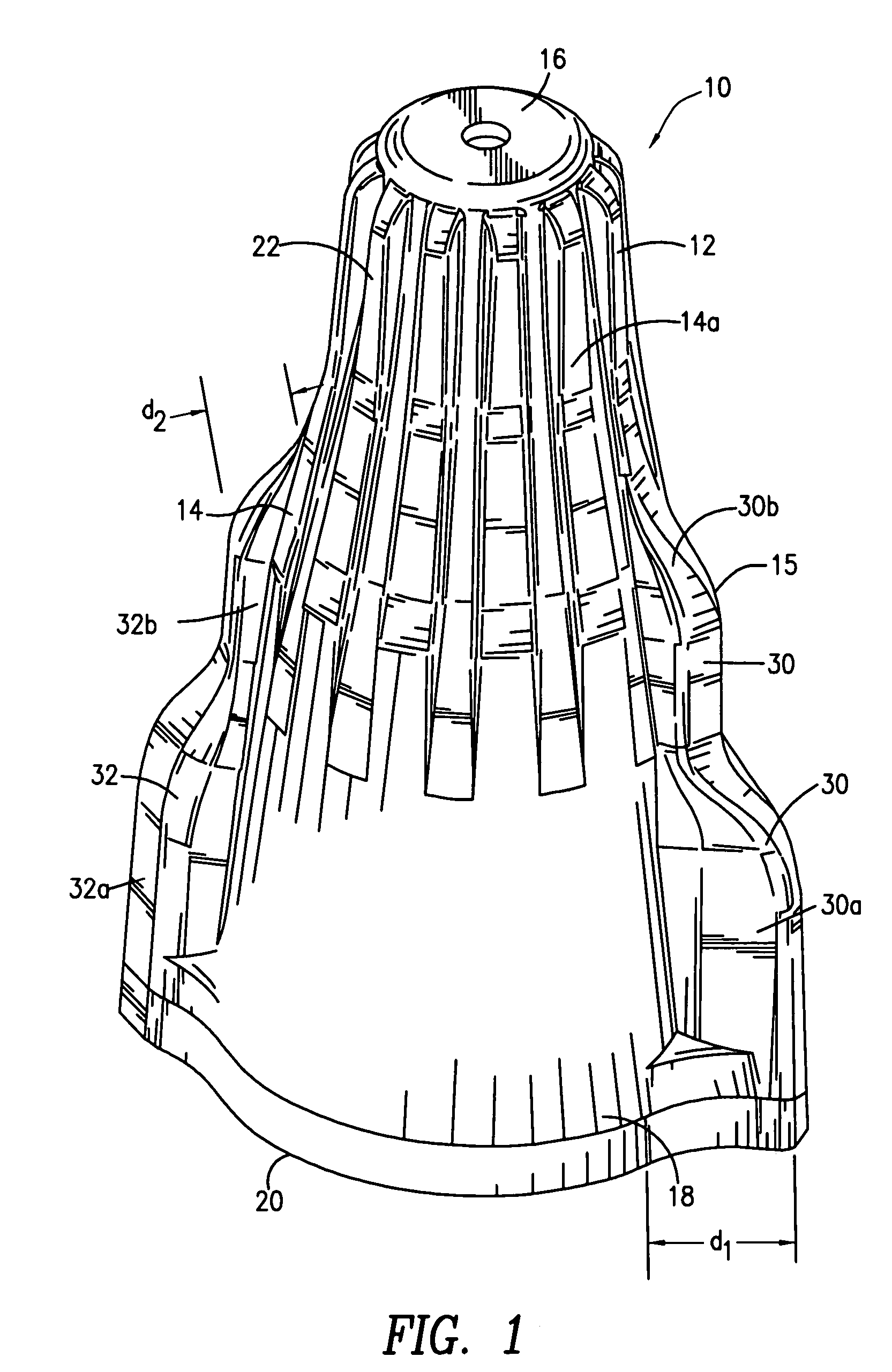

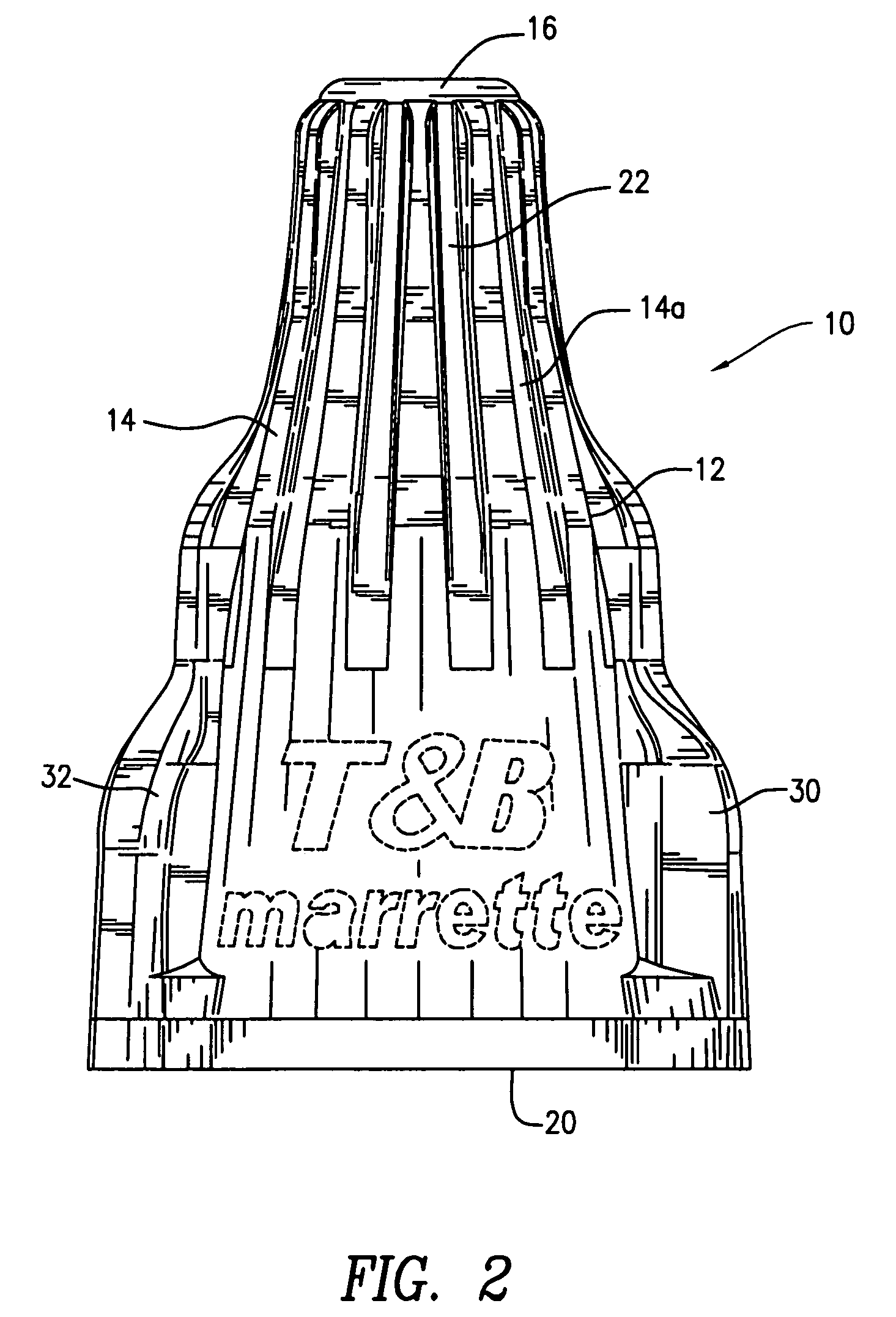

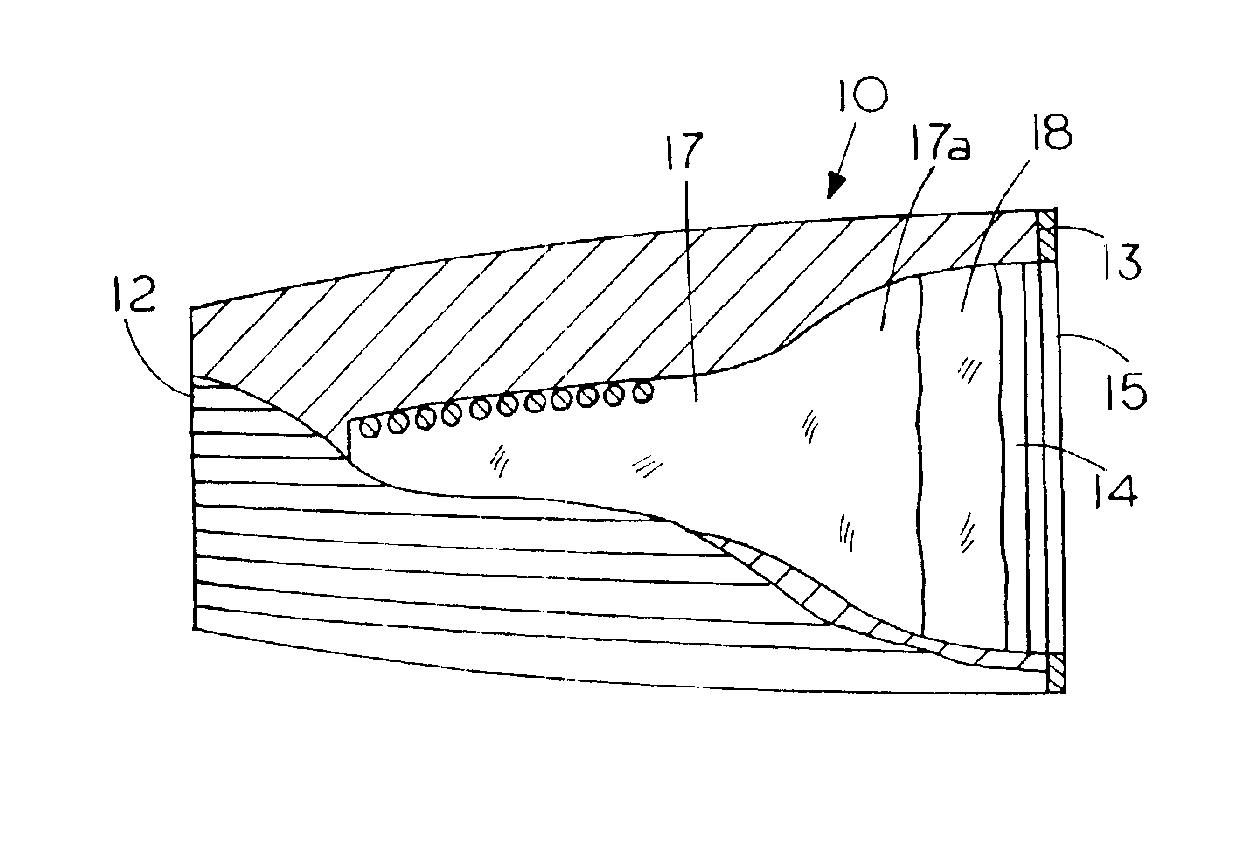

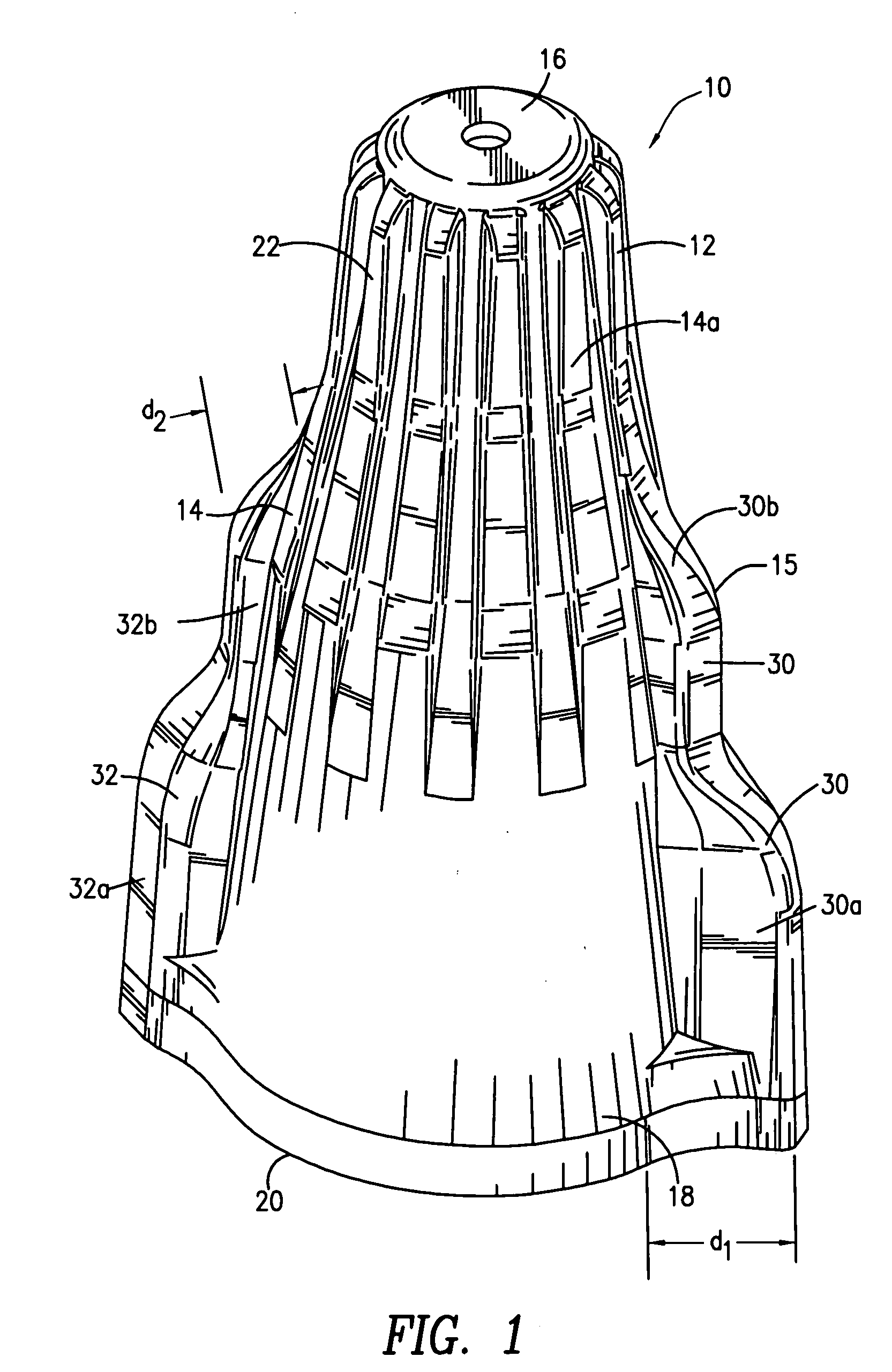

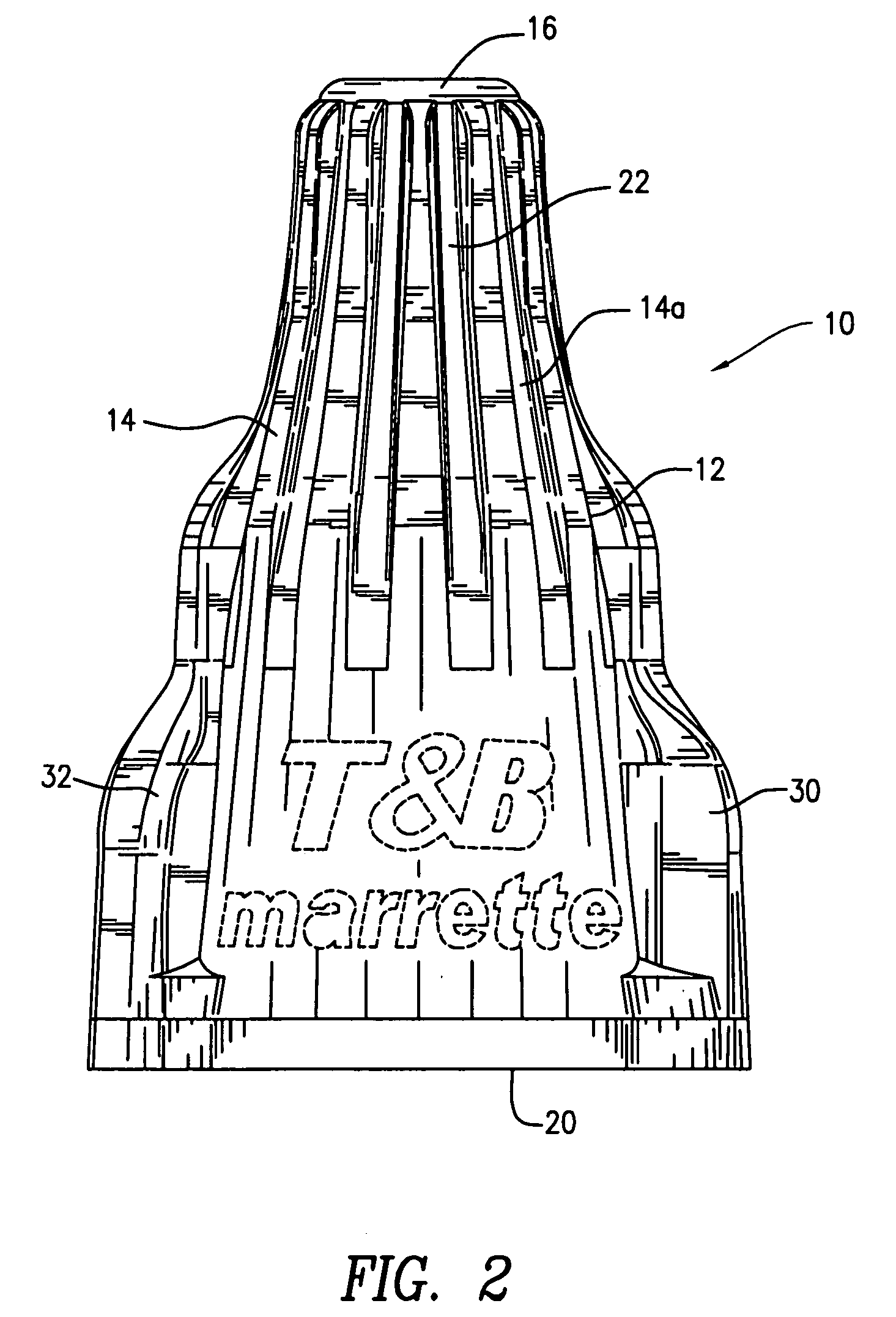

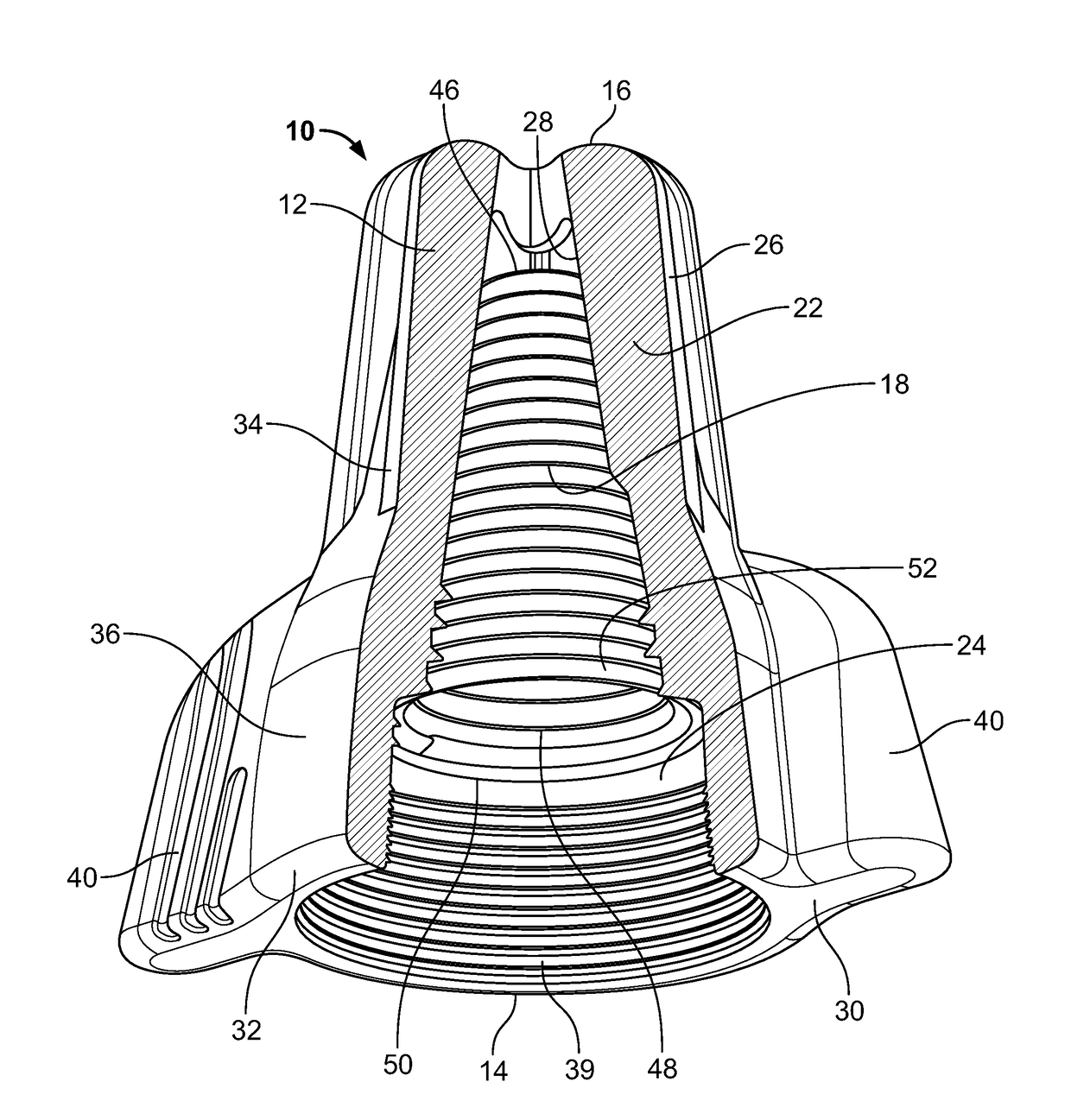

ActiveUS7365270B2Line/current collector detailsConnections effected by permanent deformationElectrical conductorEngineering

Owner:THOMAS & BETTS INT INC

Twist-on wire connector

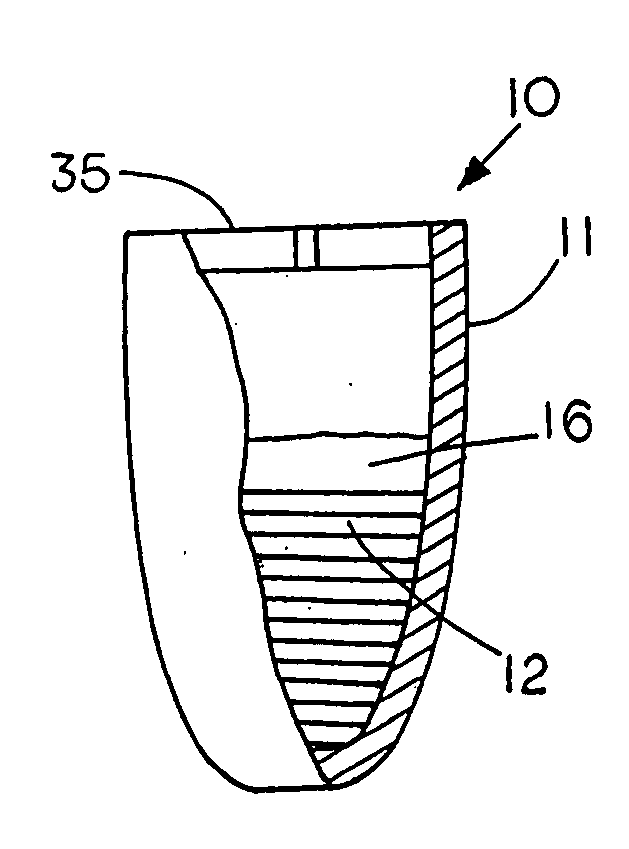

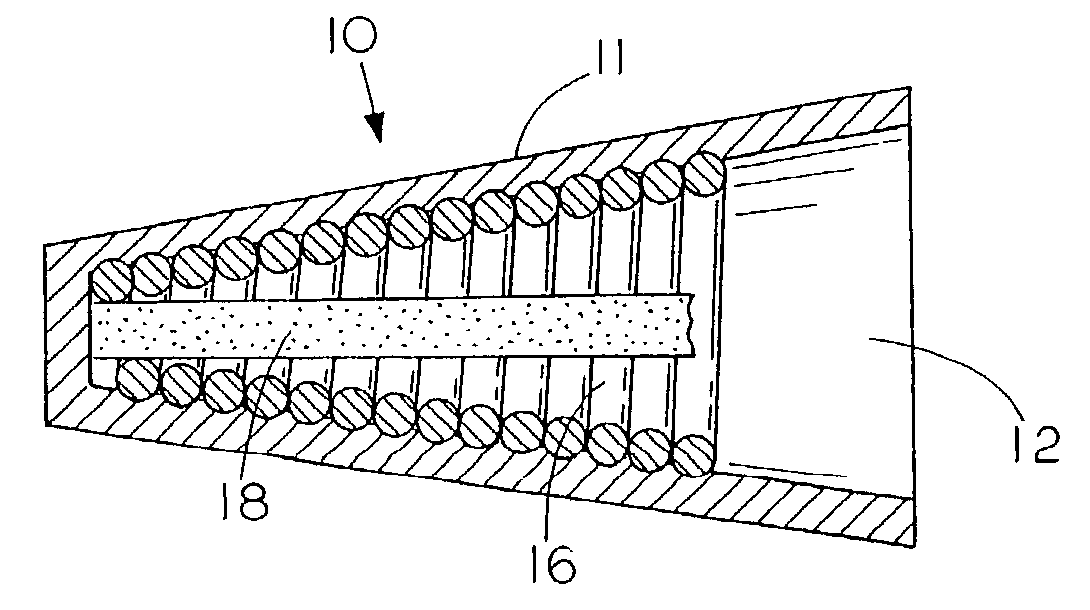

InactiveUS6878880B2Improve current carrying capacityCouplings bases/casesConnections effected by permanent deformationElectrical connectionElectric wire

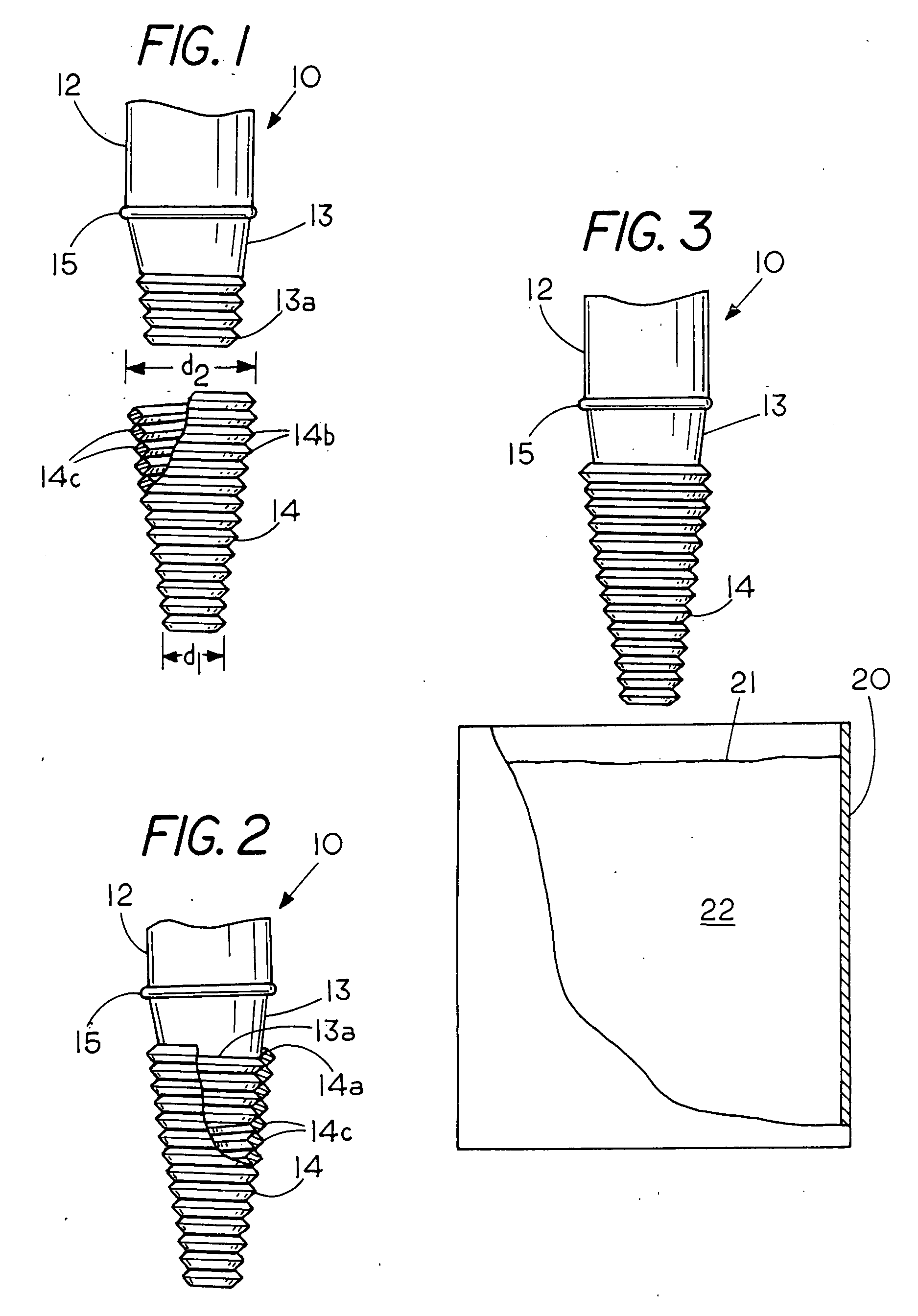

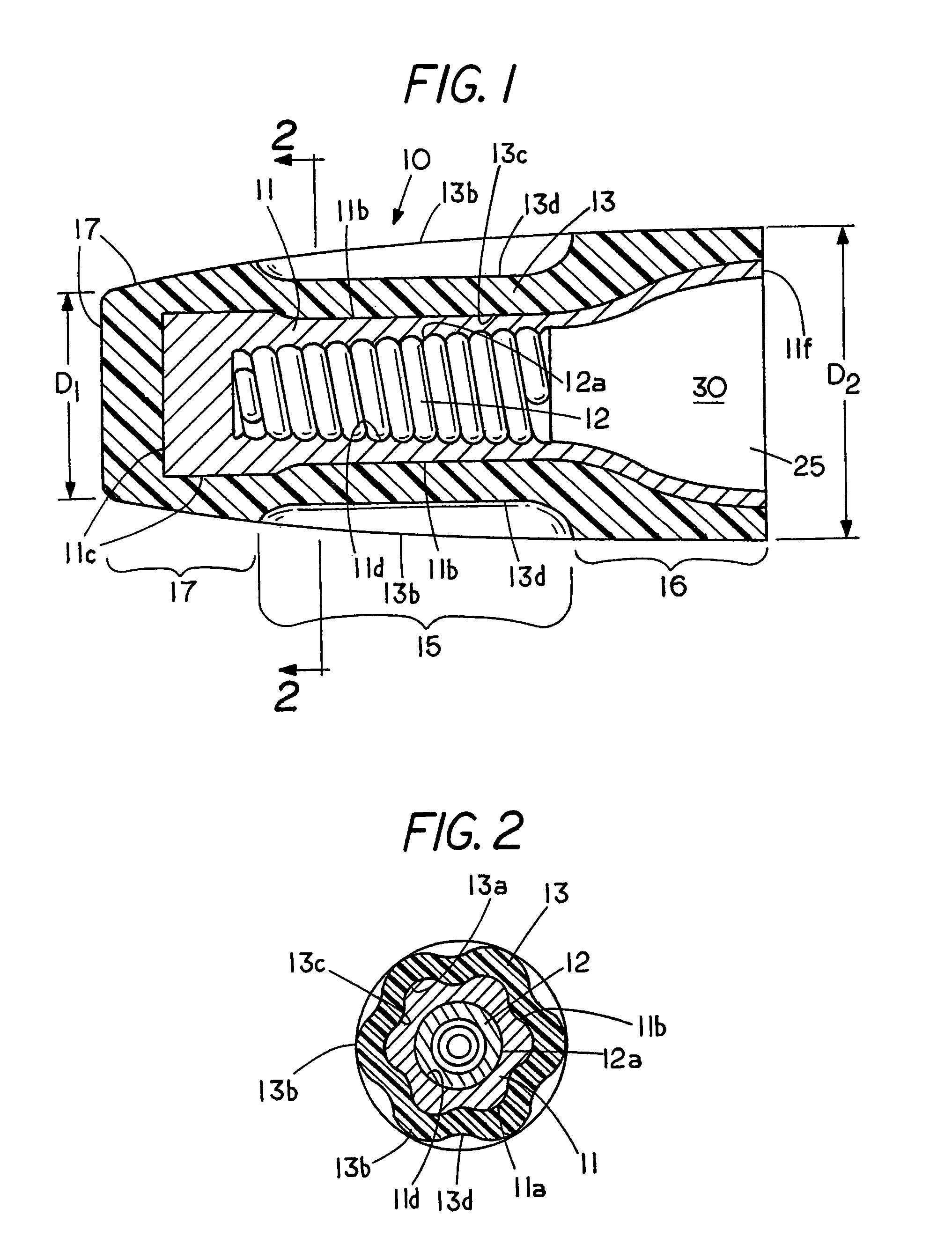

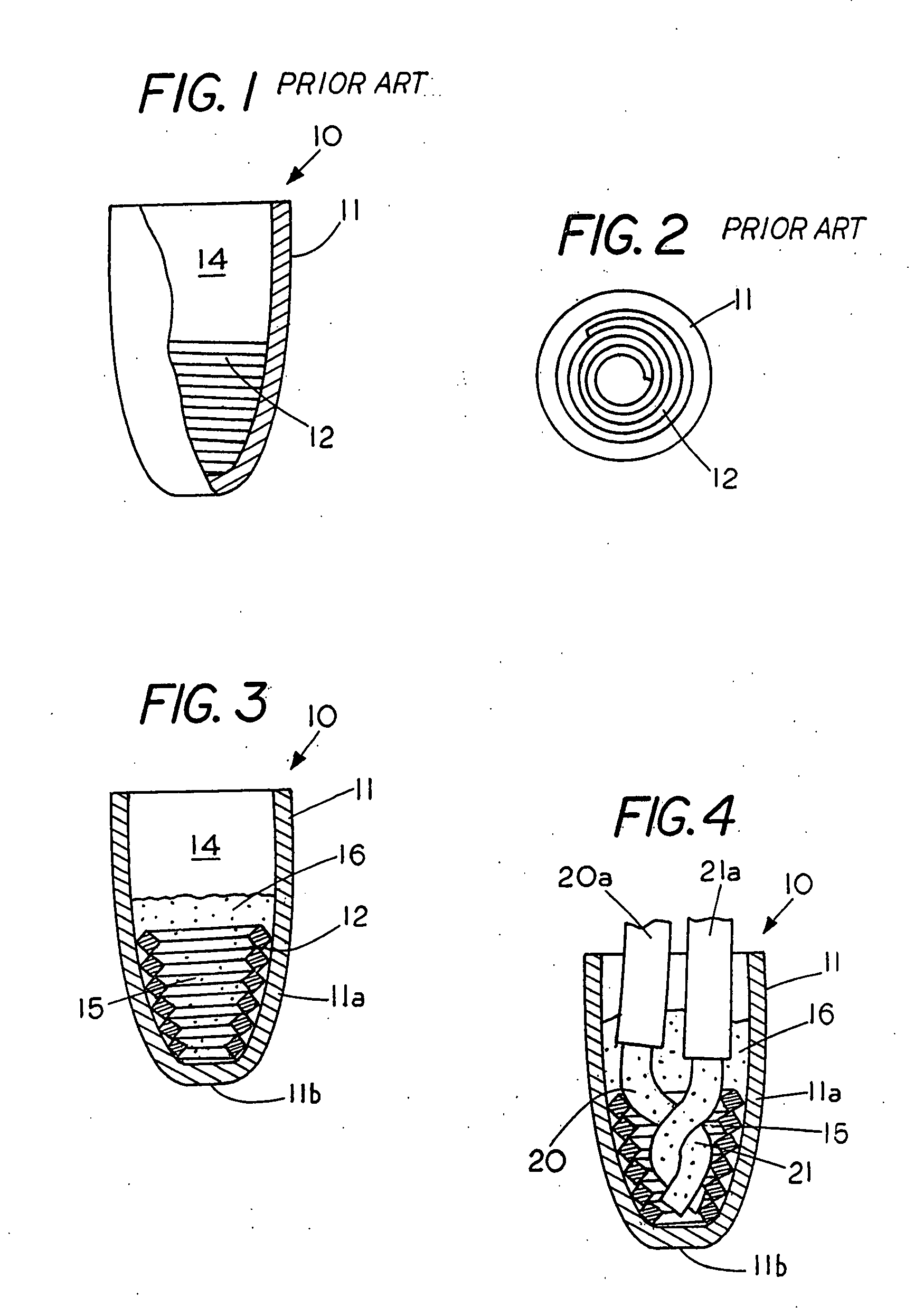

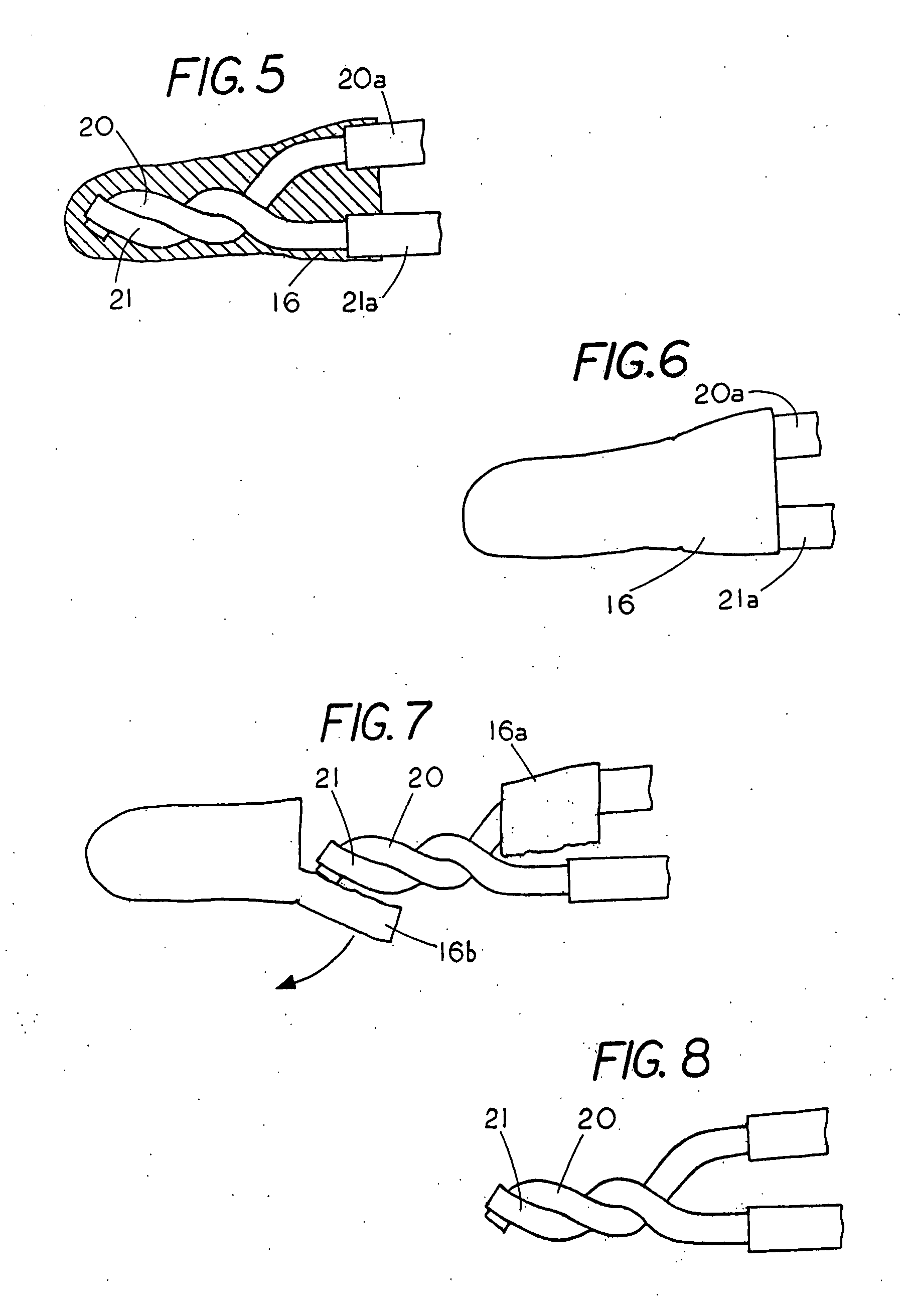

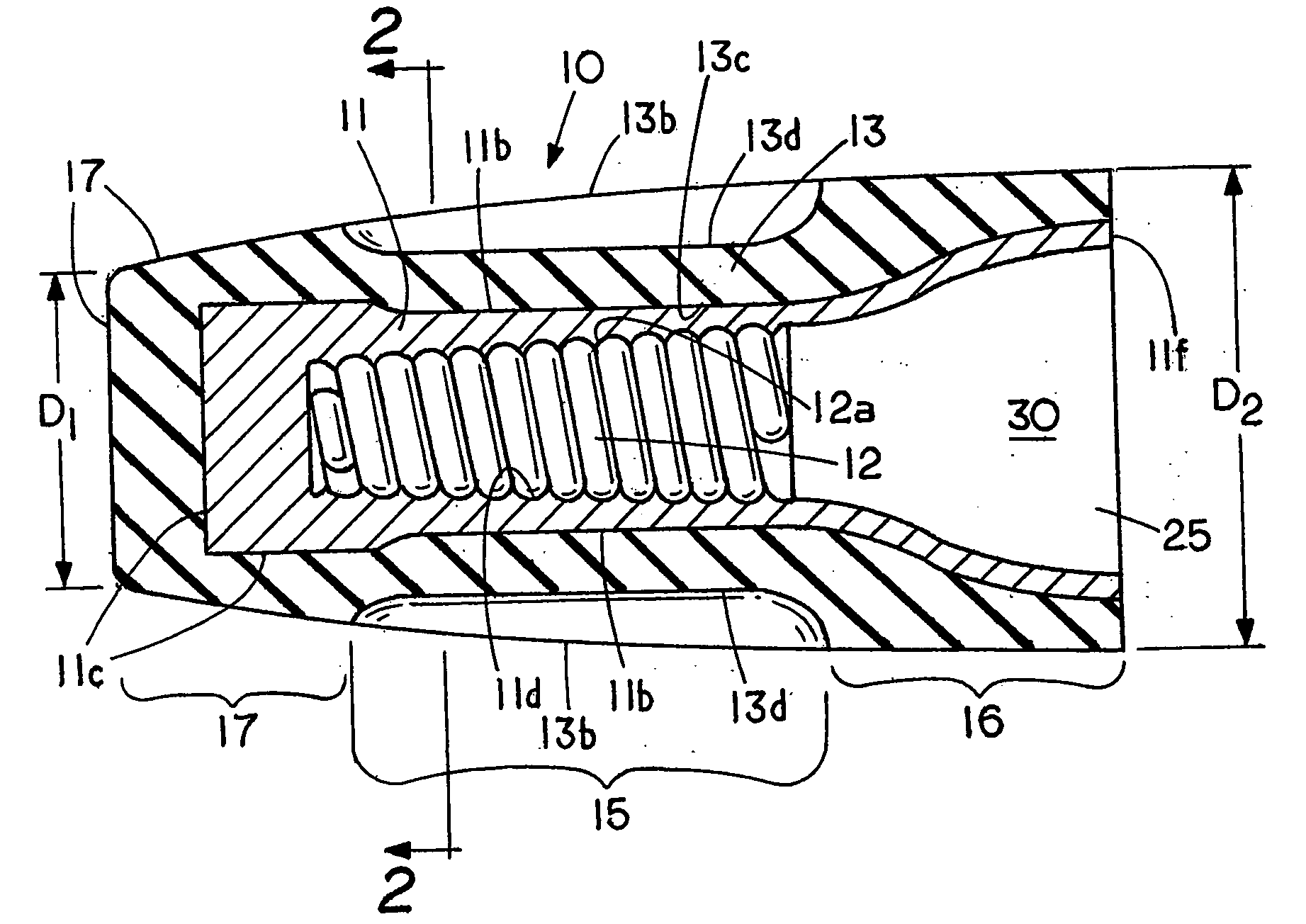

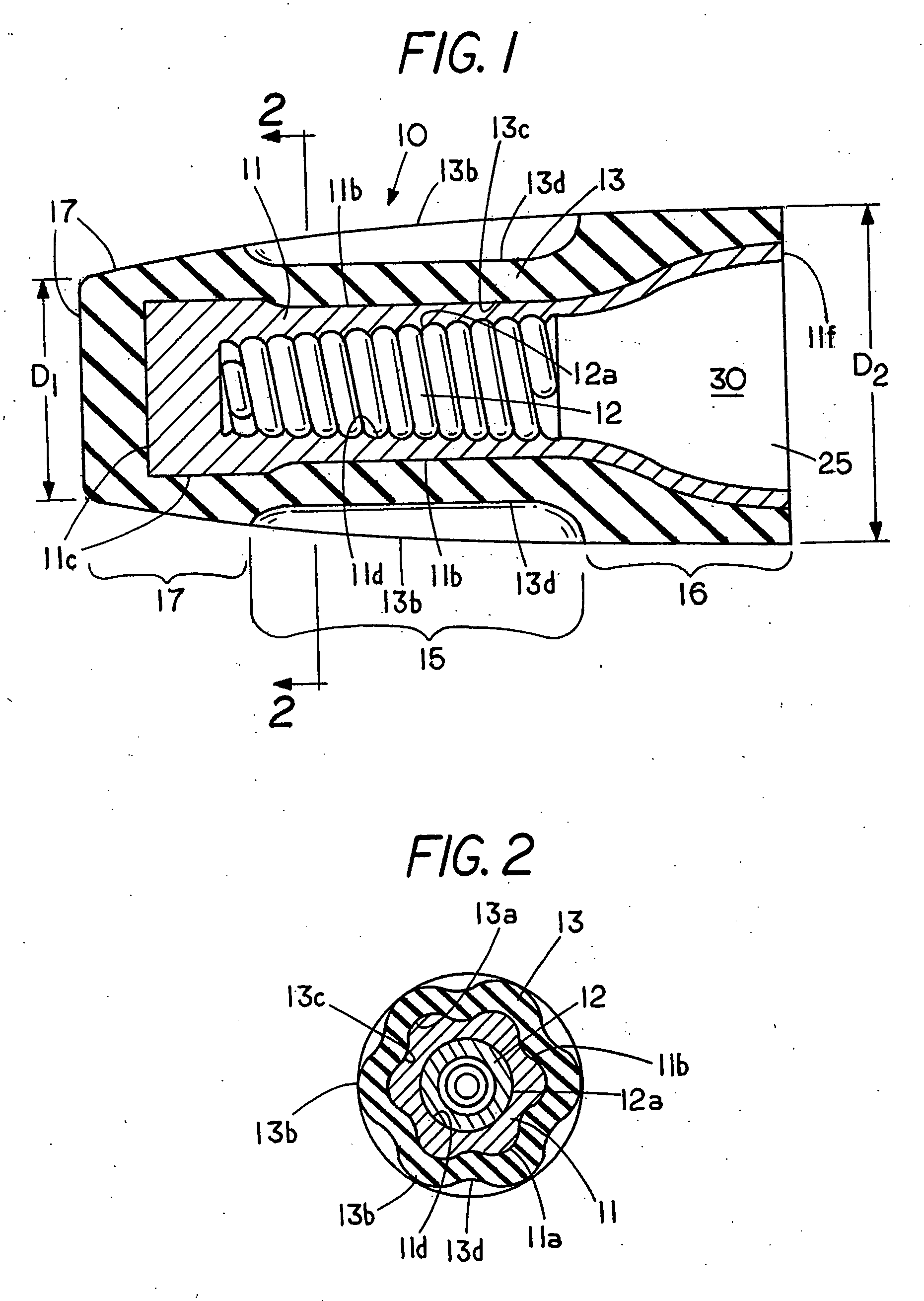

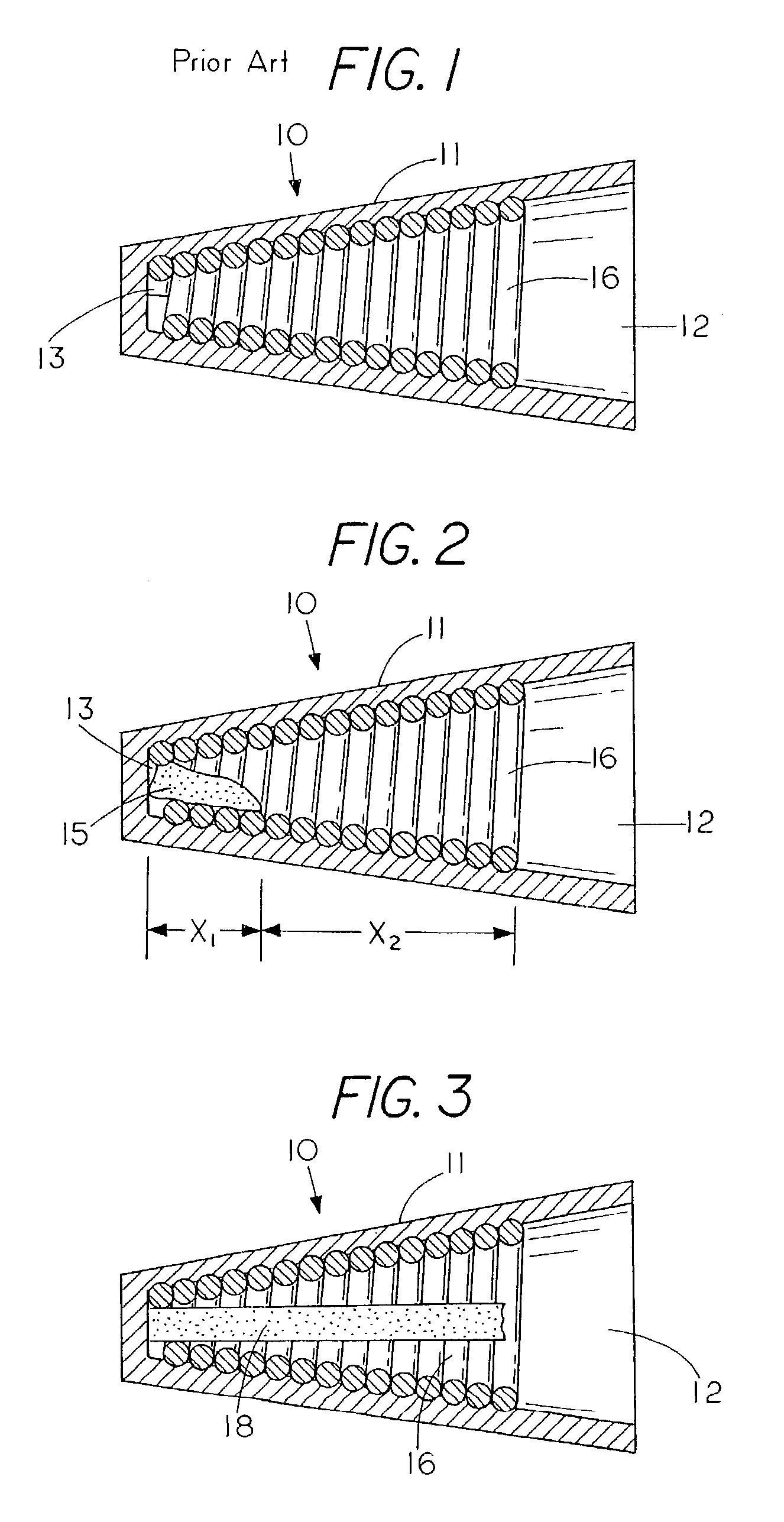

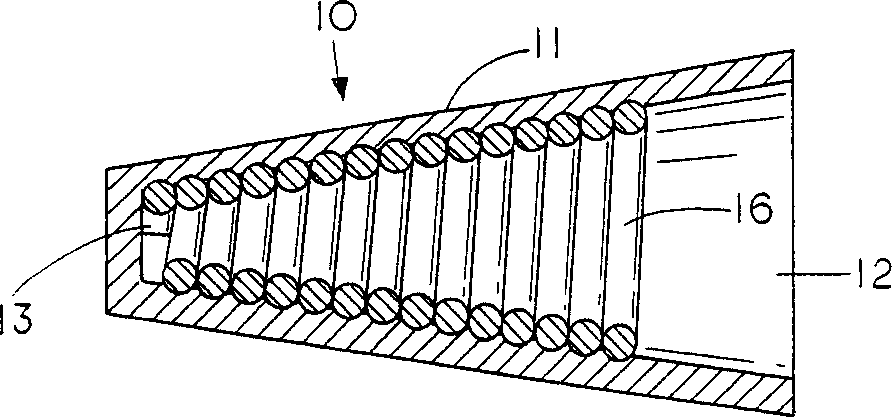

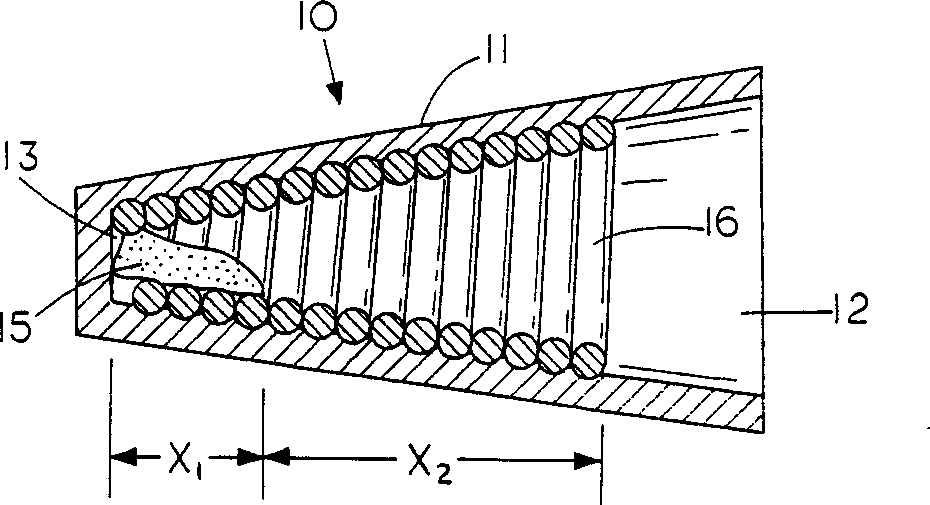

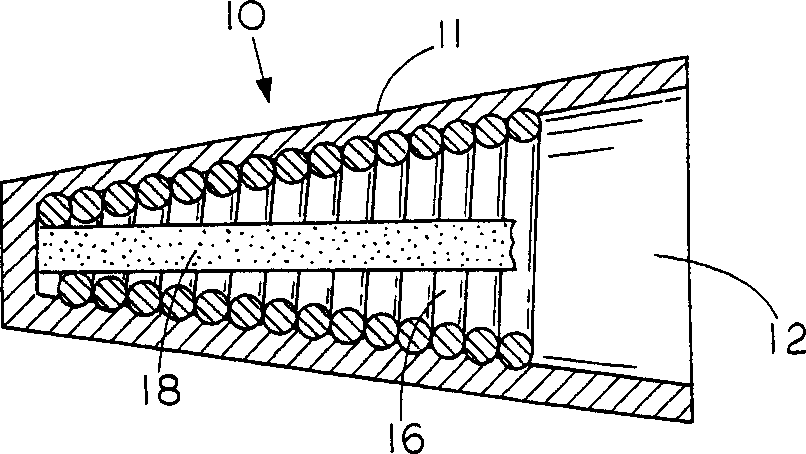

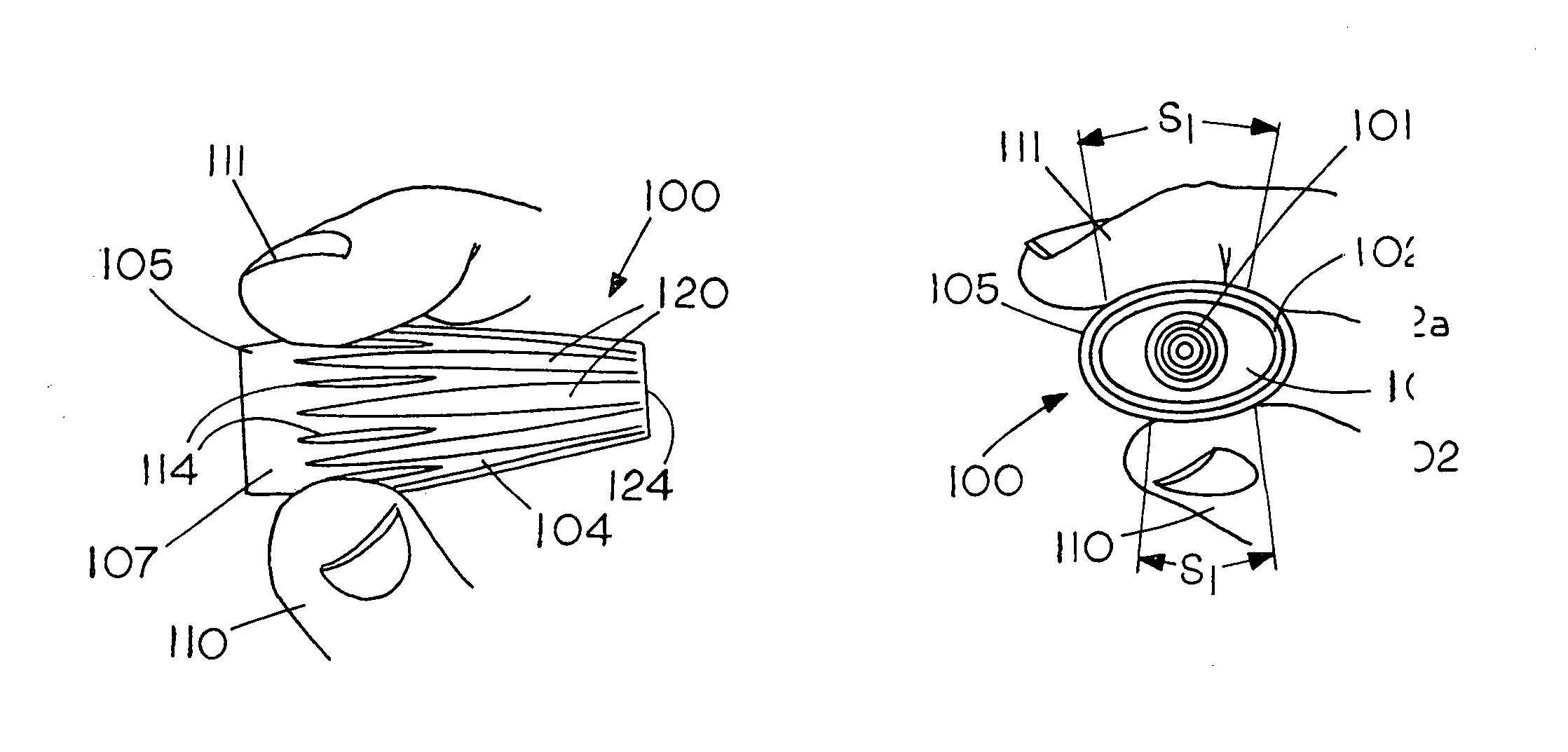

An on-the-go twist-on wire connector for enhancing the current carrying capacity of the electrical wires contained therein with the housing having a closed end and an open end with a wire engaging coil located in the closed end of the housing for bringing a plurality of wires into surface-to-surface contact to provide a direct surface-to-surface electrical path for flow of electrical energy therebetween. Located in the twist-on wire connector is a wire adhereable electrically conducting medium the adhereable electrical conducting medium is conformable around the plurality of wires as the plurality of wires are brought into surface-to-surface engagement with the conformable electrical conducting medium thereby forming an indirect current path between the ends of the plurality of wires while retaining the on-the-go ability of the twist-on wire connector to form the electrical connection solely through twisting action.

Owner:THE PATENT STORE

Twist-on wire connector with peelable covering

InactiveUS20060180336A1Fast formingCoupling device detailsConnection end capsEngineeringMechanical engineering

A twist-on wire connector containing a mass of a cohering gel in a gel state therein for forming a protective covering over a wire connection in the twist-on wire connector with the gel thereon removal from the twist-on wire connector and peelable from the wire connection to enable one to quickly form a further wire connection without having to wipe off the wire connection.

Owner:KING LLOYD HERBERT JR +3

Epidermal friendly twist-on wire connectors

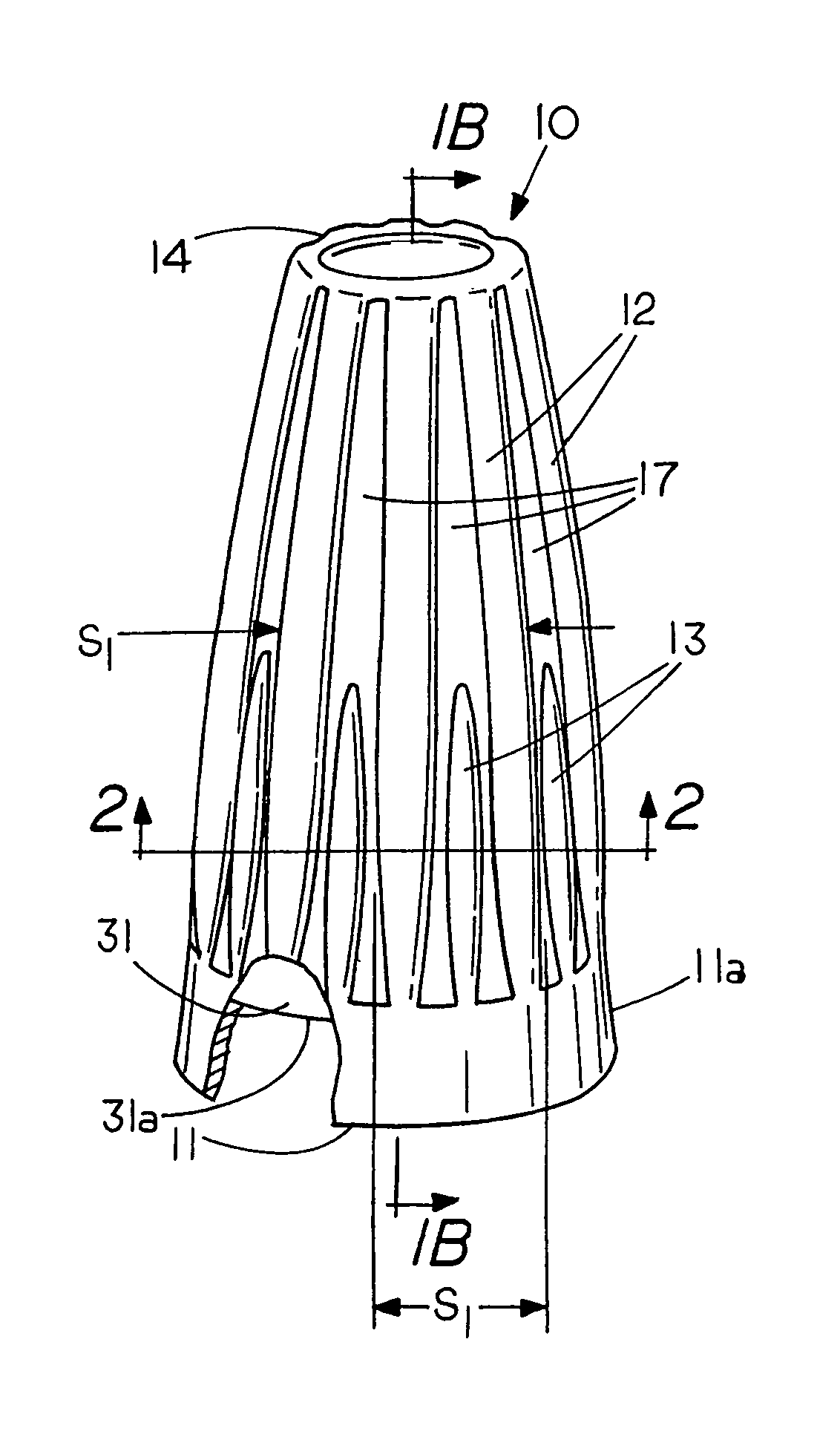

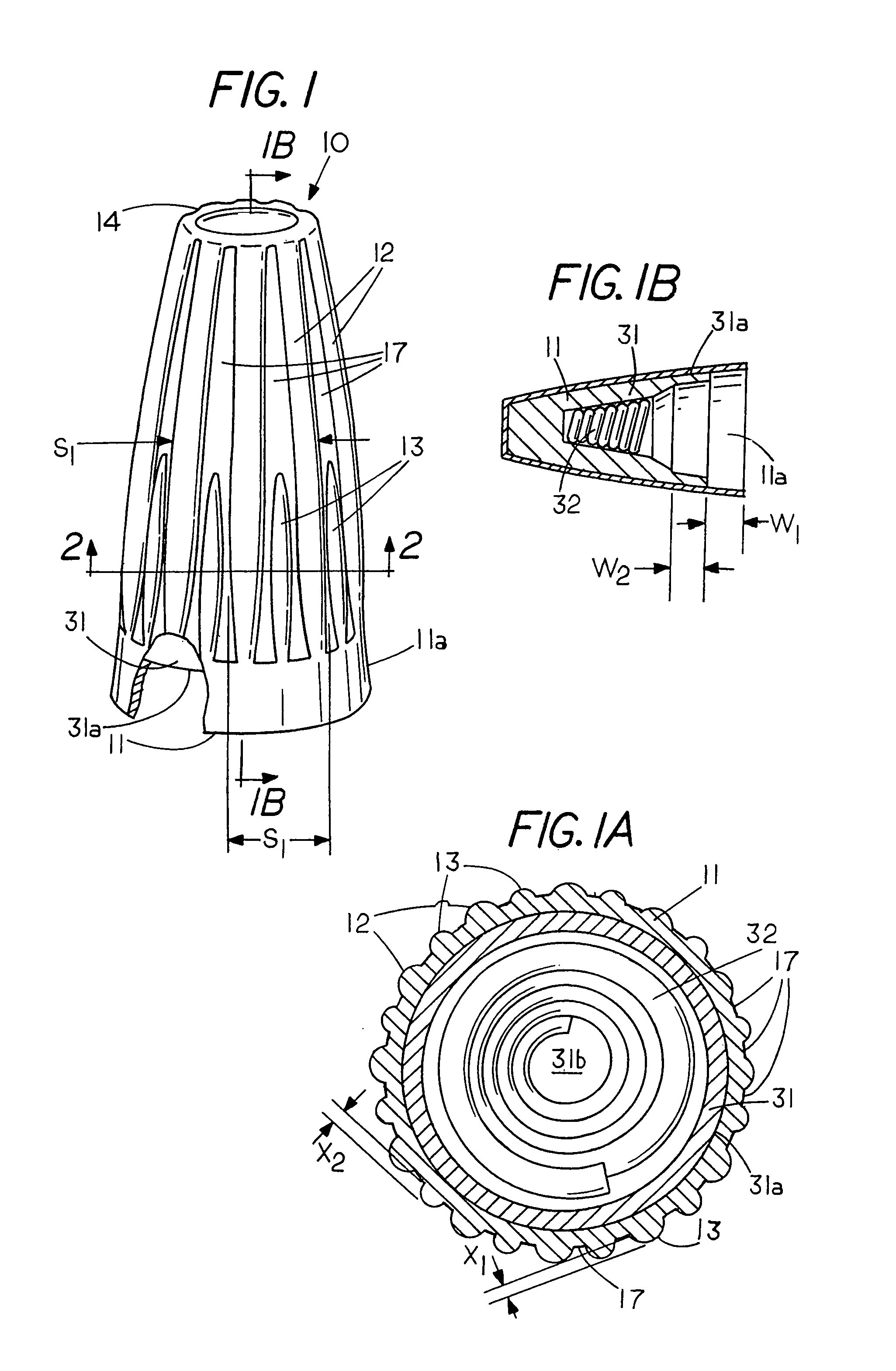

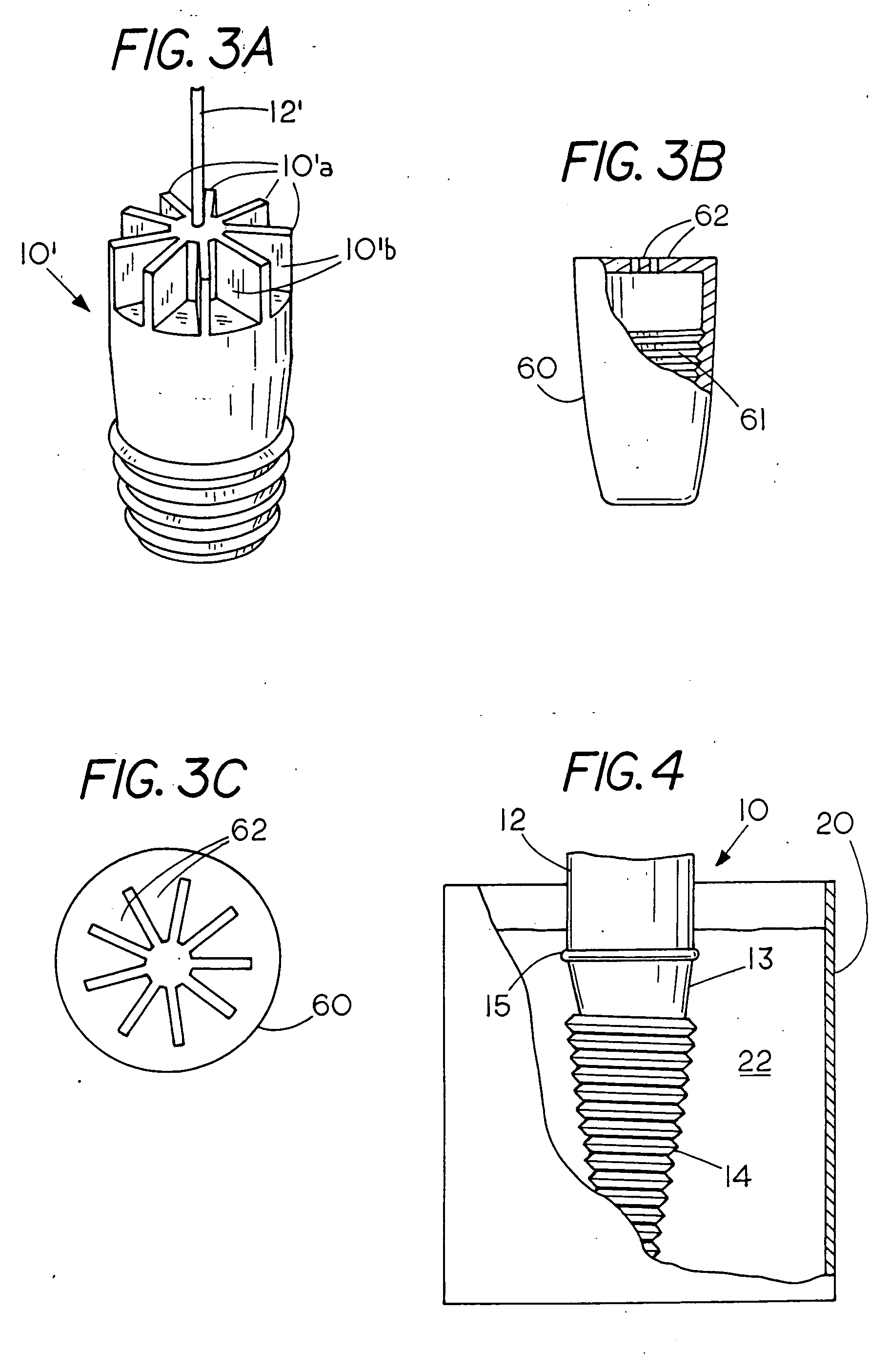

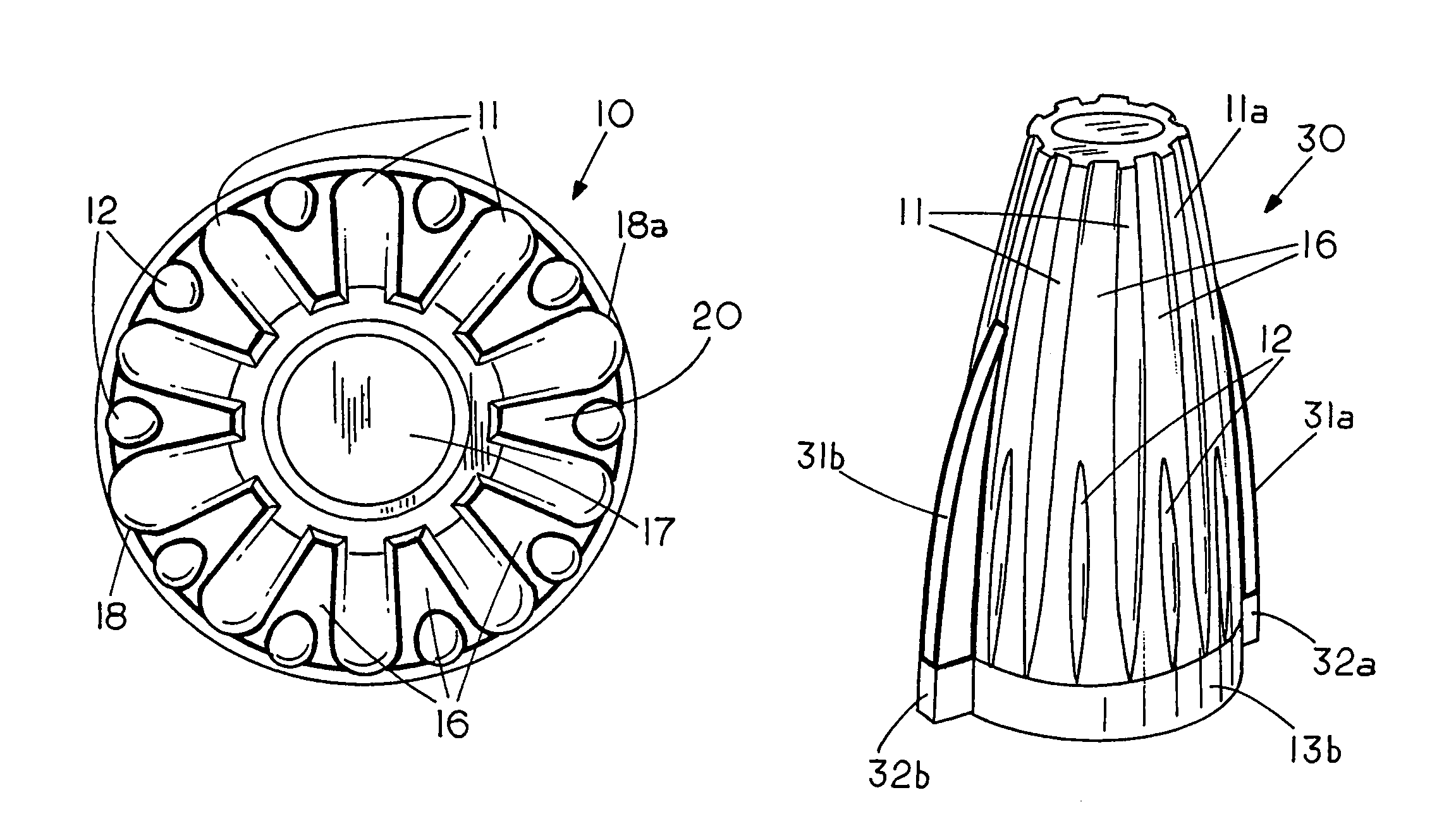

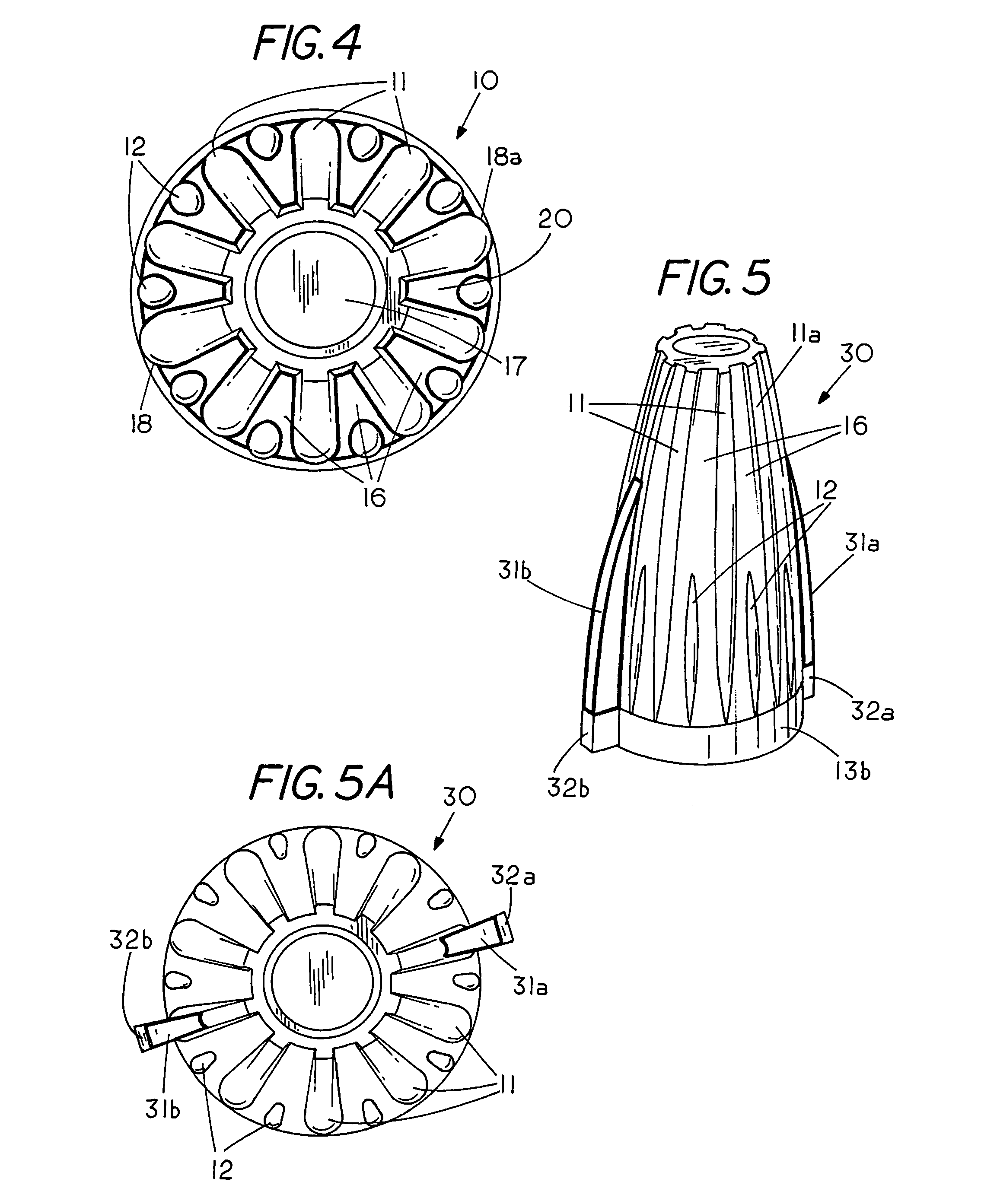

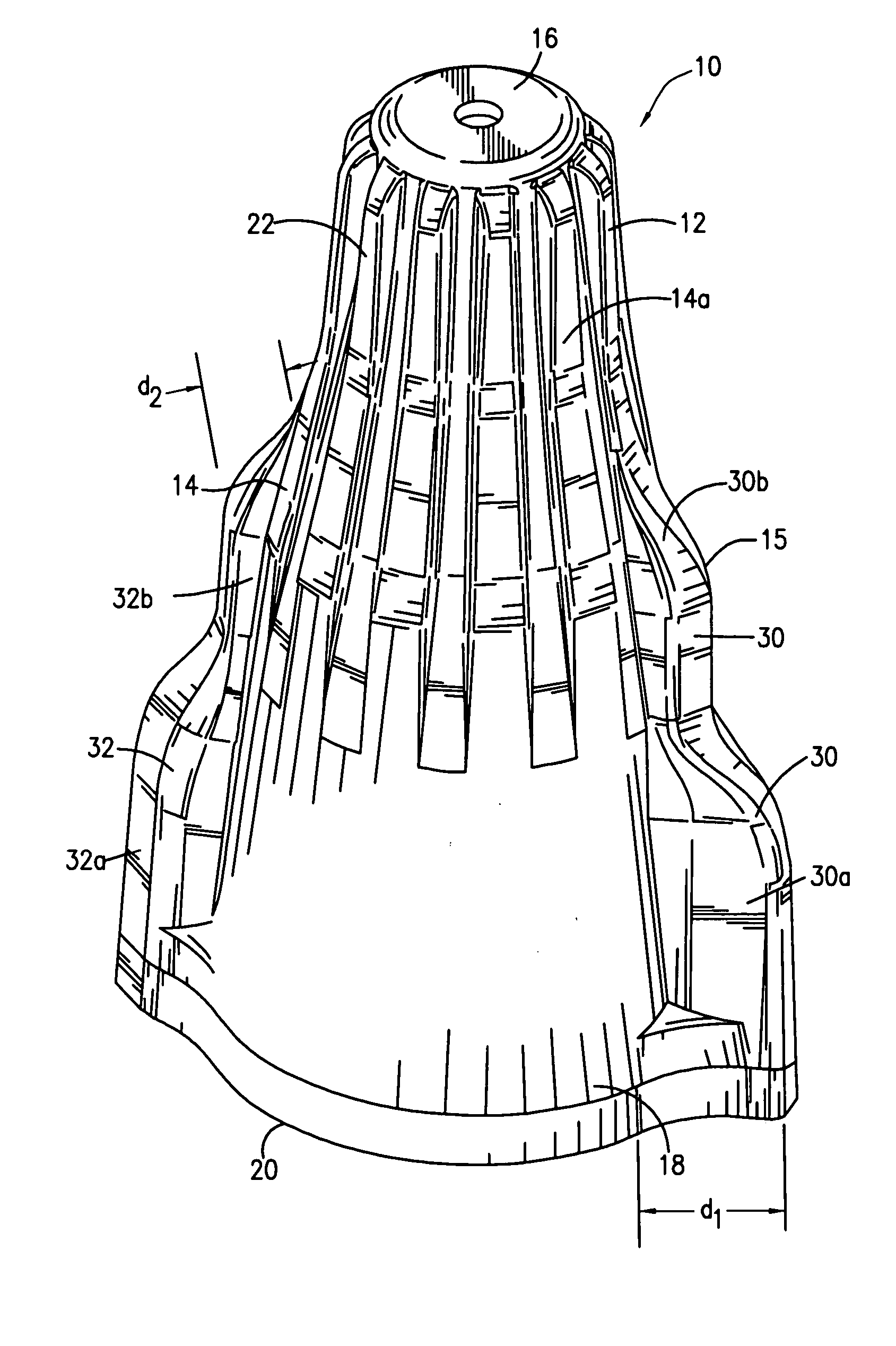

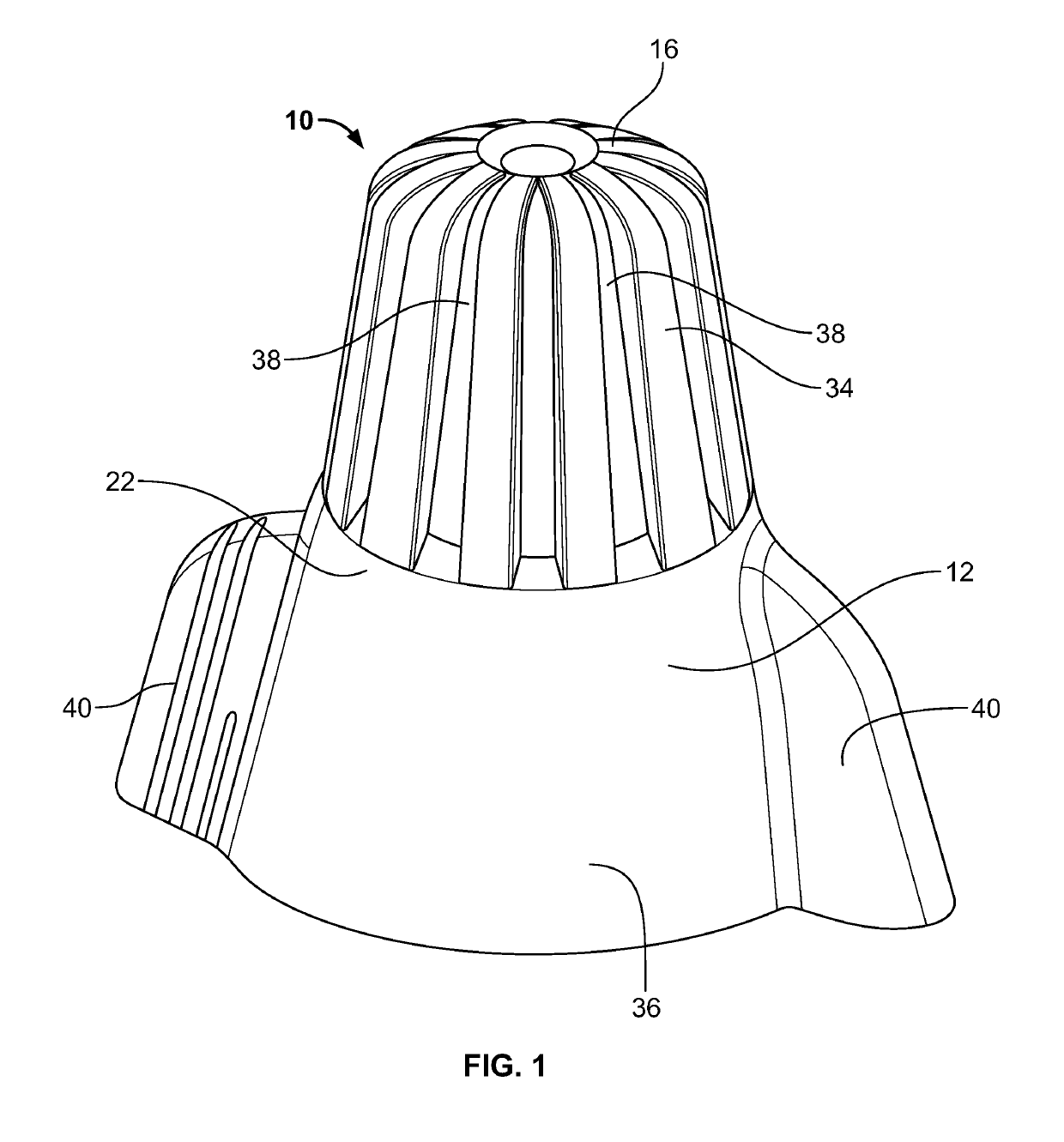

An epidermal friendly twist-on wire connector and a method of applying an epidermal twist-on wire connector having a resilient gripping region including a set of low profile, resilient ribs that are circumferentially spaced so that a users thumb and fingers can compressively and sequentially engage and compress at least a portion of a plurality of ribs as well as the valley between the ribs during application of a wire securement torque to the twist-on wire connector while at the same time inhibiting or preventing epidermal trauma in a users thumb and fingers.

Owner:THE PATENT STORE

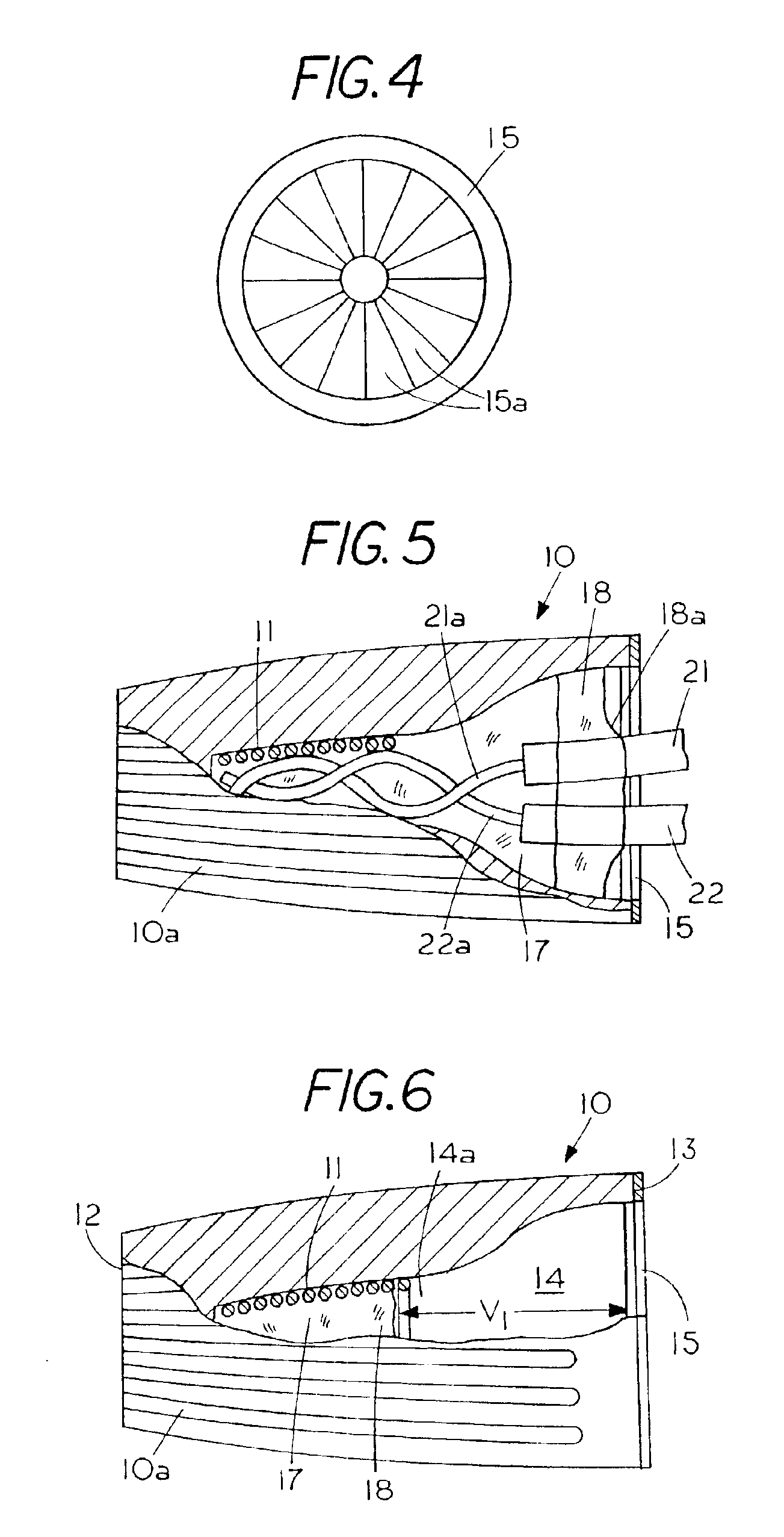

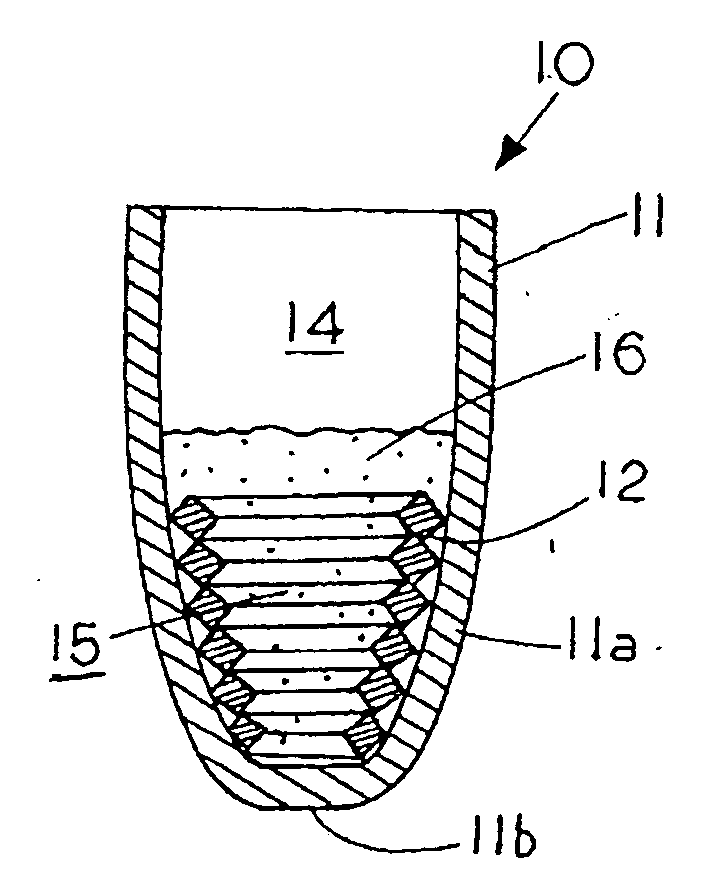

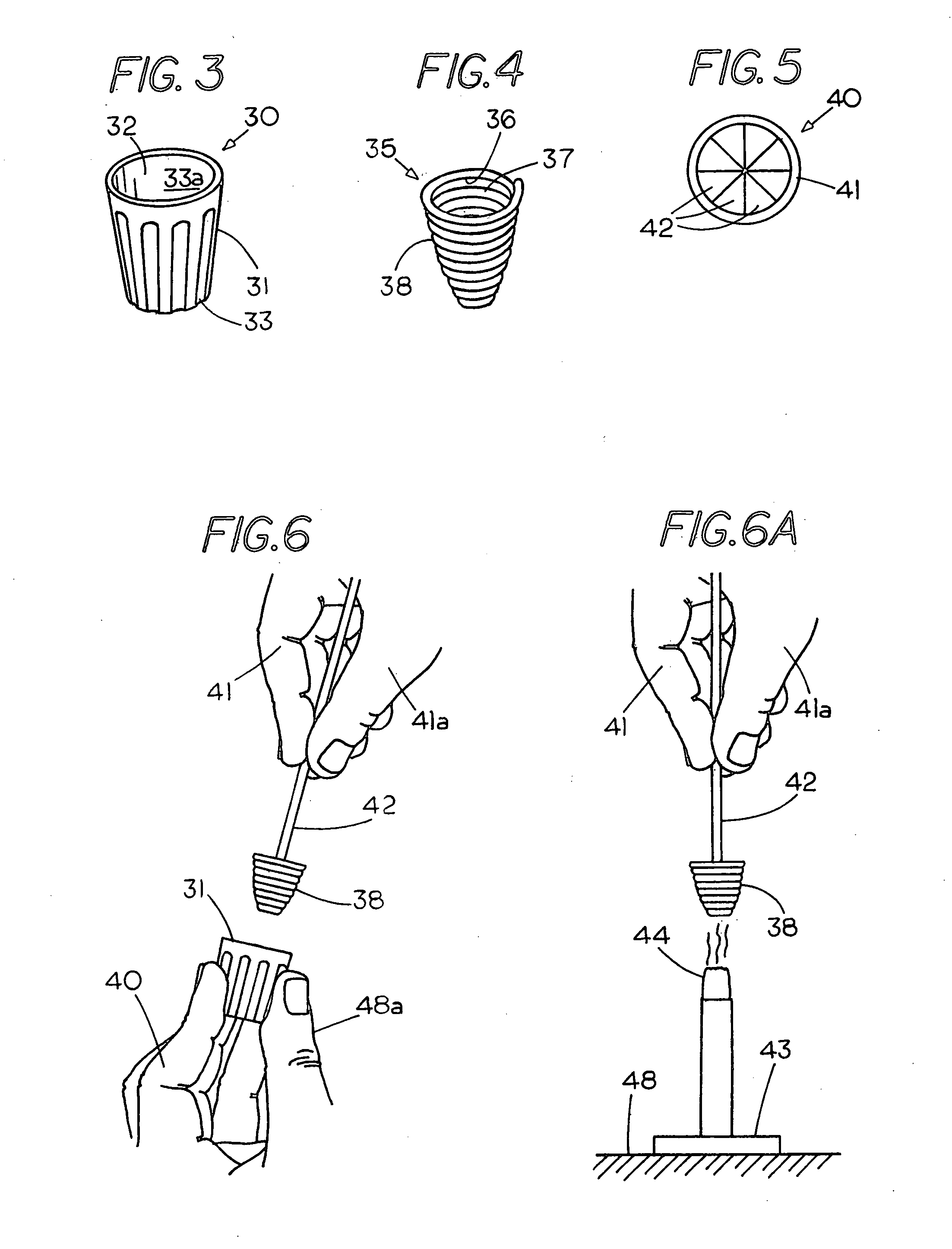

Dip molded wire connector

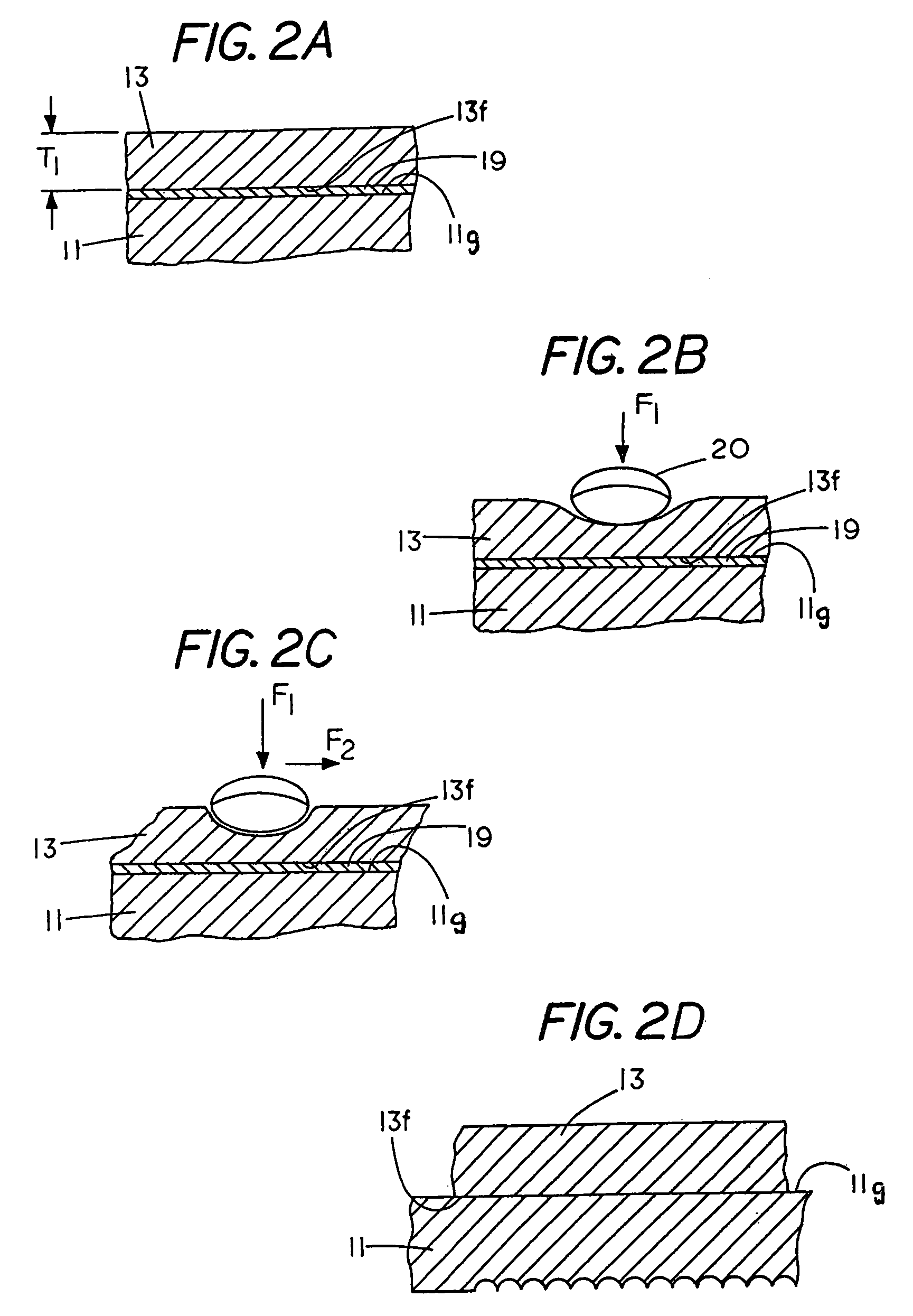

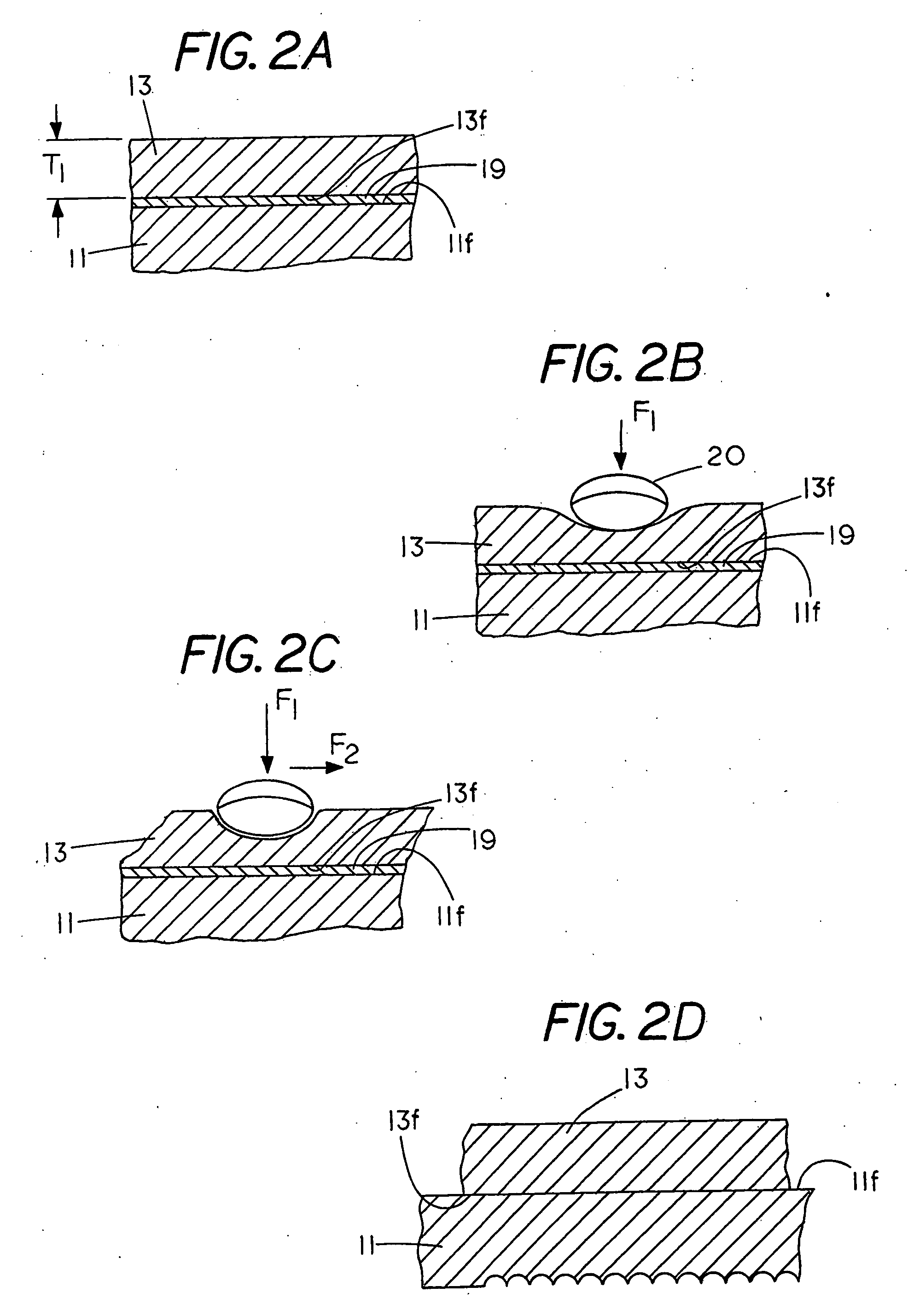

InactiveUS20060042079A1Improve impact resistancePrinted circuit assemblingContact member manufacturingMechanical engineeringSpiral coil

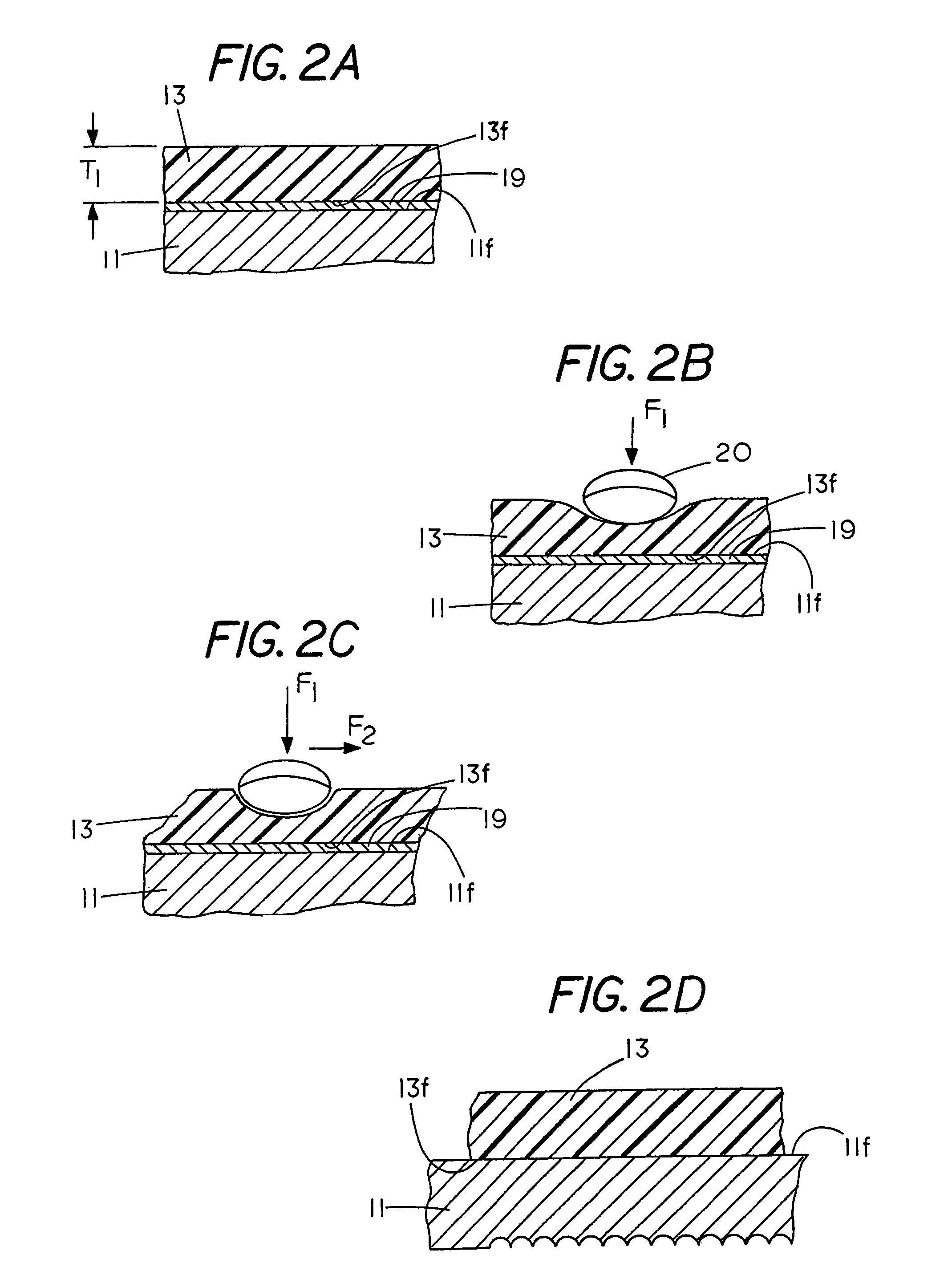

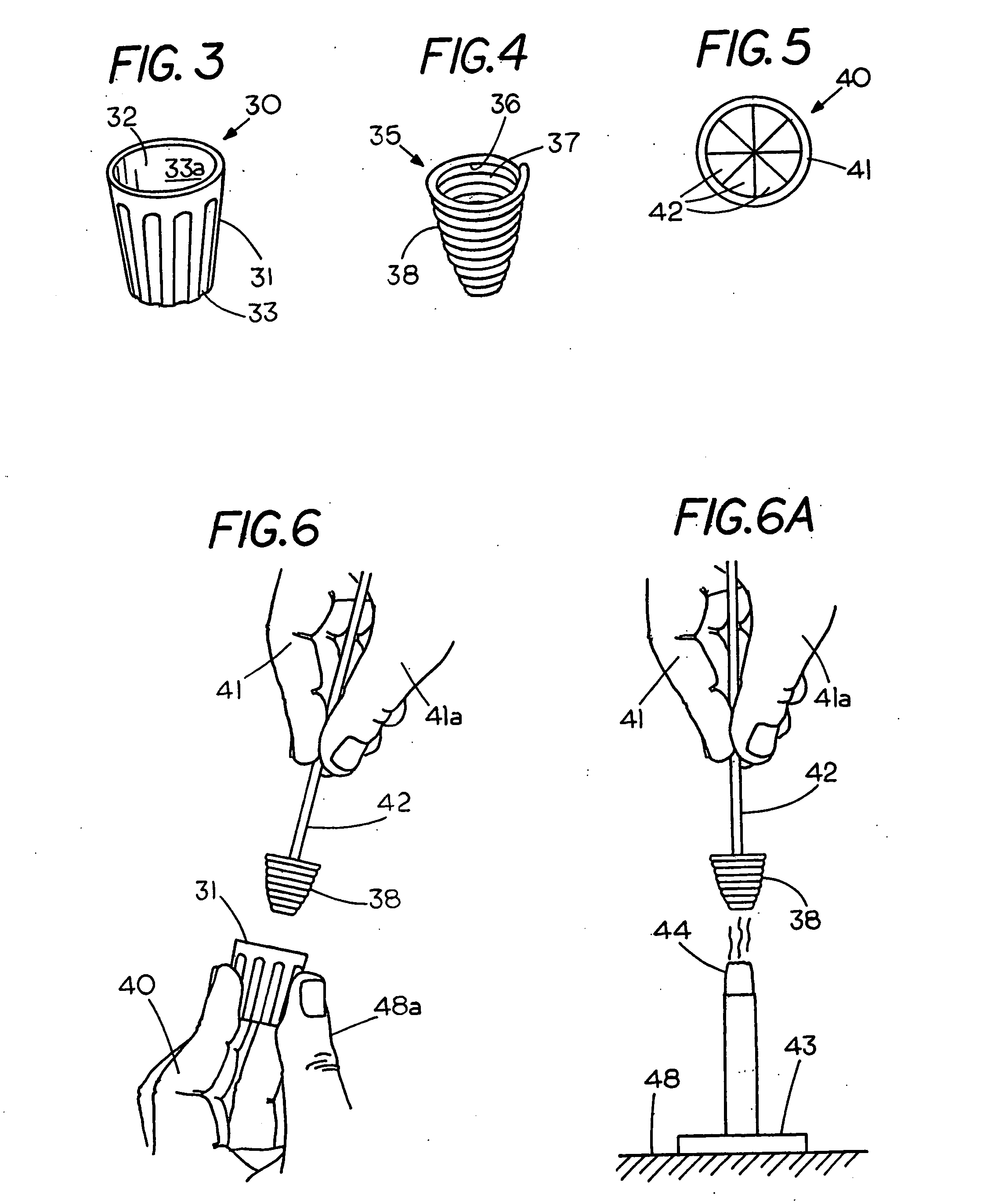

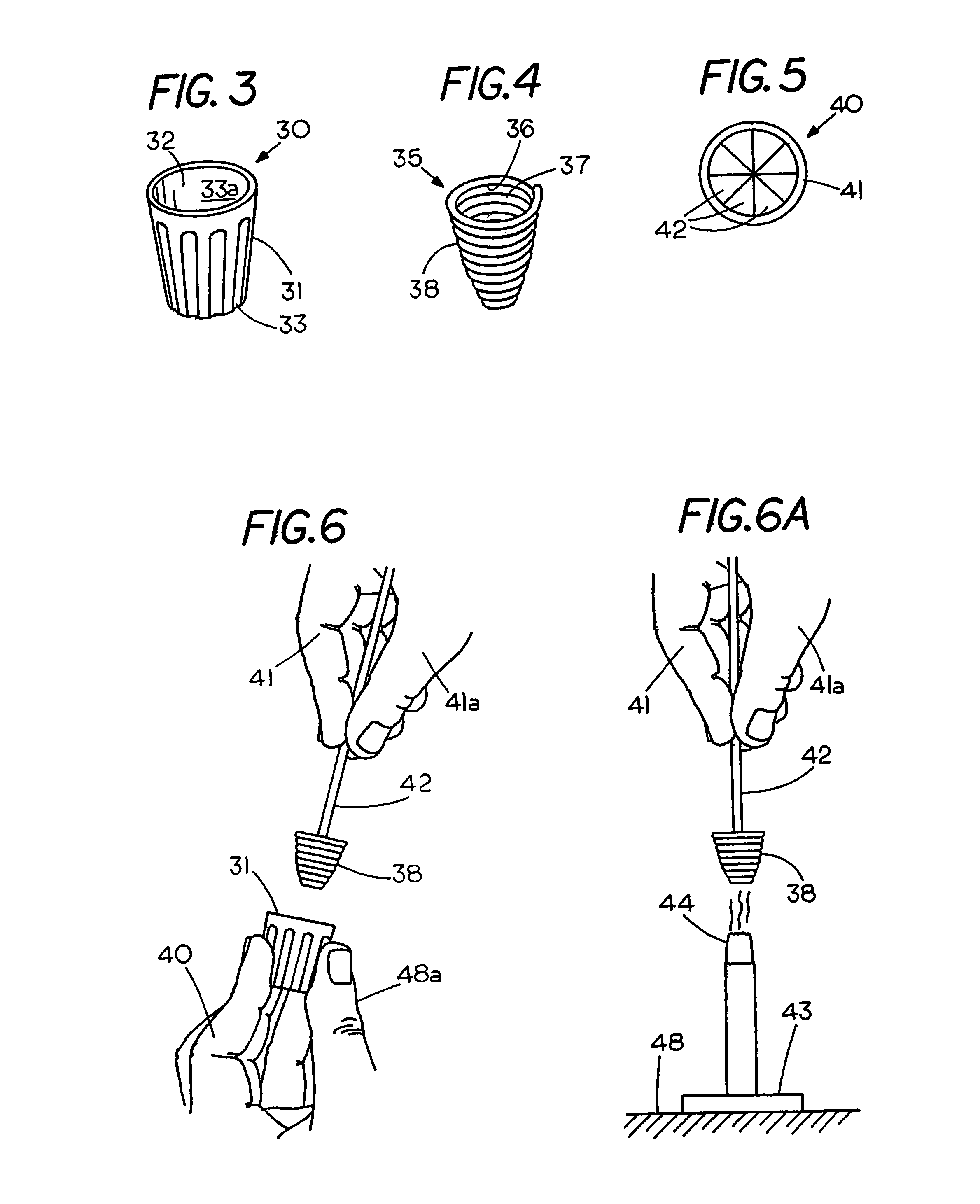

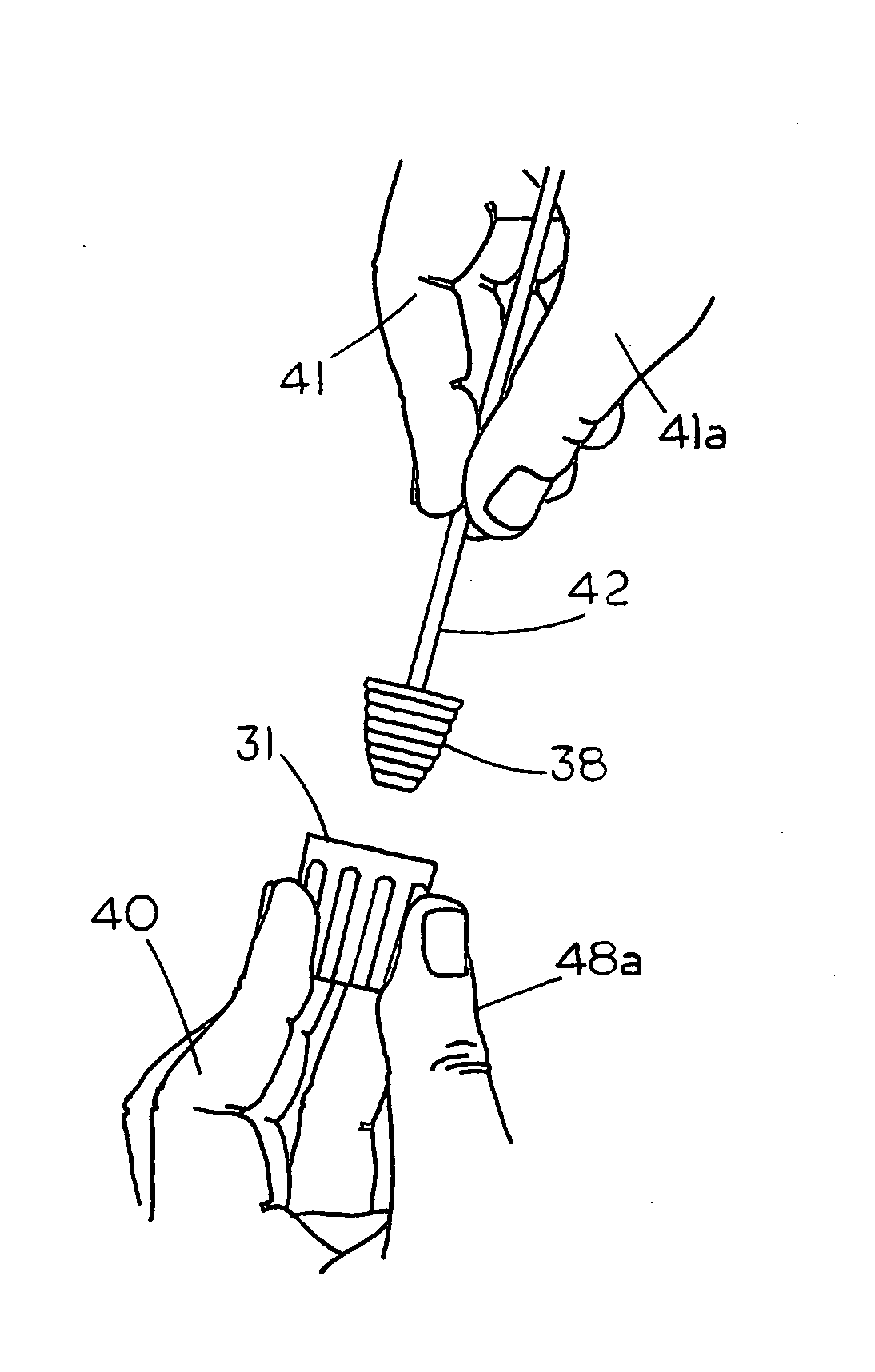

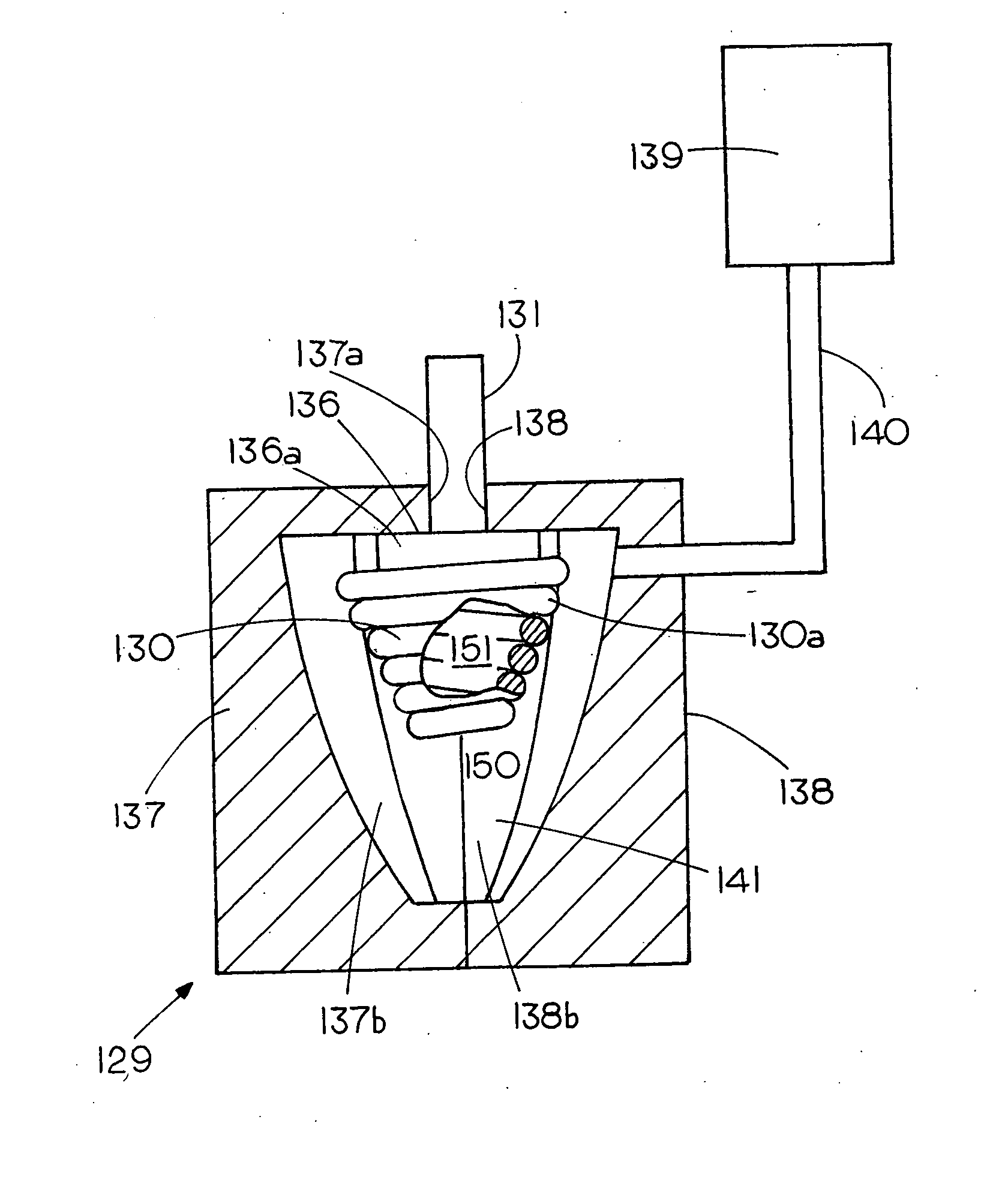

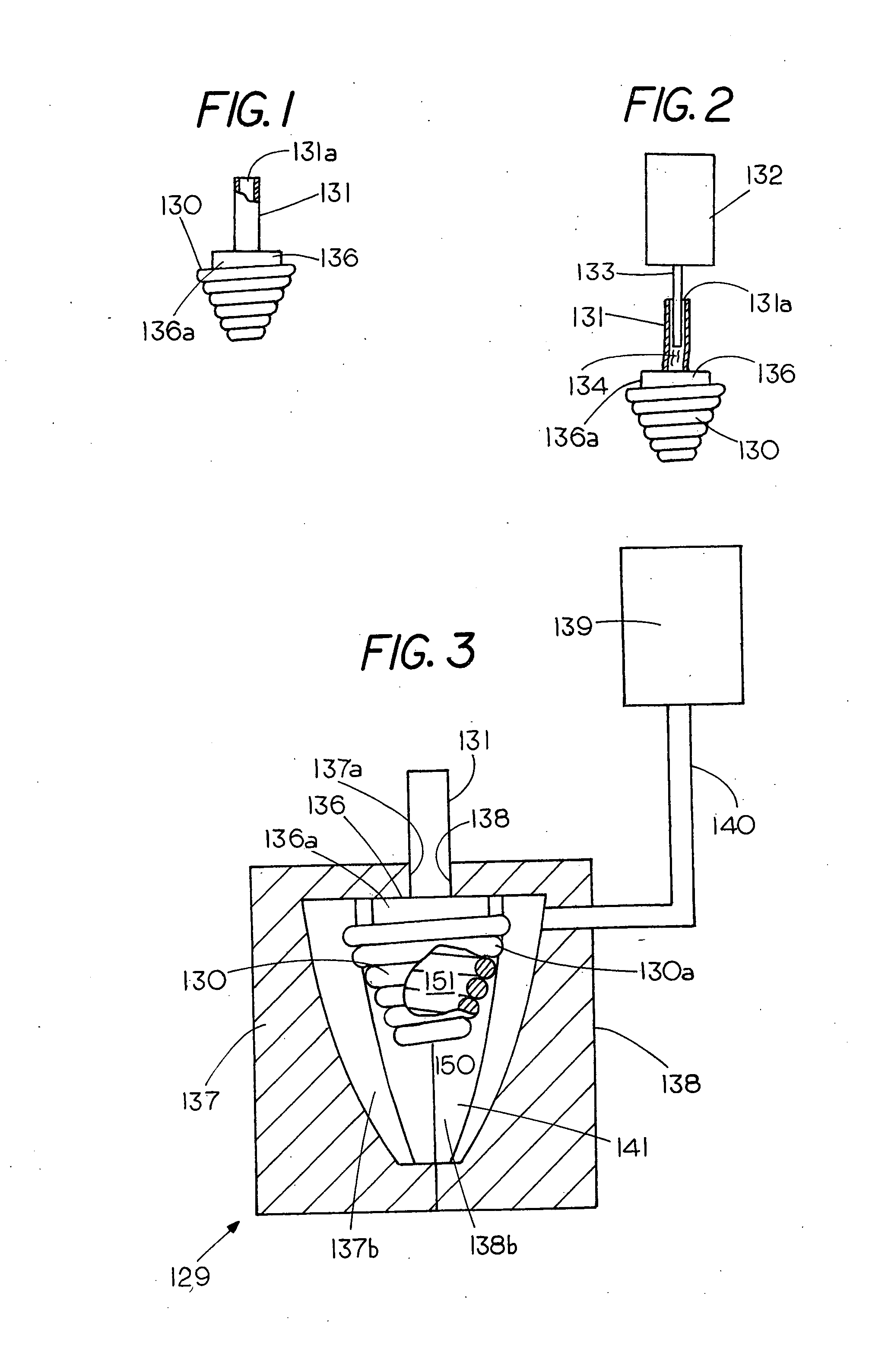

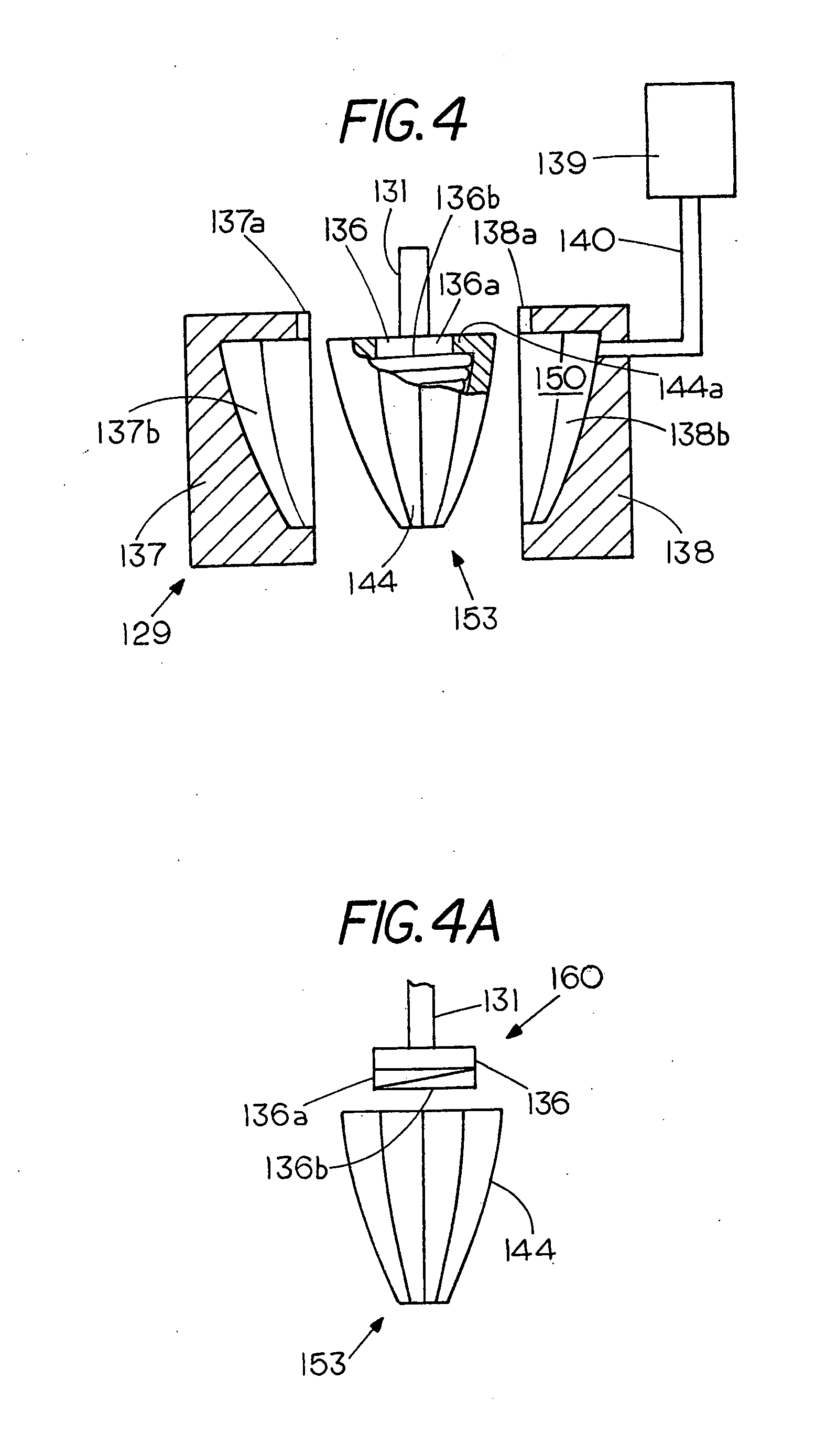

A connector with a dip-molded housing and a method for forming a twist-on wire connector with a dip-molded housing. To dip-mold a covering or housing on a twist-on wire connector either a mandrel carrying a twist-on wire coil, a mandrel having the a shape of a spiral coil or a twist-on wire connector are dipped into a bath of an in situ solidfiable dip-moldable material such as liquid plastic. The dip-moldable solidified material solidifies to form a dip-molded shell on the wire connector.

Owner:THE PATENT STORE

Cushion grip twist-on wire connector

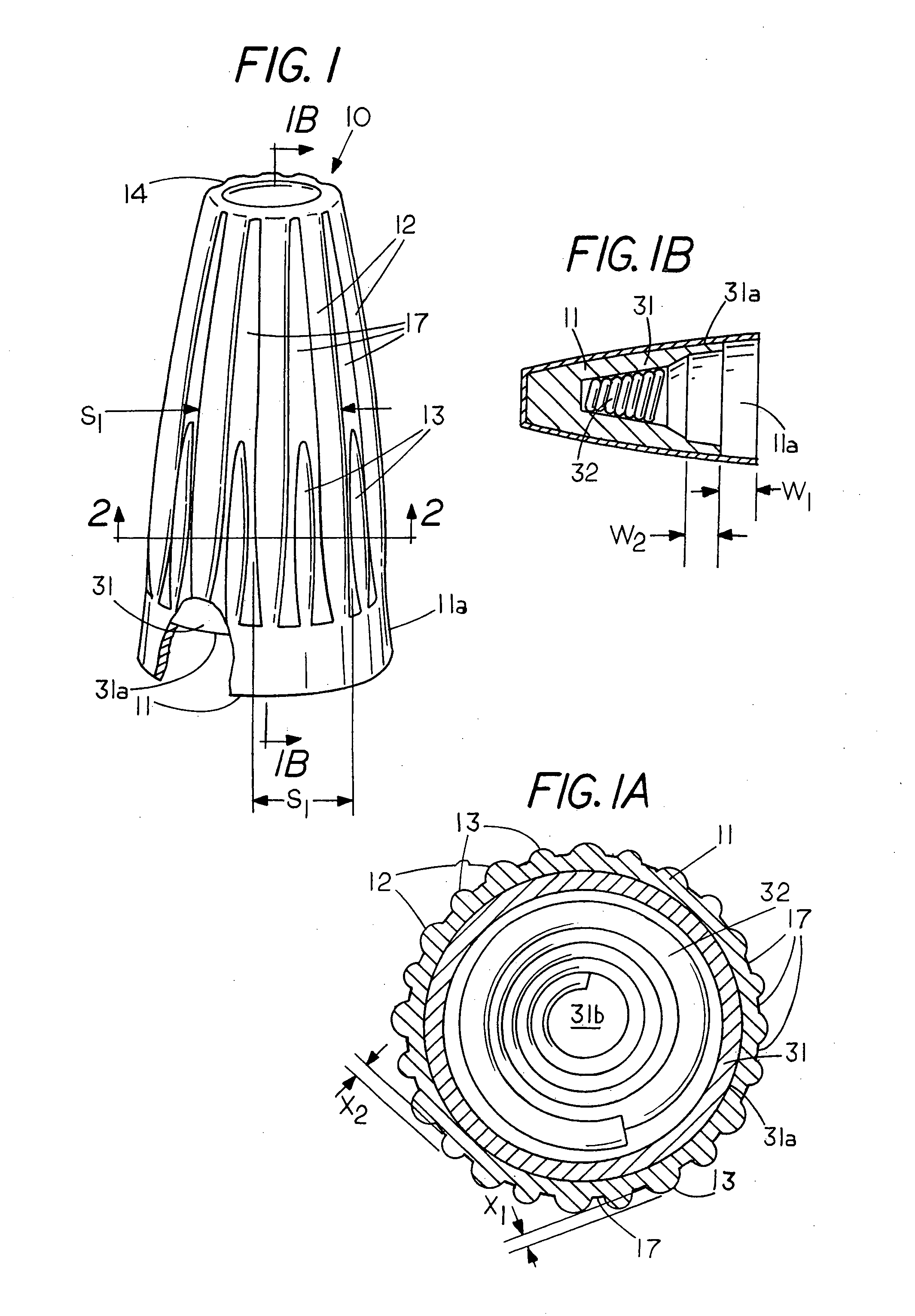

ActiveUS8067692B2Multiple degrees of responsiveness to finger pressureConnection end capsCable junctionsEngineeringHand injury

Owner:THE PATENT STORE

Finger friendly twist-on wire connector

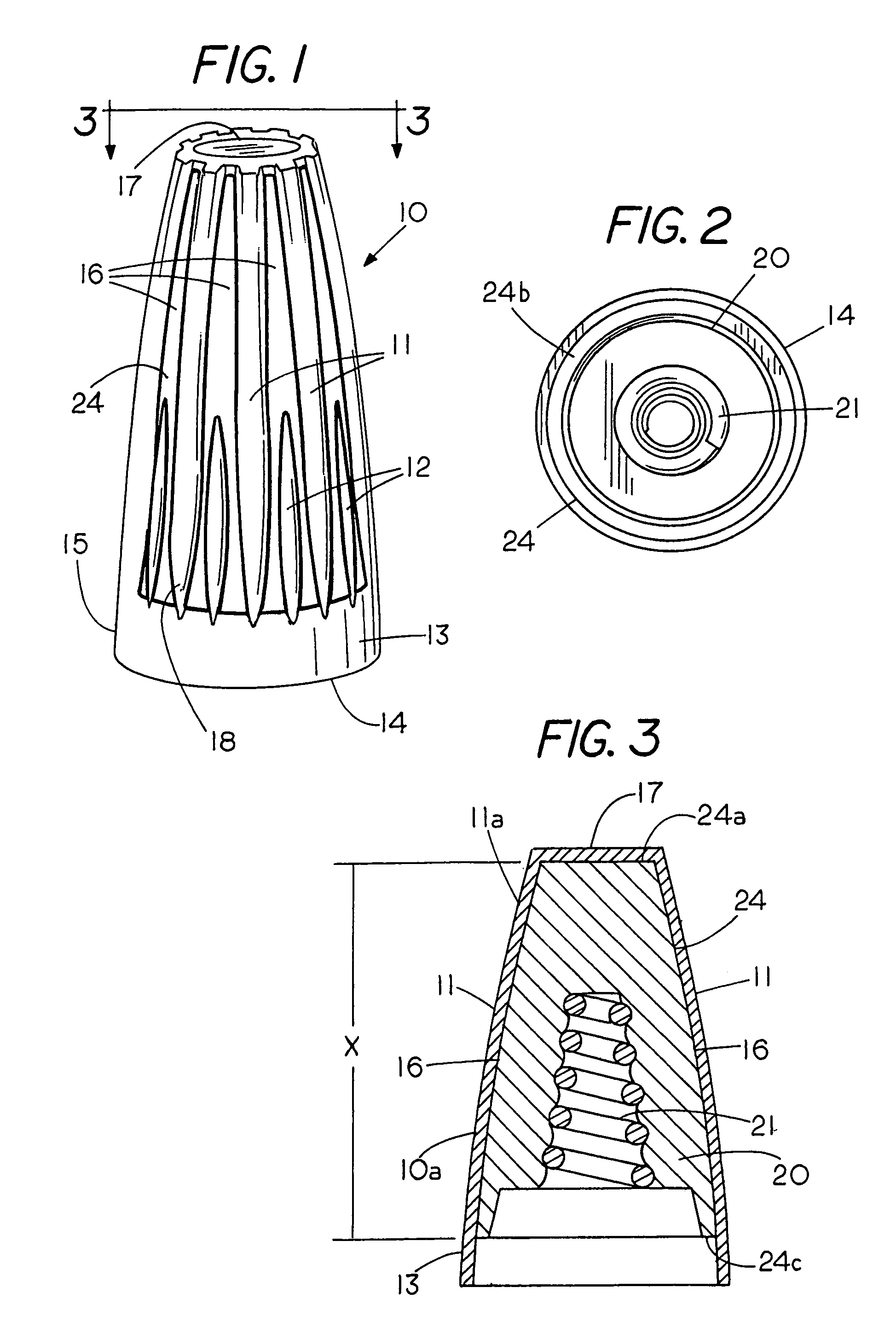

A finger friendly twist-on wire connector having a spiral coil and an open end rigid shell secured to the spiral coil with the rigid shell having an outer surface with a circumferential band and a closed end supporting a finger cushion material integral to at least a portion of the outer surface of the rigid shell with the finger cushion material including a plurality of circumferentially spaced elongated ribs resiliently deformable in response to radially and tangential finger forces thereon as rotational finger forces are transmitted to the rigid shell through the finger cushion material to thereby inhibit finger fatigue and finger injury while allowing the user to maintain a feel of the wire engagement within the wire connector.

Owner:THE PATENT STORE

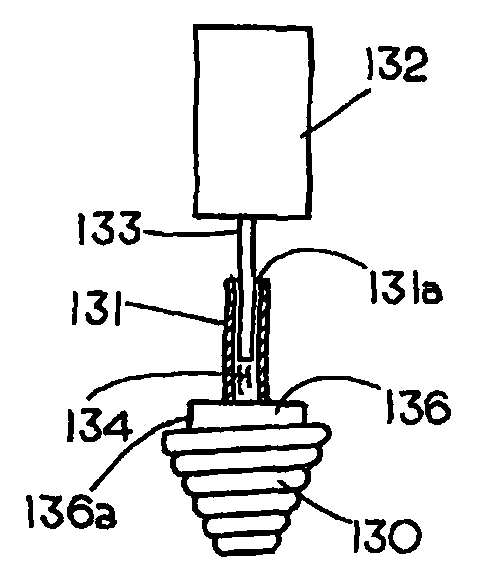

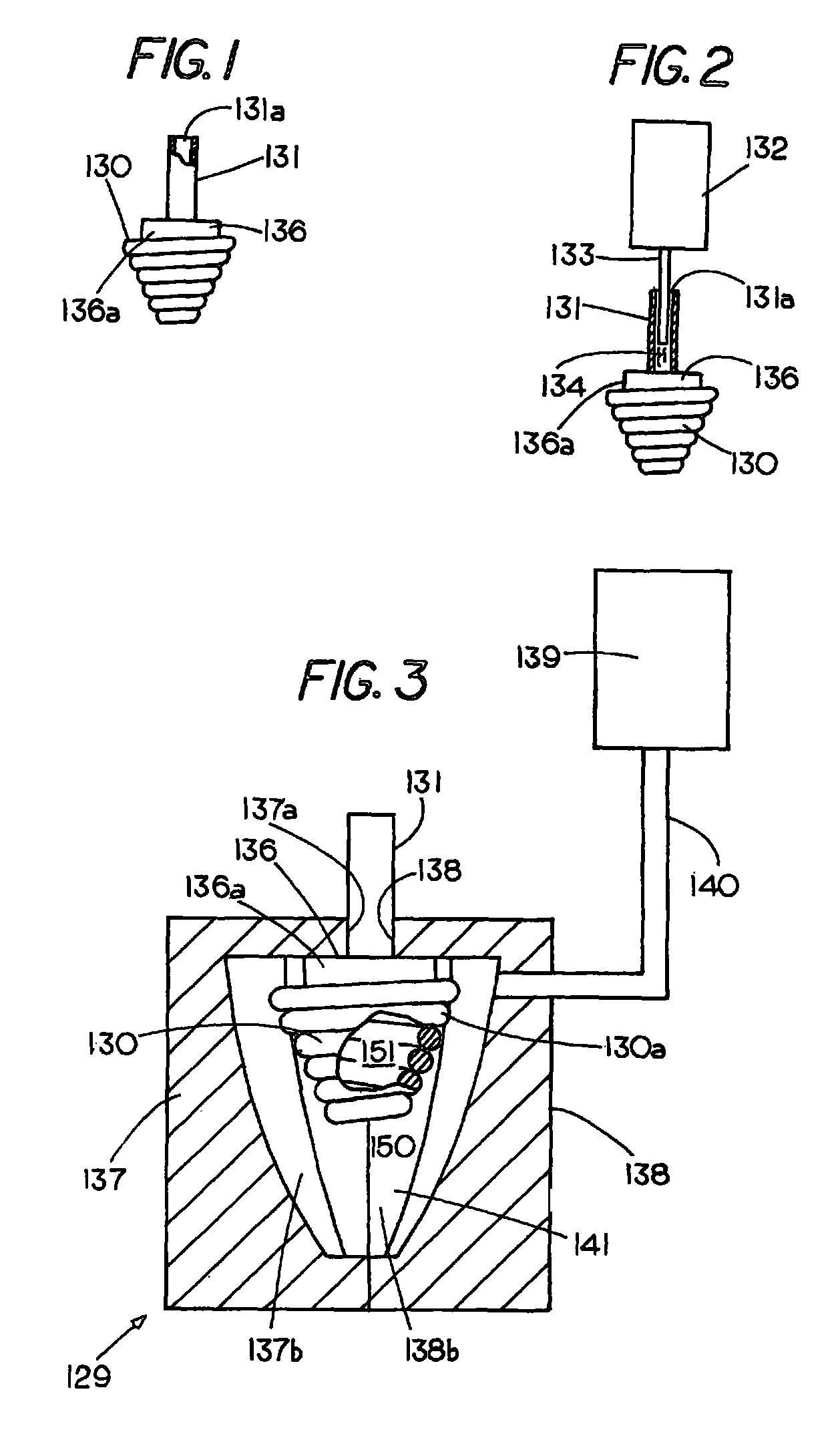

Direct bury connector

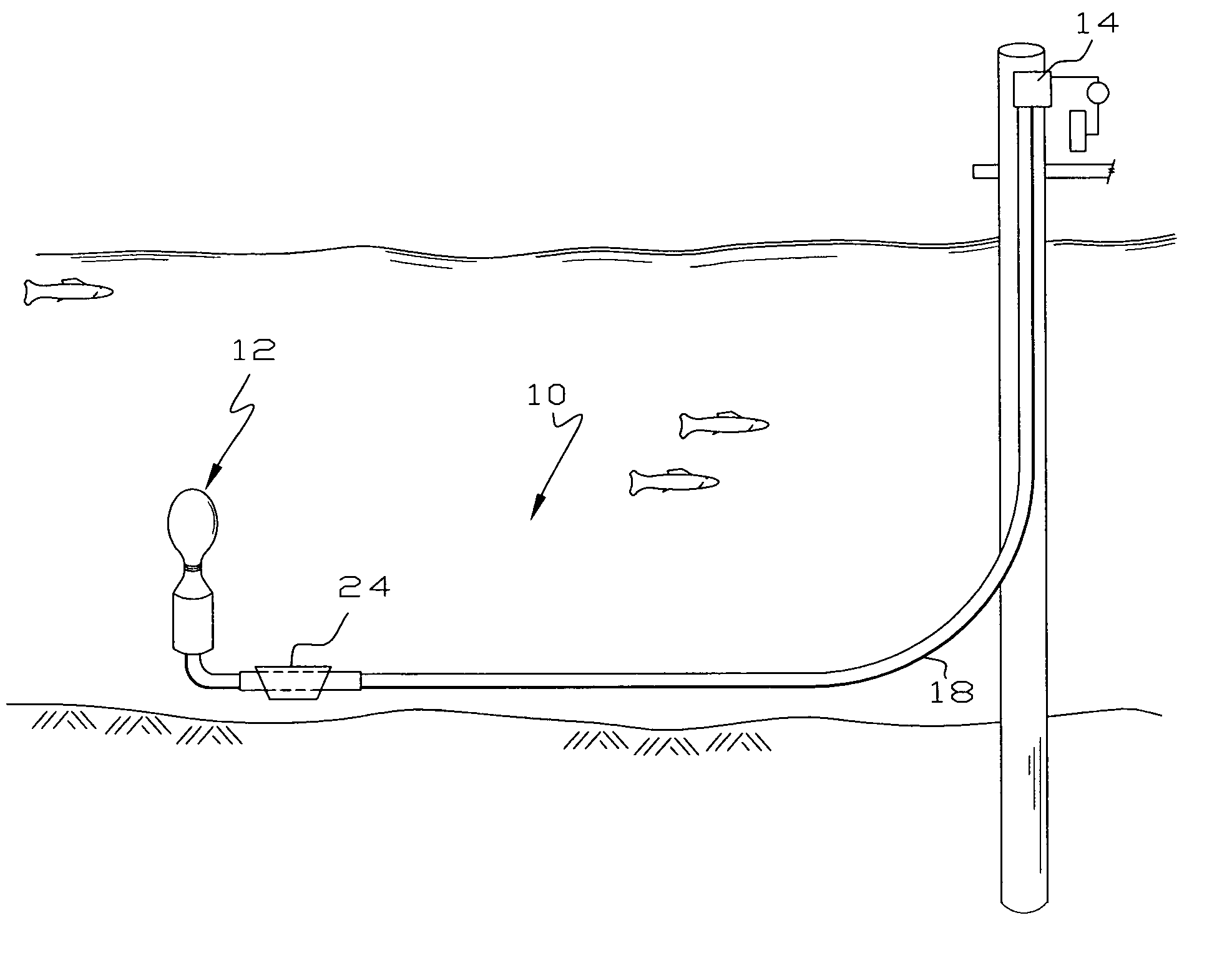

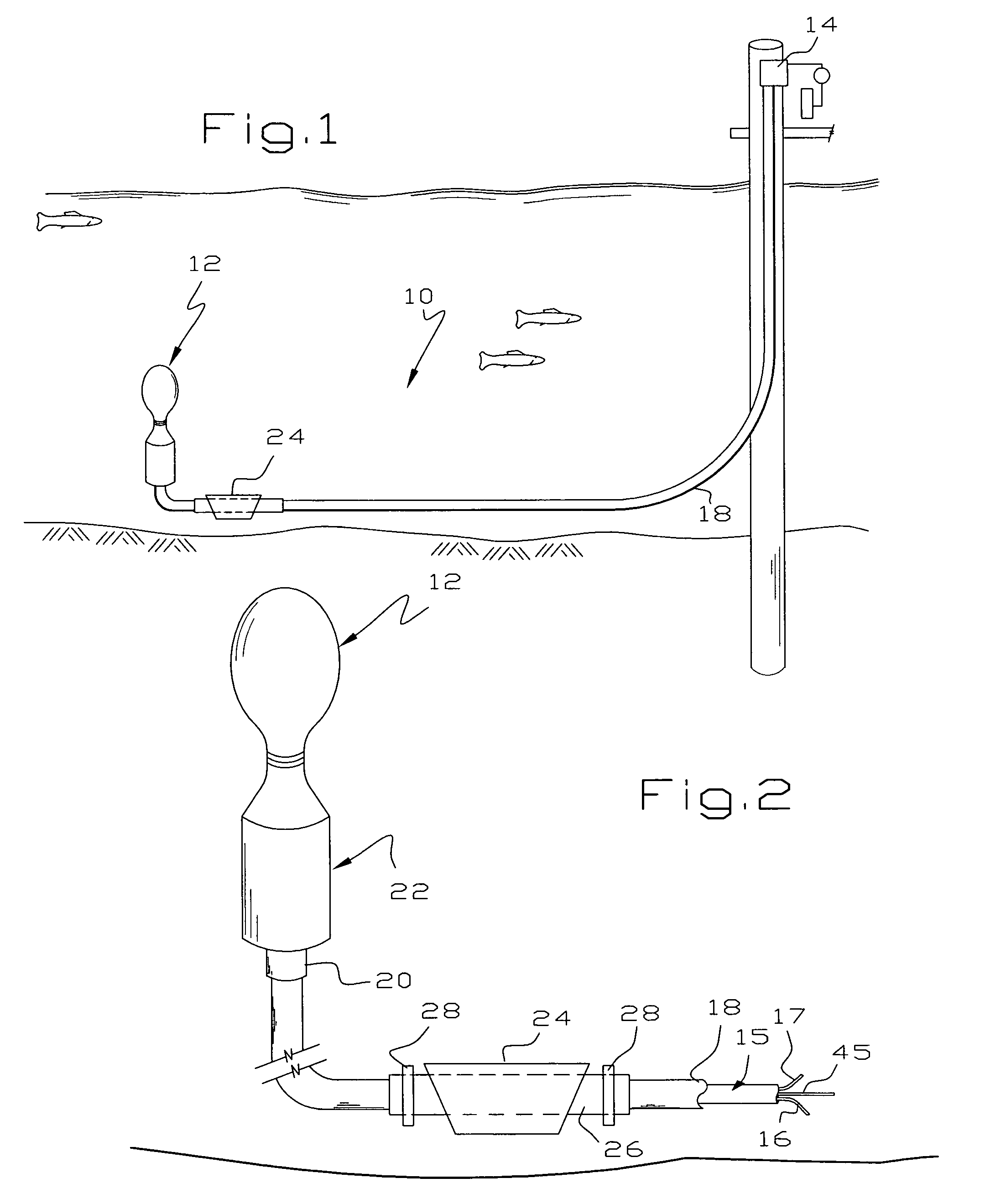

ActiveUS7170005B1Generate less wasteEasy to useRelieving strain on wire connectionConnection end capsElectrical connectionEngineering

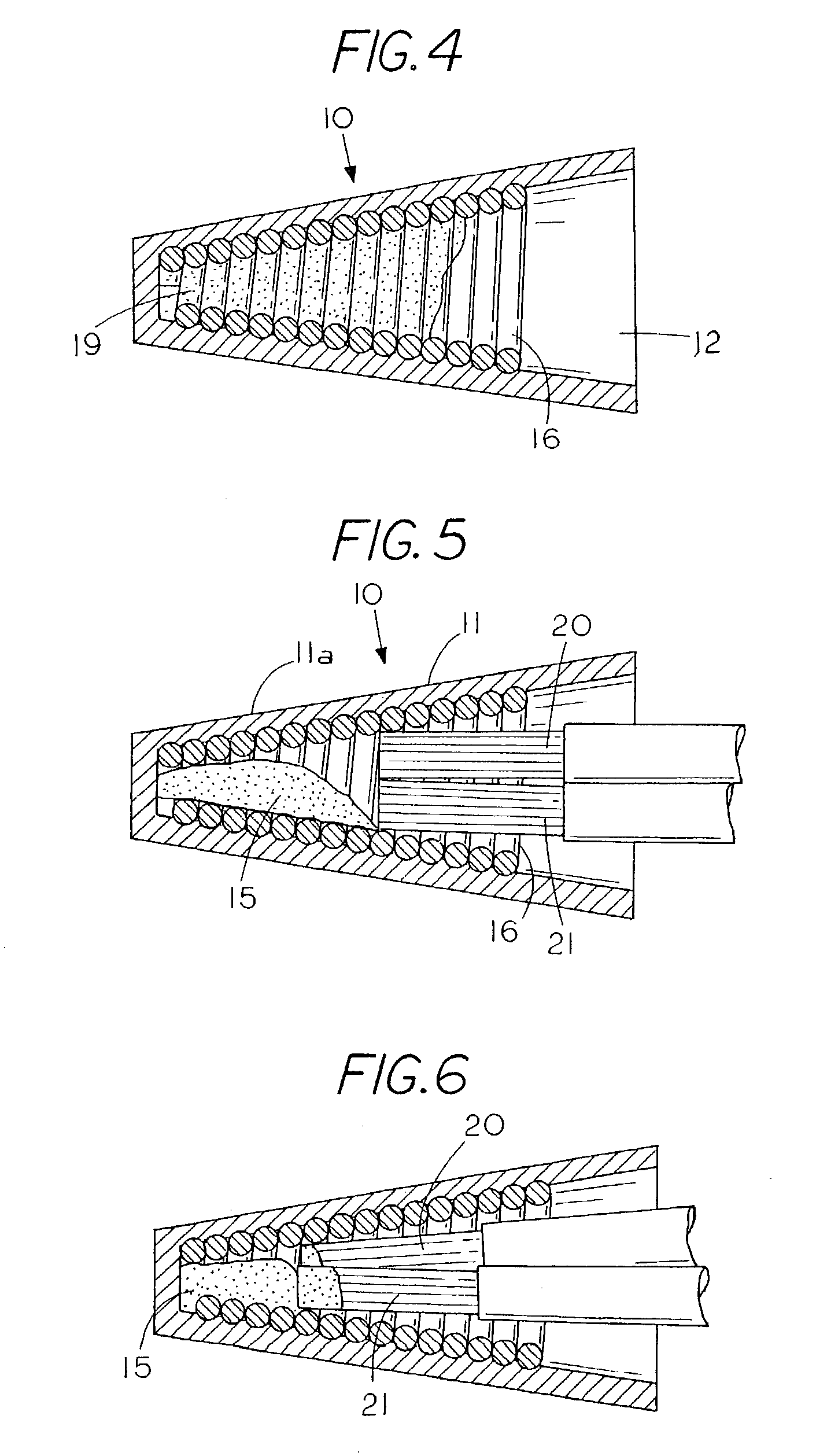

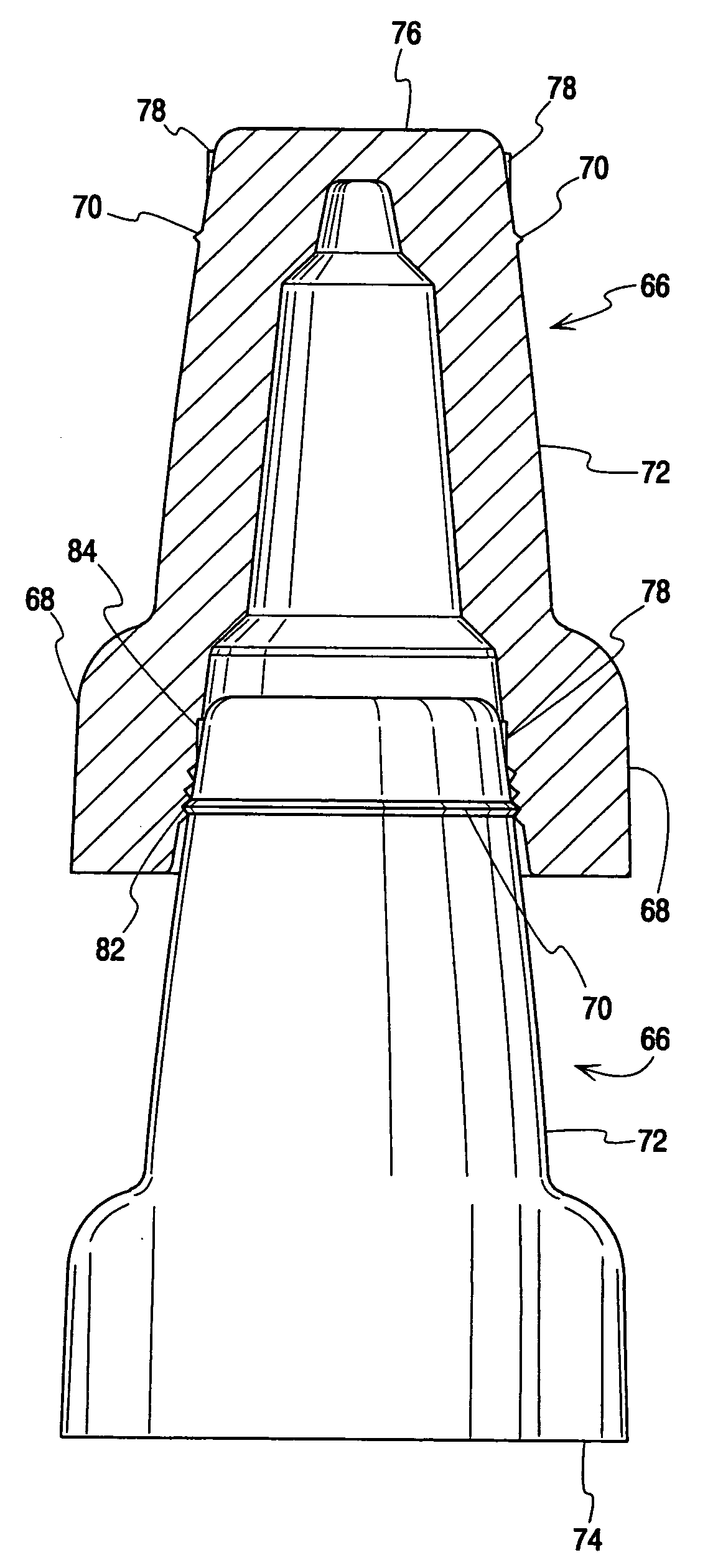

A direct bury twist-on wire connector for securing an electrical connection having a tube with an integral twist-on wire connector graspable from outside the tube while the inside of the tube and the inside of the twist-on wire connector carry a sealant therein and a cap secureable to an open end of the tube to inhibit strain on the wires to thereby provide a ready-to-bury connector.

Owner:THE PATENT STORE

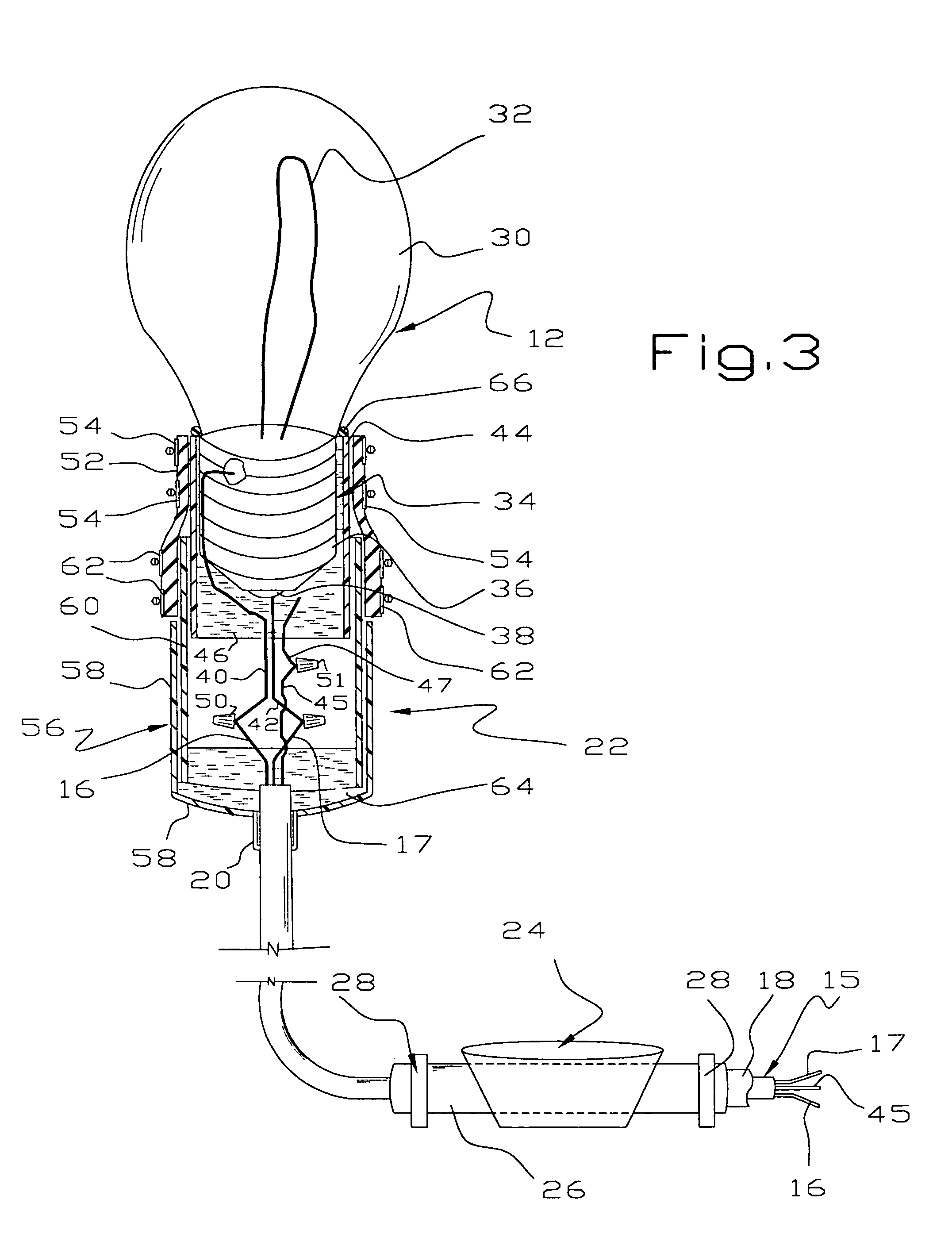

Underwater light

InactiveUS7008081B2Easy to installCheap to repairMechanical apparatusLighting elementsReverse orderEngineering

An underwater light includes a high intensity lamp placed in an enclosure that allows for easy lamp replacement in case of breakage or natural failure. Electrical wires are soldered to a metal fitting on the lamp. The metal fitting is received in a plastic nipple and the space between the fitting and nipple is filled with a sealant, leaving the ends of the wires exposed. The wires are connected by water proof twist-on wire connectors and the end of the lamp is enclosed by a rubber boot and an end cap. When the lamp burns out, it is easily replaced by fishing the light out of the water, removing the rubber boot to expose the twist-on wire connectors. The twist-on wire connectors are removed and the old lamp discarded. A new lamp is installed in reverse order.

Owner:LUNT GARY W

Twist-on wire wire connector with peelable covering

InactiveUS20080053681A1Line/current collector detailsCoupling device detailsEngineeringMechanical engineering

A twist-on wire connector containing a mass of a cohering gel in a gel state therein for forming a protective covering over a wire connection in the twist-on wire connector with the gel thereon removal from the twist-on wire connector and peelable from the wire connection to enable one to quickly form a further wire connection without having to wipe off the wire connection.

Owner:THE PATENT STORE

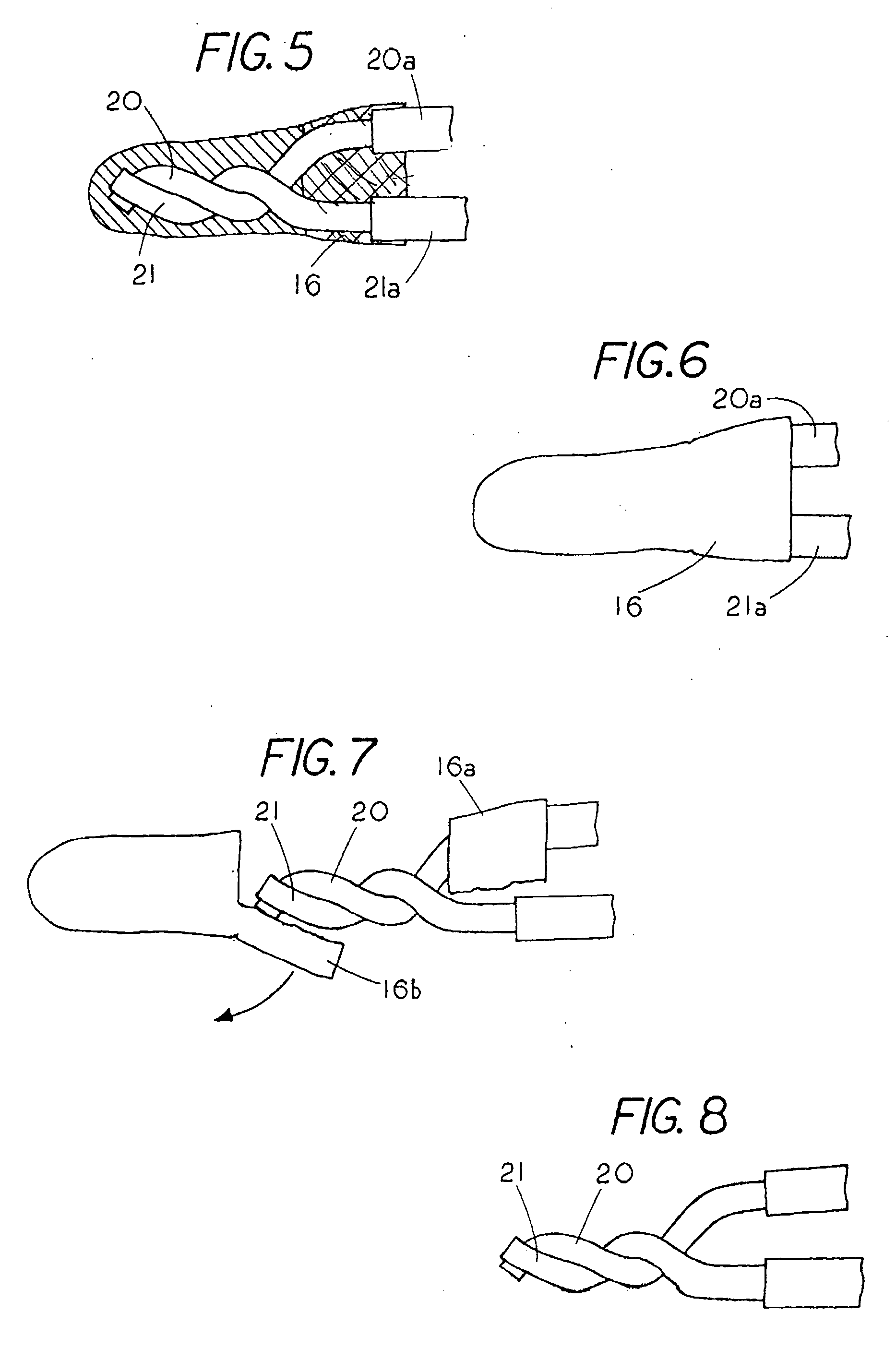

Twist-on wire connector

ActiveUS7560645B2Multiple degrees of responsiveness to finger pressureImprove insulation qualityCoupling device engaging/disengagingCoupling device detailsEngineeringMechanical engineering

Owner:THE PATENT STORE

Twist-on wire connector

ActiveUS20070084620A1Avoid fingersAvoid hand injuriesCoupling device engaging/disengagingCoupling device detailsEngineeringMechanical engineering

A twist-on wire connector having a finger friendly unbiased cushioned cover that covers not only the normal hand gripping region but at least part or all of the normal non-hand gripping region of the twist-on wire connector so that regardless of the way the twist-on wire connector is grasped the user fingers engage the cushioned cover to inhibit finger and hand injury and fatigue from repeated securement of twist-on wire connectors to electrical leads and a method of making a twist-on wire connector with a cushioned cover by placing a soft to the touch material on the exterior surface of the twist-on wire connector.

Owner:THE PATENT STORE

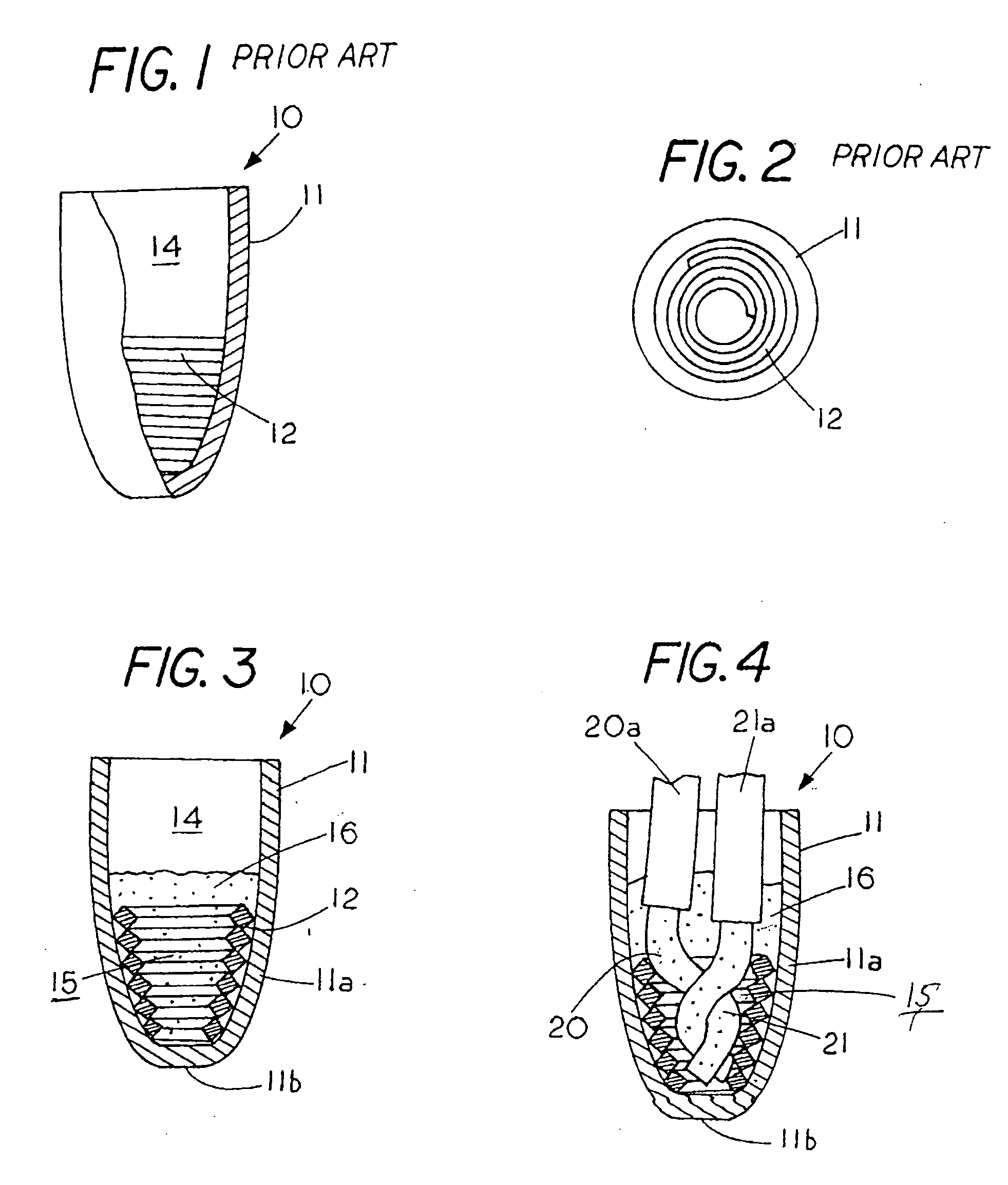

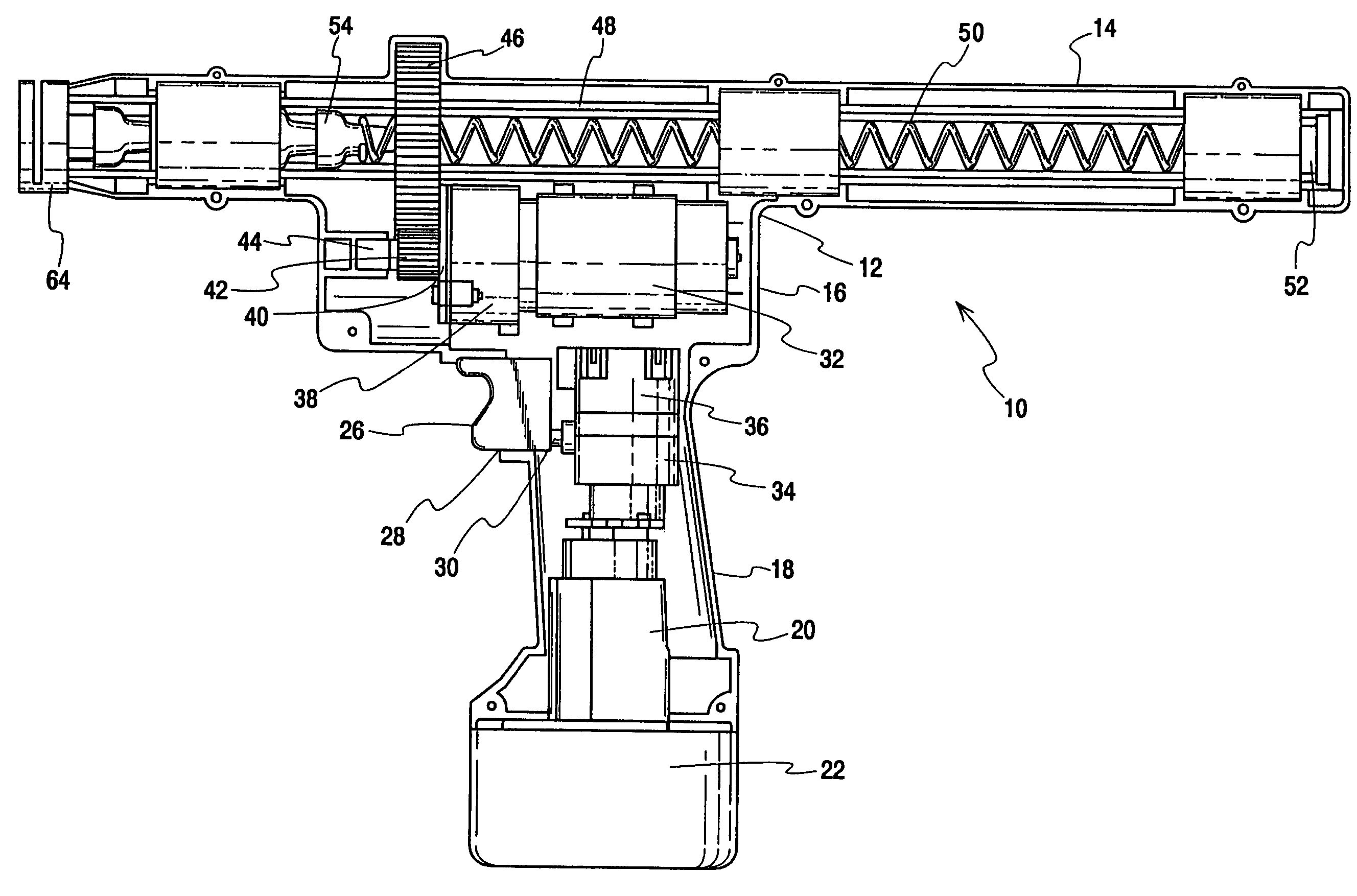

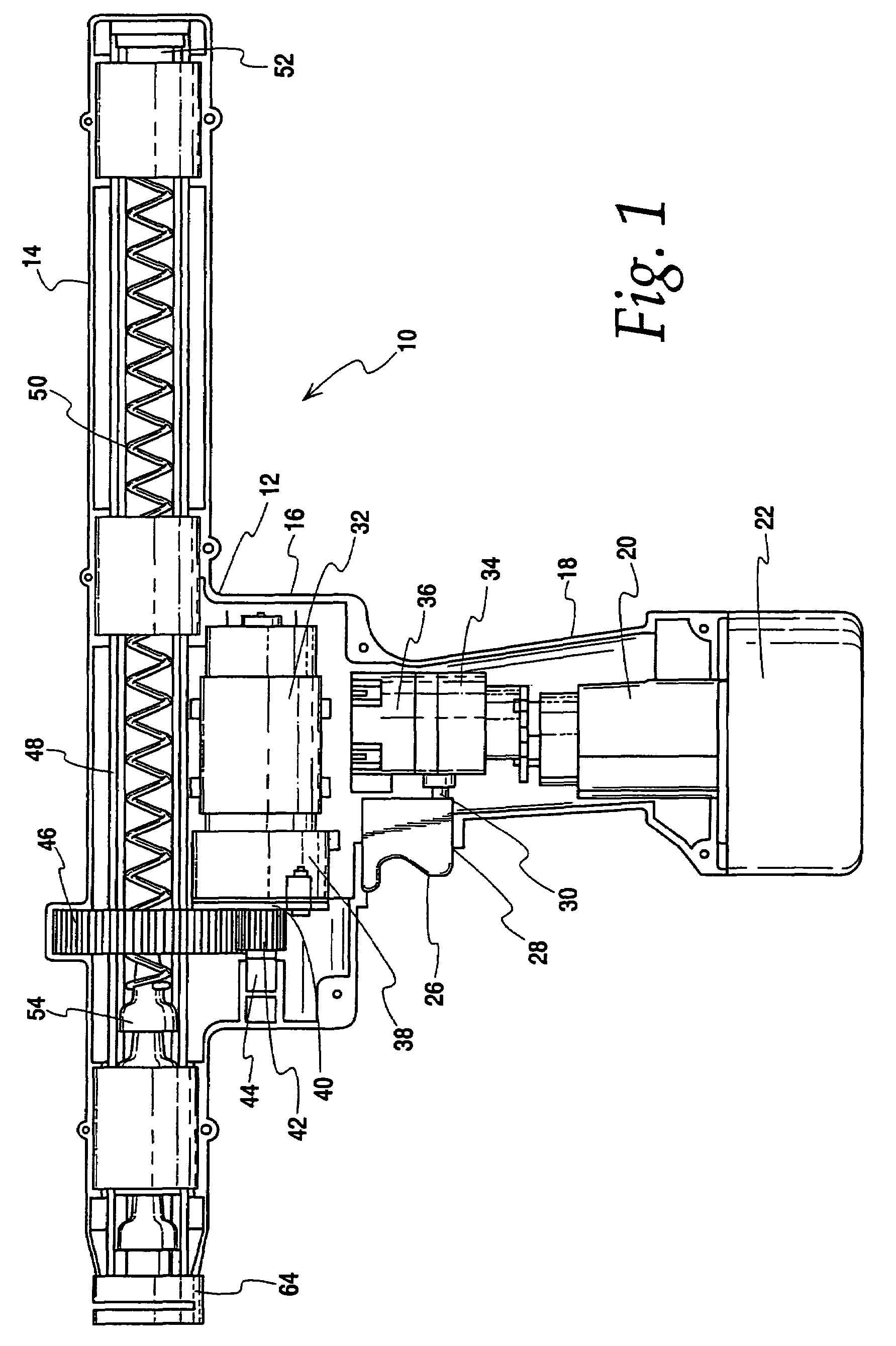

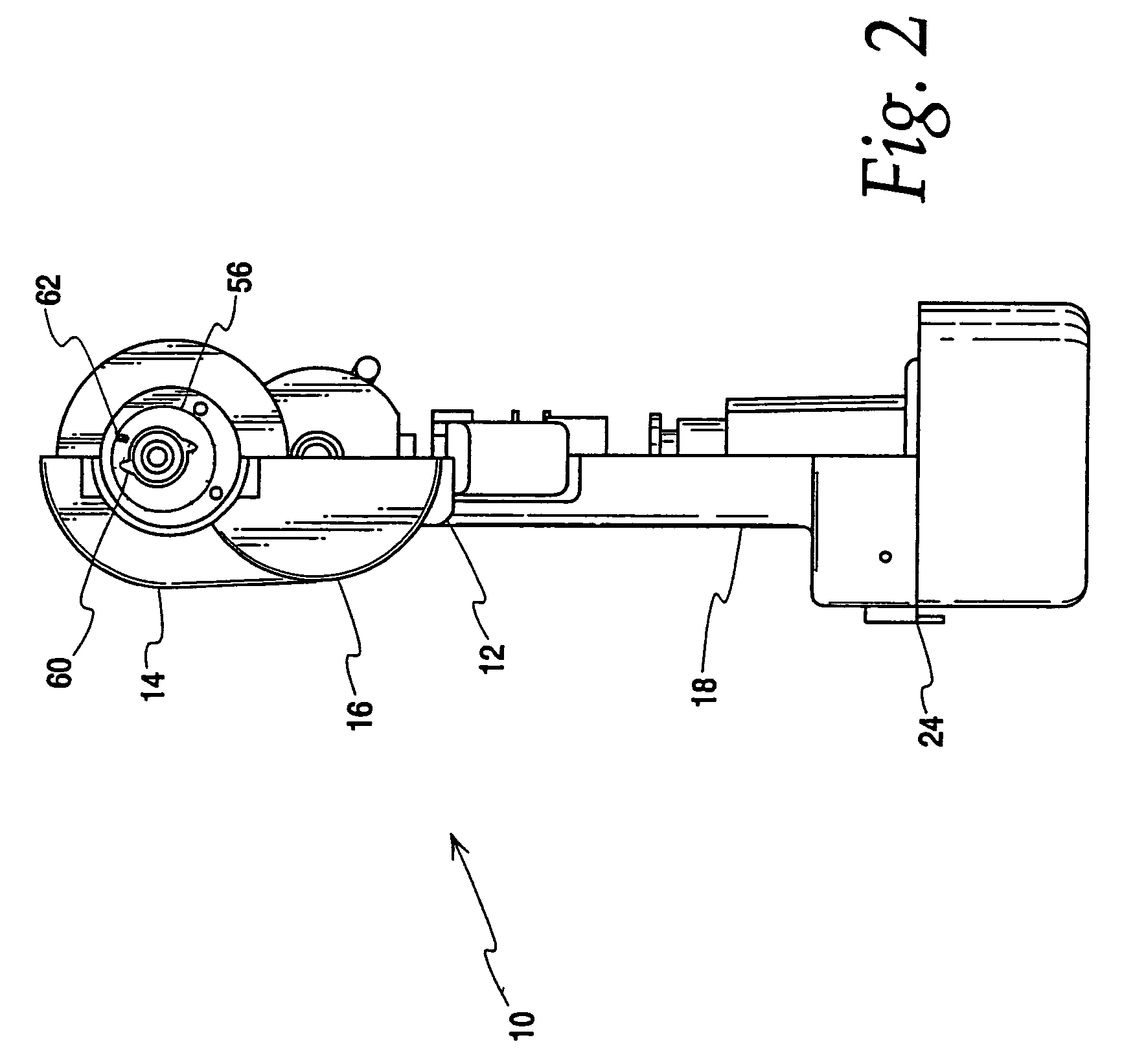

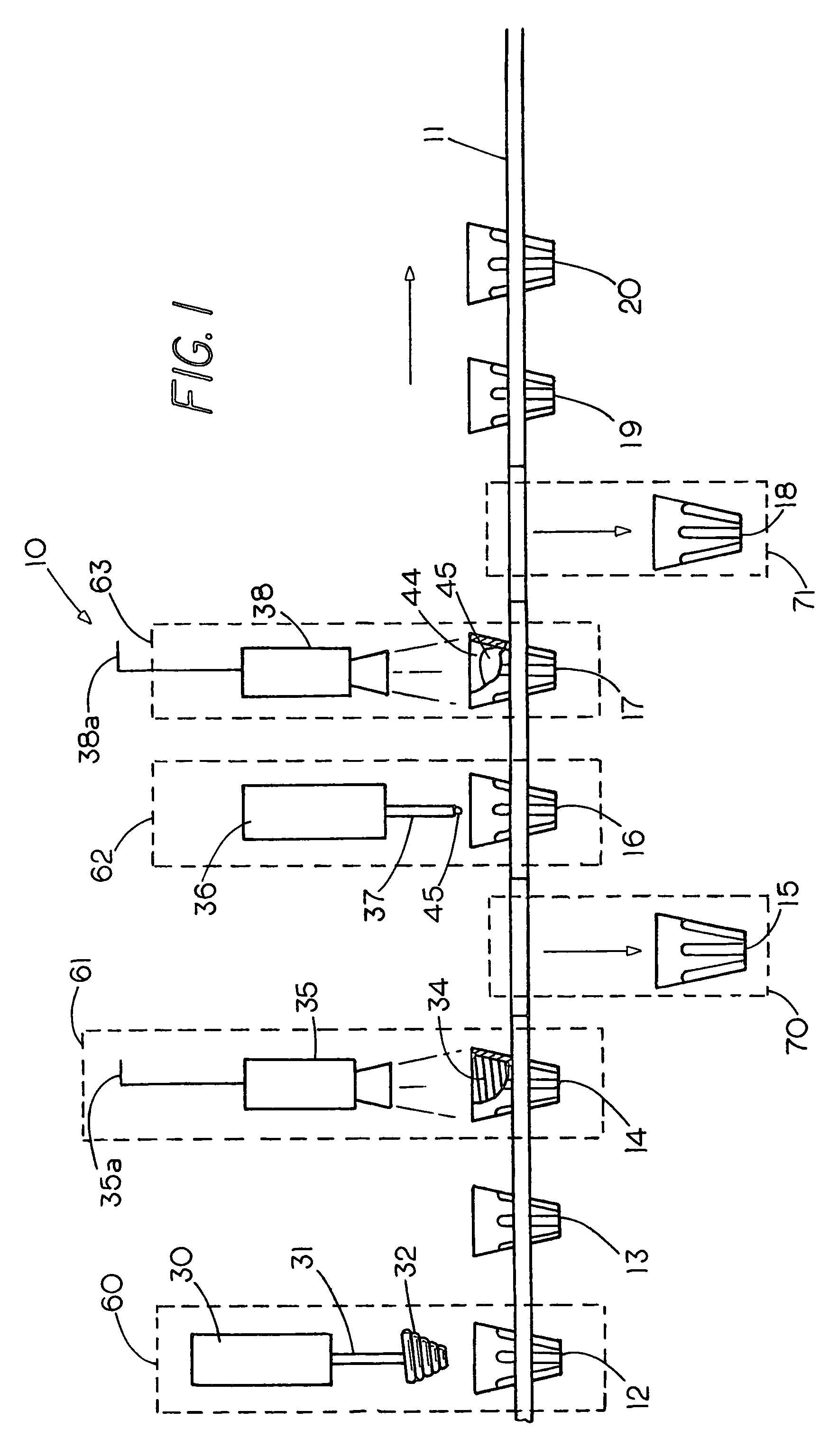

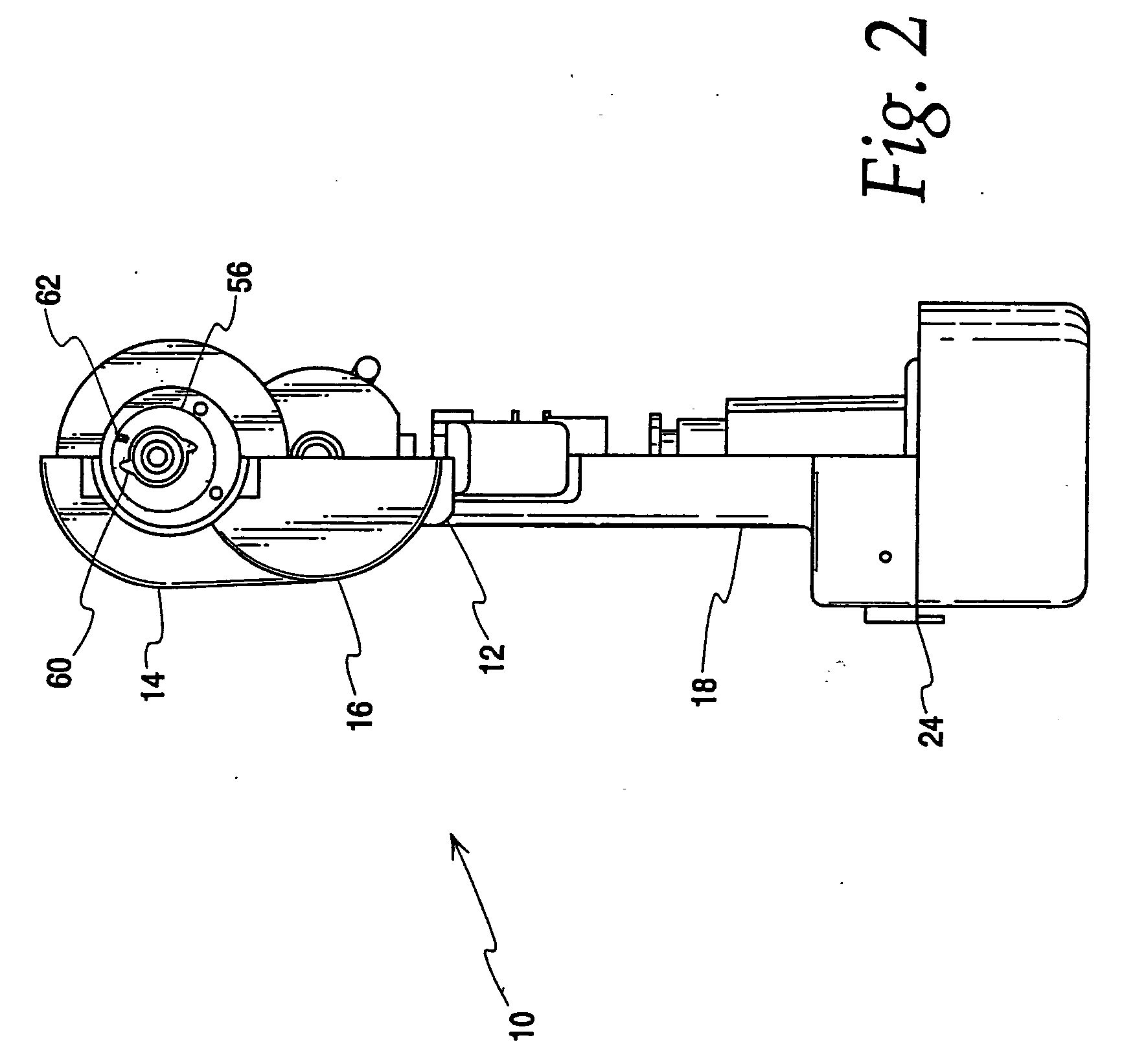

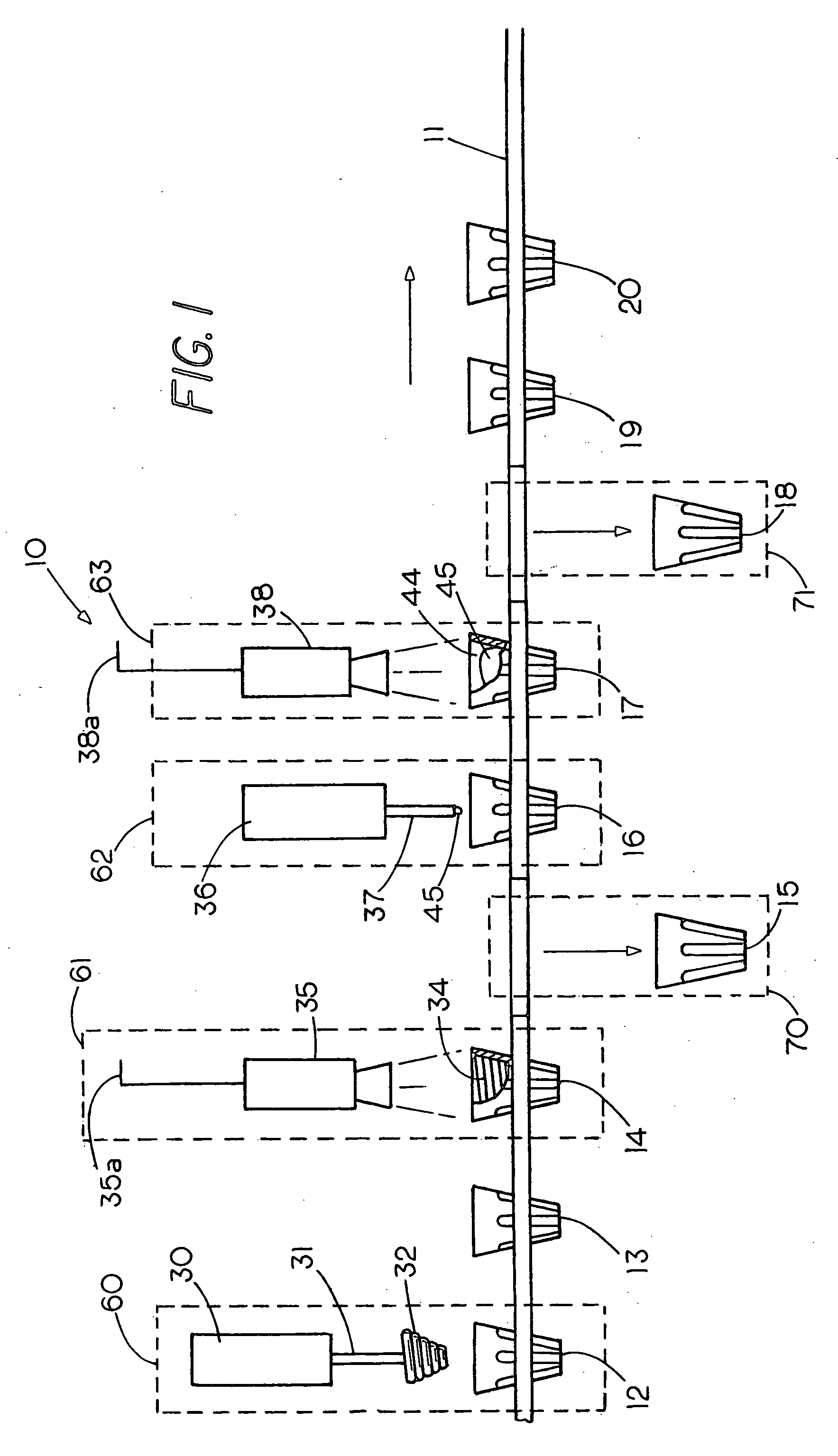

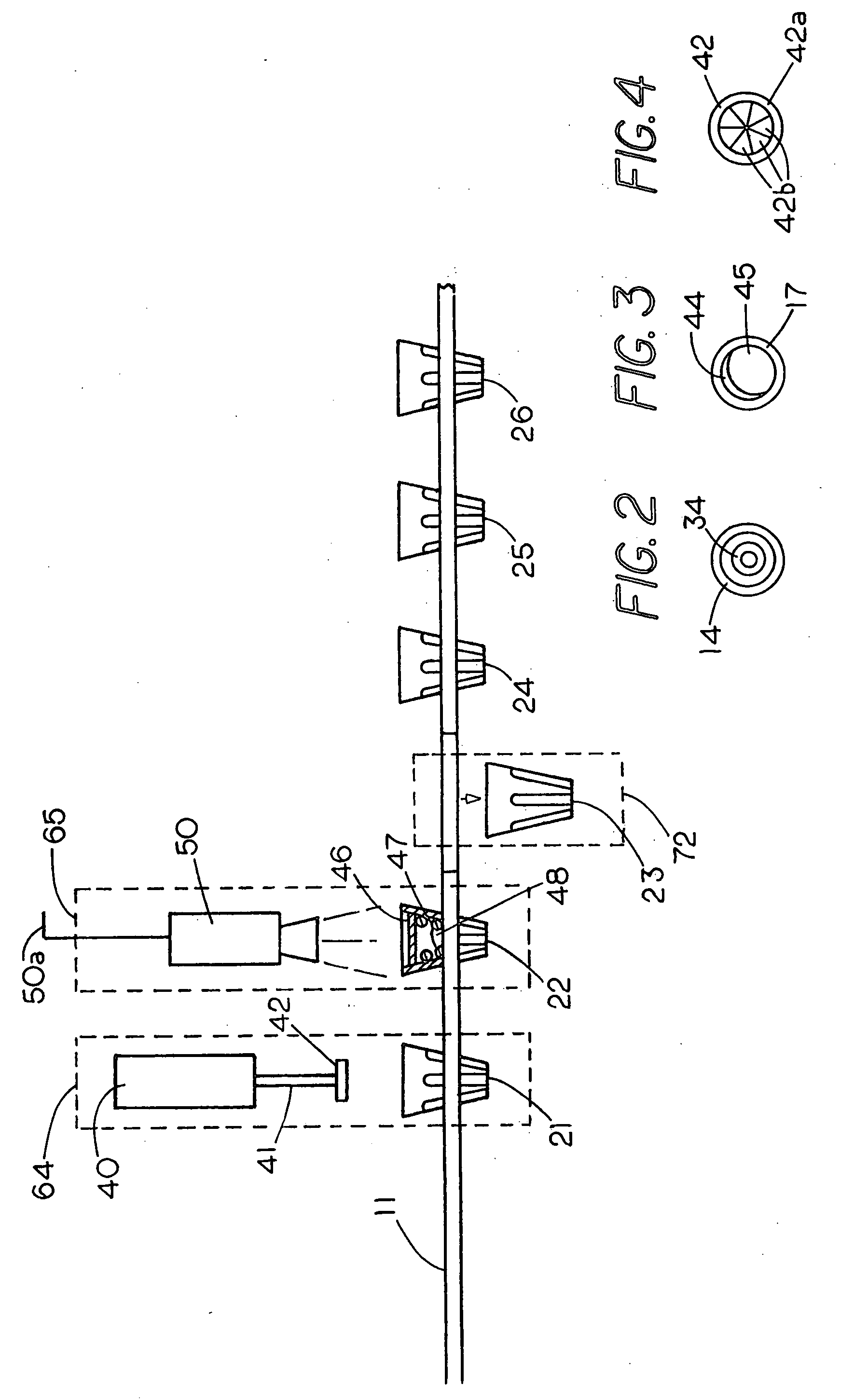

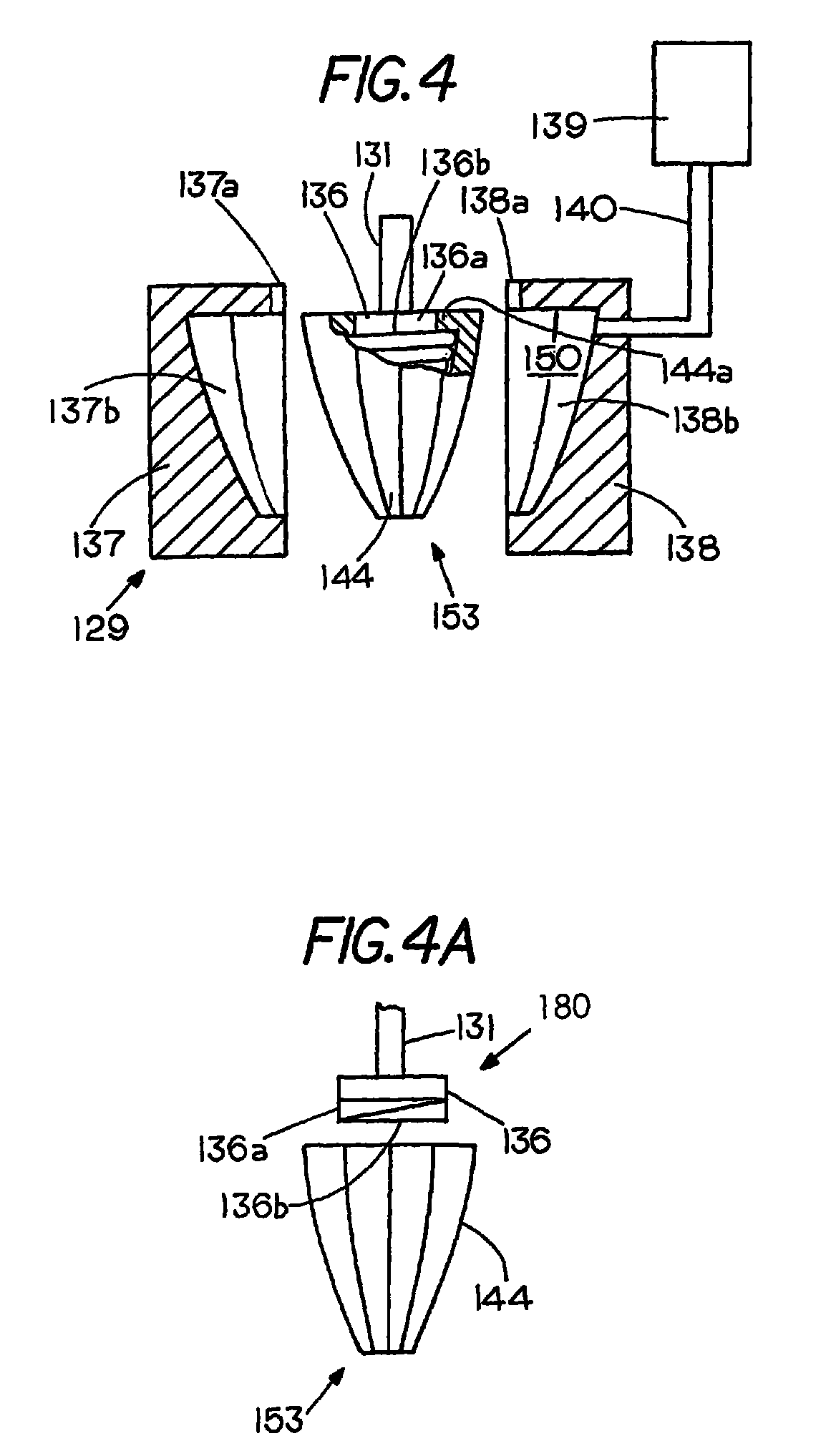

Twist-on wire connector applicator

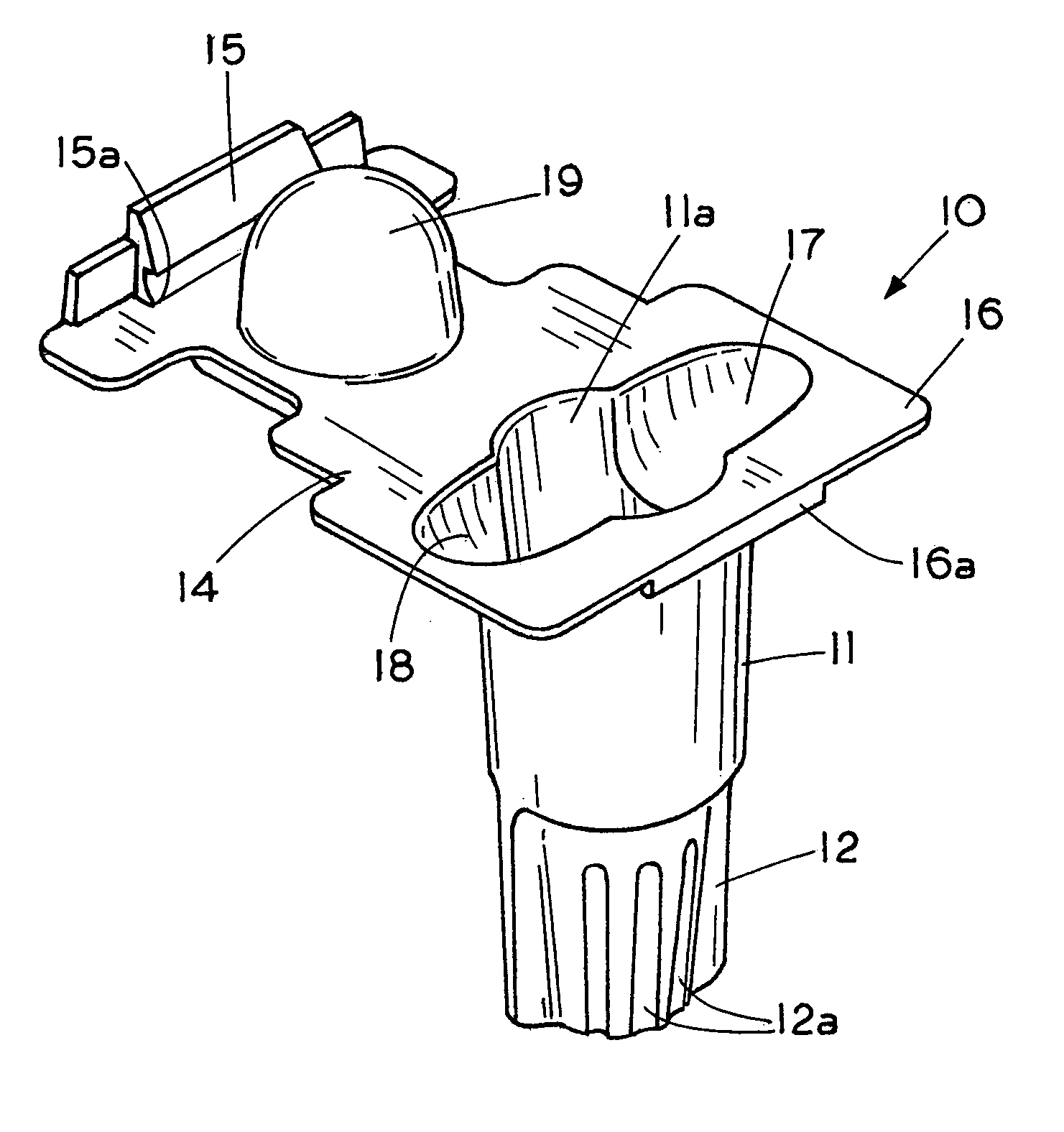

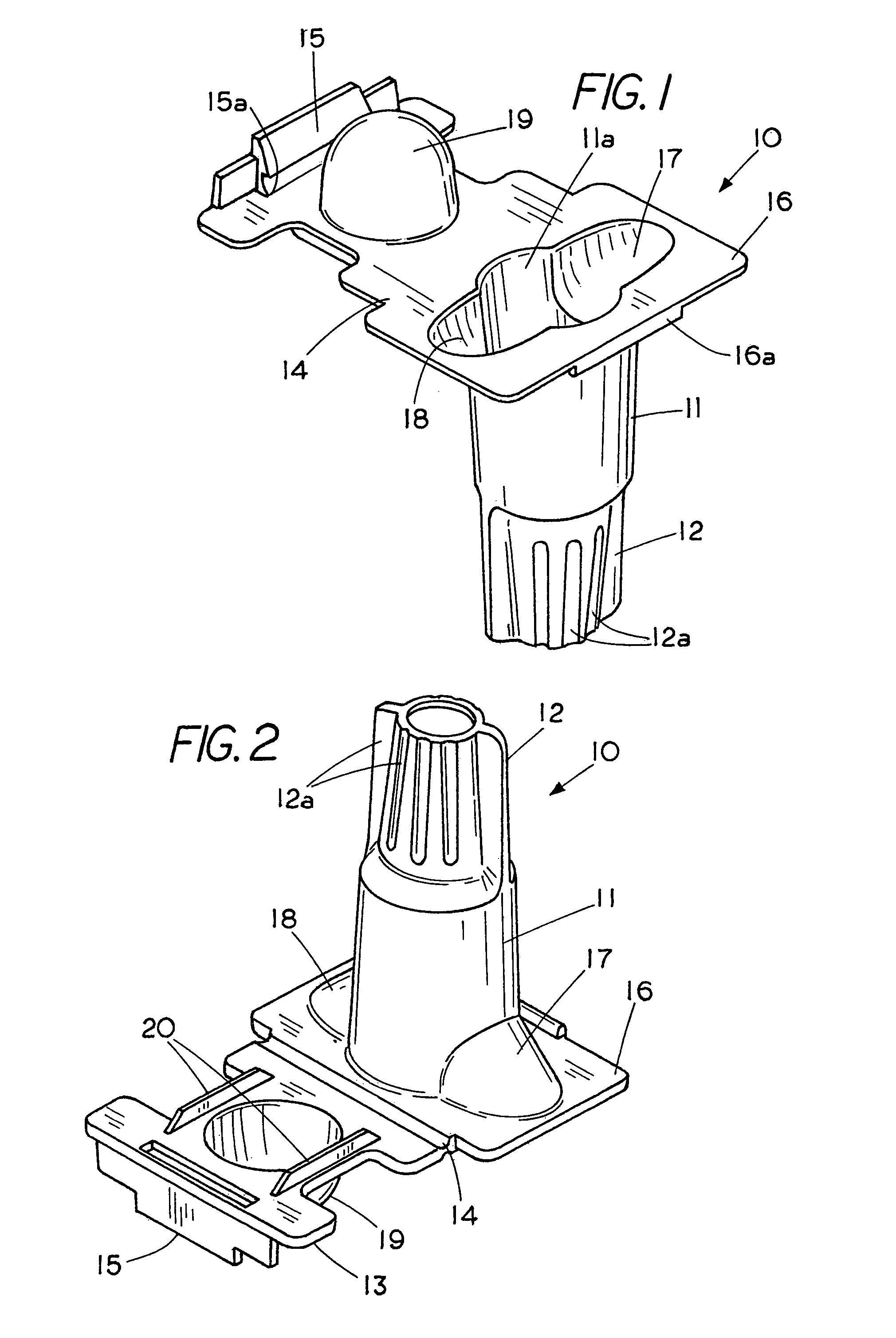

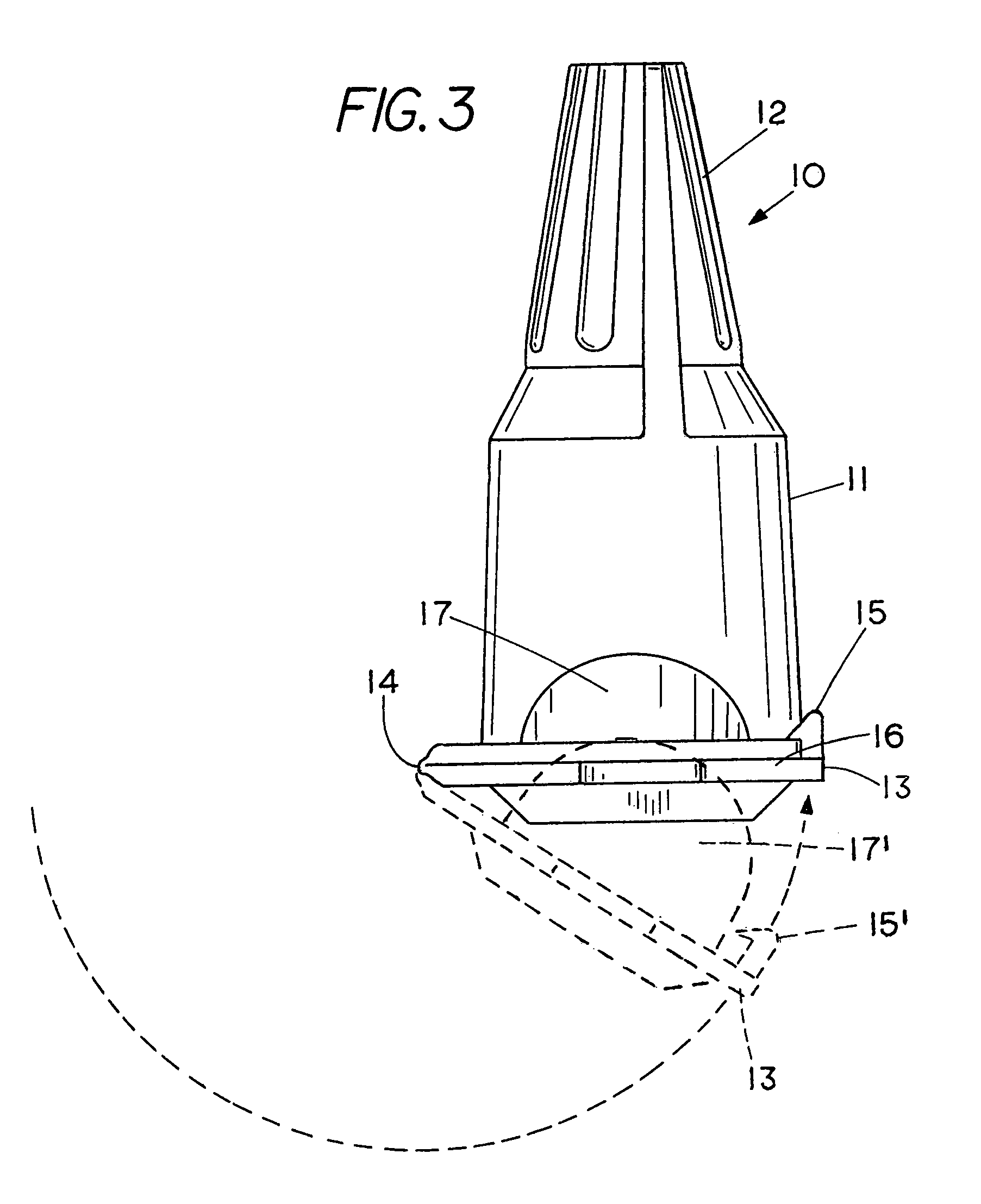

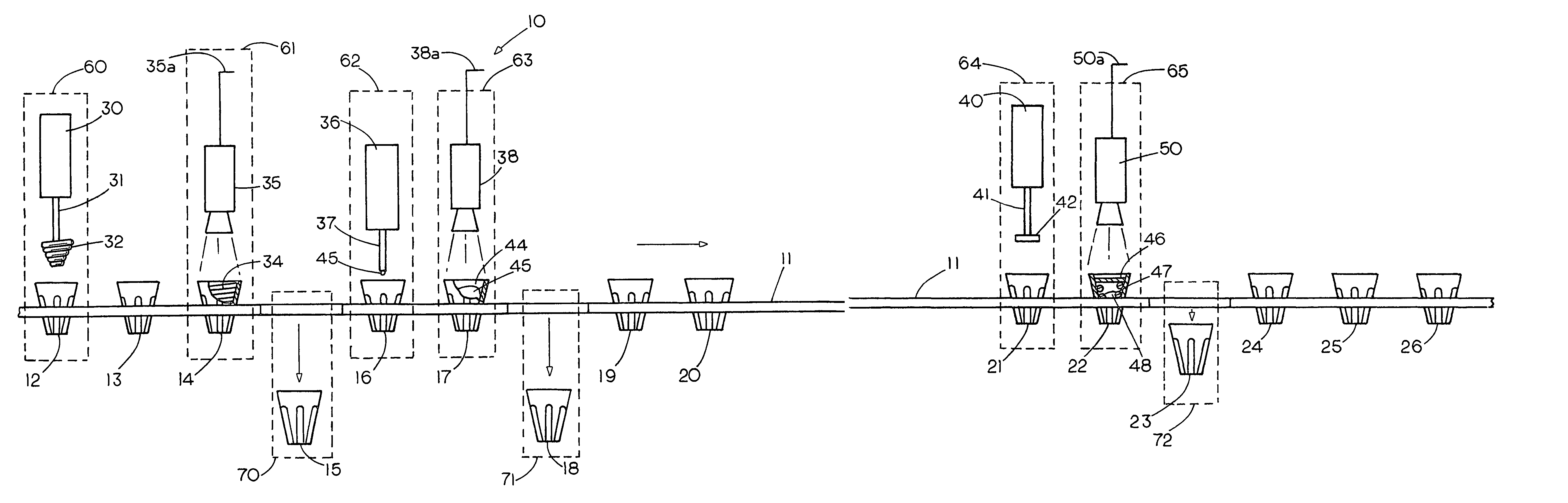

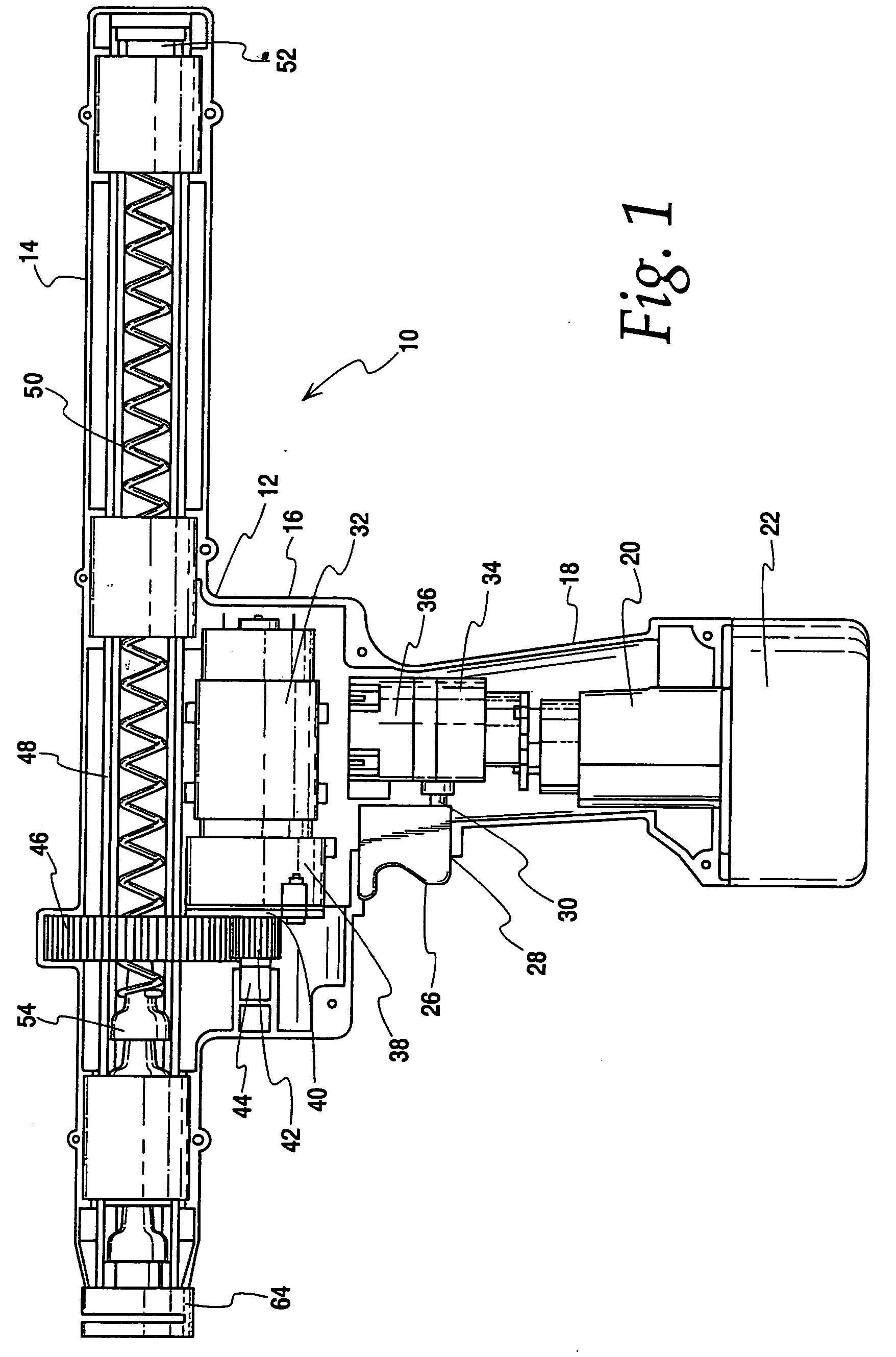

A wire connector applicator is capable of holding a clip of interconnected twist-on wire connectors in a tube which can be rotated by an electric motor. The connectors rotate with the tube for installation on the ends of stripped electrical wires. The invention is also directed to an interlocking twist-on wire connector which prevents axial separation and relative rotation of similarly configured group or clip of interlocked connectors.

Owner:IDEAL IND INC

Low torque twist-on wire connector

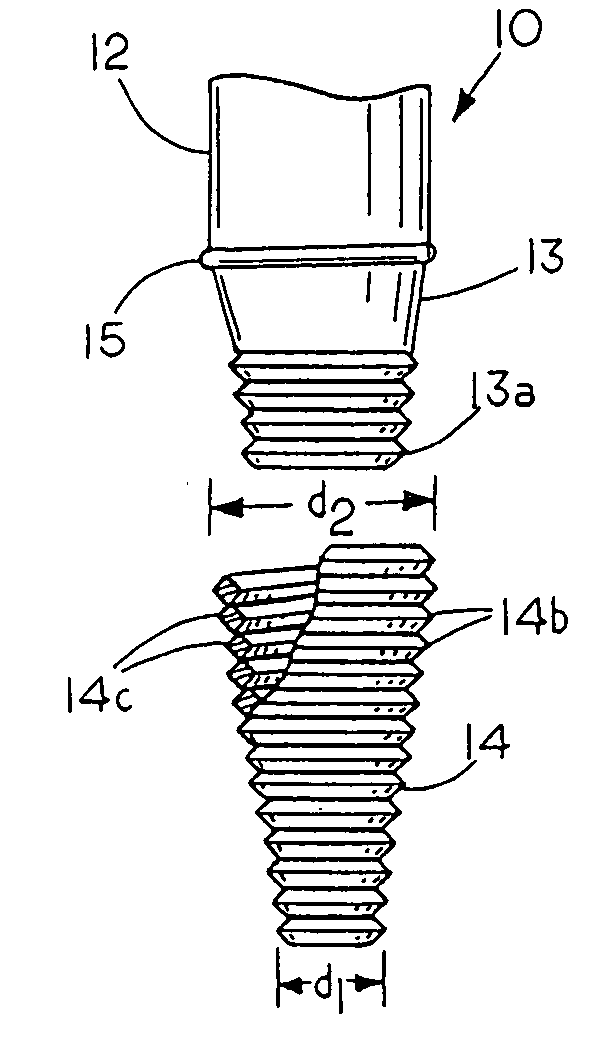

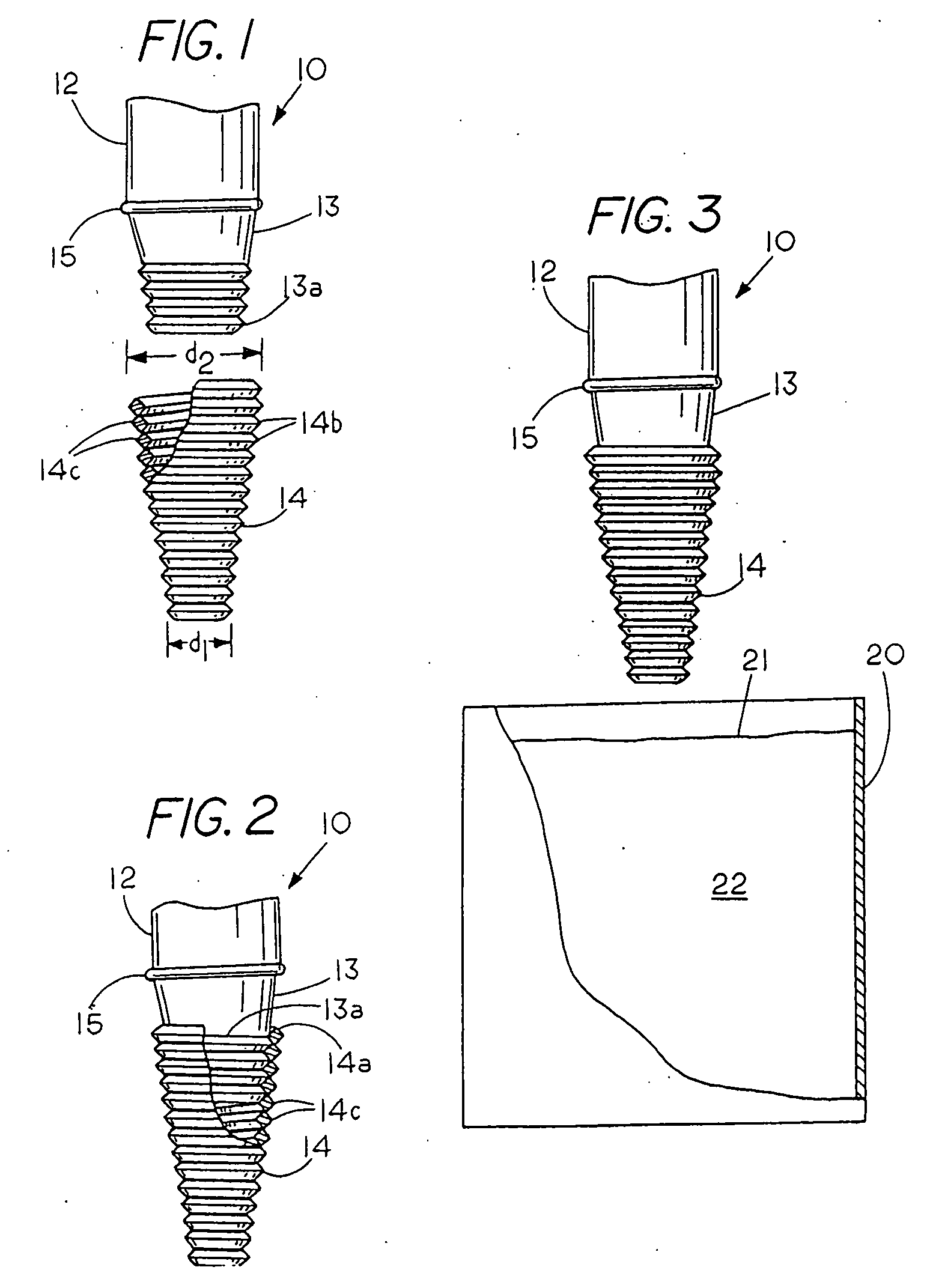

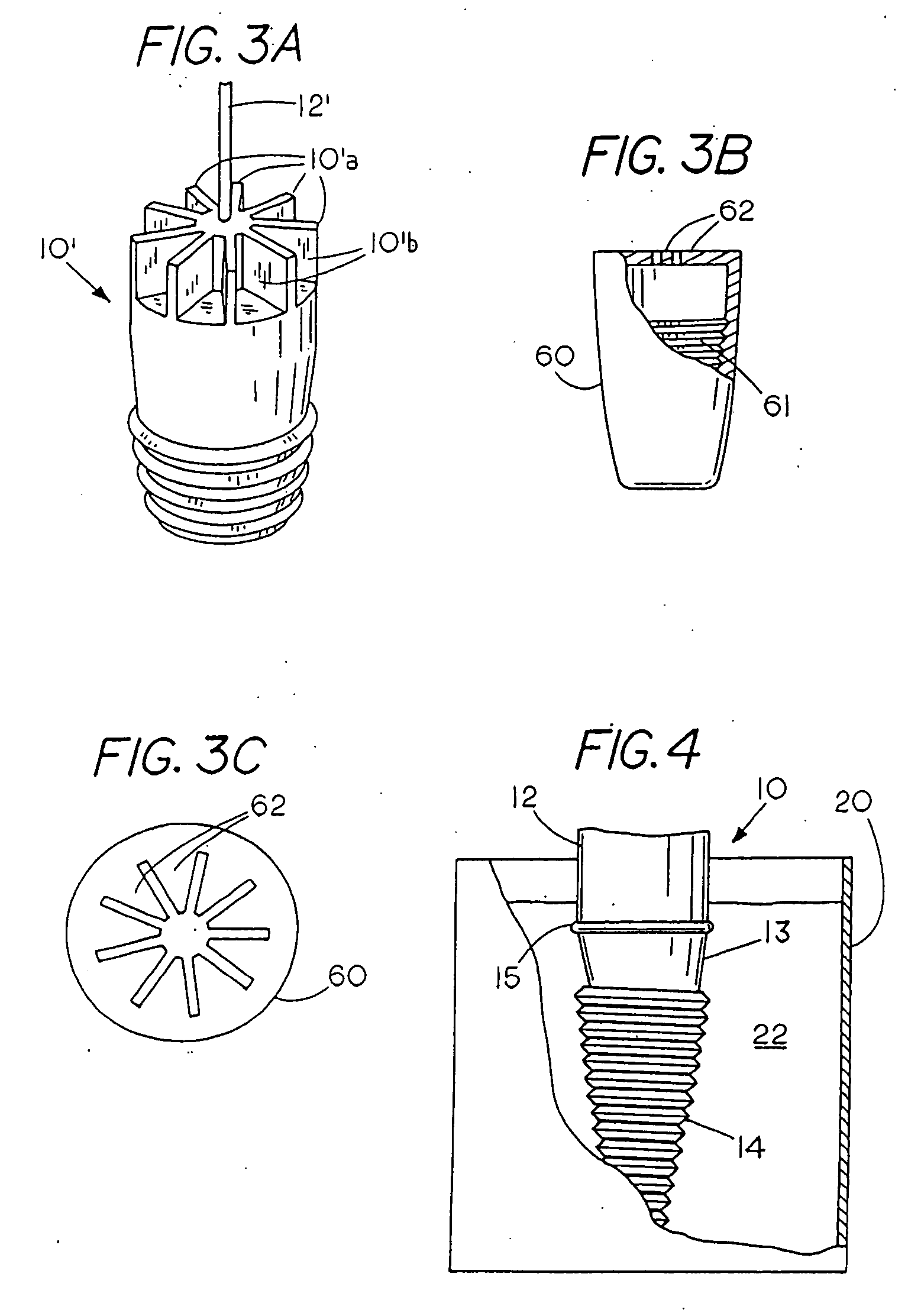

InactiveUS7038136B2Lower resistanceEnhanced low-resistance electrical connection problemLine/current collector detailsConnection end capsEngineeringScrew thread

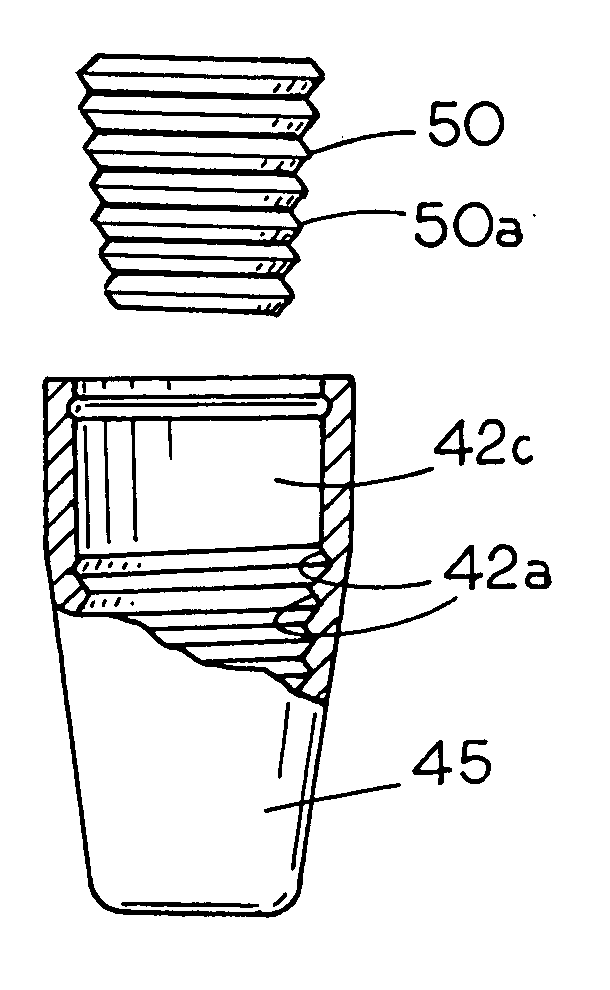

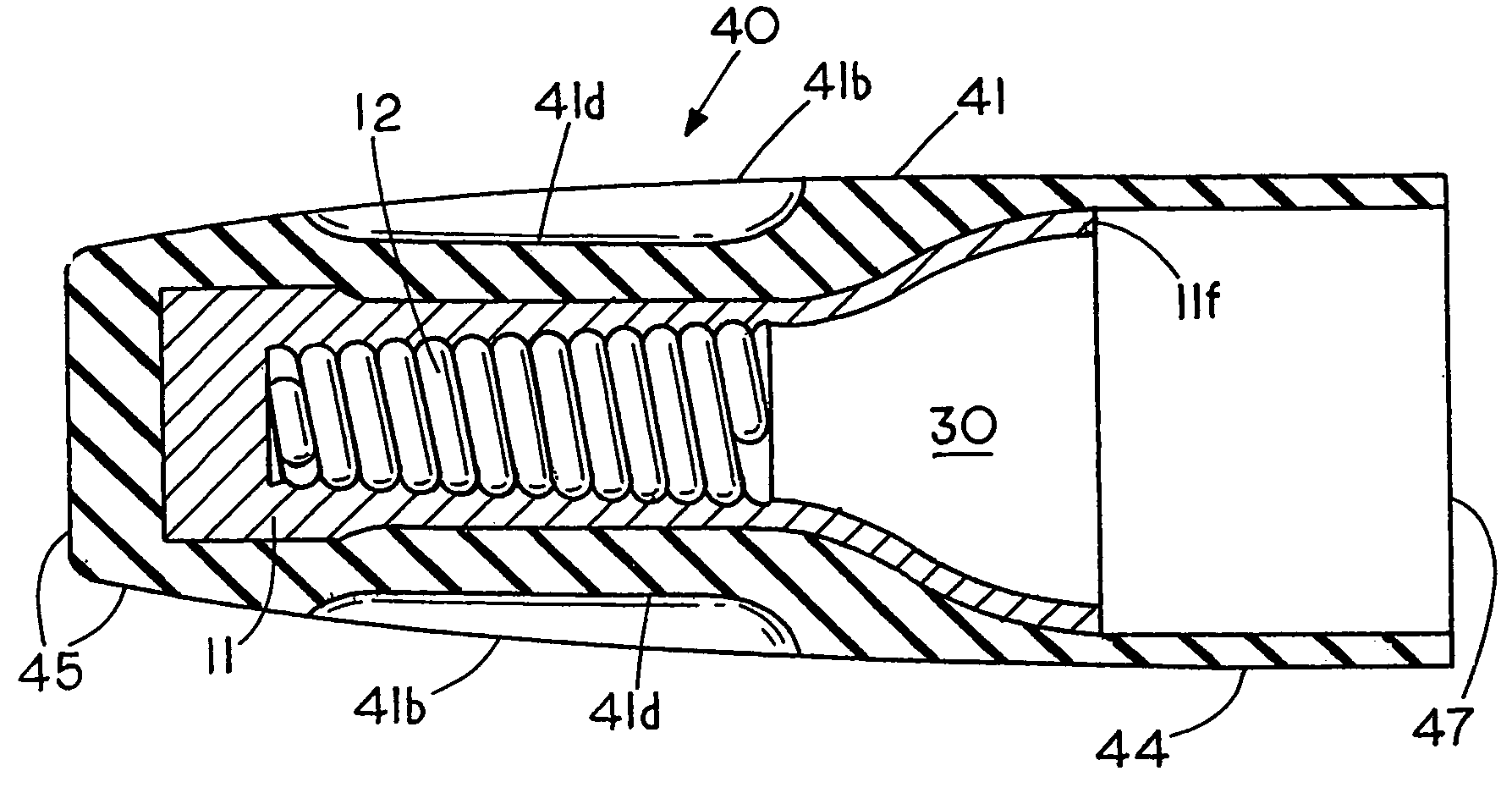

A method of making a two-stage twist-on wire connector comprising the steps of forming a housing; placing a spiral thread on an interior of the housing with the spiral thread having an open end and a closed end with a diameter of the open end of the spiral thread larger than the diameter of the closed end, the spiral thread diametrically converging in an axial direction toward the closed end; inserting a lubricant into the closed end of the spiral thread; inserting a plurality of wire ends to be splice into the open end of the spiral thread; twisting the plurality of wires and the wire connector to draw the plurality of wire ends proximate the closed end of the spiral thread to improve the continuity of said the splice; and applying the lubricant to the spiral threads by the twisting engagement of the wires with respect to the spiral threads.

Owner:KING JR LLOYD H

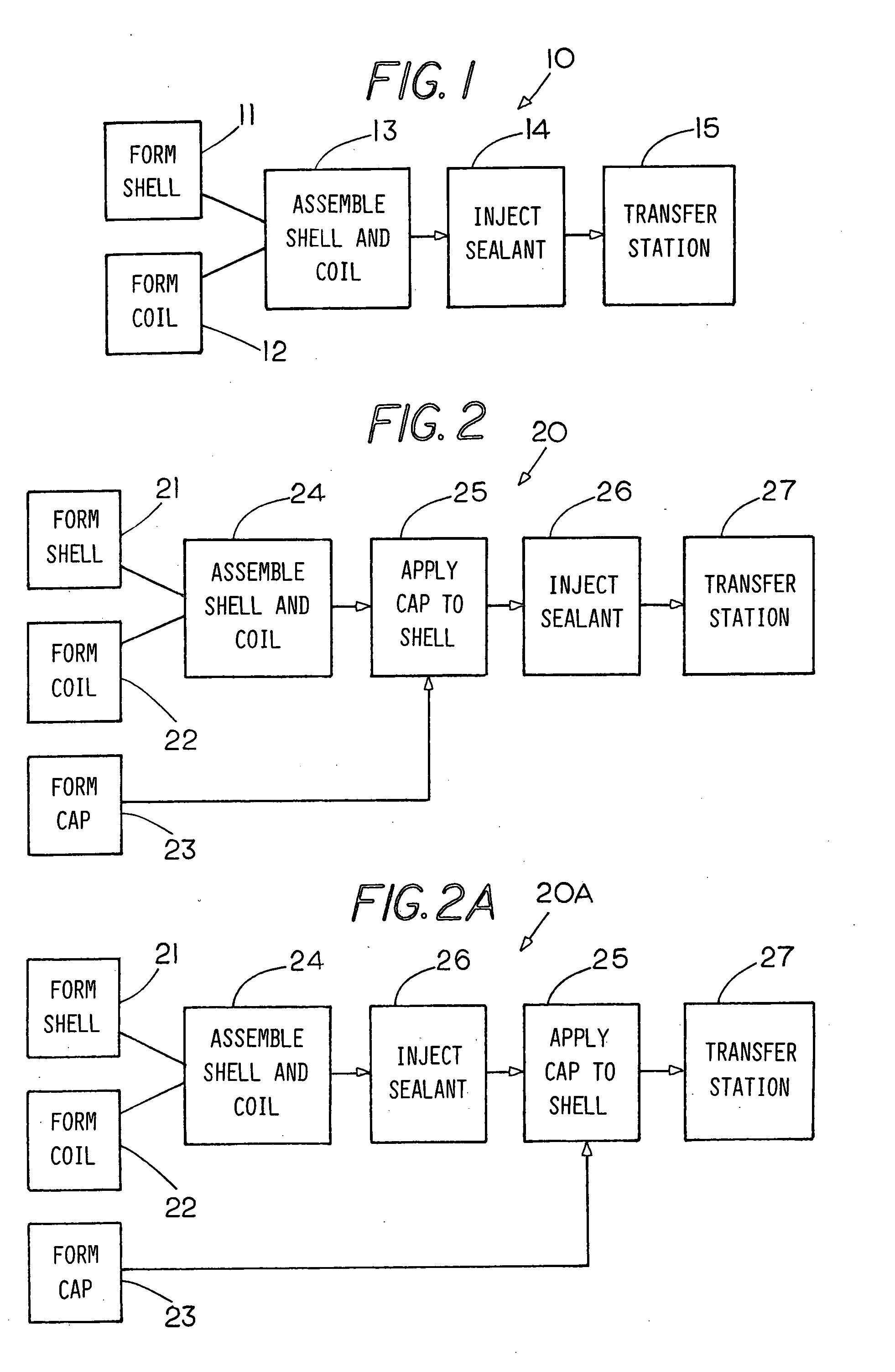

Making sealant containing twist-on wire connectors

Owner:THE PATENT STORE

Low-torque swivel connector

InactiveCN1357942ARadial pressure is not affectedReduced torsional resistance ratioLine/current collector detailsConnections effected by permanent deformationElectrical resistance and conductanceElectrical connection

An improved twist-on wire connector that permits the user to form the junction ends of wire leads into a low resistance electrical connection with the twist-on wire connector including a self adhering lubricant located along a portion of the interior of the twist-on wire connector. As the wires are drawn into the spiral thread, the torque applied to the wires increases until the wires can no longer be hand twisted into the wire connector. Once the wires are drawn into contact with the lubricant the torque resistance, which is a result of frictional resistance between the wires and the spiral thread, decreases while the radial compressive forces between the wires and the spiral thread are substantially unaffected. Consequently, the rate of torsonial resistance decreases allowing the wires to be brought into further electrical contact along a greater length through only hand tightening while at the same time the radially compressive forces on the wires are greater thus ensuring a low resistance electrical contact that remains stable over an extending period of time. Because only a small amount of self-adhering lubricant is needed within the wire connector to provide an enhanced low-resistance electrical connection problems of the self-adhering lubricant accidentally coming into contact with the exterior housing of other twist-on wire connectors is minimized even if not caps are used on the twist-on wire connectors.

Owner:劳埃德·H·小金

Epidermal friendly twist-on wire connector method

ActiveUS9331445B1Connection end capsConnection formation by deformationEngineeringMechanical engineering

An epidermal friendly twist-on wire connector and a method of applying an epidermal twist-on wire connector having a resilient gripping region including a set of low profile, resilient ribs that are circumferentially spaced so that a users thumb and fingers can compressively and sequentially engage and compress at least a portion of a plurality of ribs as well as the valley between the ribs during application of a wire securement torque to the twist-on wire connector while at the same time inhibiting or preventing epidermal trauma in a users thumb and fingers.

Owner:THE PATENT STORE

Assembling sealant containing twist-on wire connectors

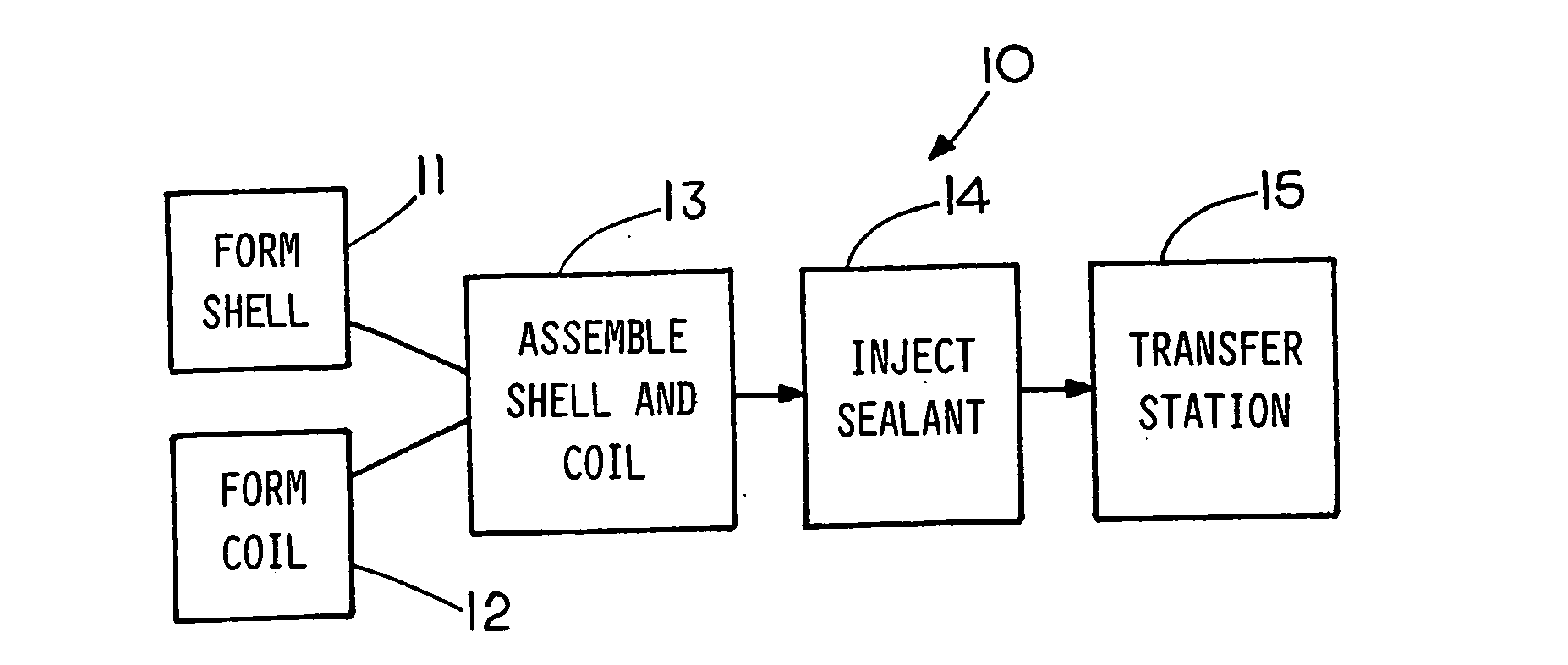

ActiveUS20100064513A1Eliminating upfront investment costMinimizes rejectionContact member cases/bases manufactureContact member assembly/disassemblyEngineeringImproved method

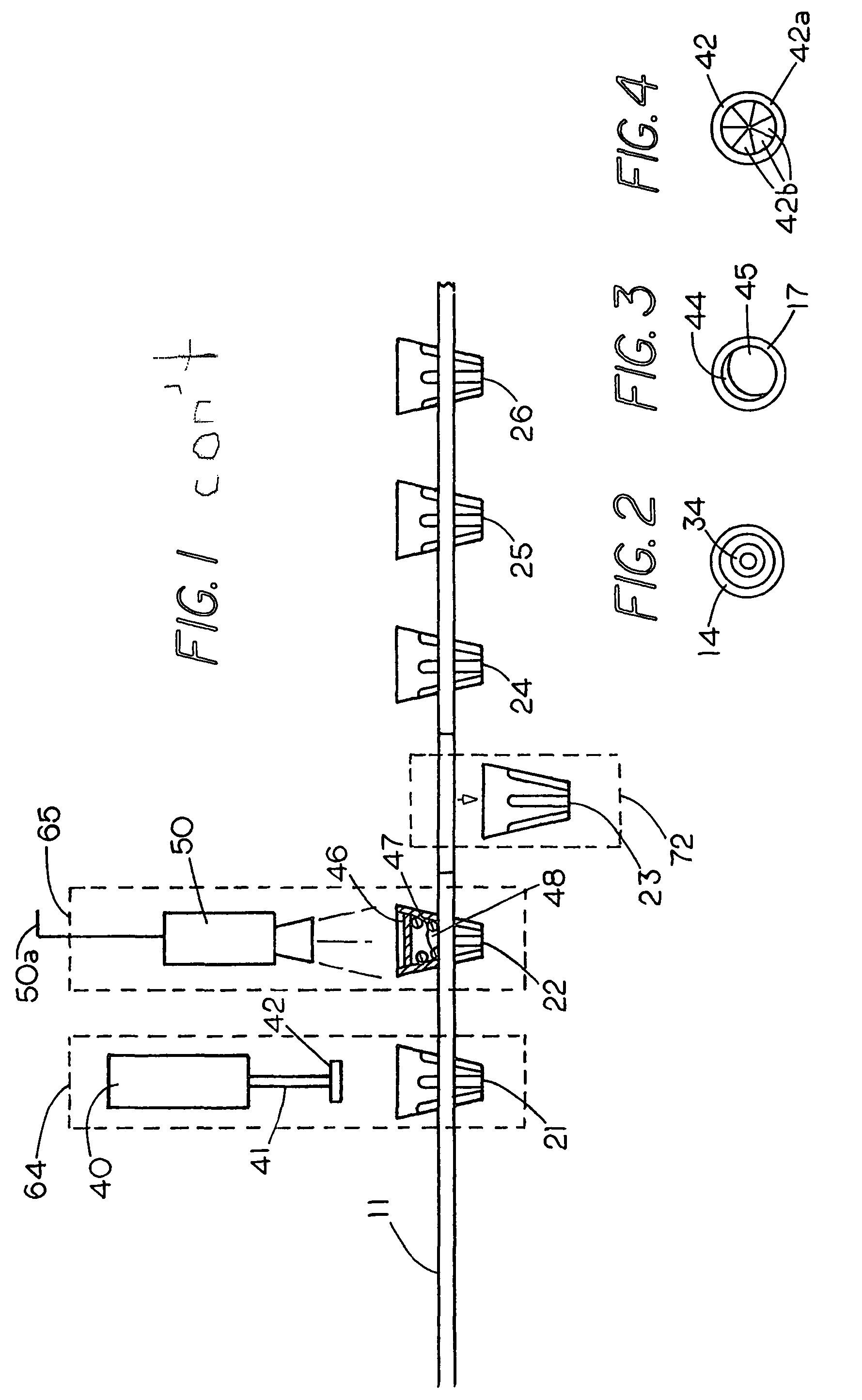

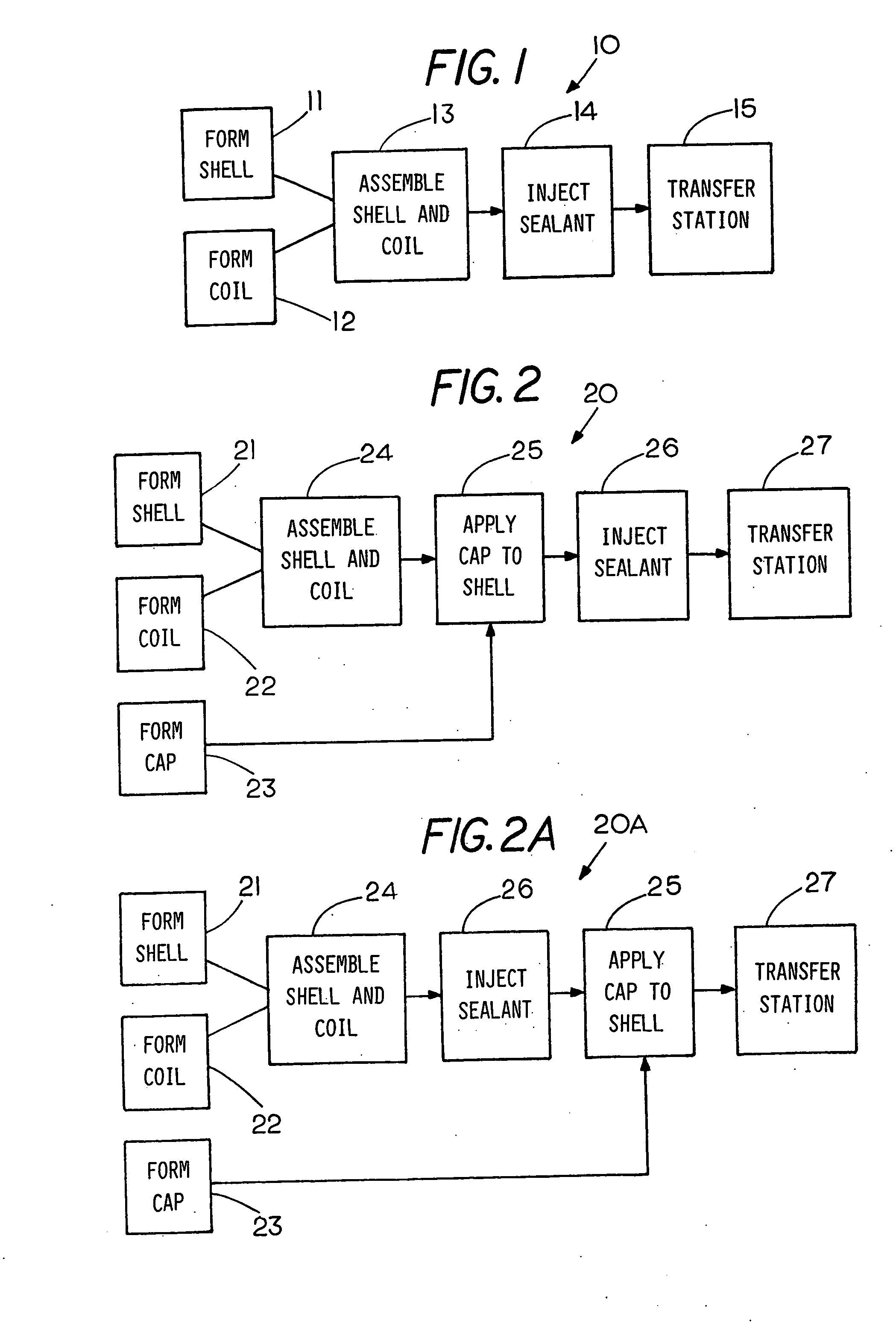

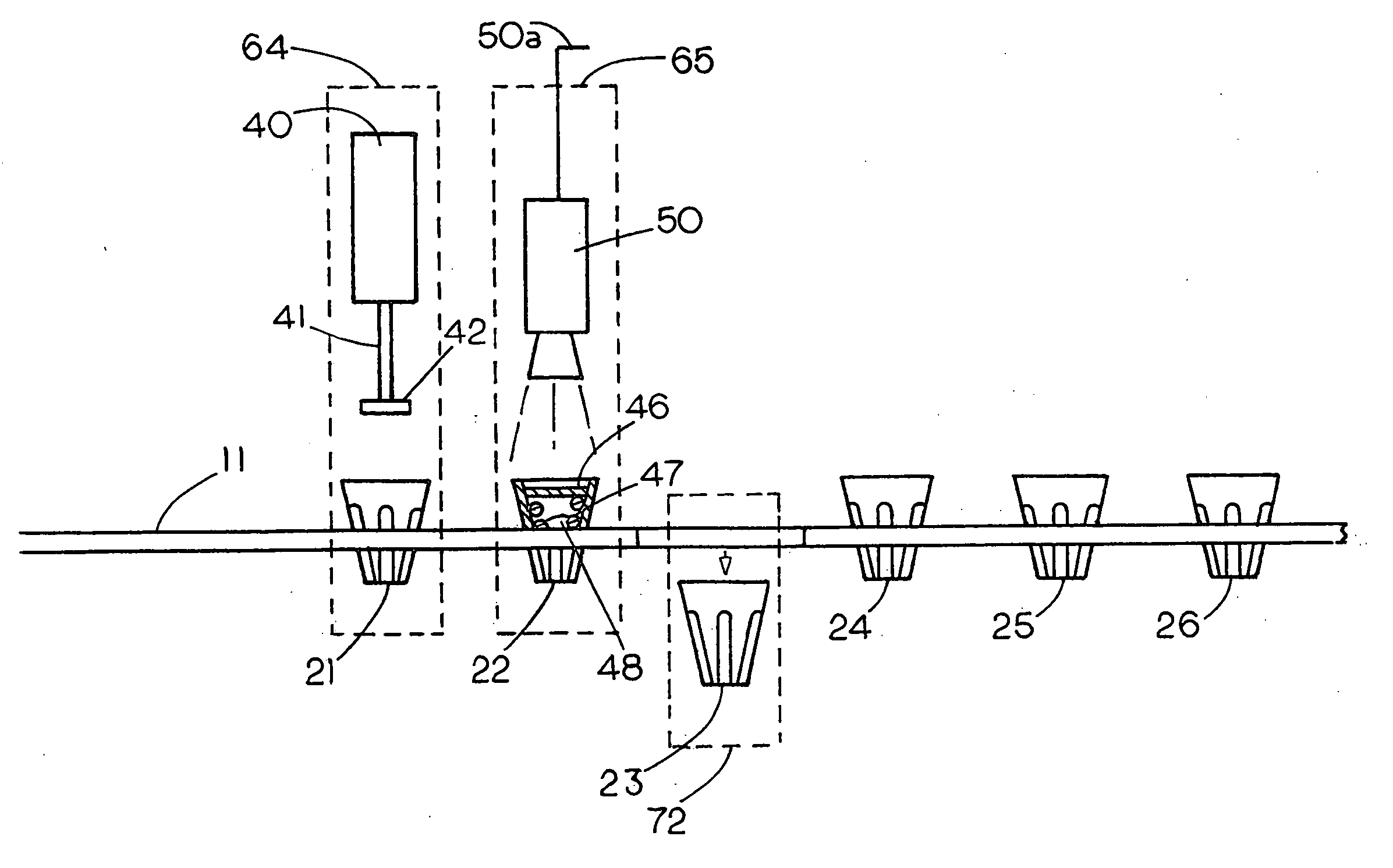

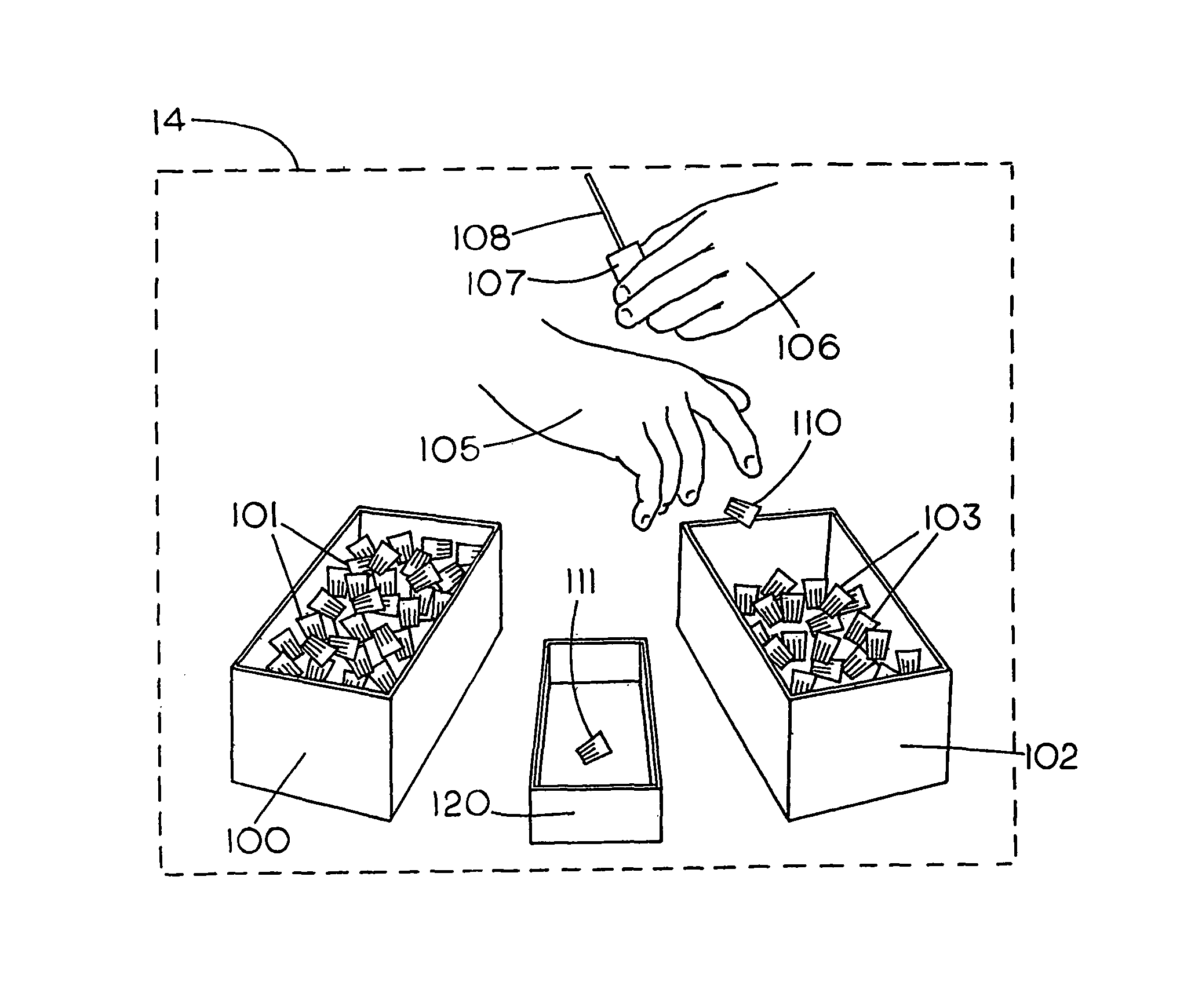

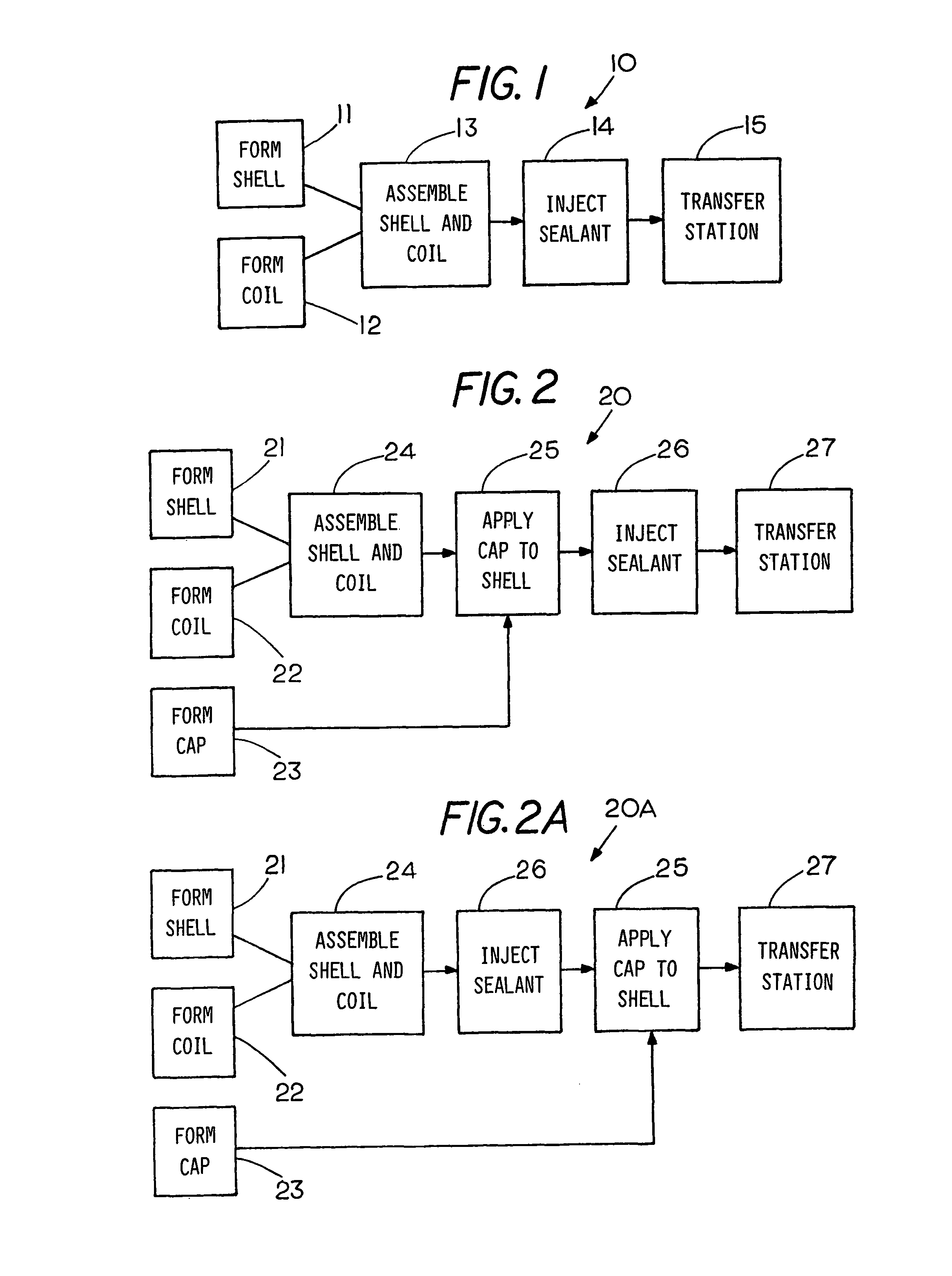

An improved method of making sealant containing twist-on wire connectors from a batch of components, wherein some of the components may be preassembled through automated equipment and at least one or more of the steps performed in the making of a sealant containing twist-on wire connector is performed manually at a station where an operator can simultaneously perform one or more steps to enhance the formation of a twist-on wire connector containing a sealant while at the same time eliminating upfront investments costs for a work station as well as costs for maintenance of a work station.

Owner:THE PATENT STORE

Twist-on wire connector applicator and interlocking wire connectors for use therewith

A wire connector applicator is capable of holding a clip of interconnected twist-on wire connectors in a tube which can be rotated by an electric motor. The connectors rotate with the tube for installation on the ends of stripped electrical wires. The invention is also directed to an interlocking twist-on wire connector which prevents axial separation and relative rotation of similarly configured group or clip of interlocked connectors.

Owner:IDEAL IND INC

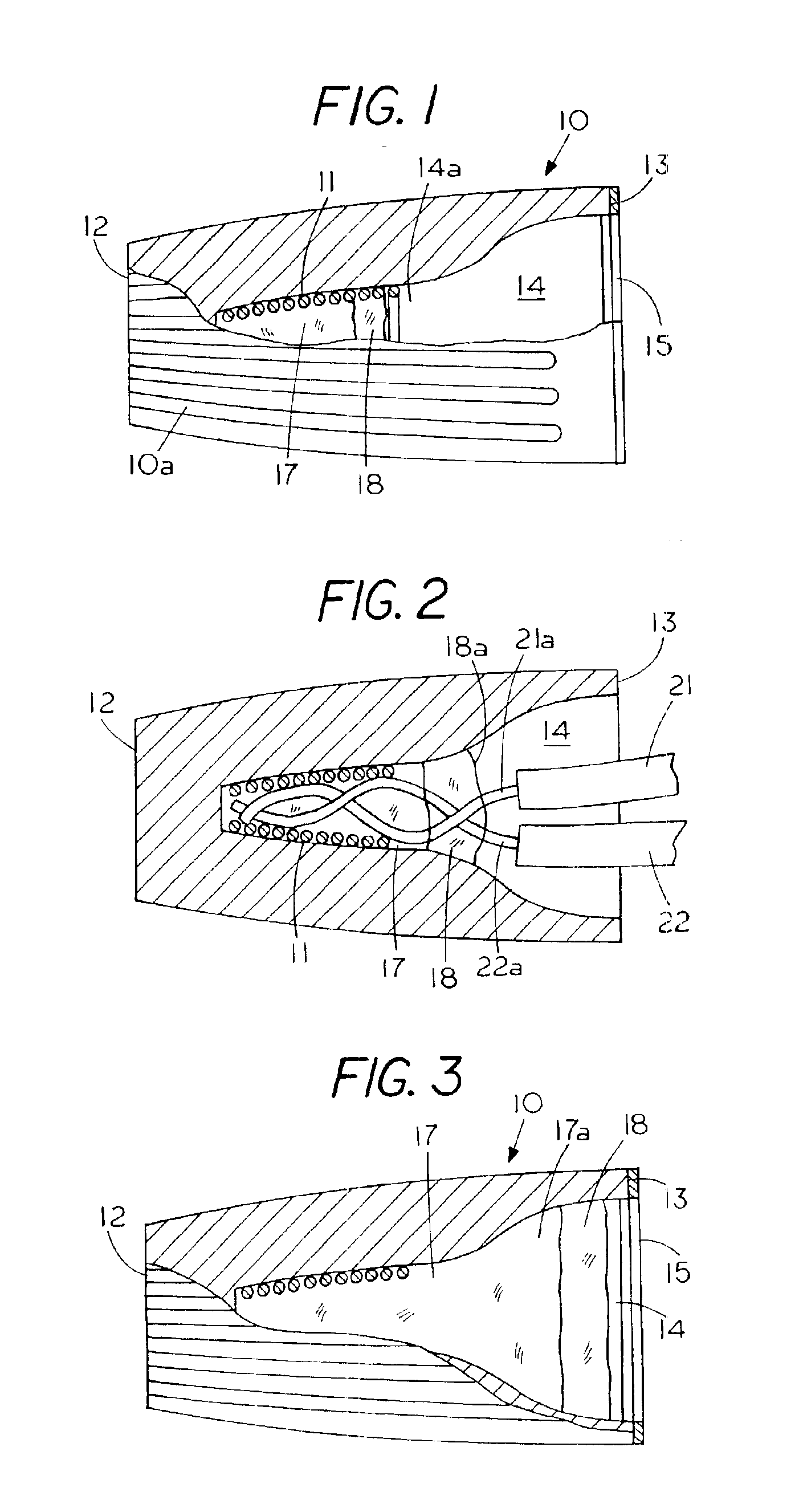

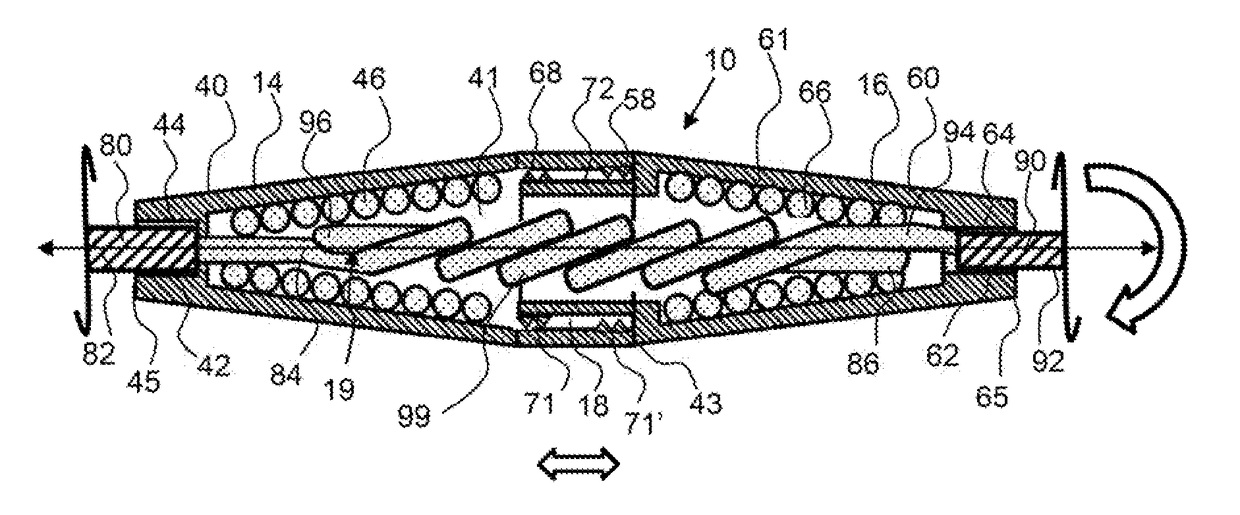

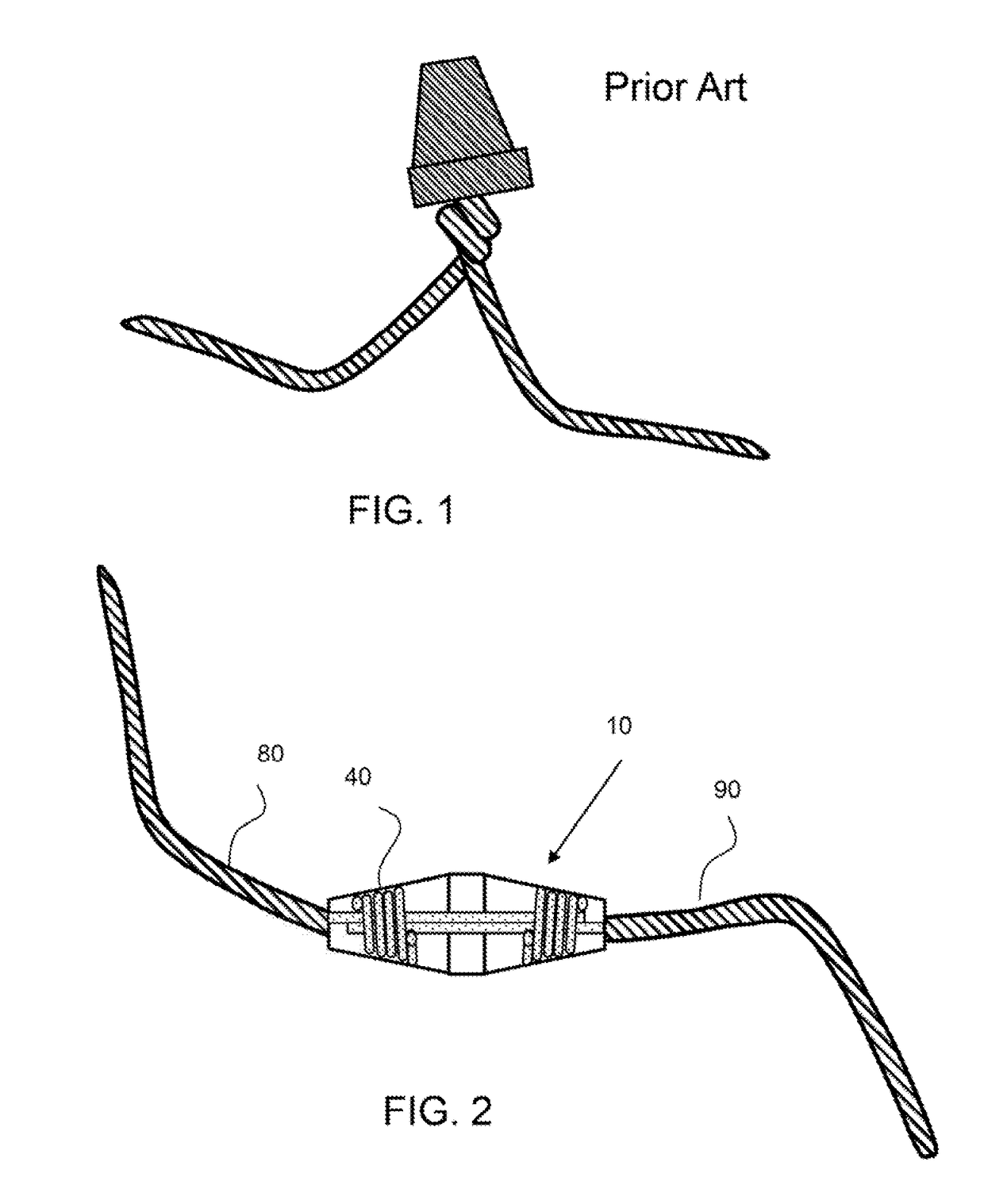

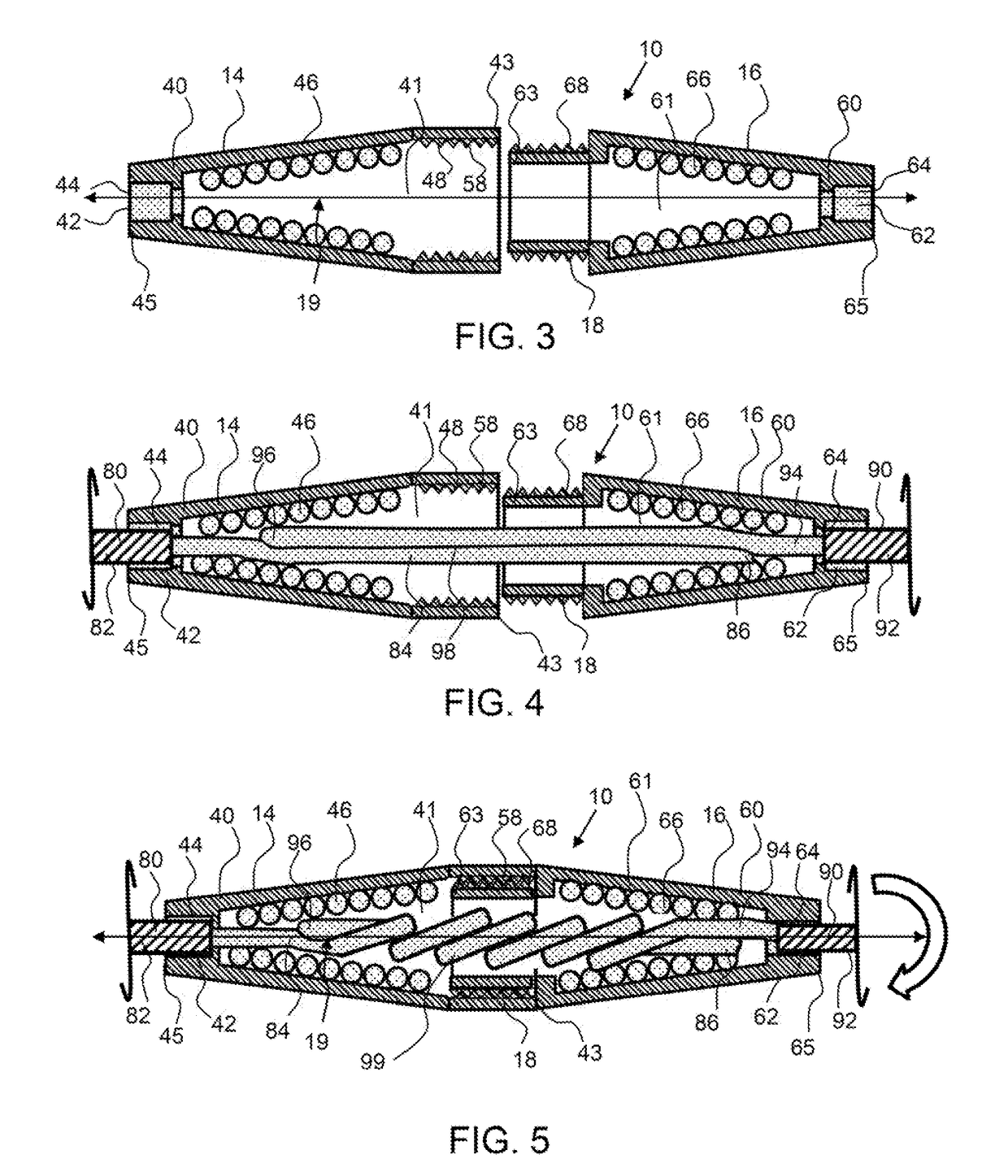

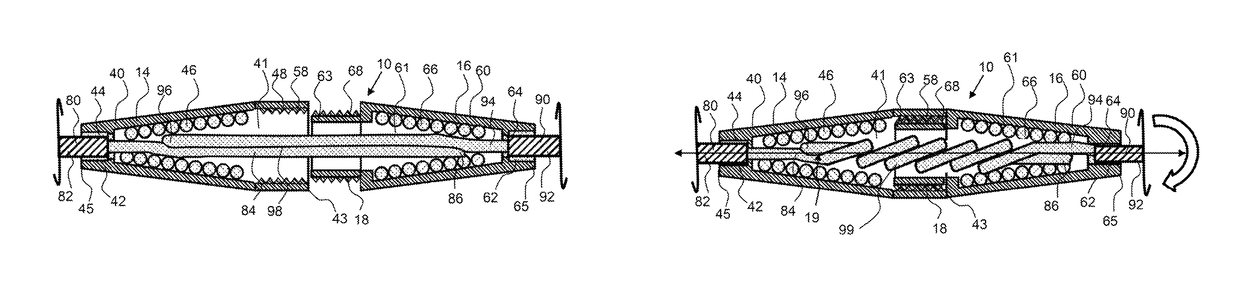

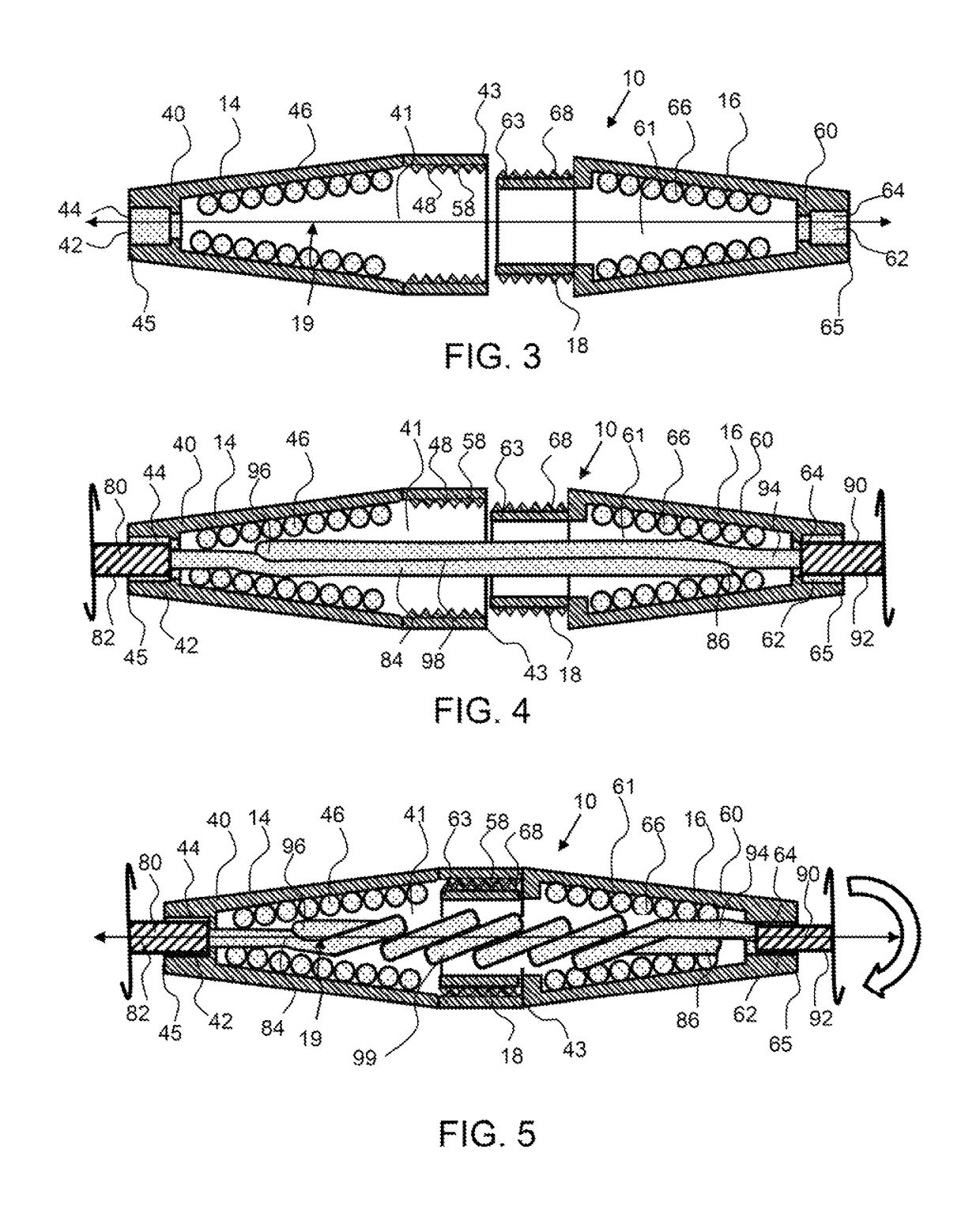

In-line twist on electrical wire connector

ActiveUS20180191085A1Increase contact areaLower resistanceConnections effected by permanent deformationElectrical conductorEngineering

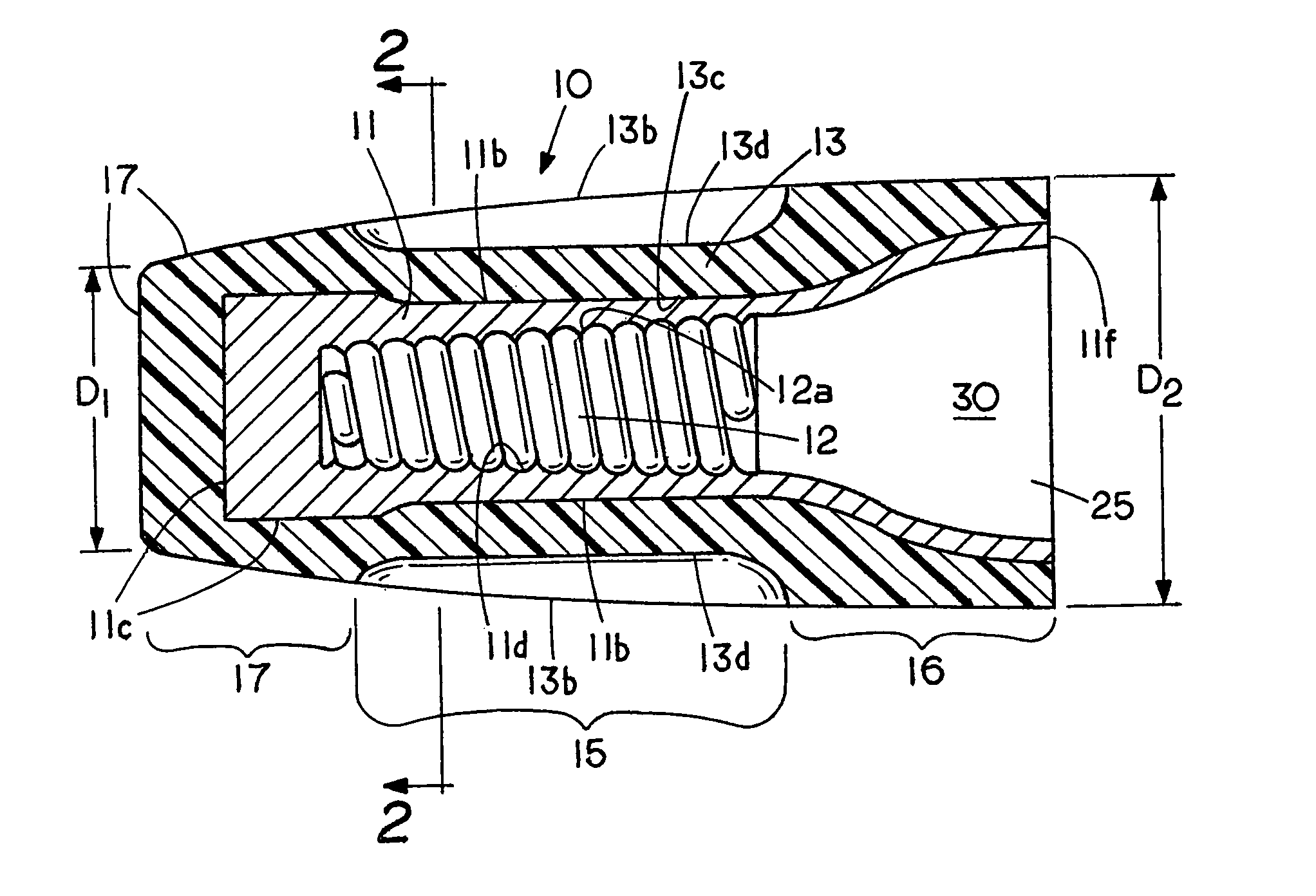

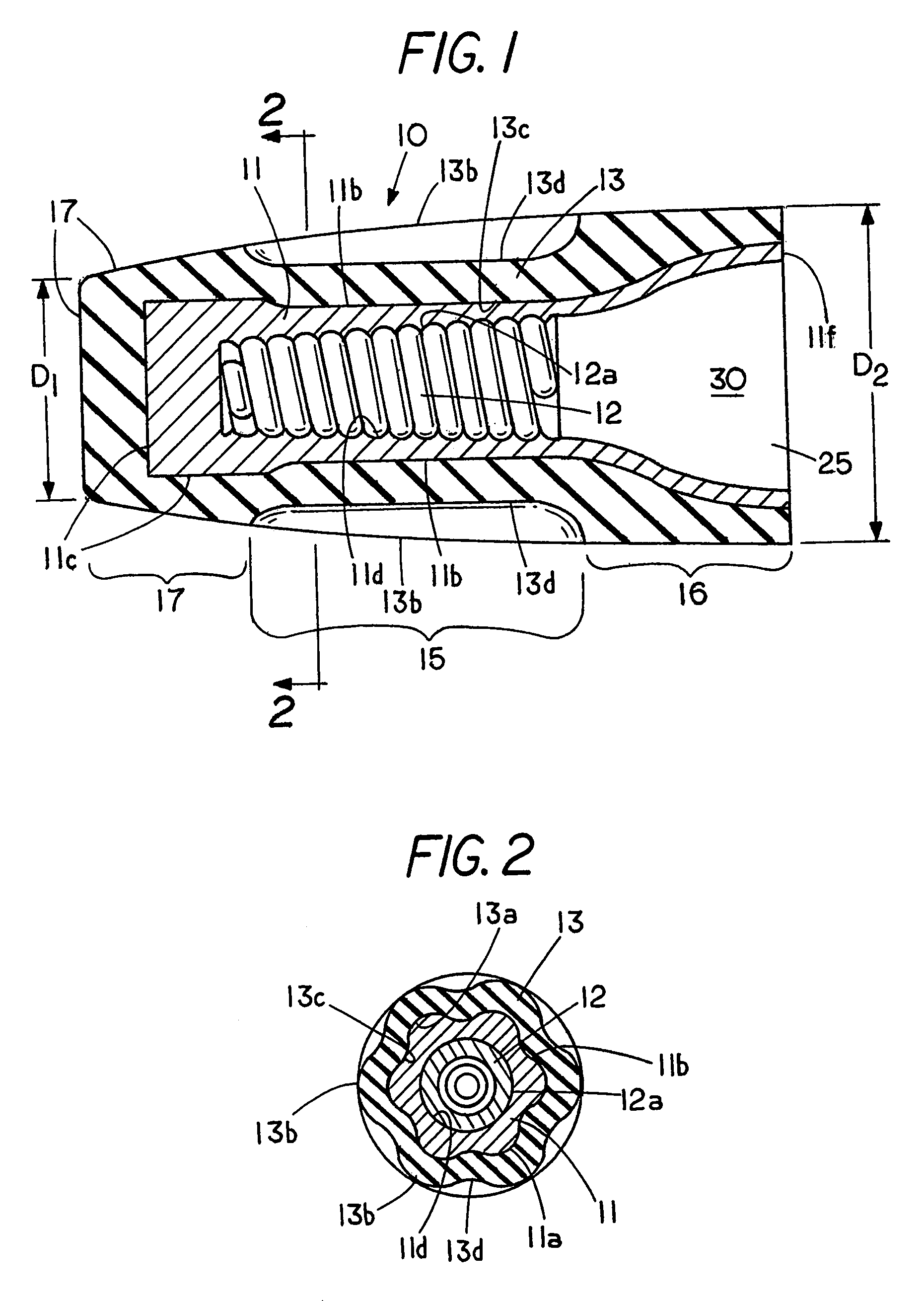

An in-line wire connector has a connector body with two insert ends on opposing ends for receiving a first and a second wire into apertures. A truncated tapered coil is configured within the connector body to secure the first and second wires to the in-line wire connector. The in-line twist on wire connector connects wires in line and may be low profile to allow the wires and the wire connector to slide through apertures and tight spaces as it often required in construction and remodeling projects. An in-line wire connector may have two truncated tapered coils that taper toward the opposing ends. A first and second wire conductor extend past each other toward opposing insert ends to produce an overlap portion to create electrical contact between wires. When the connector body is rotated, the wires rotate about each other and are retained by the tapered coil.

Owner:ZUKOWSKI STANISLAW L

Making sealant containing twist-on wire connectors

InactiveUS20100086193A1Coupling device detailsDustproof/splashproof/drip-proof/waterproof/flameproof connectionReference imageSealant

A system and a method of identifying, accepting or rejecting faulty sealant containing twist-on wire connectors wherein an image sensor generates an output image signal of a partly assembled twist-on wire connector or an assembled twist-on wire connector and compares the output image signal to a reference image signal to identify or reject a twist-on wire connector if the output image signal of the twist-on wire connector is outside an acceptable range and accept the twist-on wire connector if the output image signal is within the acceptable range.

Owner:THE PATENT STORE

Twist-on connector

ActiveUS20060070765A1Line/current collector detailsConnections effected by permanent deformationElectrical conductorEngineering

Owner:THOMAS & BETTS INT INC

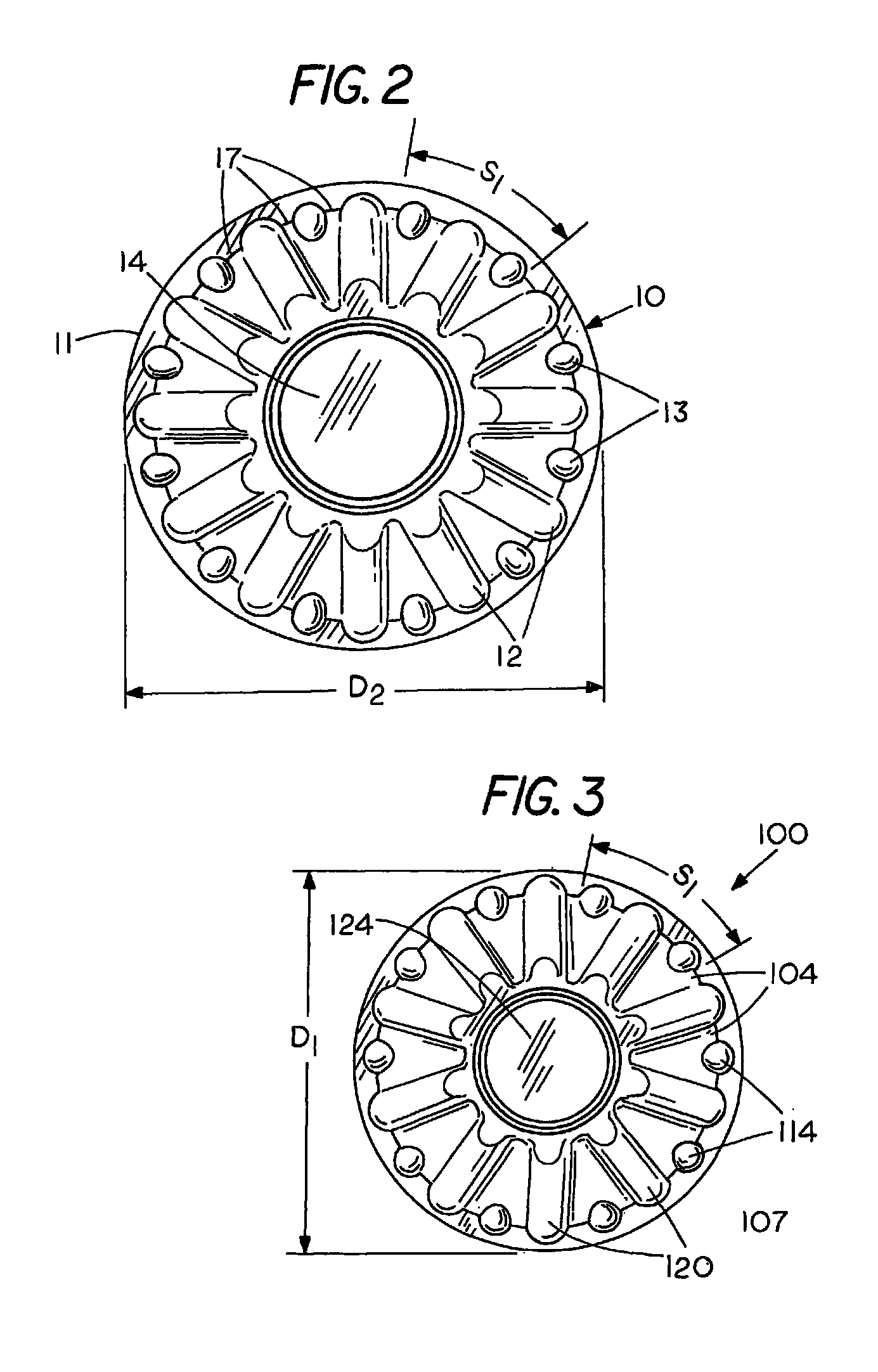

Twist-on wire connector

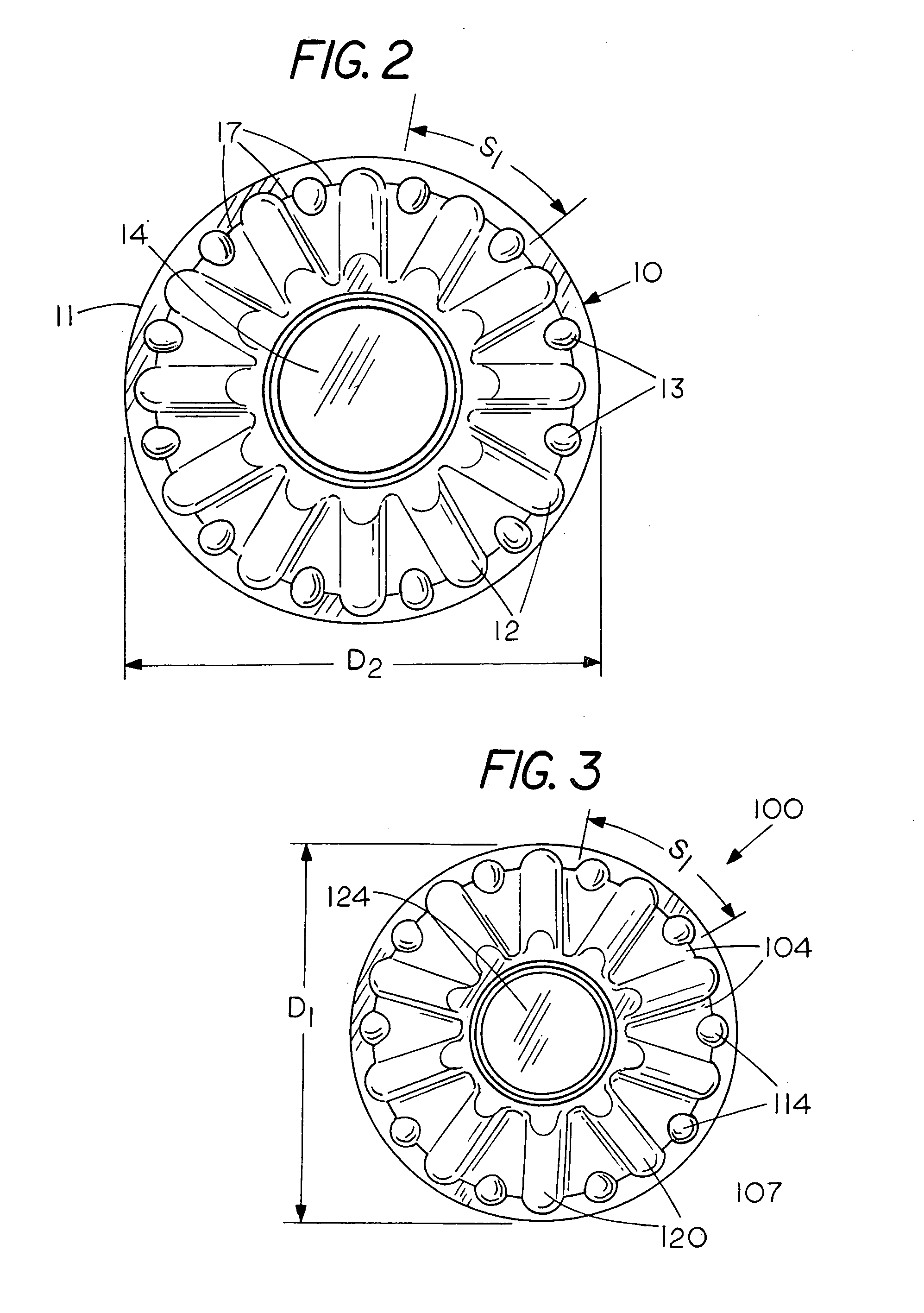

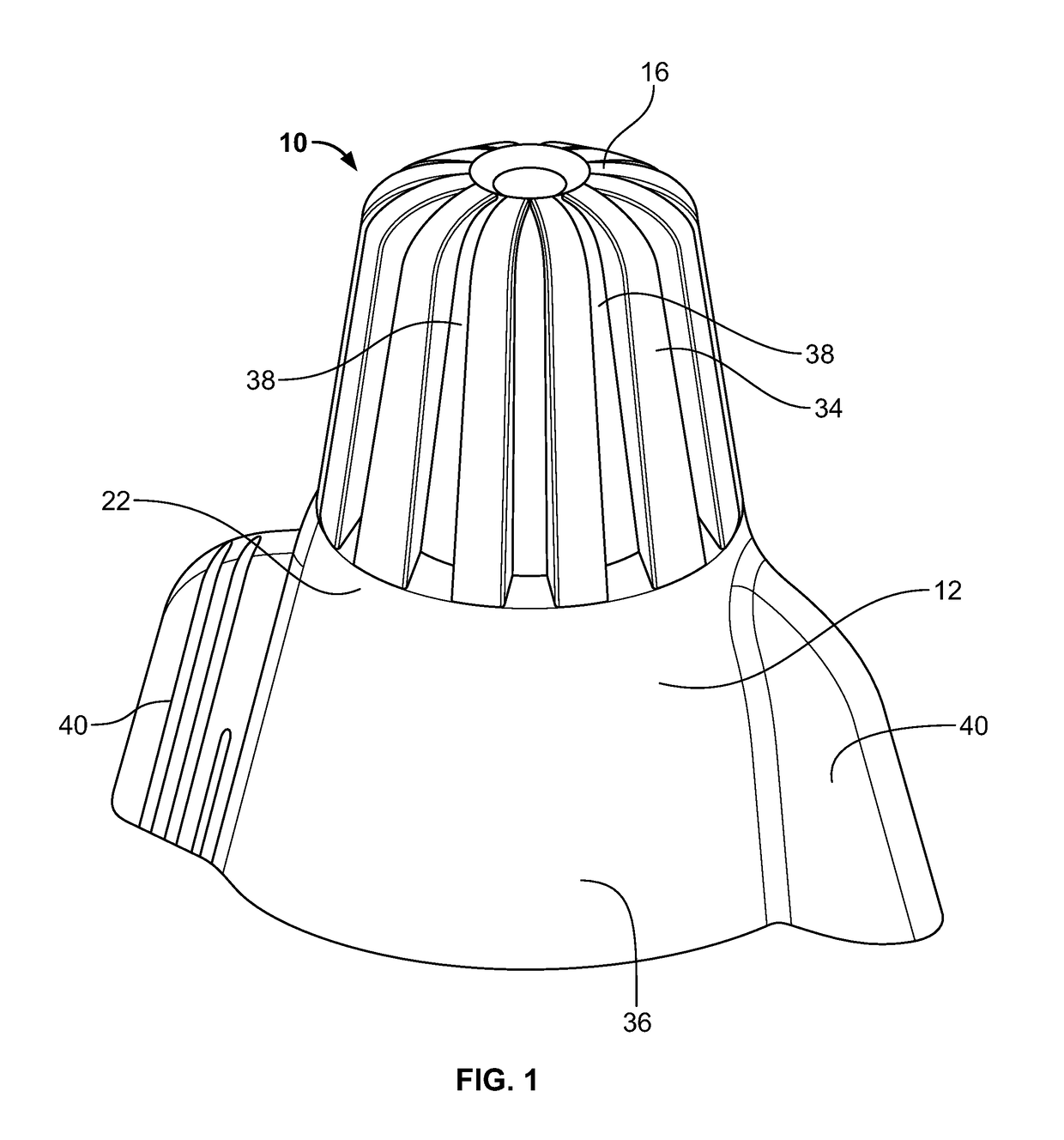

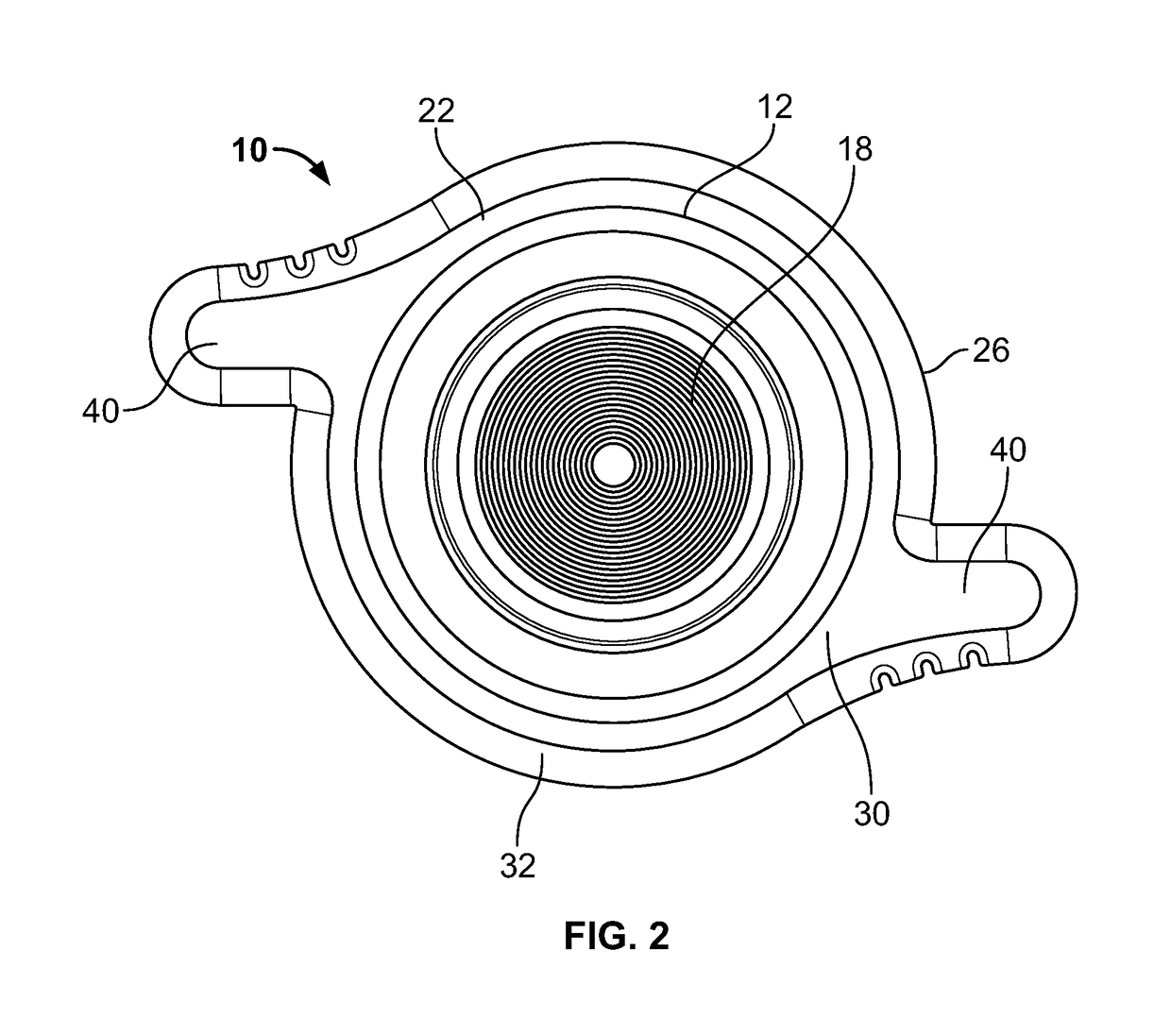

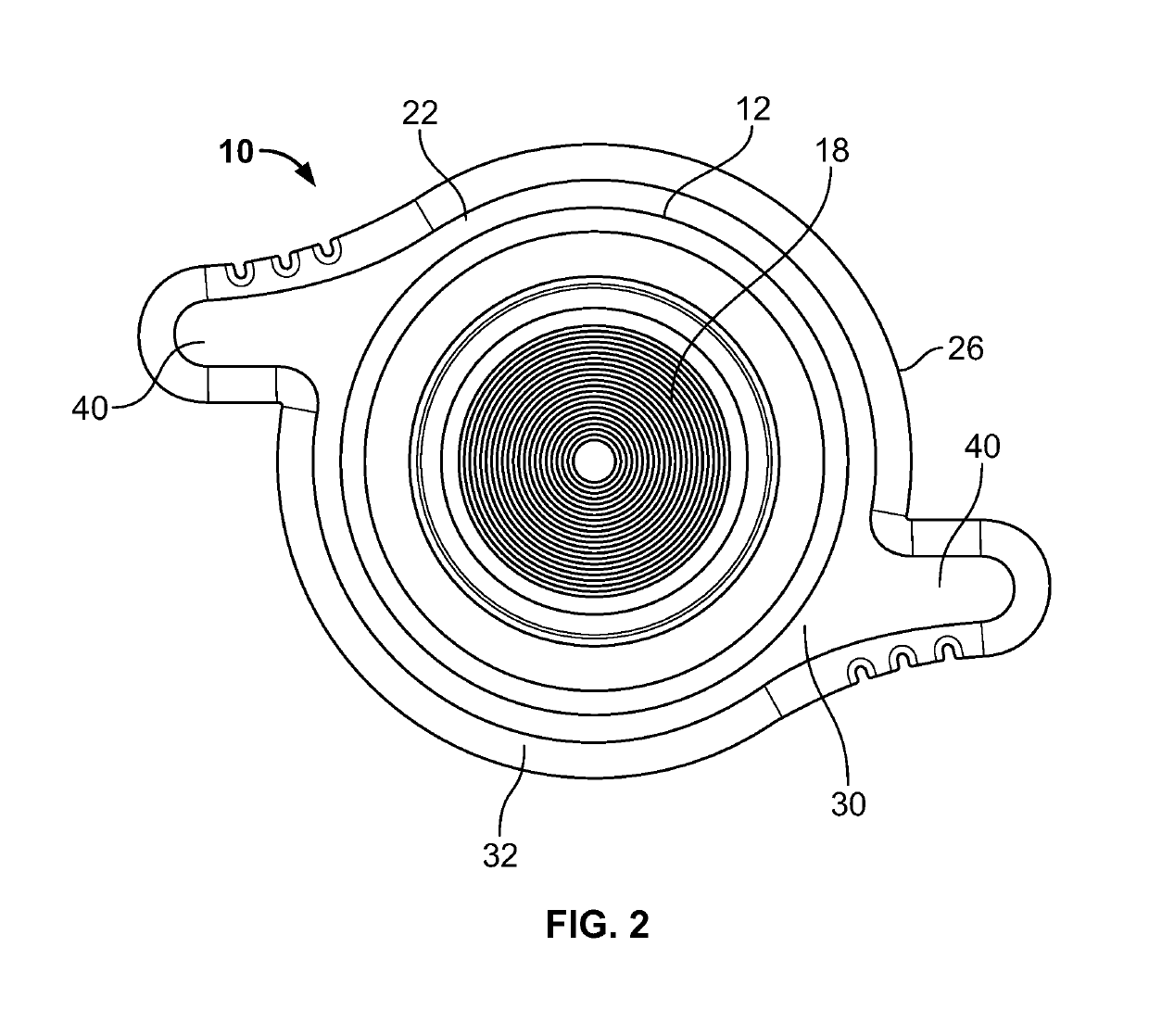

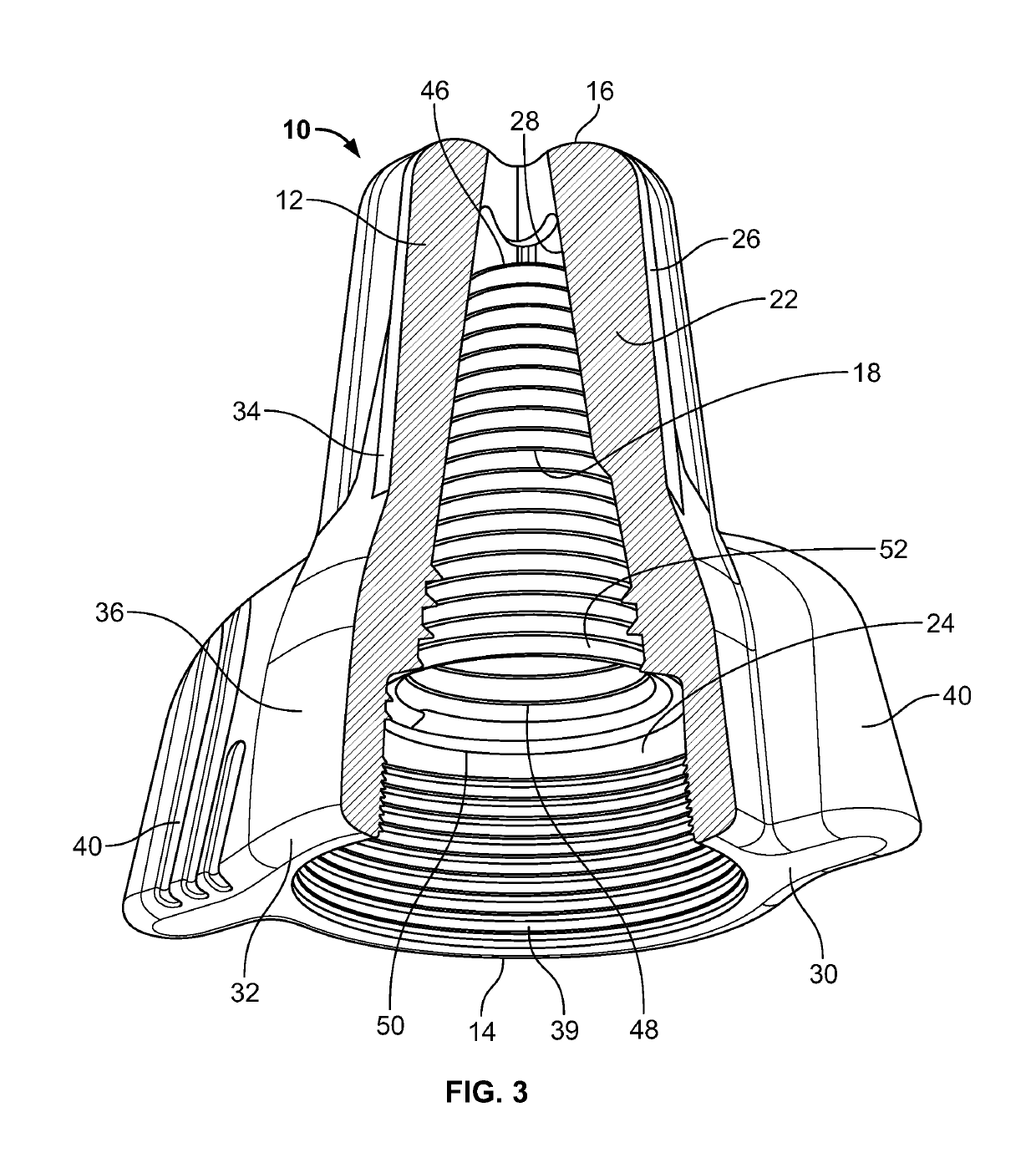

ActiveUS20180248277A1Comfortable gripContact member assembly/disassemblyConnections effected by permanent deformationCoil springEngineering

A twist-on wire connector includes a connector cap and a tapered coil spring configured to be secured within the connector cap. The connector cap includes a peripheral wall extending between open and closed ends of the connector cap and defining a connector cap recess, top portion having the closed end, bottom portion having the open end, and asymmetrically opposed wings. The asymmetrically opposed wings are positioned to offset from a centerline of the connector cap to provide a comfortable grip while turning the twist-on wire connector during electrical wire installation

Owner:THOMAS & BETTS INT INC

Dip molded wire connector

InactiveUS20060169476A1Improve impact resistanceContact member assembly/disassemblyConnection end capsEngineeringMechanical engineering

A connector with a dip-molded housing and a method for forming a twist-on wire connector with a dip-molded housing. To dip-mold a covering or housing on a twist-on wire connector either a mandrel carrying a twist-on wire coil, a mandrel having the a shape of a spiral coil or a twist-on wire connector are dipped into a bath of an in situ solidfiable dip-moldable material such as liquid plastic. The dip-moldable solidified material solidifies to form a dip-molded shell on the wire connector.

Owner:KING JR L HERBERT +2

Assembling sealant containing twist-on wire connectors

ActiveUS8997347B2Minimizes rejectionLow investment costContact member assembly/disassemblyElectronic circuit testingImproved methodSealant

An improved method of making sealant containing twist-on wire connectors from a batch of components, wherein some of the components may be preassembled through automated equipment and at least one or more of the steps performed in the making of a sealant containing twist-on wire connector is performed manually at a station where an operator can simultaneously perform one or more steps to enhance the formation of a twist-on wire connector containing a sealant while at the same time eliminating upfront investments costs for a work station as well as costs for maintenance of a work station.

Owner:THE PATENT STORE

Method of assembling sealant containing twist-on wire-connectors

InactiveUS20150171585A1Minimizes rejectionLow investment costContact member assembly/disassemblyConnection end capsImproved methodWorkstation

An improved method of making sealant containing twist-on wire connectors from a batch of components, wherein some of the components may be preassembled through automated equipment and at least one or more of the steps performed in the making of a sealant containing twist-on wire connector is performed manually at a station where an operator can simultaneously perform one or more steps to enhance the formation of a twist-on wire connector containing a sealant while at the same time eliminating upfront investments costs for a work station as well as costs for maintenance of a work station.

Owner:THE PATENT STORE

Making twist-on wire connectors

A method of making a twist-on wire connector including a method of making a sealant containing twist-on wire connector by in situ formation of a shell around the coil wherein a sealant may be injected into a cavity in the coil prior to removing the shell from the mold to form a ready-to-use sealant containing twist on wire connector without further steps outside the mold.

Owner:THE PATENT STORE

Twist-on wire connector

ActiveUS10270190B2Comfortable gripContact member assembly/disassemblyConnections effected by permanent deformationCoil springEngineering

A twist-on wire connector includes a connector cap and a tapered coil spring configured to be secured within the connector cap. The connector cap includes a peripheral wall extending between open and closed ends of the connector cap and defining a connector cap recess, top portion having the closed end, bottom portion having the open end, and asymmetrically opposed wings. The asymmetrically opposed wings are positioned to offset from a centerline of the connector cap to provide a comfortable grip while turning the twist-on wire connector during electrical wire installation.

Owner:THOMAS & BETTS INT INC

Making twist-on wire connectors

A method of making a twist-on wire connector including a method of making a sealant containing twist-on wire connector by in situ formation of a shell around the coil wherein a sealant may be injected into a cavity in the coil prior to removing the shell from the mold to form a ready-to-use sealant containing twist on wire connector without further steps outside the mold.

Owner:THE PATENT STORE

In-line twist on electrical wire connector

ActiveUS9768523B1Reduce resistanceLower resistanceConnections effected by permanent deformationElectrical conductorEngineering

An in-line wire connector has a connector body with two insert ends on opposing ends for receiving a first and a second wire into apertures. A truncated tapered coil is configured within the connector body to secure the first and second wires to the in-line wire connector. The in-line twist on wire connector connects wires in line and may be low profile to allow the wires and the wire connector to slide through apertures and tight spaces as it often required in construction and remodeling projects. An in-line wire connector may have two truncated tapered coils that taper toward the opposing ends. A first and second wire conductor extend past each other toward opposing insert ends to produce an overlap portion to create electrical contact between wires. When the connector body is rotated, the wires rotate about each other and are retained by the tapered coil.

Owner:ZUKOWSKI STANISLAW L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com