Deformation-resistant installation structure for portable apparatus

A technology for portable devices and installation structures, which is applied in the direction of support structure installation, printed circuit stress/deformation reduction, electrical equipment structural parts, etc., and can solve the problem of reduced effective area of printed circuit boards and insufficient absorption of external mechanical stress And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

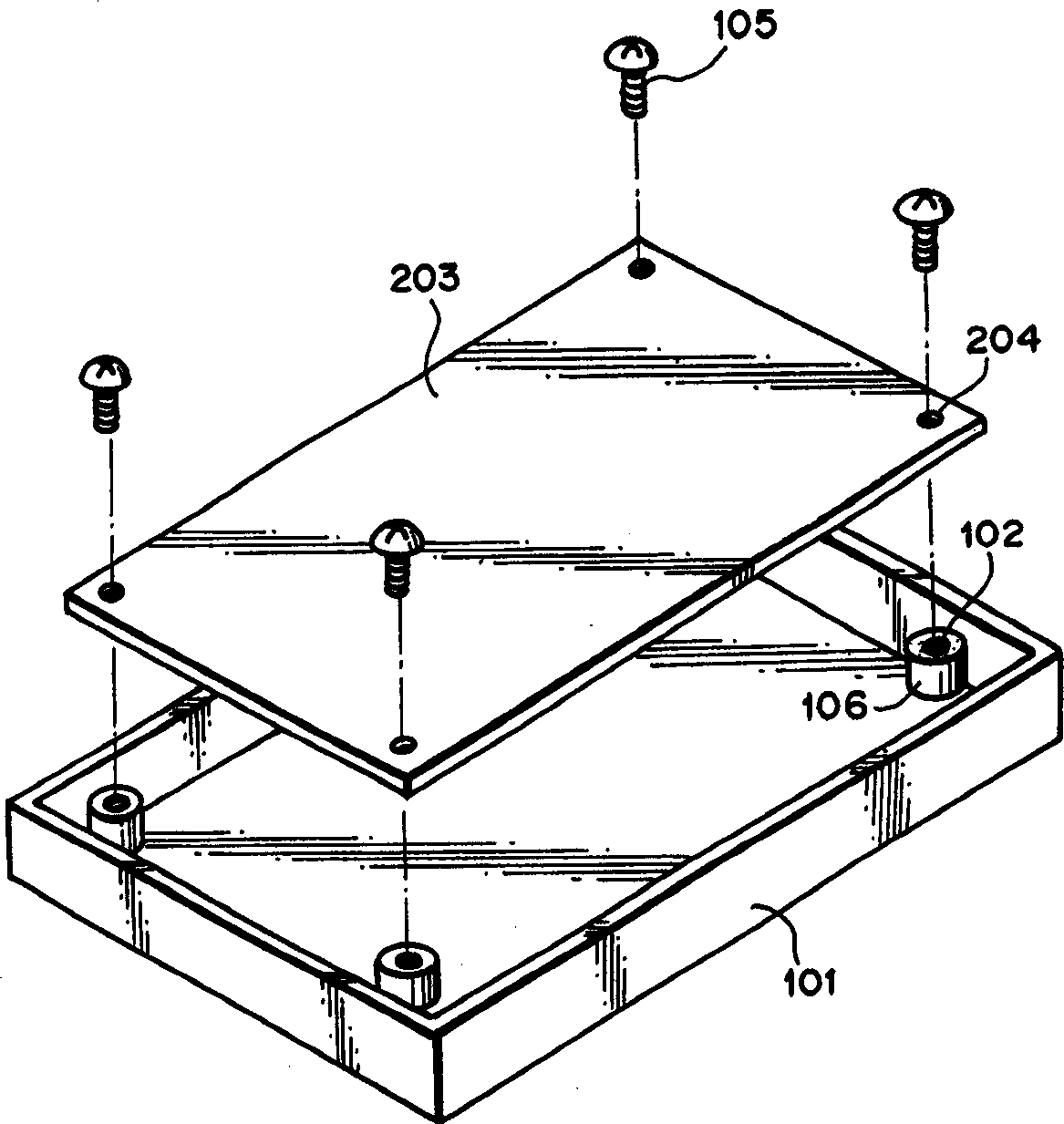

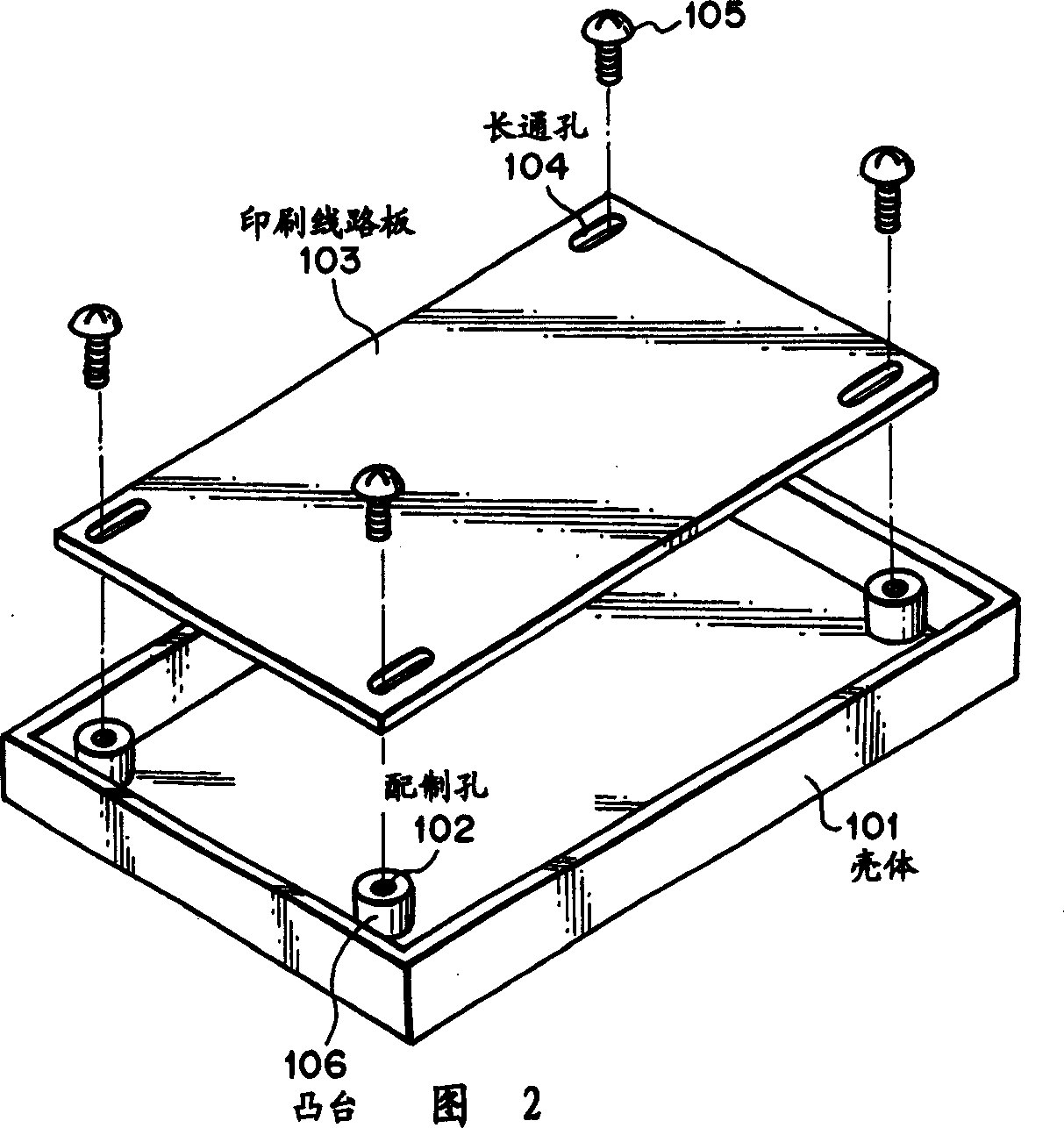

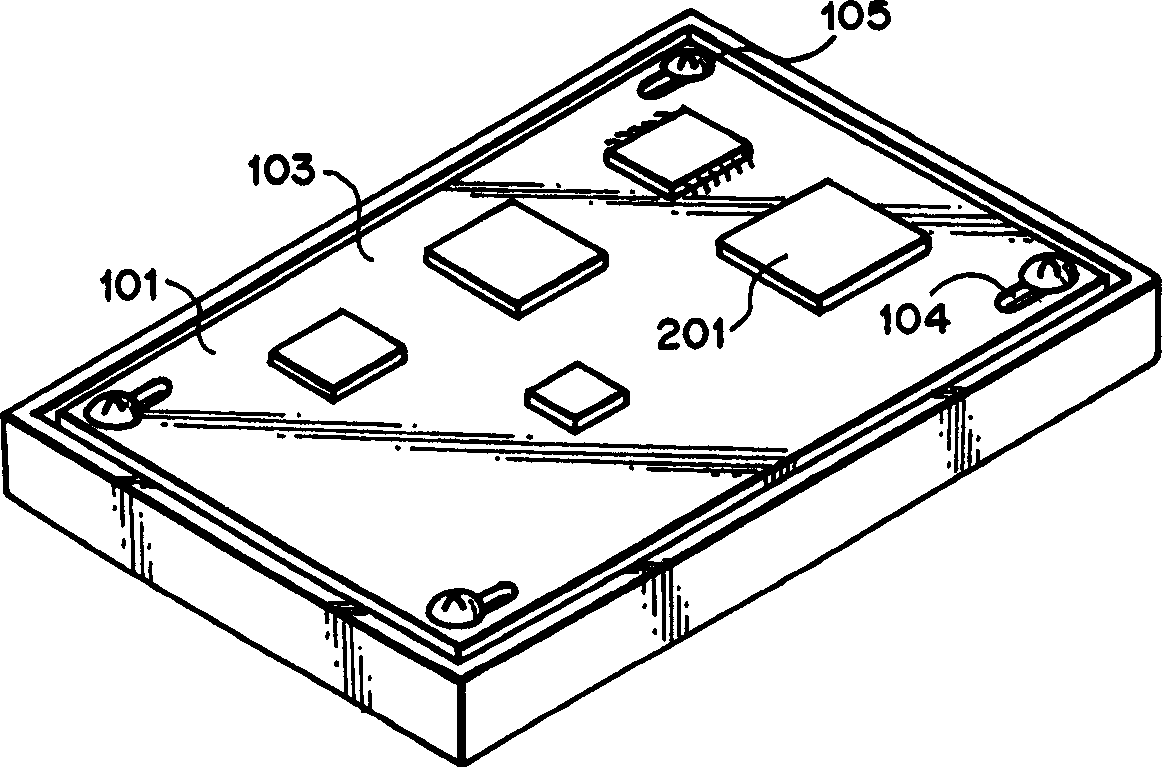

[0035] Refer to Figure 2 to Figure 4 , the boss 106 formed with the preparation hole 102 is disposed at the corner of the housing 101 . The preparation hole 102 is suitable for tap tapping. The preparation holes can also be replaced by threaded holes.

[0036] In order to reduce external mechanical stress applied to the printed wiring board 103 , the holes passed by the screws 105 are long through holes 104 formed on the printed wiring board 103 .

[0037] Specifically, as described above, in the printed wiring board 103, the long through hole 104 is formed at a position corresponding to the boss 106 on the housing 101, as shown in Fig. 2 and Figure 4 shown. In the example of the first embodiment, the long through holes 104 are formed in the longitudinal direction at the four corners of the printed wiring board 103 . However, the long through hole 104 may also be formed in a direction perpendicular to the longitudinal direction or in any direction.

[0038] The printed ...

no. 2 example

[0040] exist Figure 5A and 5BIn the second embodiment of the present invention, in order to further reduce the external mechanical stress applied to the printed circuit board 103, a through boss 401 is used, and the through boss 401 includes a central part 402, the central part 402 is formed as a part with a smaller diameter through the long through hole 104 on the printed circuit board 103, and the central part 402 has a preparation hole 102, the through boss 401 also includes a part 404 with a larger diameter, This part has a base 403 for mounting the printed wiring board 103, although usually the printed wiring board 103 is fixed between the bosses 106 with the prepared holes 102 and the screws 105. It is desirable to make the inner diameter of the long through hole 104 slightly larger than the outer diameter of the central portion 402 so that the central portion 402 can freely displace in the long through hole 104 .

[0041] In addition, in order to smoothly displace th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com