Disk brake of bicycle

A technology for bicycles and moving discs, applied to bicycle accessories, bicycle brakes, etc., can solve the problems of high manufacturing cost, drag torque, difficult processing of driving discs and fixed discs, etc., and achieve cost reduction, compact structure and flexible braking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

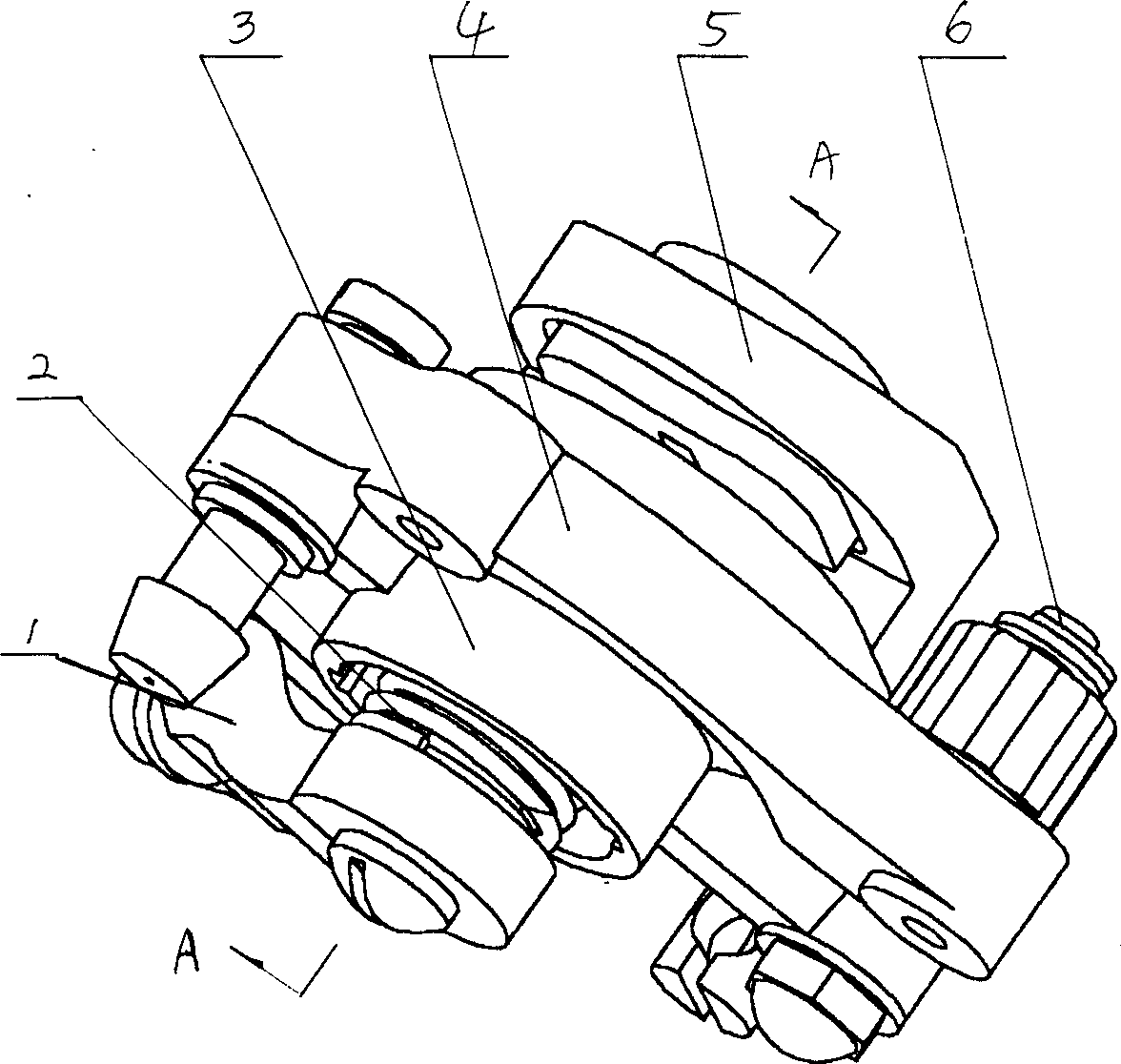

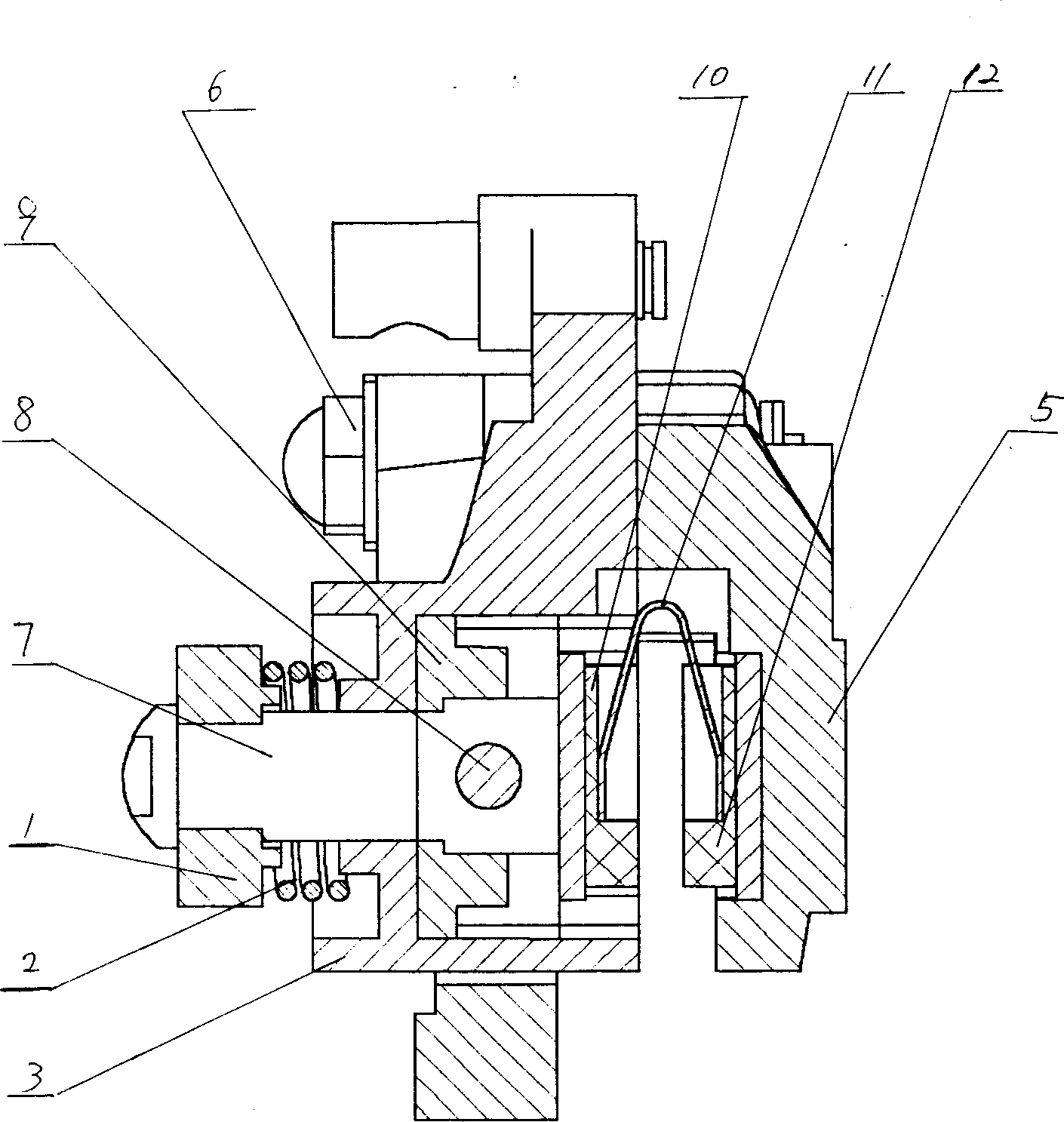

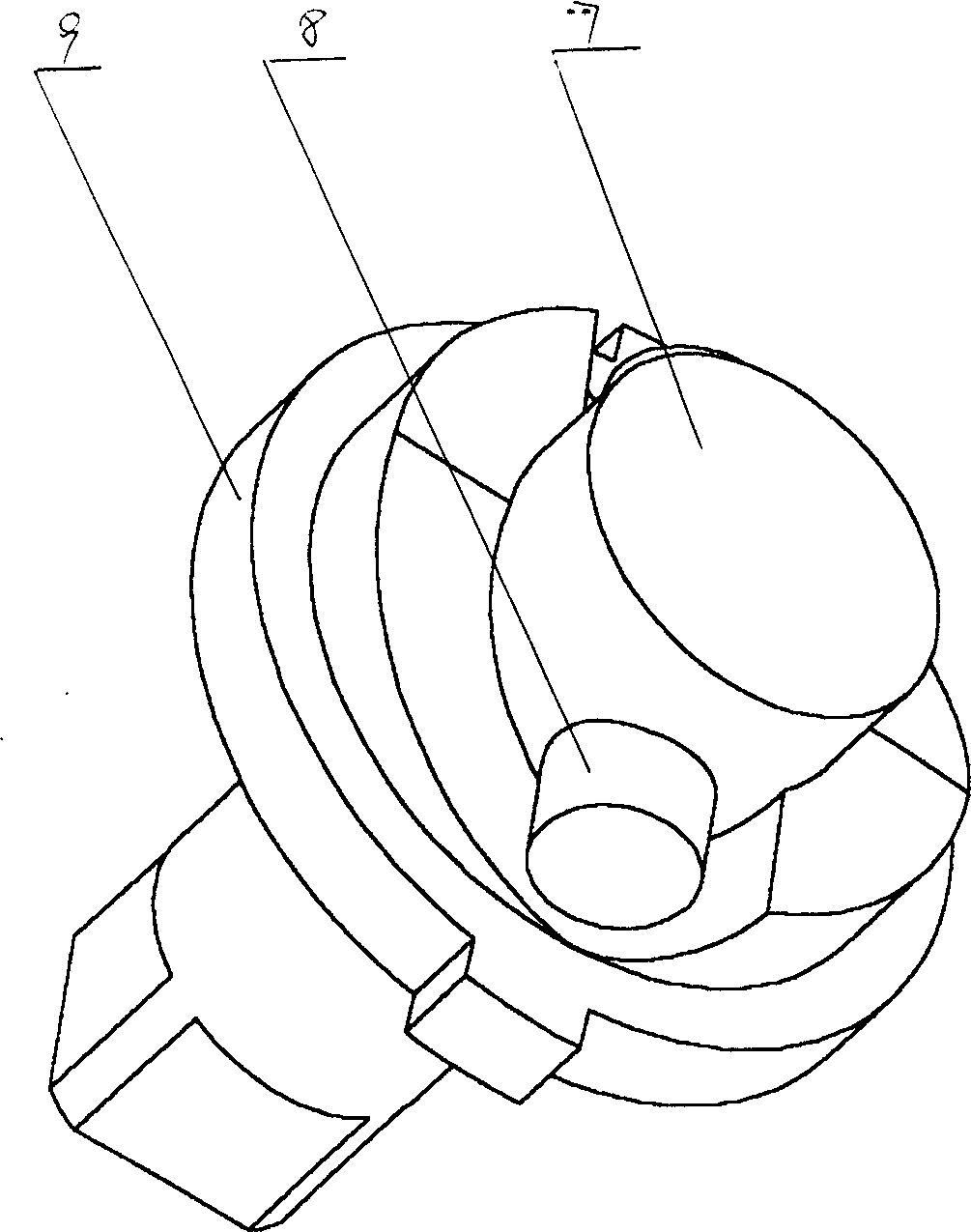

[0023] Embodiment one, the specific implementation mode of the present invention is as figure 1 , figure 2 , image 3 , Figure 4 Shown: a kind of bicycle disc brake, it comprises brake brake driving device and brake brake caliper body 5, a pincer arm of brake brake caliper body 5 is fixedly connected with housing 3 of brake brake drive device, in brake brake caliper body 5 Left and right friction plate assemblies 10, 12 are installed, and a V-shaped leaf spring 11 is arranged between the two friction plate assemblies. The housing 3 of the brake drive device is provided with a drive shaft 7 perpendicular to the friction plates. One end of the drive shaft 7 is connected to the right friction plate assembly, the other end of the drive shaft 7 protrudes from the housing 3, and a rocker arm 1 is installed at its end, and a return spring 2 is installed between the rocker arm 1 and the housing 3 , the casing 3 is equipped with a fixed disk 9 that is sleeved on the drive shaft 7 ...

Embodiment 2

[0024] Embodiment 2. In the above embodiment, the two drive pins on the drive shaft 7 are fixedly connected as a whole. Such as Figure 5 As shown, another embodiment of the present invention is that a bearing 14 that rotates concentrically with the center line of the pin shaft is respectively installed at the end of each driving pin 8 .

Embodiment 3

[0025] Embodiment three, such as Figure 6 As shown, in the third embodiment of the present invention, a spherical crown-shaped groove is opened on the surface corresponding to the end of each driving pin 8 and the fixed plate 9, and steel balls 15 are housed in the spherical crown-shaped groove. The frictional resistance can also be partially reduced through steel ball transmission, increasing the flexibility of operation and the return effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com