Hydrogen-bearing rare-earth alloy as electrode and its quenching process

An electrode alloy and processing method technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory high-current discharge capacity, difficulty in practical application, capacity decline, etc., and improve comprehensive electrochemical performance and cycle stability. The effect of improving and improving the discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

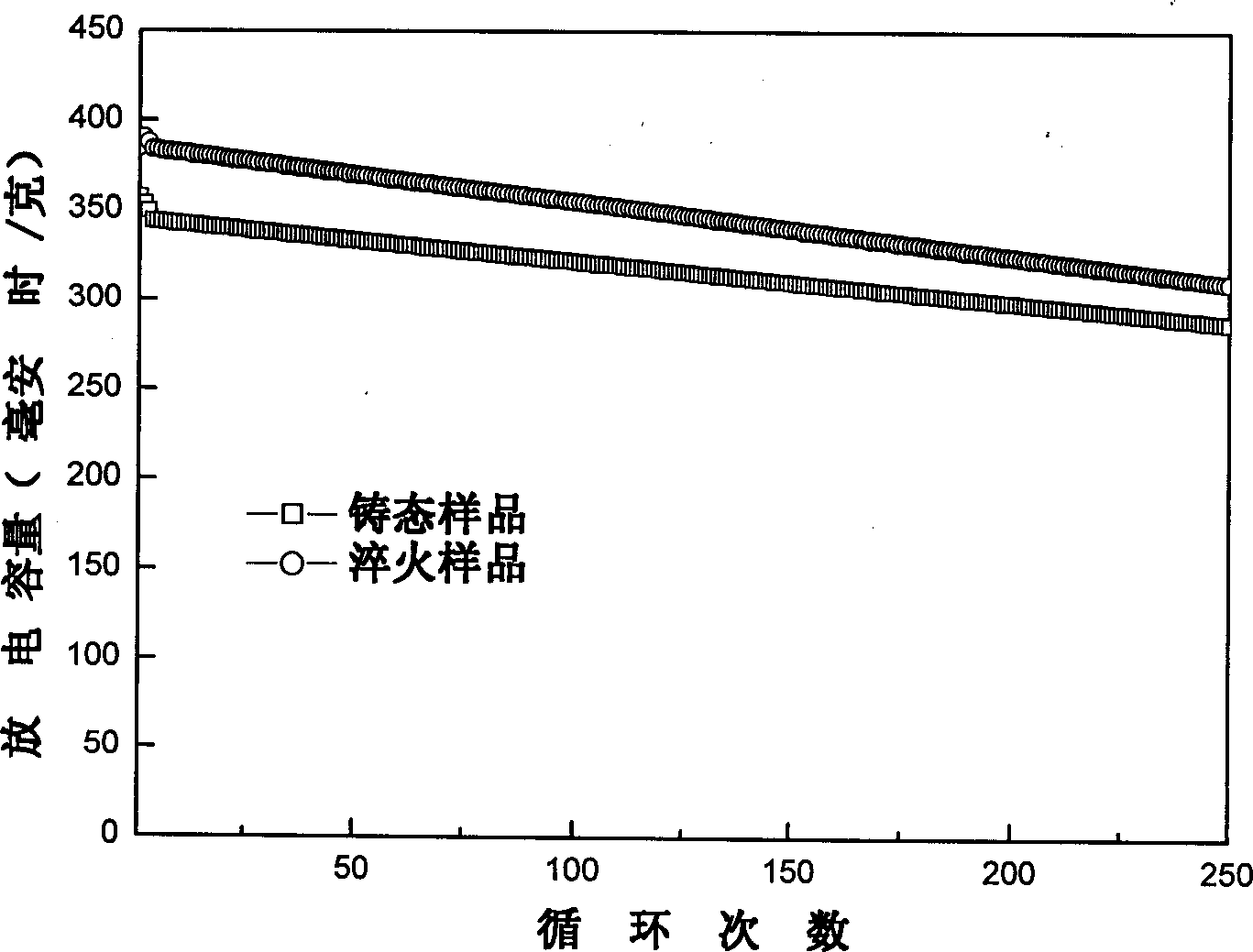

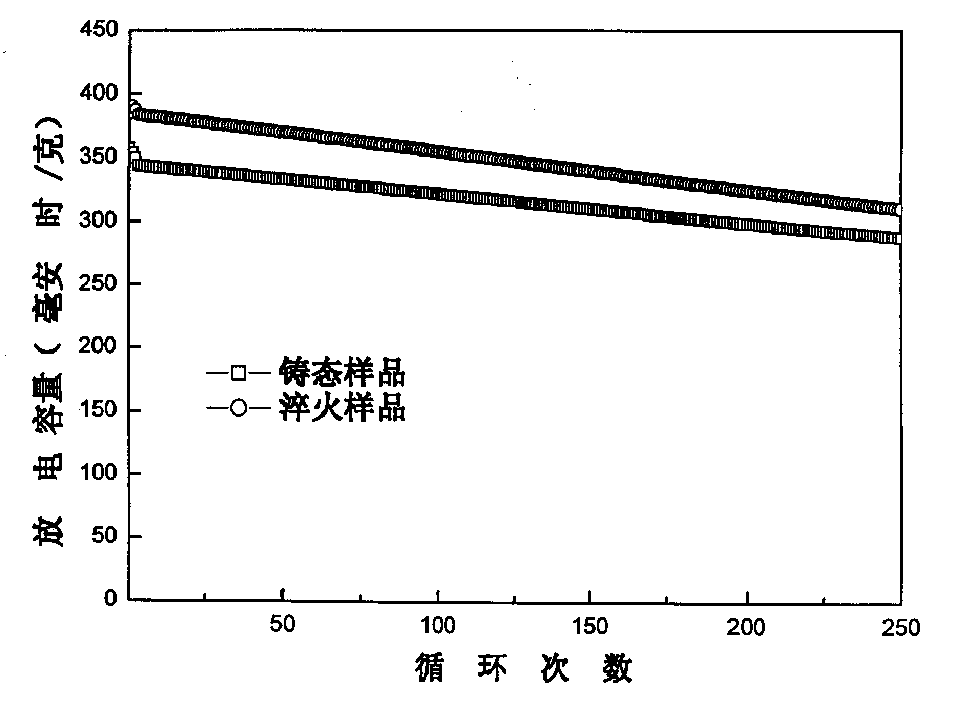

[0017] According to the new rare earth series A 1-y B y C x The design composition of the hydrogen storage electrode alloy is smelted in a vacuum magnetic levitation furnace or an electric arc furnace, and is recorded as alloy X. Among them, the purity of the alloy components is above 90%. Take part of the alloy X and seal them in vacuum quartz glass tubes respectively. The vacuum degree in the quartz glass tubes is 10 -5 support. Then put the tubes into the annealing furnace for heating and heat preservation respectively. The heating condition is 850℃×8h. After the holding time is up, immediately take out the quartz glass tube sealed with the hydrogen storage electrode alloy and put it into water. At the same time, smash the glass tube to make the alloy completely contact with water, that is, quenching treatment. The electrochemical performance test is carried out in an open three-electrode system, which includes a working electrode (that is, a hydrogen storage alloy ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap