Soft foundation composite ground base construction method for field pouring pipe pile with large diameter

A technology of composite foundation and construction method, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult control of the construction quality of cement-soil mixing pile composite foundation, expensive foundation reinforcement, and limited reinforcement depth, etc., to achieve convenience The effect of quality control, high bearing capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

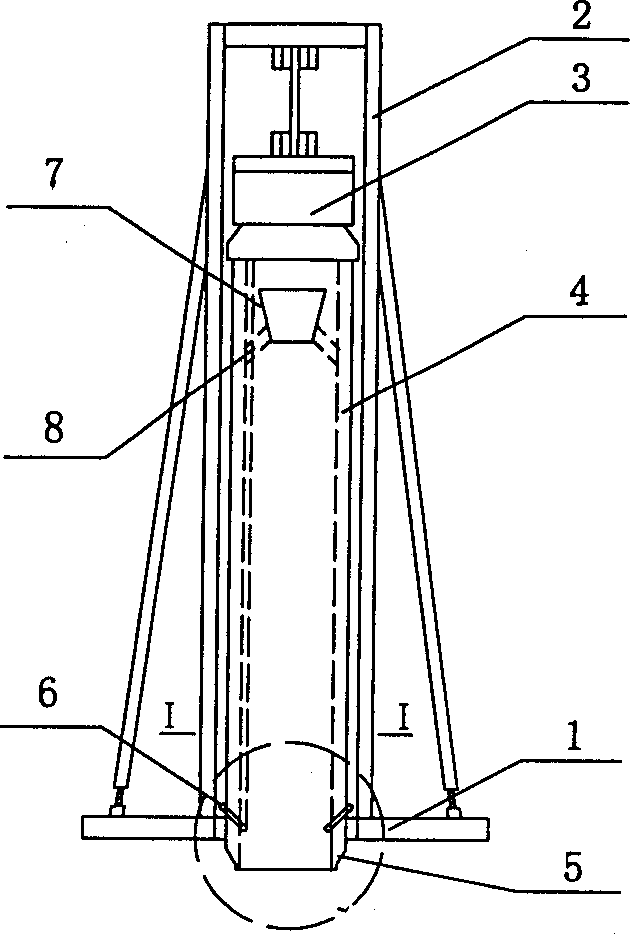

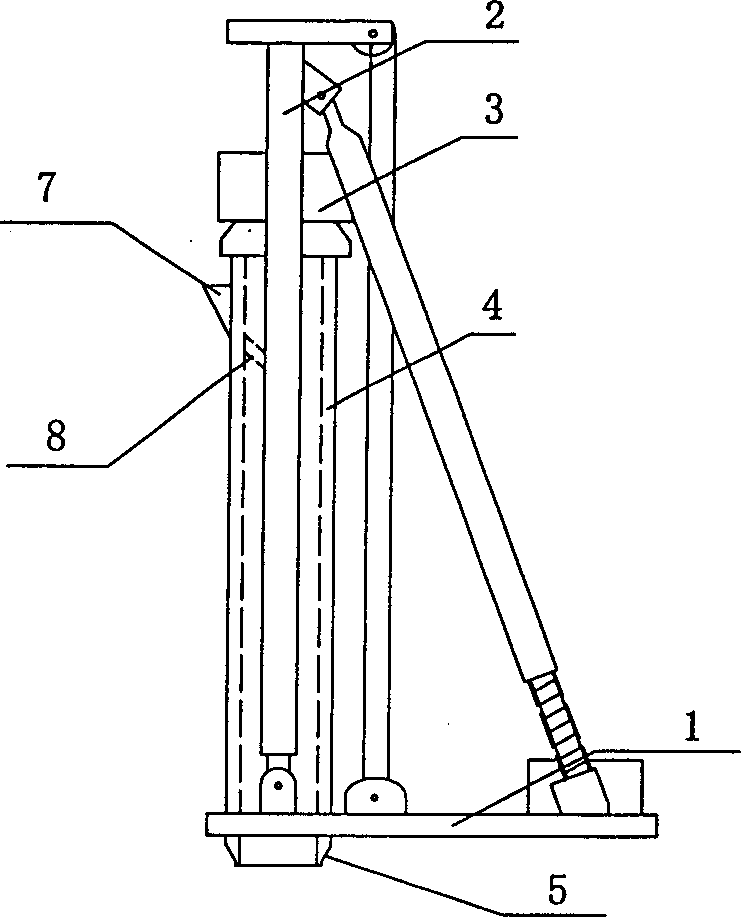

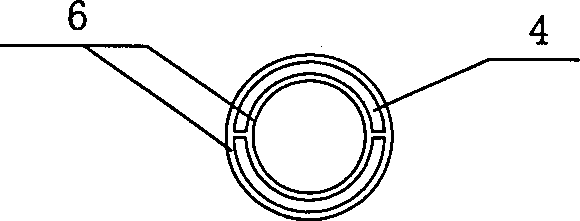

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The casing molded large-diameter cast-in-place pipe pile machine shown is arranged on the foundation (soft soil foundation) 12 to be piled. The vibrating head 3 is connected below, and the feeding hopper 7 is arranged outside the upper part of the cavity structure 4 of the inner and outer casings. The feeding hopper 7 is connected to the concrete splitter 8, and the concrete splitter 8 corresponds to the upper part of the inner side of the cavity structure 4 of the inner and outer casings. The lower part of the vibration head 3 is fixedly connected to the upper end of the inner and outer casing cavity structure 4. The inner and outer casing cavity structure 4 is made of steel material with considerable hardness and strength. The inner and outer sides of the lower end of the inner and outer casing cavity structure 4 are set as The mold lubricates the slurry maker 6 to form inner and outer rings, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com