Sewing machine

A technology for sewing machines and sewing objects, which is applied to sewing machine components, sewing machines, control devices for sewing machines, etc., can solve the problems of undocumented inspection methods, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

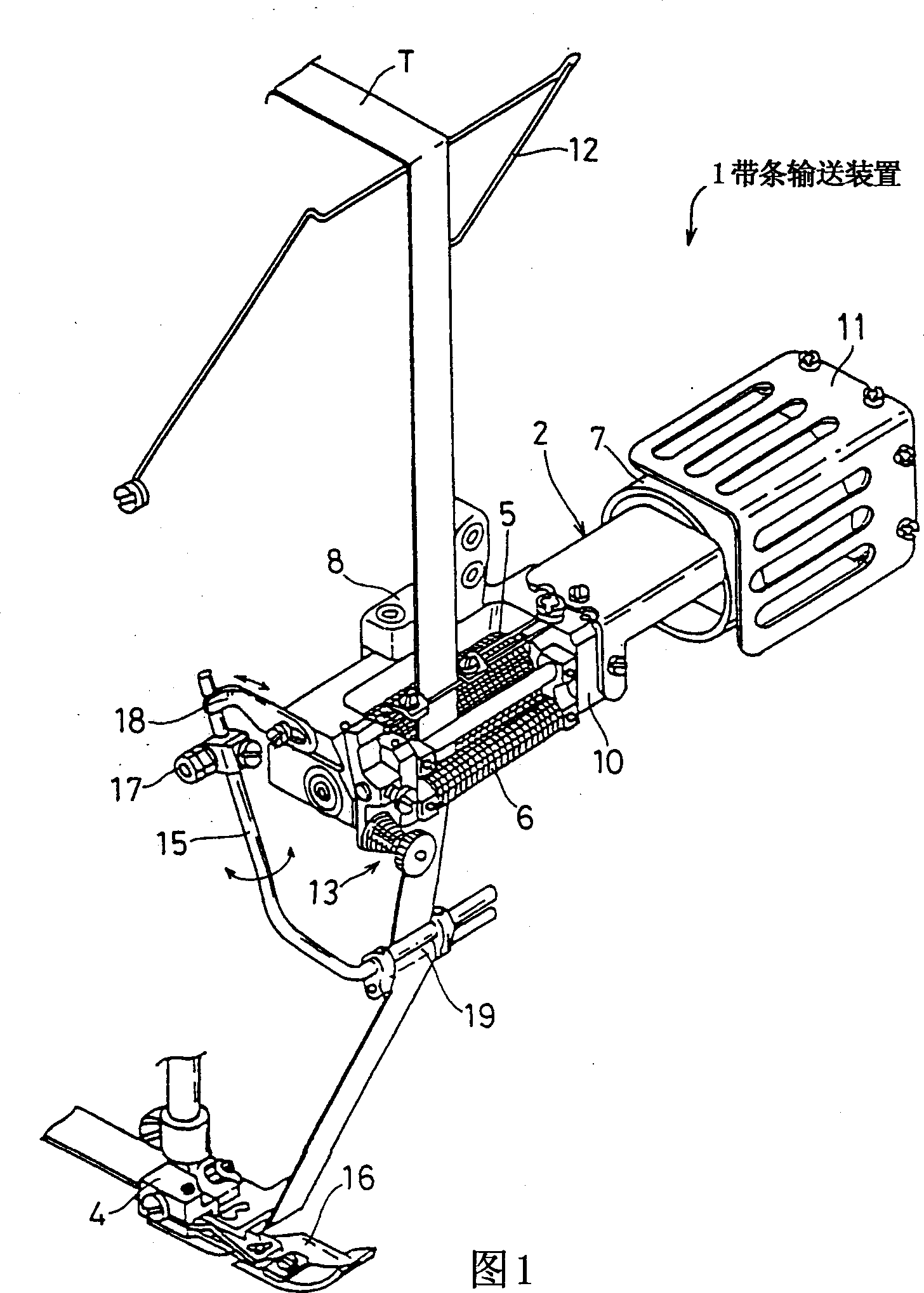

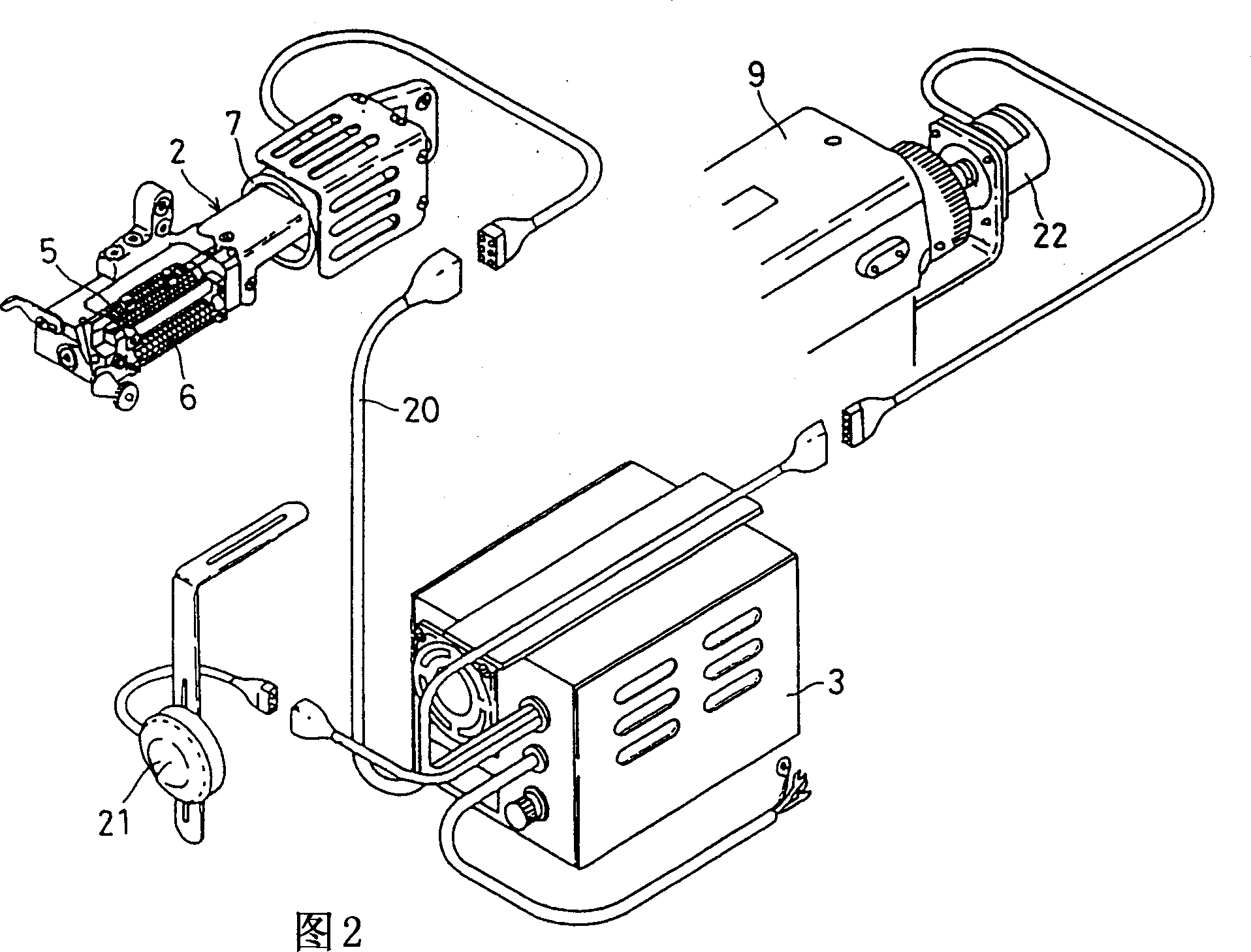

[0027] Fig. 1 is a perspective view of a use state of a strip conveying device 1 according to a specific embodiment of the present invention. Tape conveying device 1 is contained in sewing machine body (not shown in the figure), and is used when tape (ribbon) T such as lace elastic band and elastic band is sewn on cloth (not shown in the figure), is controlled by conveying device body 2 and Box 3 (as shown in Figure 2) constitutes.

[0028] The conveying device body 2 has a large roller 5 for pinching the strip T, a small roller 6 and a stepping motor 7 for driving the large roller 5 to rotate. The rollers 5, 6 are supported by the roller mounting table 10, and the roller mounting table 10 is fixed to the sewing machine body by the bracket 8, so that the rollers 5, 6 are arranged above the cloth presser 4 of the sewing machine body. The outer peripheral surfaces of the rollers 5 and 6 are roughened by knurling, and they are in elastic contact with each other. Thereby, the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com