Electronic element installation device

An electronic component installation, electronic component technology, applied in the direction of electrical components, electrical components, electrical components assembling printed circuits, etc., can solve the problems of increased size and number of components, shortened life of leads 8, increased costs, etc., to reduce the number of parts. , the effect of shortening the rotation time and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

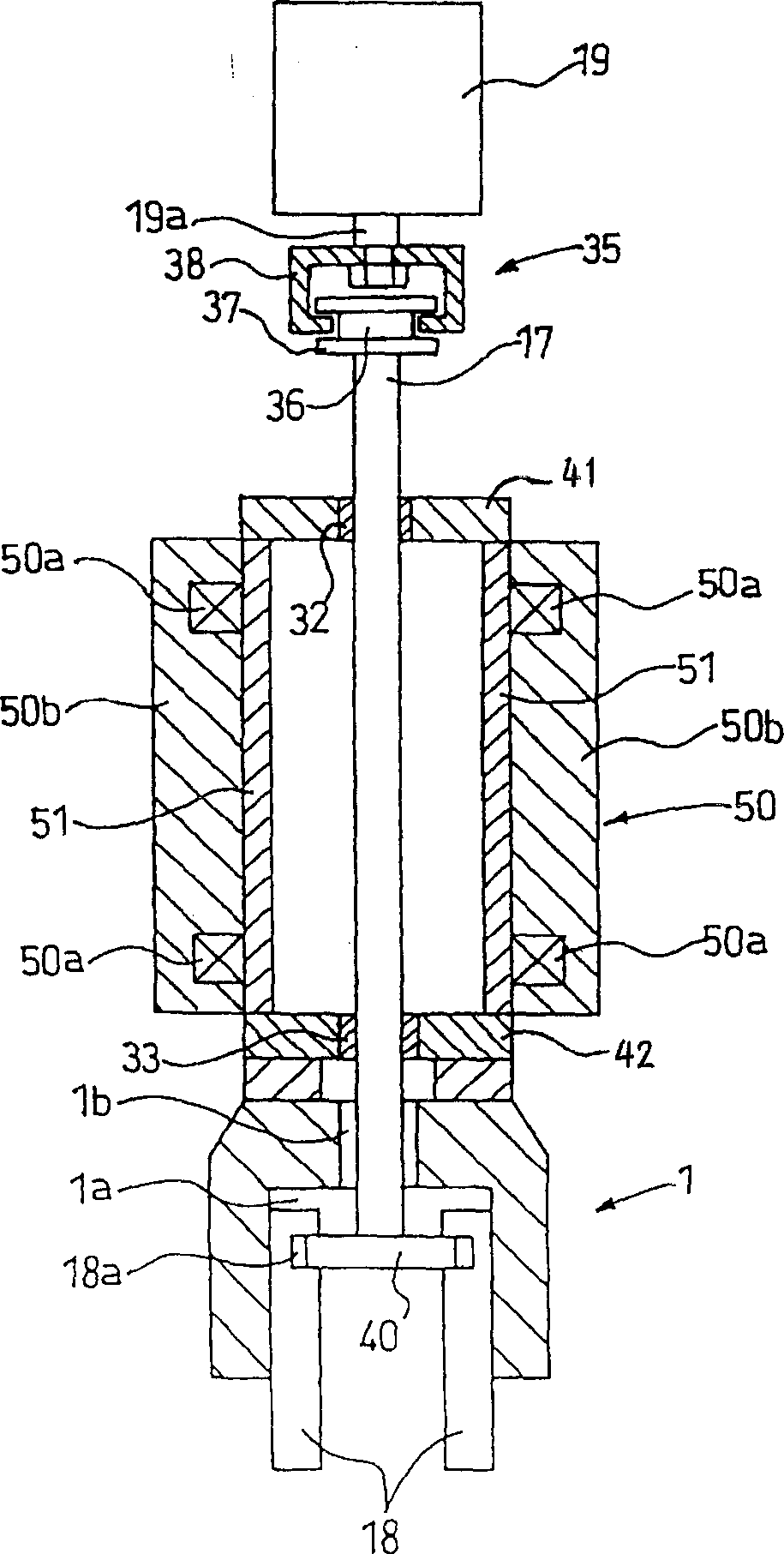

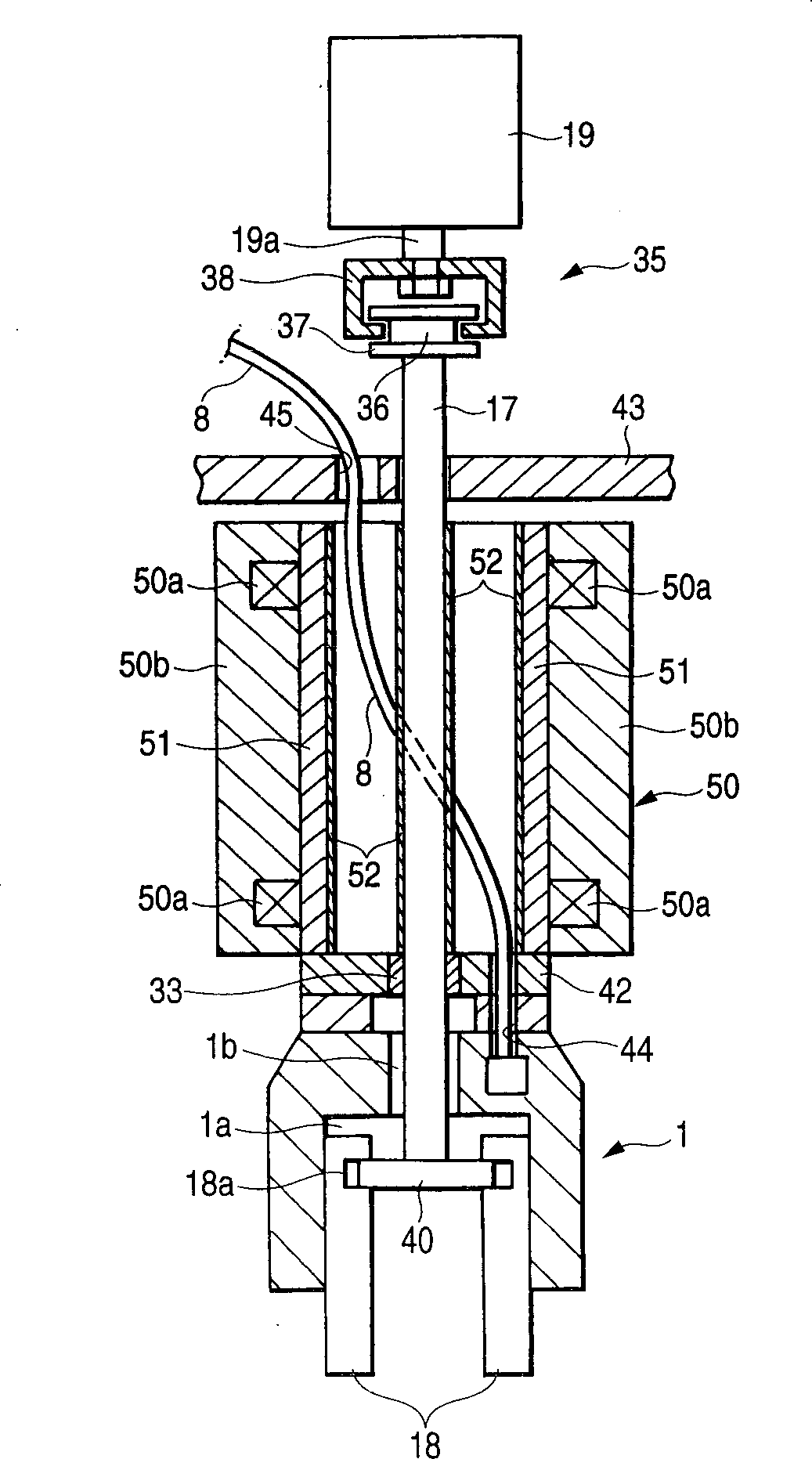

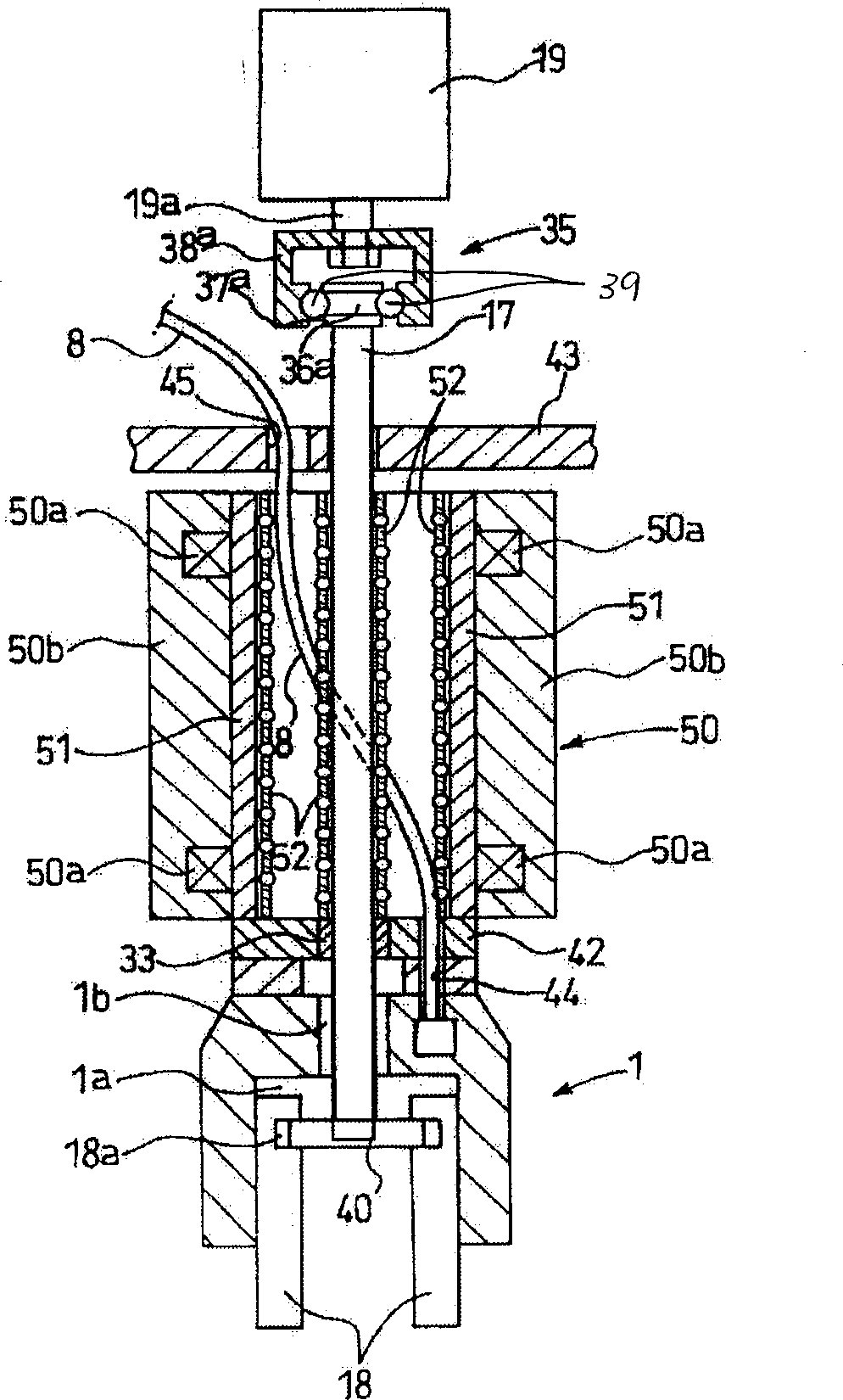

[0034] Combine below figure 1 A first embodiment of the electronic component mounting apparatus of the present invention will be described. figure 1is a cross-sectional view showing the structure of a rotating body which is a part of the electronic component mounting device. The reference numerals used in the foregoing description and in the example electronic component mounting apparatus 100 of the prior art will also be applicable to the description of the present embodiment.

[0035] As with the previous technique example, shown in figure 1 The rotating body 1 at the lower part installs various electronic components successively on predetermined positions of the bottom plate in different installation directions. A hollow motor 50 is arranged above the rotating body 1 , the flange 42 is inserted between the hollow motor 50 and the rotating body 1 , and a driver 19 is arranged above the rotating body 1 . The hollow motor 50 has a stator 50b, and a coil 50a is wound arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com