Snake-shaped robot

A snake-like robot and snake tail technology, applied in the field of robotics, can solve the problems of restricting heat transfer and heat dissipation of shape memory alloys, and the limitation of utilization surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

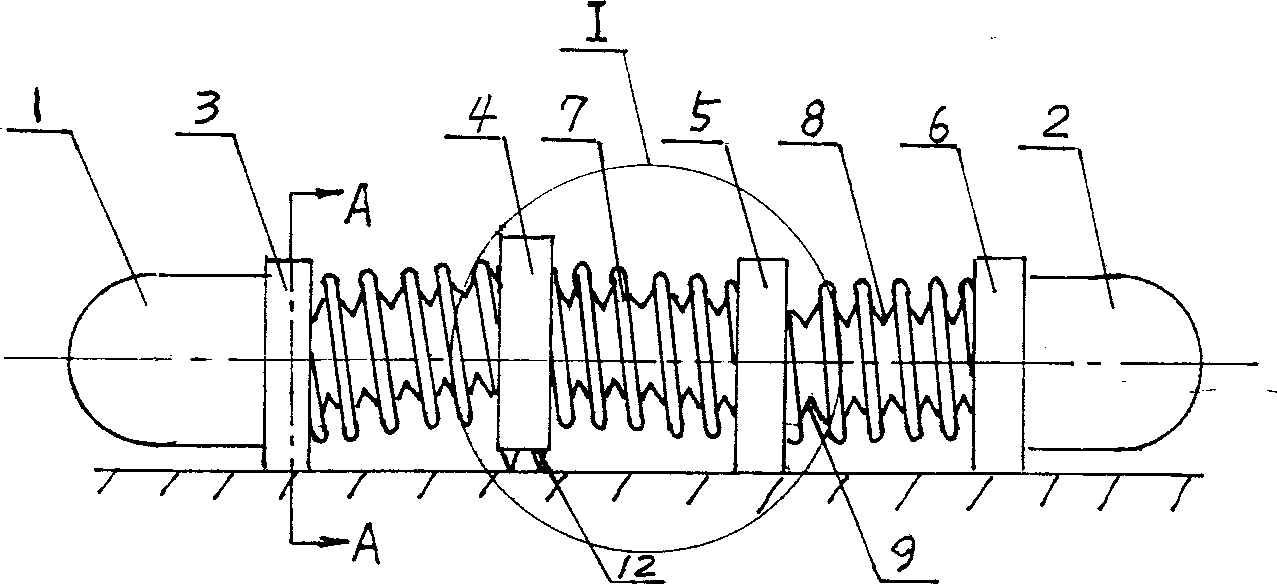

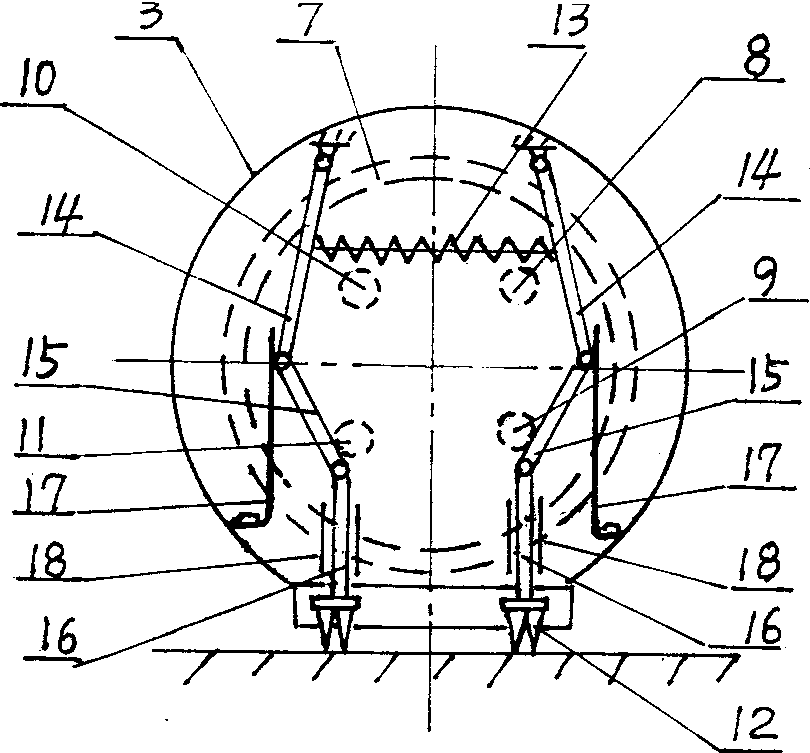

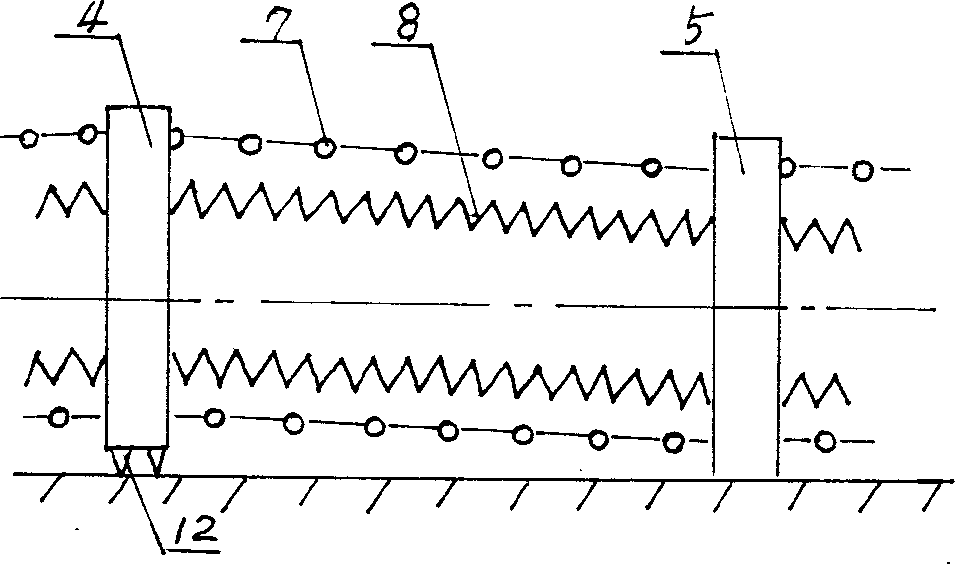

[0010] figure 1 Among them, a snake-shaped robot is mainly composed of a snake head 1, a snake tail 2, several joint ends 3, 4, 5, 6, ordinary steel wire springs 7, shape memory alloy (SMA) springs 8, 9, 10, 11 and feet 12. Component composition. The joint end 3 and the joint end 4 are connected by ordinary steel wire spring 7 and four shape memory alloy (SMA) springs 8, 9, 10, 11 fixed on the joint end 3, 4, and the other joints are deduced by analogy, namely Can form a snake robot. The joint ends are made of insulating material, and each joint end is equipped with a mechanism that can control the extension and retraction of the foot 12 (see details). figure 2 ). This control mechanism is composed of shape memory alloy (SMA) spring 13, connecting rod 14, 15, 16, spring leaf 17 and slideway 18 installed at the joint end, and foot 12. According to the characteristics of the crawling ground, rubber pads or metal tines. Its working principle is: the shape memory alloy (SMA)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com