Processing box image device and inter-transferring belt

An intermediate transfer and imaging device technology, applied in the field of process boxes, can solve problems such as increased management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-1

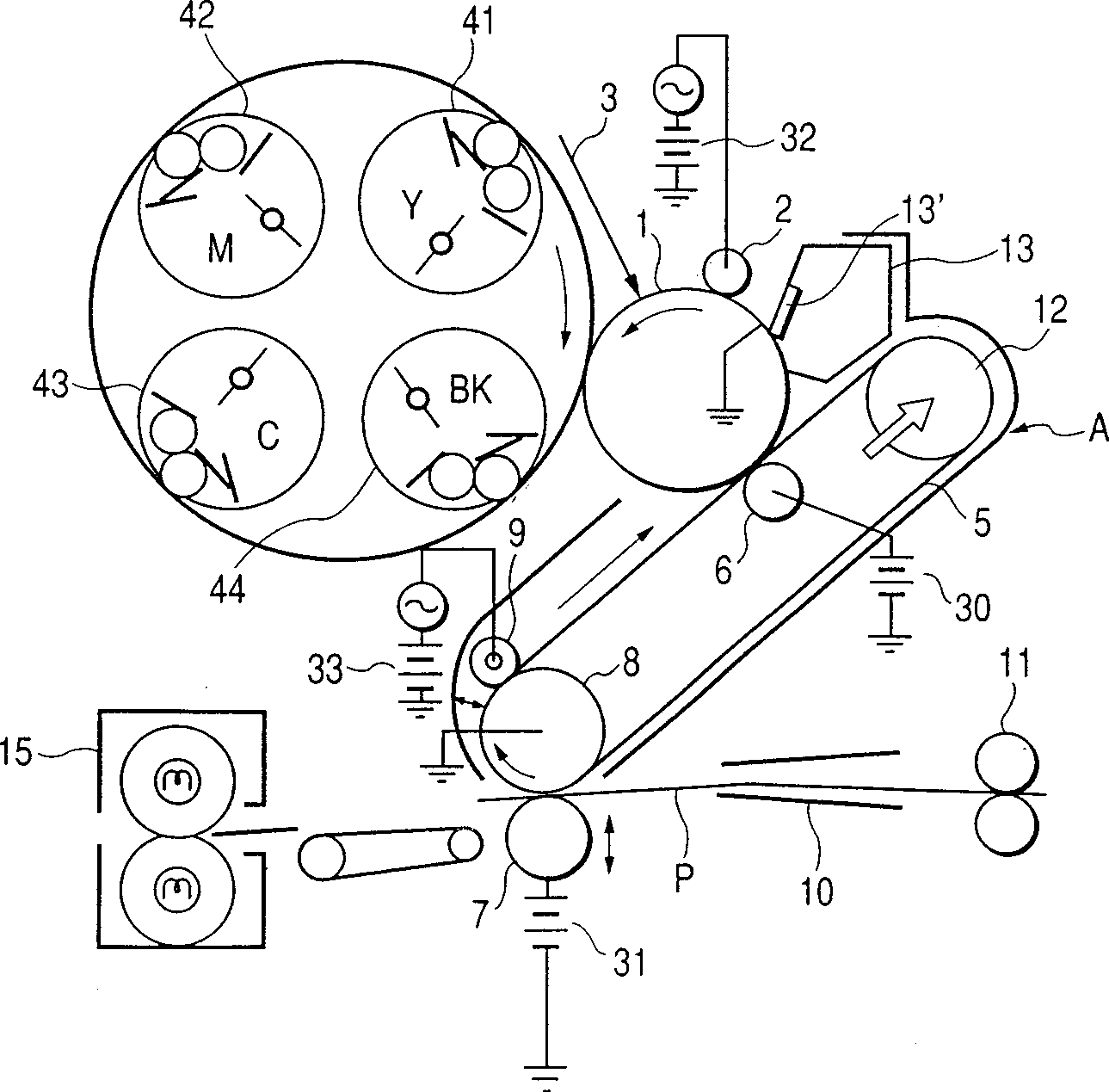

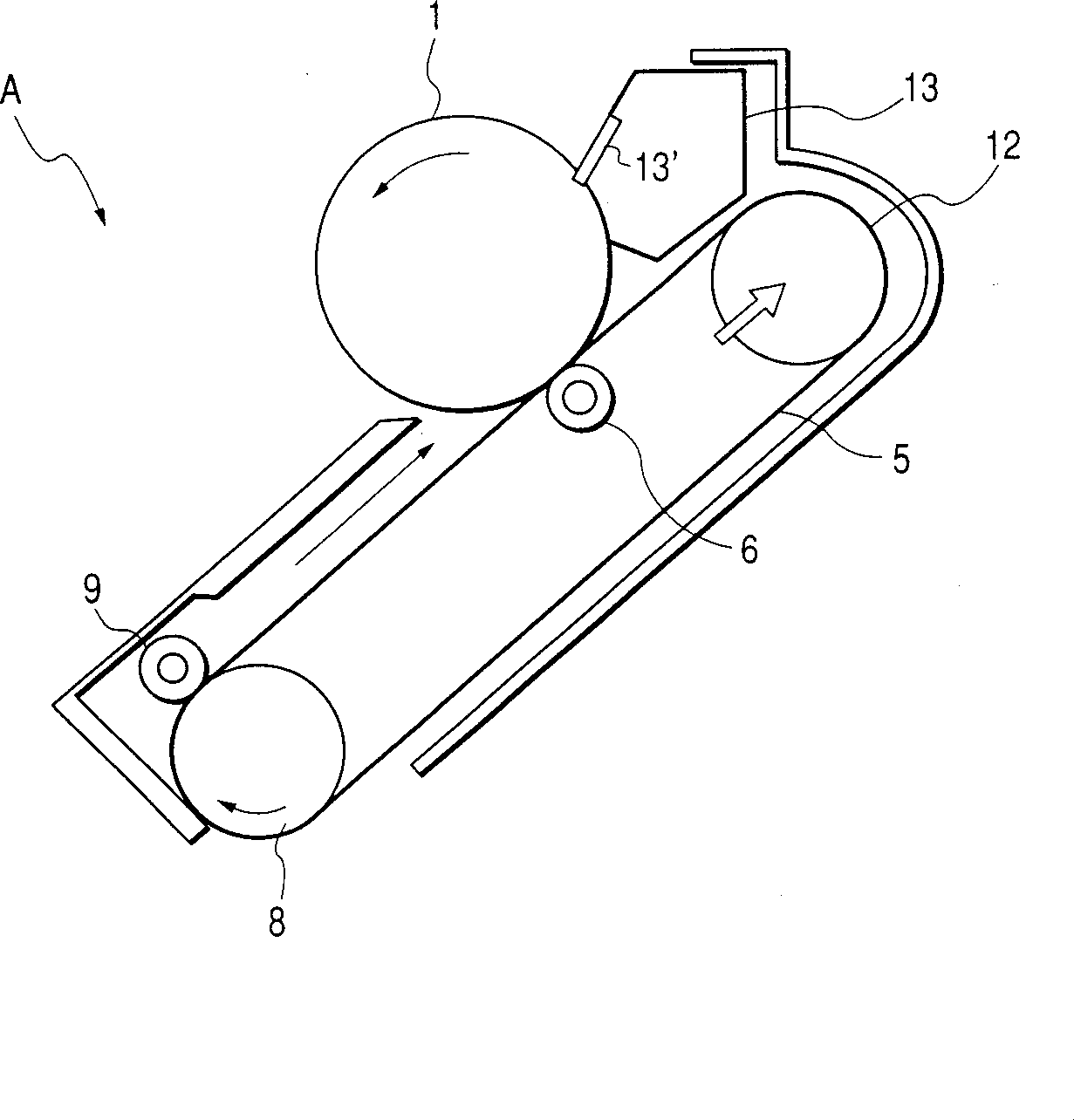

[0113] (1) Manufacture of intermediate transfer belt 5:

[0114] Formula a: (by weight)

[0115] 100 parts of polyvinylidene chloride resin (PVDF)

[0116] Polyetherester fiber amide resin 12 parts

[0117] 1. The above formulation is mixed by melt kneading at 210° C. through a twin-screw extruder, and the obtained mixture is extruded in the shape of a rope with a diameter of about 2 mm, and then cut into sheets. This substance is denoted extruded material a'.

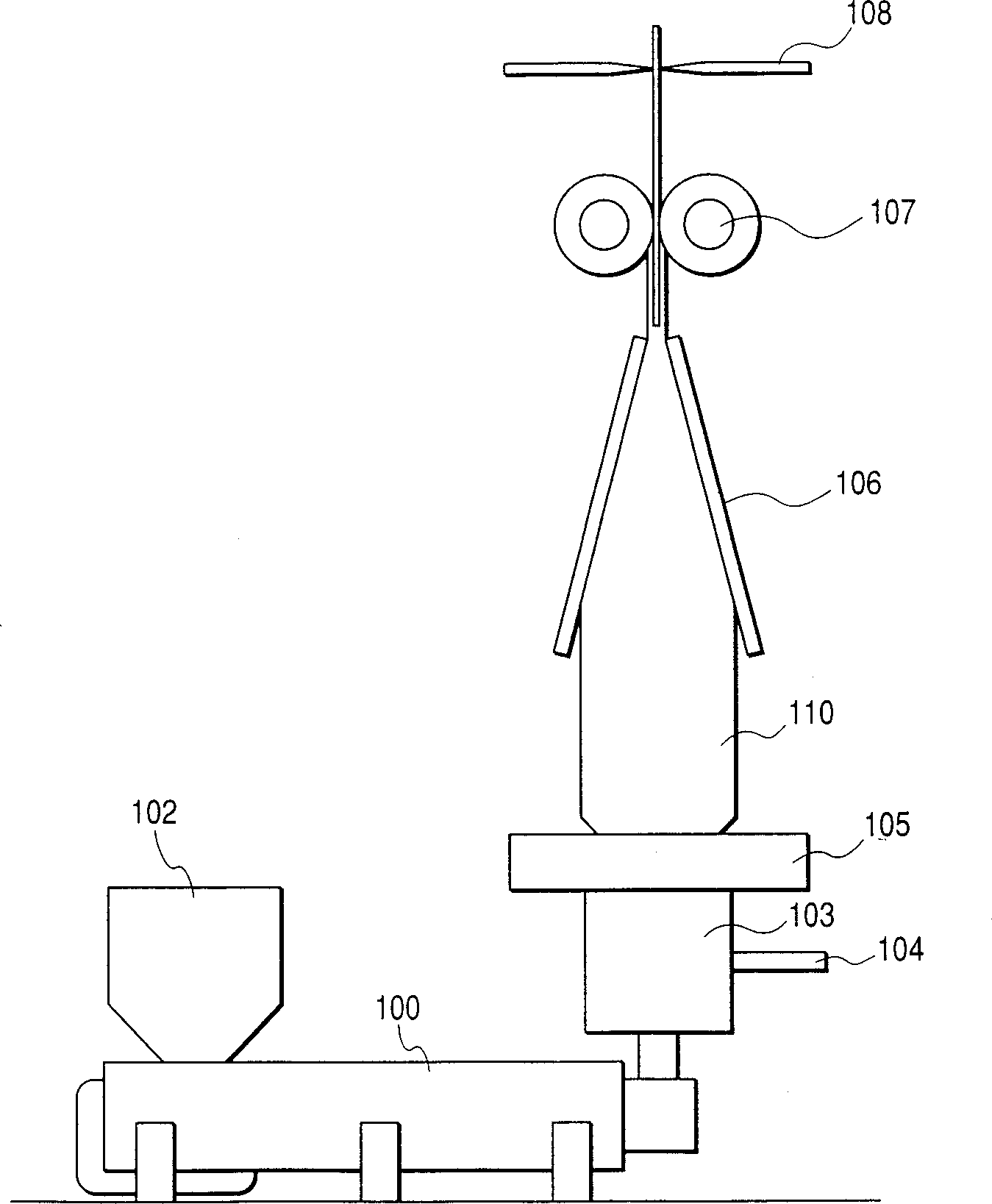

[0118] 2. Next, in image 3 In the extrusion device shown, the die head 103 of the extruder is set as a single-layer circular die, and the outer diameter of the die slit is 100mm. The width of the die seam was 0.8 mm. The above extruded material a' heated and dried well is put into the hopper 102 of the extruder, and then heated and melted. The molten product was extruded from the circular die 103 at 210°C. An outer cooling ring 105 surrounds the circular die 103 and air from the atmosphere is blown into the fil...

example 1-2

[0132] (1) Manufacture of intermediate transfer belt 5:

[0133] Two kinds of intermediate transfer belts 5 were manufactured in the same manner as in Example 1-1 except that the recipe was changed to the following recipe b.

[0134] Formulation b: (by weight)

[0135] 100 parts of polyvinylidene chloride resin (PVDF)

[0136] Conductive carbon black 8 parts

[0137] (2) Manufacture of the latent image bearing member 1:

[0138] As the latent image bearing member 1, the same latent image bearing member 1 as in Example 1-1 was used.

[0139] (3) Measurement of physical properties and image printing test

[0140] On the intermediate transfer belt 5, physical properties were measured and an image printing test was performed in the same manner as in Example 1-1. Therefore, when the intermediate transfer belt 5 and the latent image bearing member 1 are rubbed against each other, the surface potential Vt of the latent image bearing member 1 is +180V.

[0141] The surface rough...

example 1-3

[0144] 1) Manufacture of intermediate transfer belt 5:

[0145] Two kinds of intermediate transfer belts 5 were manufactured in the same manner as in Example 1-1 except that the recipe was changed to the following recipe c and both the kneading temperature and the extrusion temperature were set to 220°C.

[0146] Formulation c: (by weight)

[0147] Amorphous polyamide resin 100 parts

[0148] 20 parts of polyether ester amide resin

[0149] (2) Manufacture of the latent image bearing member 1:

[0150] As the latent image bearing member 1, the same latent image bearing member 1 as in Example 1-1 was used.

[0151] (3) Measurement of physical properties and image printing test

[0152] On the intermediate transfer belt 5, physical properties were measured and an image printing test was performed in the same manner as in Example 1-1. Therefore, when the intermediate transfer belt 5 and the latent image bearing member 1 are rubbed against each other, the surface potential Vt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com