Acoustic wave device comprising alternating polarisation domains

A technology of acoustic wave devices and polarized regions, applied in electrical components, impedance networks, etc., to solve problems such as electrode short-circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

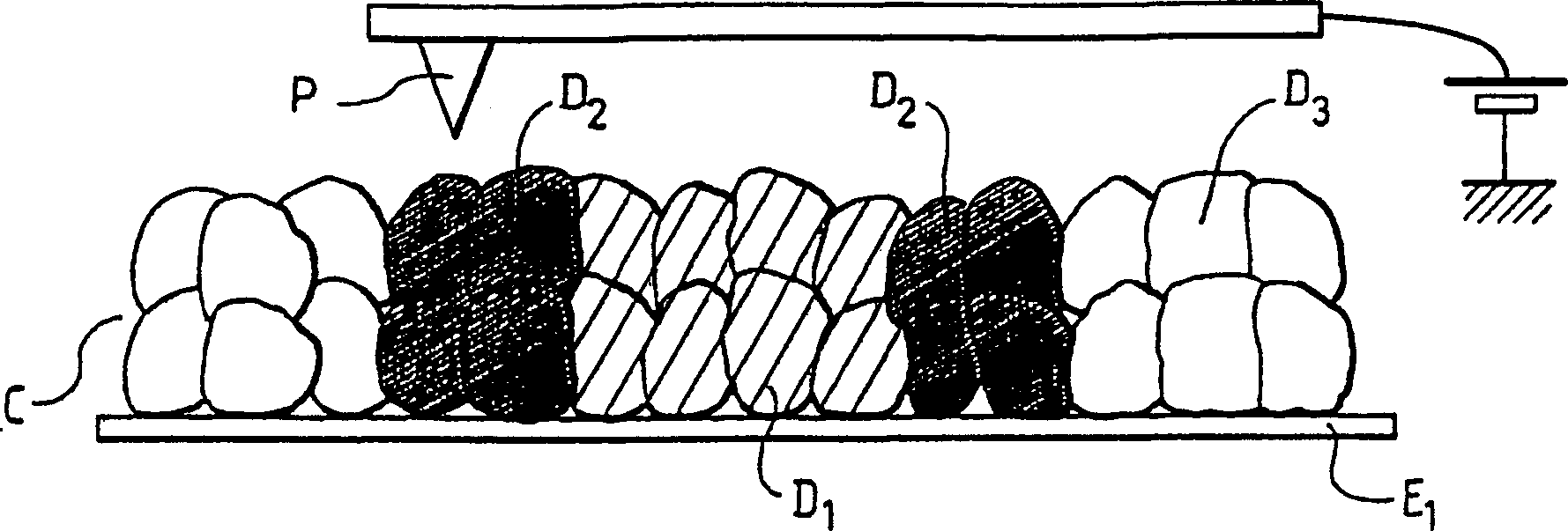

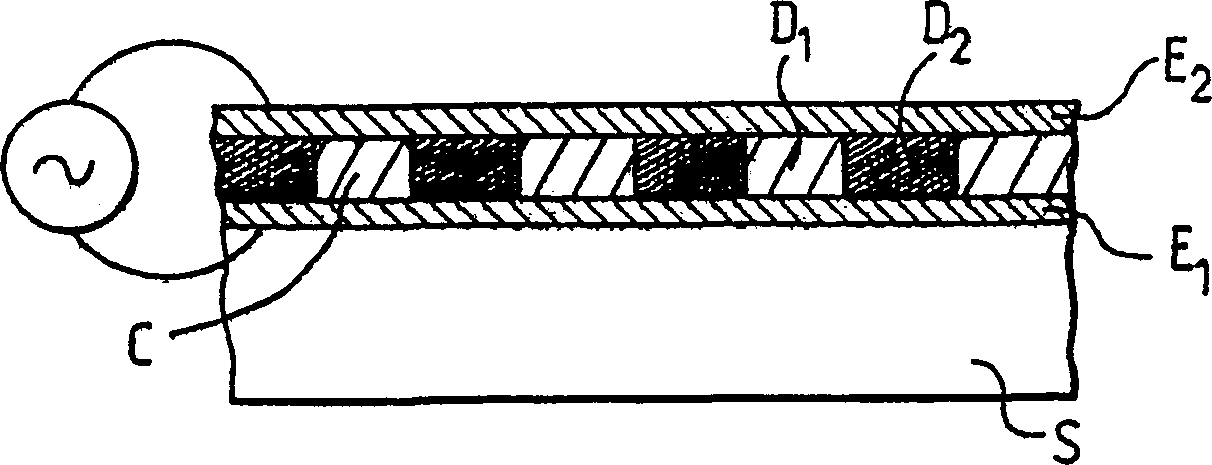

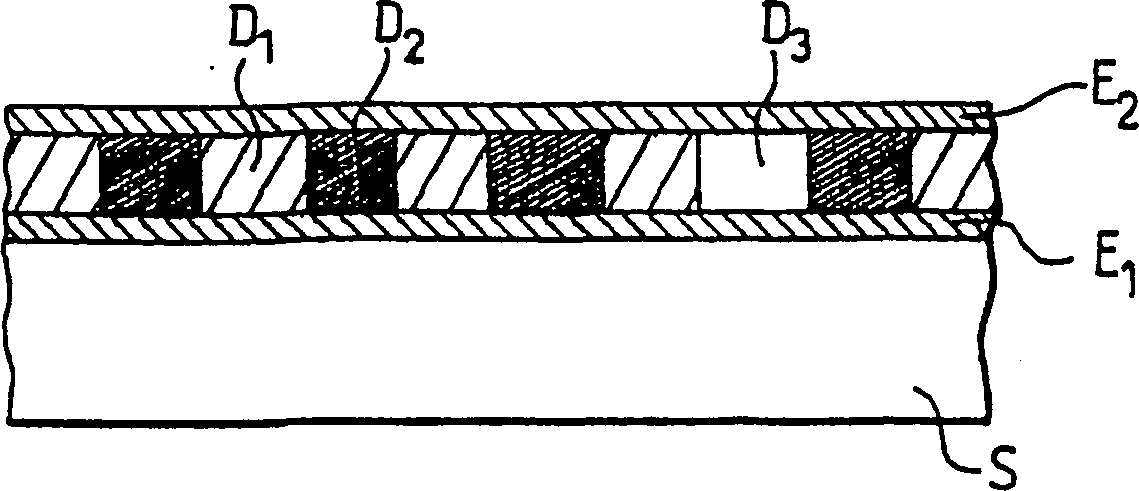

[0021] In summary, the present invention provides an acoustic wave device employing a layer of ferroelectric material in which regions of alternating polarization are formed.

[0022] In particular, the present invention proposes to generate regions of localized polarization and to derive advantages from such localized polarizations in order to functionalize or periodize the electroacoustic properties of the formed material in order to produce acoustic wave devices which, due to the local electric polarization, rely on Piezoelectrically actuate ferroelectric materials on any type of metal substrate or metallized surface.

[0023] For this purpose, a layer of ferroelectric material is formed in conventional manner on the surface of the metal substrate or on the surface of the metallized substrate. In general, this can be any single or polycrystalline ferroelectric material, for example, lead titanium zirconium oxide (PZT), LiNbO 3 , LiTaO 3 or KNbO 3 . Typically, the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com