Washing machine

A technology for washing machines and washing shafts, which is applied in the field of washing machines and can solve problems such as damage to the control drive device 17

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

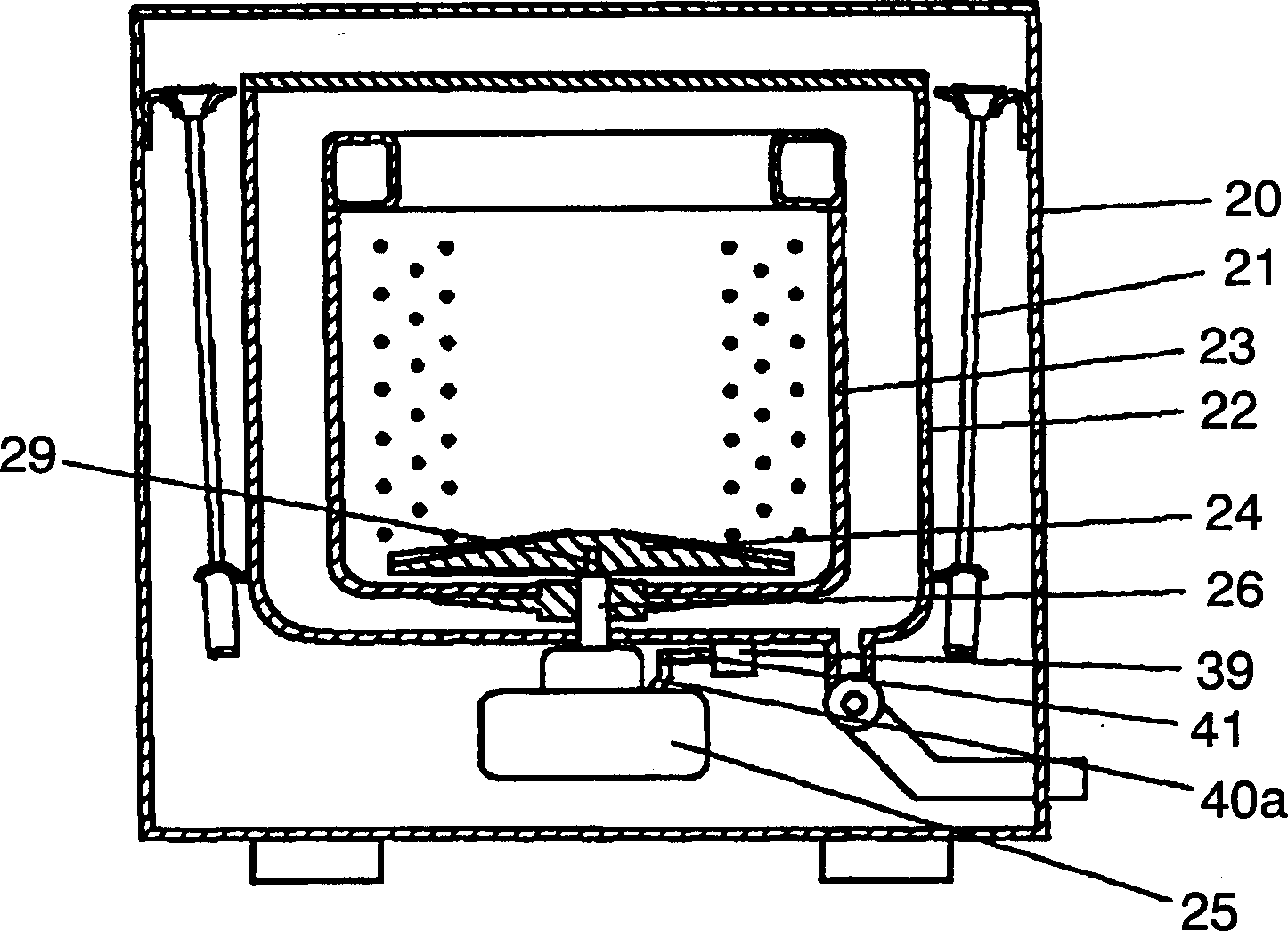

Image

Examples

Embodiment 2

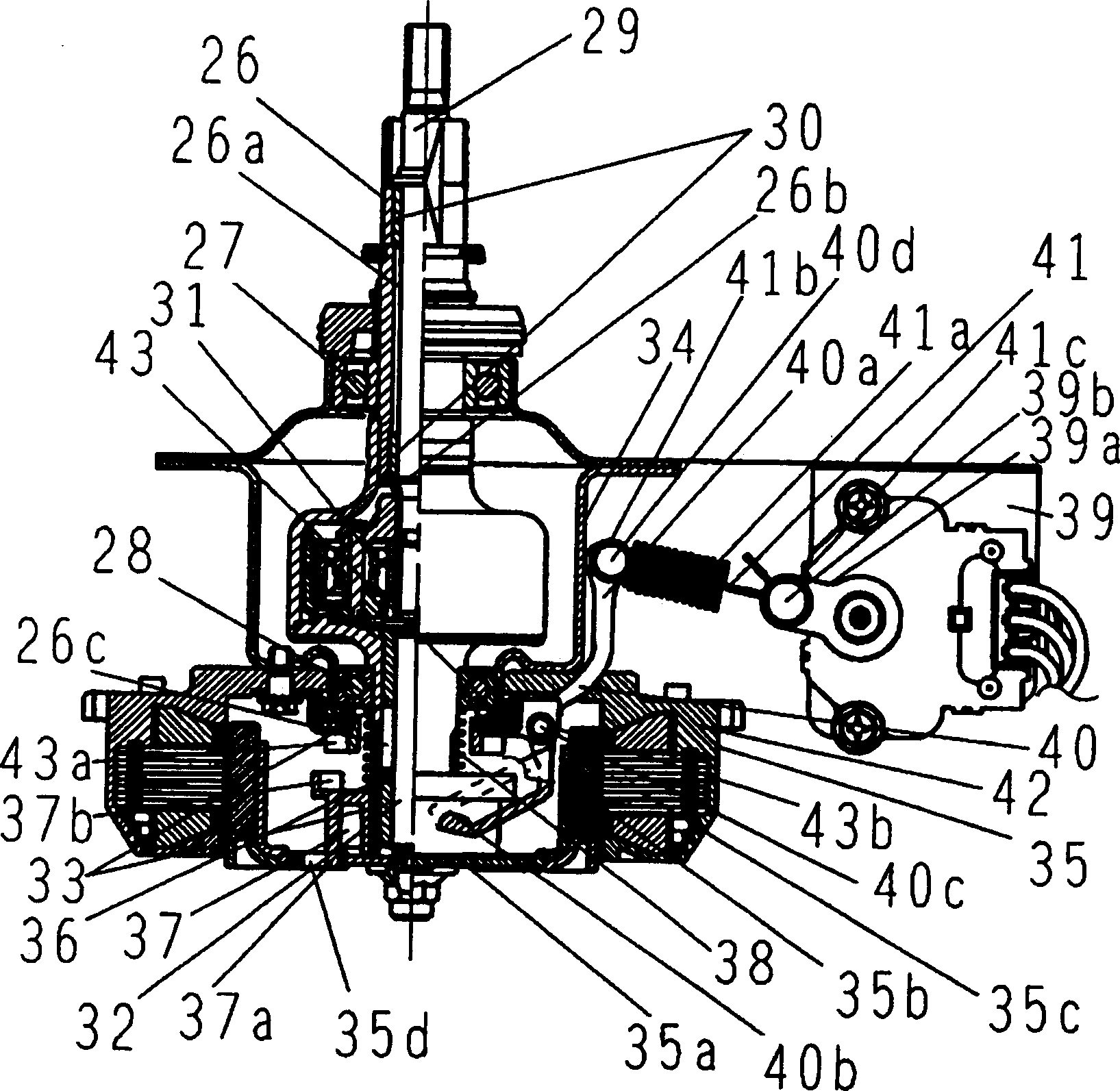

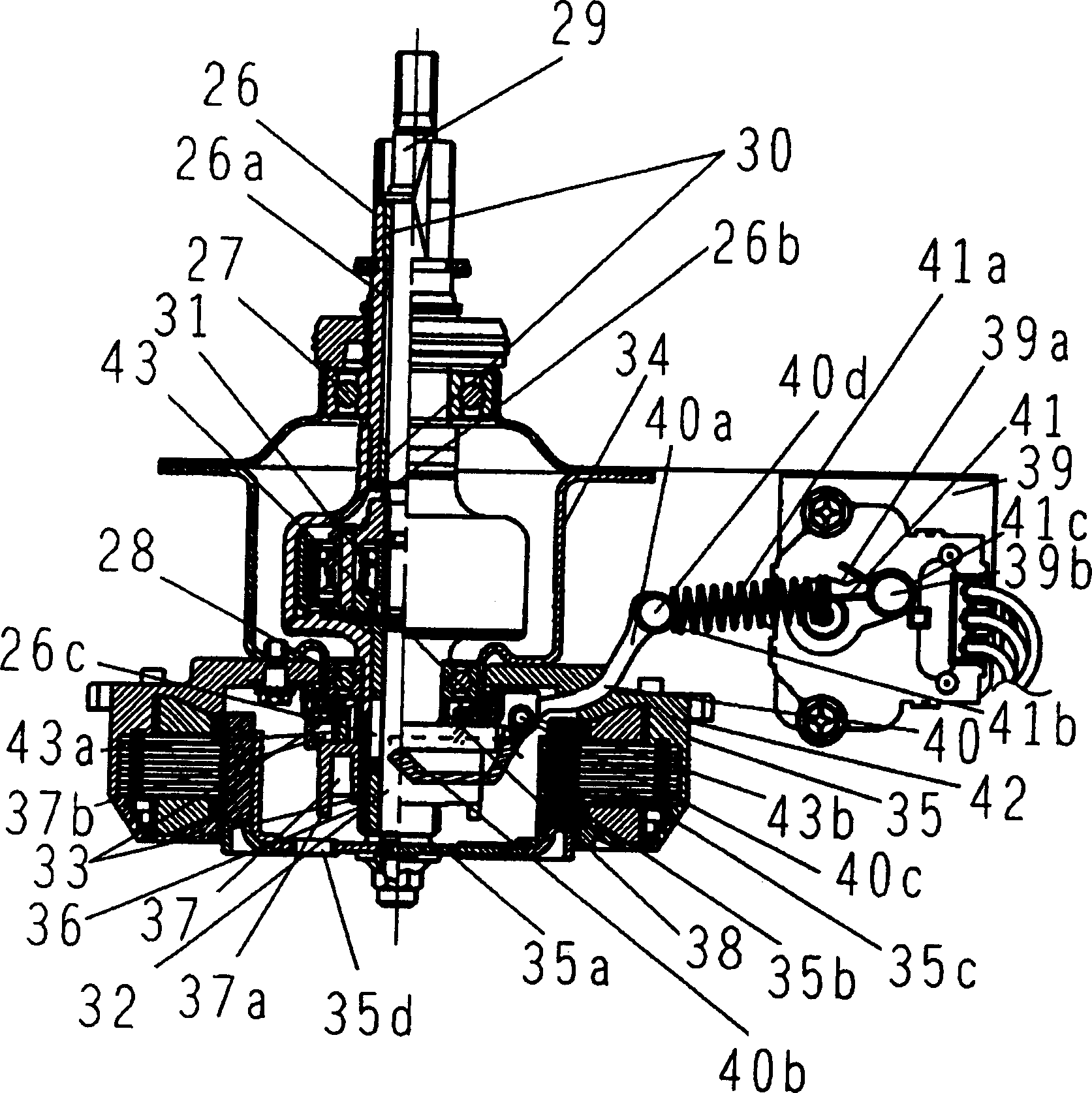

[0040] exist Figure 5 In Fig. 6, the intermediary member 41 is made of a metal wire (wire rod) (spring steel wire, piano wire, etc.), near the end of the clutch lever connecting portion 40a side of the clutch lever 40, there is a spring as an elastic member. The spring structure part 41a. The two ends of the media member 41 are respectively formed with a clutch lever side hook 41b that fits with the clutch lever connection protrusion 40d provided at the clutch lever connection portion 40a and is connected with the drive mechanism at the drive mechanism connection portion 39a. The driving device matched with the protrusion 39b is connected to the hook 41c on one side. The hook 41c on the driving device connection side is rolled into a (substantially) annular linear shape, and the angle between the curled end surface 41d and the straight portion 41e forms a predetermined angle (for example, 0°<A<90°). Other structures are the same as the washing machine of Embodiment 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com