Dip soldering method and dip soldering device

A technology of dip soldering and oblique top, which can be used in tin feeding devices, welding equipment, assembling printed circuits with electrical components, etc., and can solve problems such as poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described below based on the embodiments shown in the accompanying drawings.

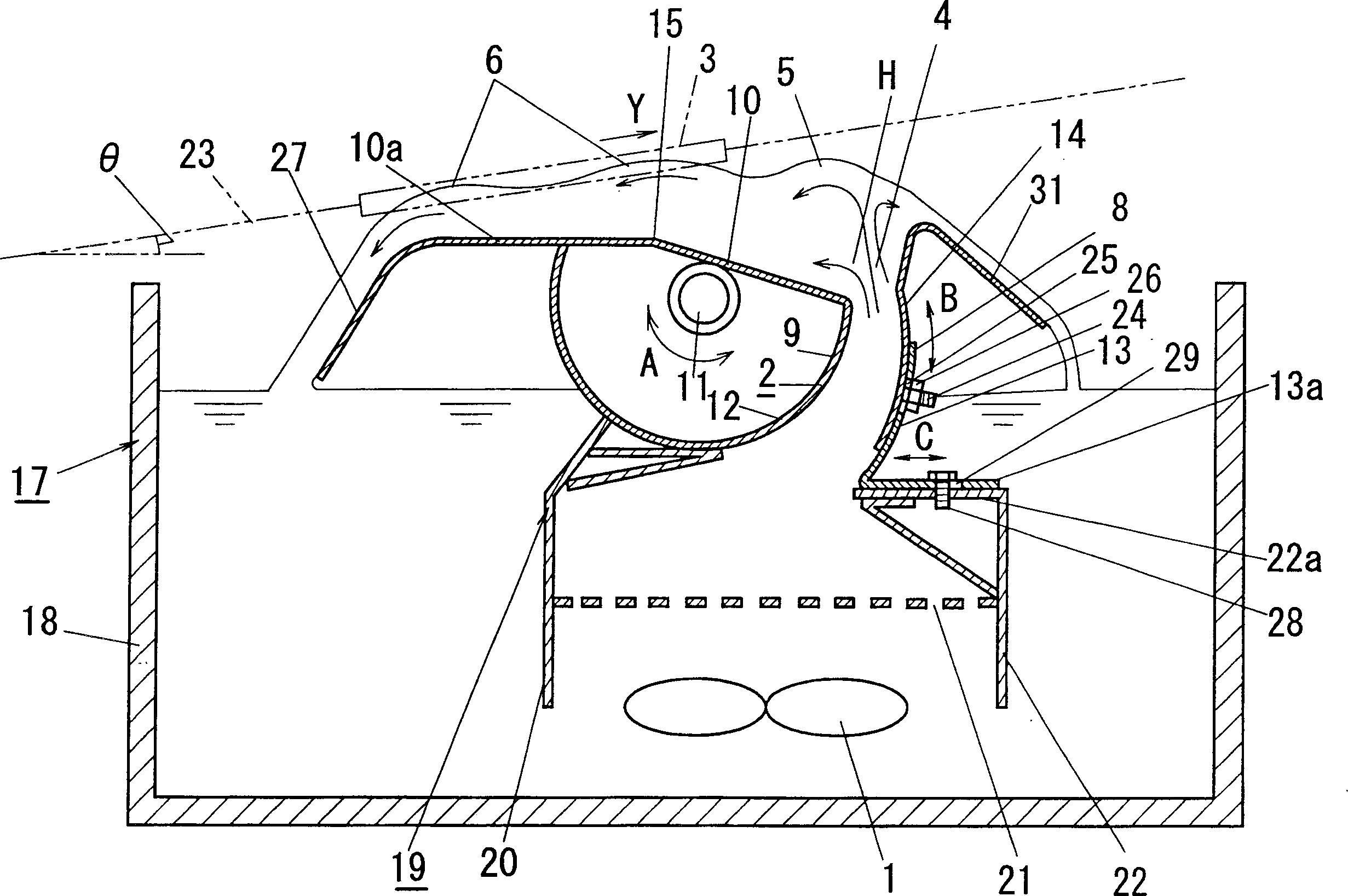

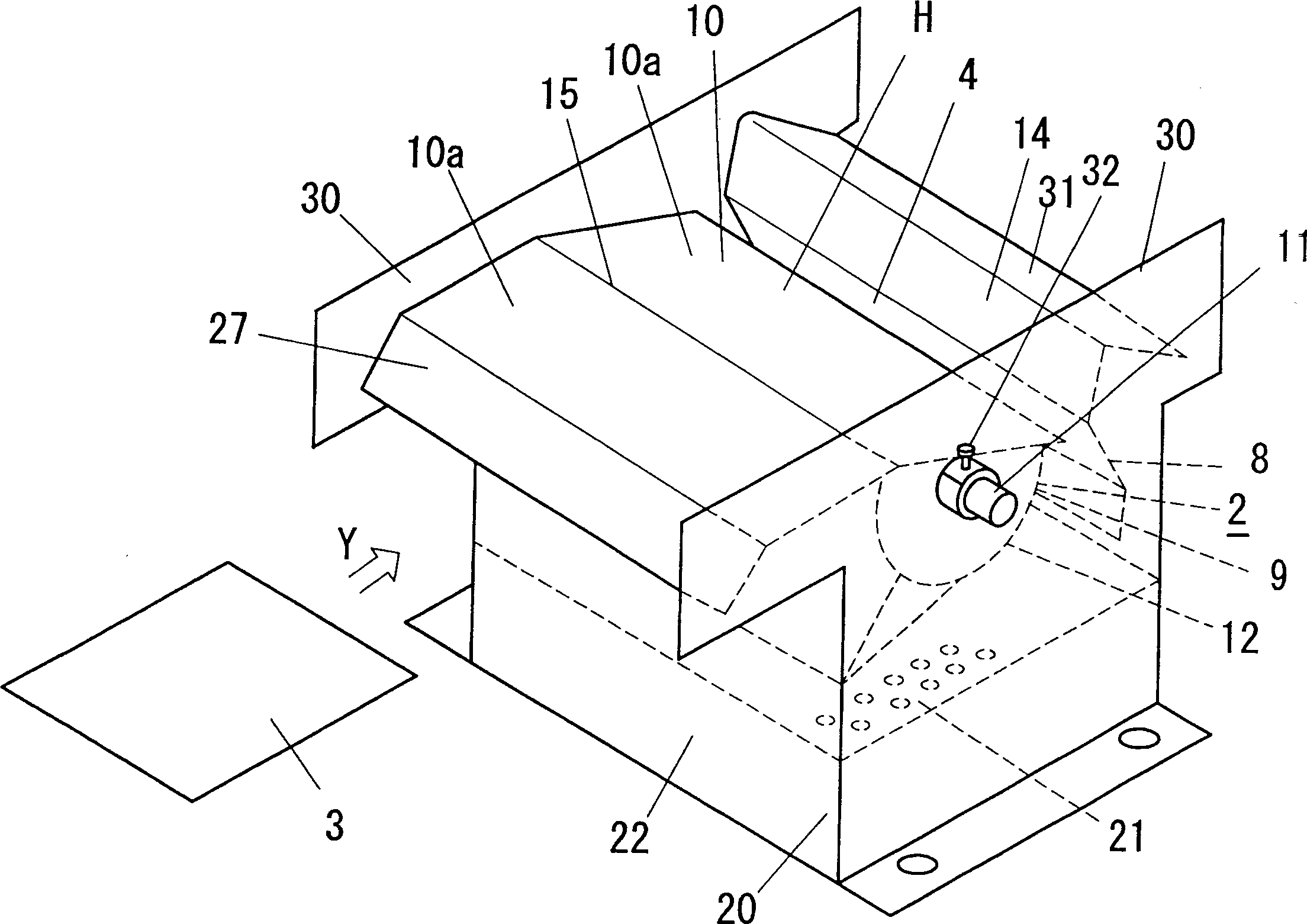

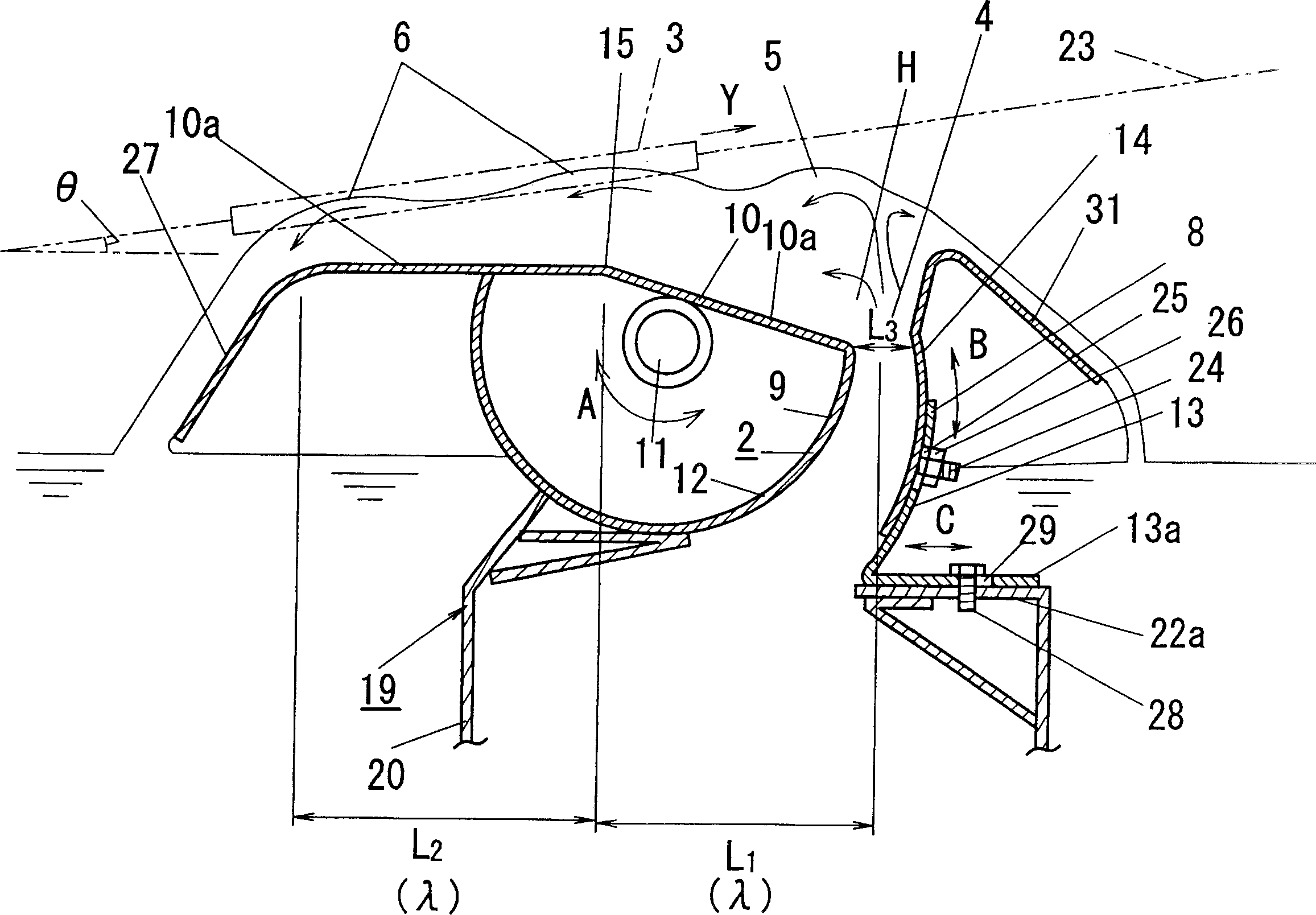

[0041] figure 1 It is a side sectional view showing the solder dipping device of the present invention, figure 2 yes figure 1 Partial perspective view of part of spout 4 shown.

[0042] Such as figure 1 , figure 2 As shown, the dipping soldering device 17 is heated to a solder tank 18 of molten solder in a molten state by accommodating a heater (not shown in the figure) and dips the molten solder contained in the solder tank 18 to the workpiece 3 to be dipped. The molten solder jetting device 19 above is configured, wherein the molten solder jetting device 19 is arranged in the upper part of the solder tank 18 .

[0043] The spout body 20 is set on the molten solder spray device 19, the bottom of the spout body 20 constitutes the lower cylinder portion 22 of the built-in pressure feeding device 1 and rectifying plate 21 such as a pump, and the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com