Spindle motor, information recording and reading device with same, and spindle motor mfg. method

A technology for spindle motor and information recording, which is applied in the directions of information recording, magnetic recording, and information storage on magnetic disks, and can solve the problems of inability to improve the coaxiality of inner and outer diameters, increase in cost, and large processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

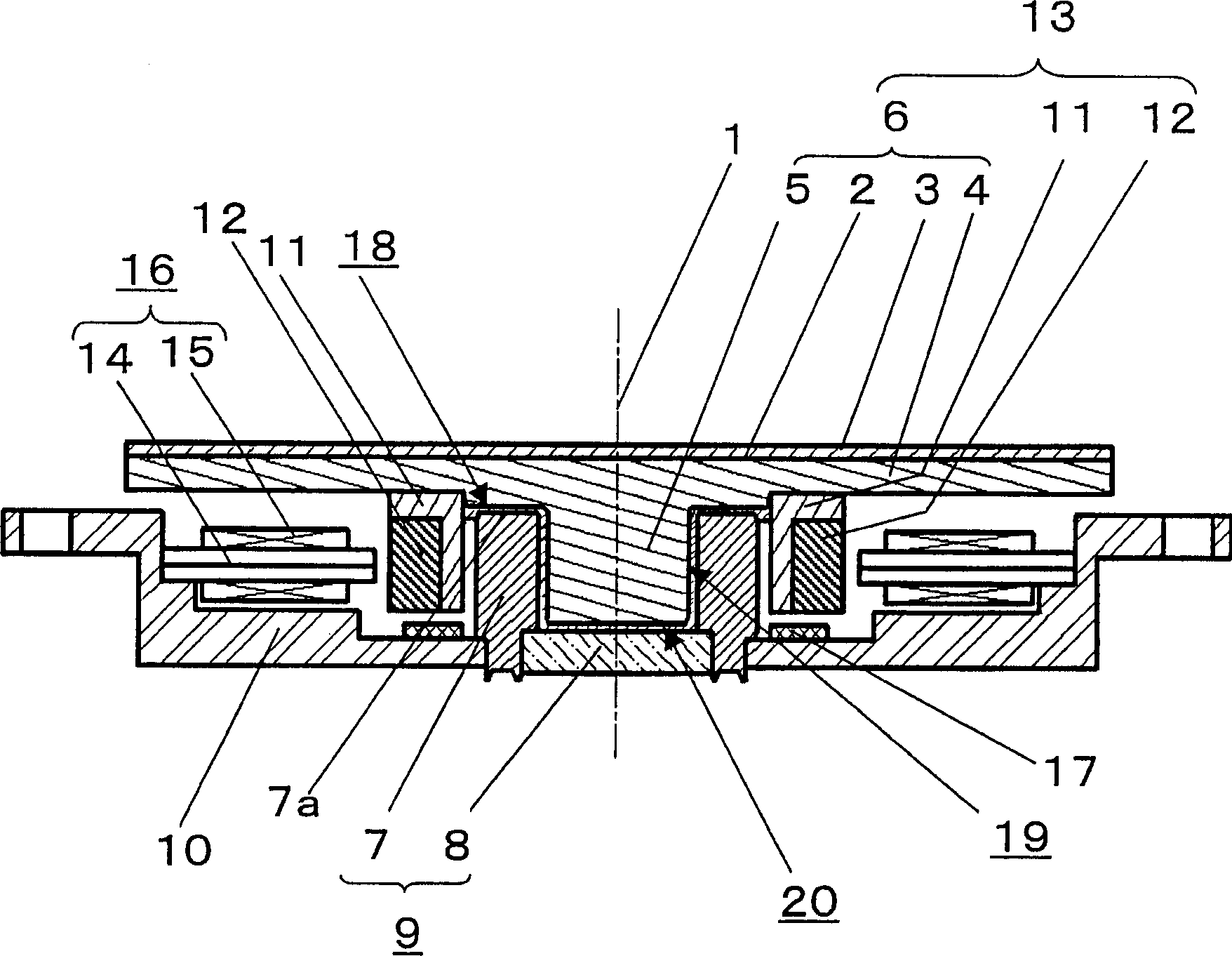

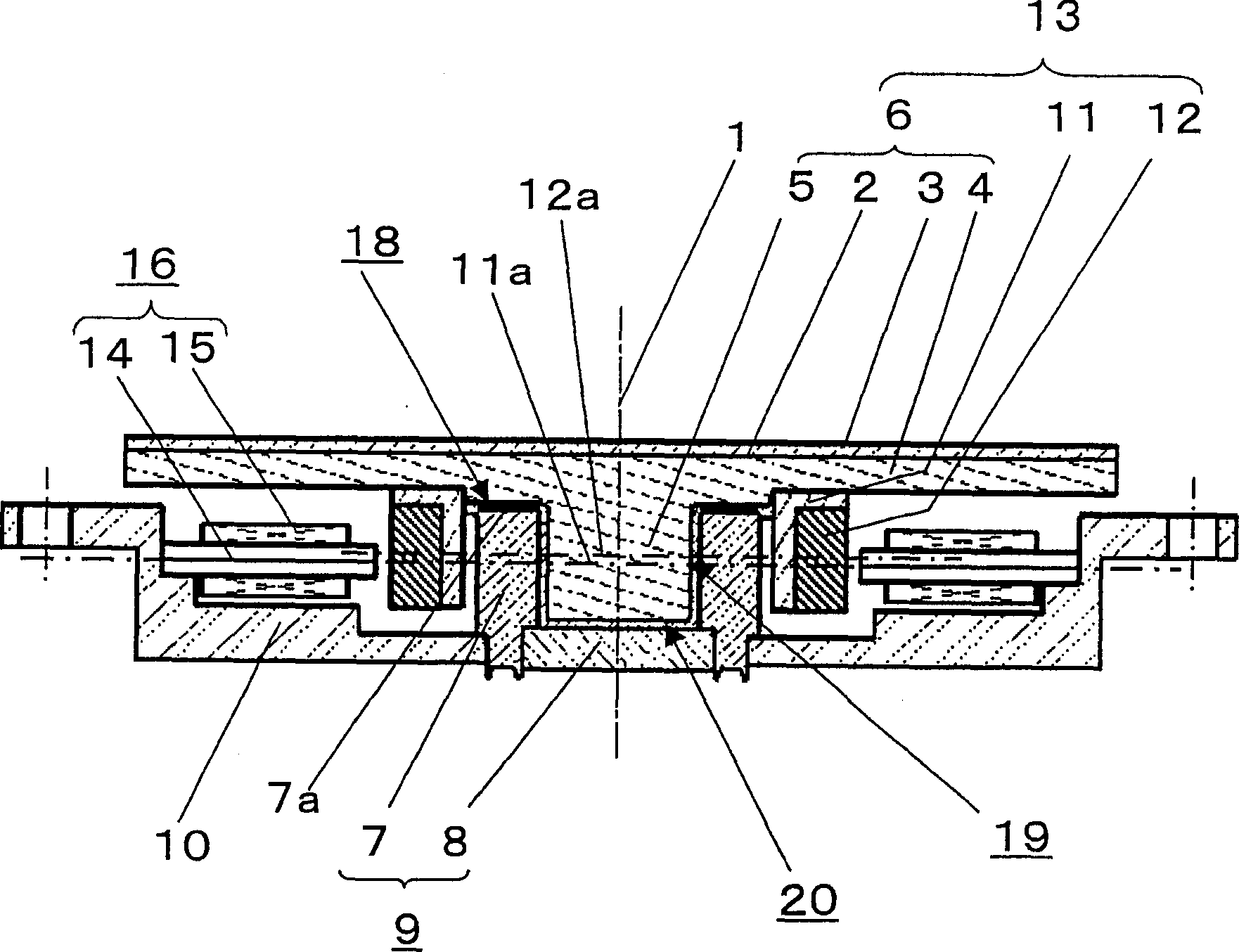

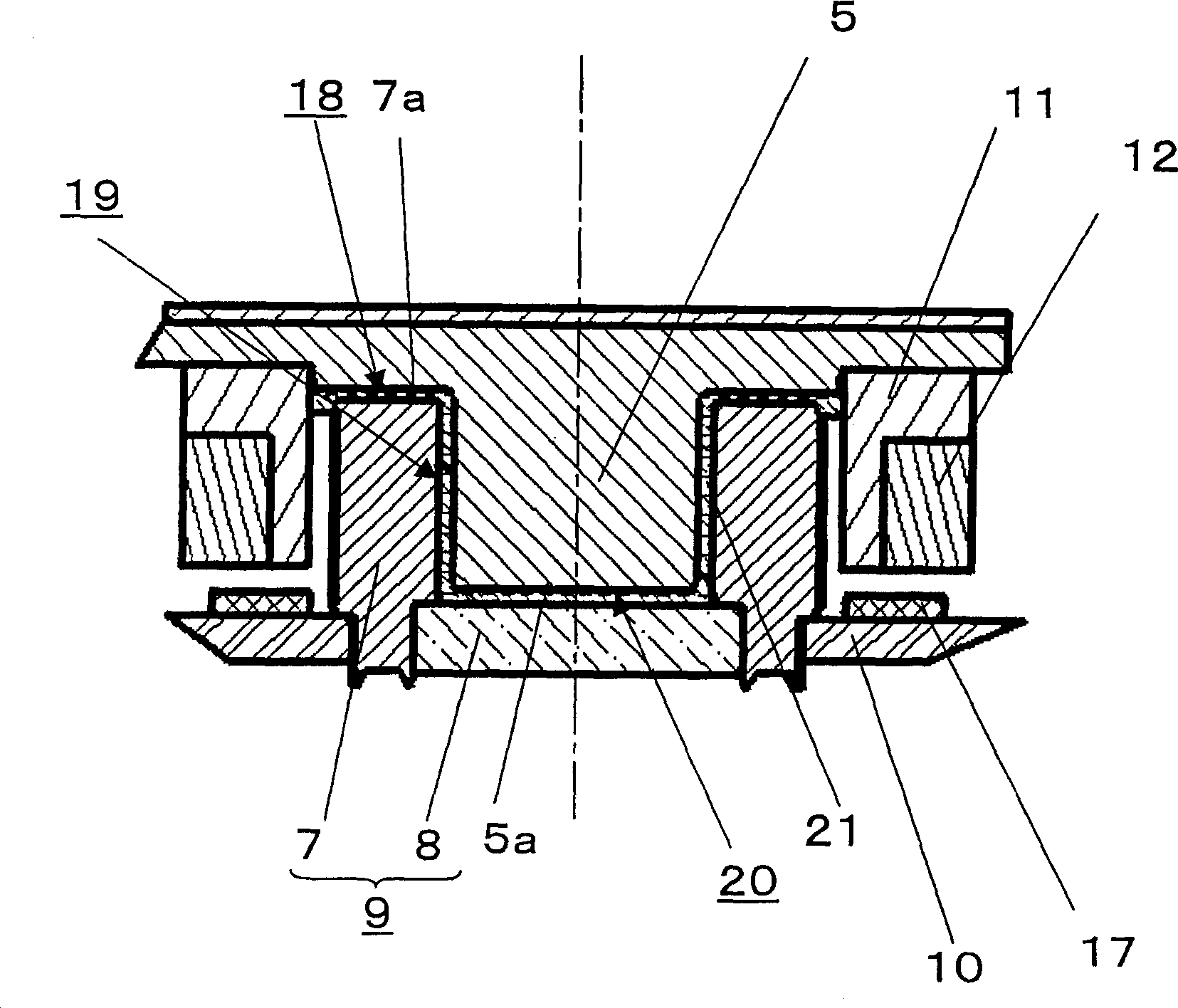

[0109] Figure 1A and figure 2 is a schematic diagram of the main components of the spindle motor, which shows the first embodiment of the present invention, specifically, Figure 1A is a sectional view taken along the section of the main part of the spindle motor, figure 2 for Figure 1A Partial enlarged view of the bearing part in , while Figure 3A is a view from the top of a part that excludes the Figure 1A Rotating disk and rotor yoke in .

[0110] Figure 1A A rotating magnetic disk 6 is shown, which is integrally formed by a magnetic disk device 4 and a solid cylindrical rotating shaft 5, wherein the magnetic disk device 4 forms a Information recording medium layer 3. The magnetic disk device 4 and the rotary shaft 5 may be made of separately manufactured members, which may be assembled by insert molding, adhering, to form the rotary magnetic disk 6 by using an adhesive, hot-melt, or other methods. A small gap is formed between the inner circumference of the cylin...

no. 2 example

[0149] Figure 14 A cross-sectional view of main parts for illustrating a spindle motor according to a second embodiment of the present invention. exist Figure 14 In , the reference numerals of the elements corresponding to the constituent elements in the first embodiment are the same as Figure 1Ain the same. The spindle motor of the second embodiment differs from the first embodiment in that the rotary magnetic disk is a structure in which the magnetic disk device and the cylindrical rotating cylinder portion are integrally formed, and the rotary magnetic disk is supported around a bearing fixed to the base as the center of rotation. The central axis of the shaft rotates.

[0150] exist Figure 14 Among them, the rotary magnetic disk 6 is composed of a magnetic disk device 4 and a rotating cylindrical part 141, wherein the magnetic disk device 4 has an information recording medium layer (not shown) on the main plane perpendicular to the rotation center 1, and the rotatin...

no. 3 example

[0170] Figure 18 and FIG. 19 is a view illustrating the structure of main parts of a spindle motor according to a third embodiment of the present invention, specifically, Figure 18 Fig. 19 is a partial enlarged view of the vicinity of the central portion of the spindle motor for the purpose of showing a cross-sectional view of the structure of the main parts of the spindle motor. exist Figure 18 and Figure 19, with Figure 1A components corresponding to the Figure 1A Indicated by the same symbols.

[0171] exist Figure 18 , through the near as Figure 19A A first lubricant groove 181 can be formed in the rotor yoke 11 by cutting an annular groove close to the triangular cross-section of the magnetic disk device 4 at the inner peripheral side of the shown bearing housing 7 . In addition, a taper 182 is formed from the edge of the rotor yoke 11 to the groove for forming the first lubricant groove 181, and the diameter of the taper becomes wider near the magnetic disk de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com