Hydraulic energy source equipment

A technology of hydraulic energy and hydraulic source, applied in accumulator devices, fluid pressure actuating devices, measuring devices, etc., can solve problems such as burnout, inability to withstand ultra-high temperature and ultra-low temperature, dry friction, etc., to reduce friction and cost. Low, prolonged working life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

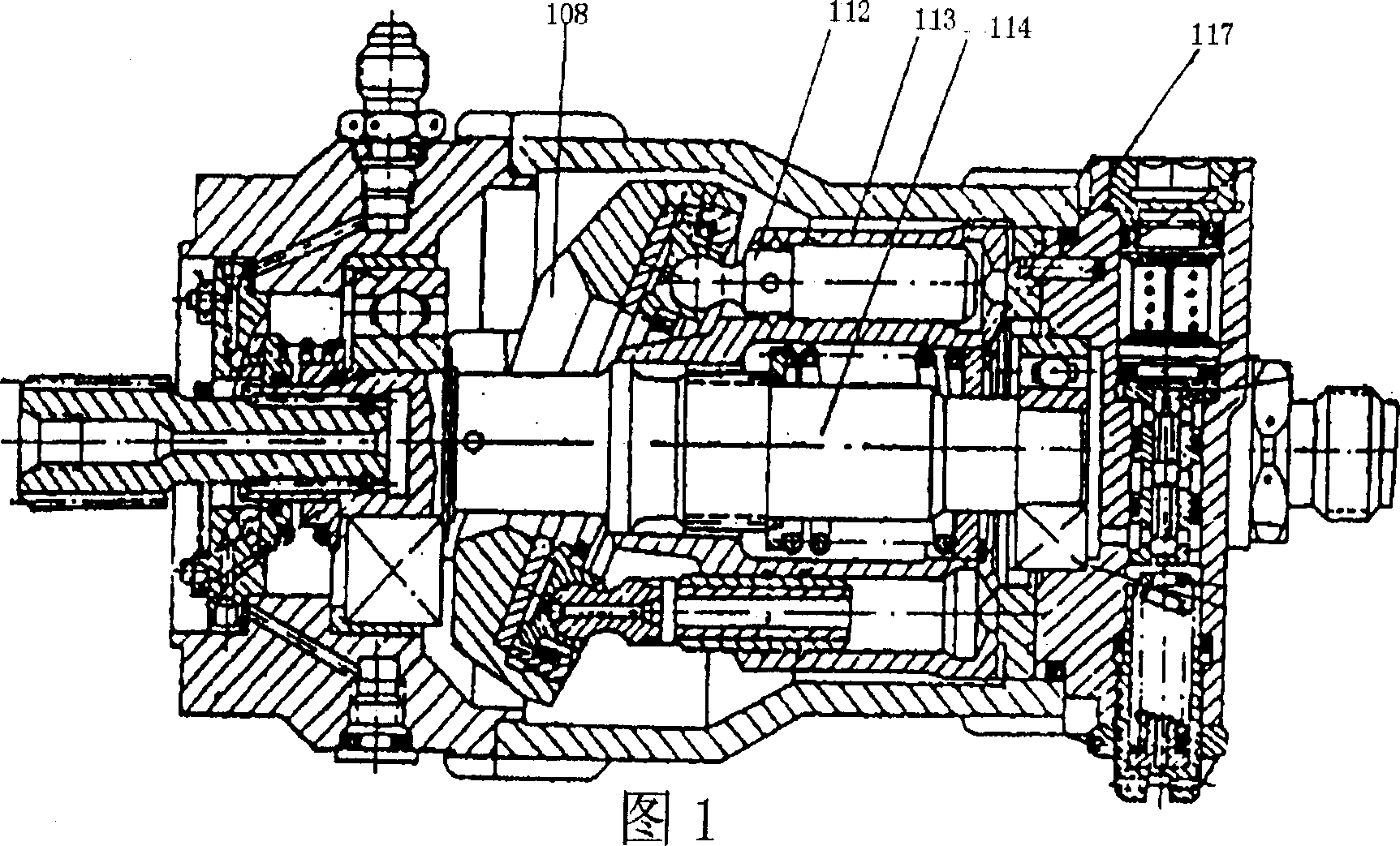

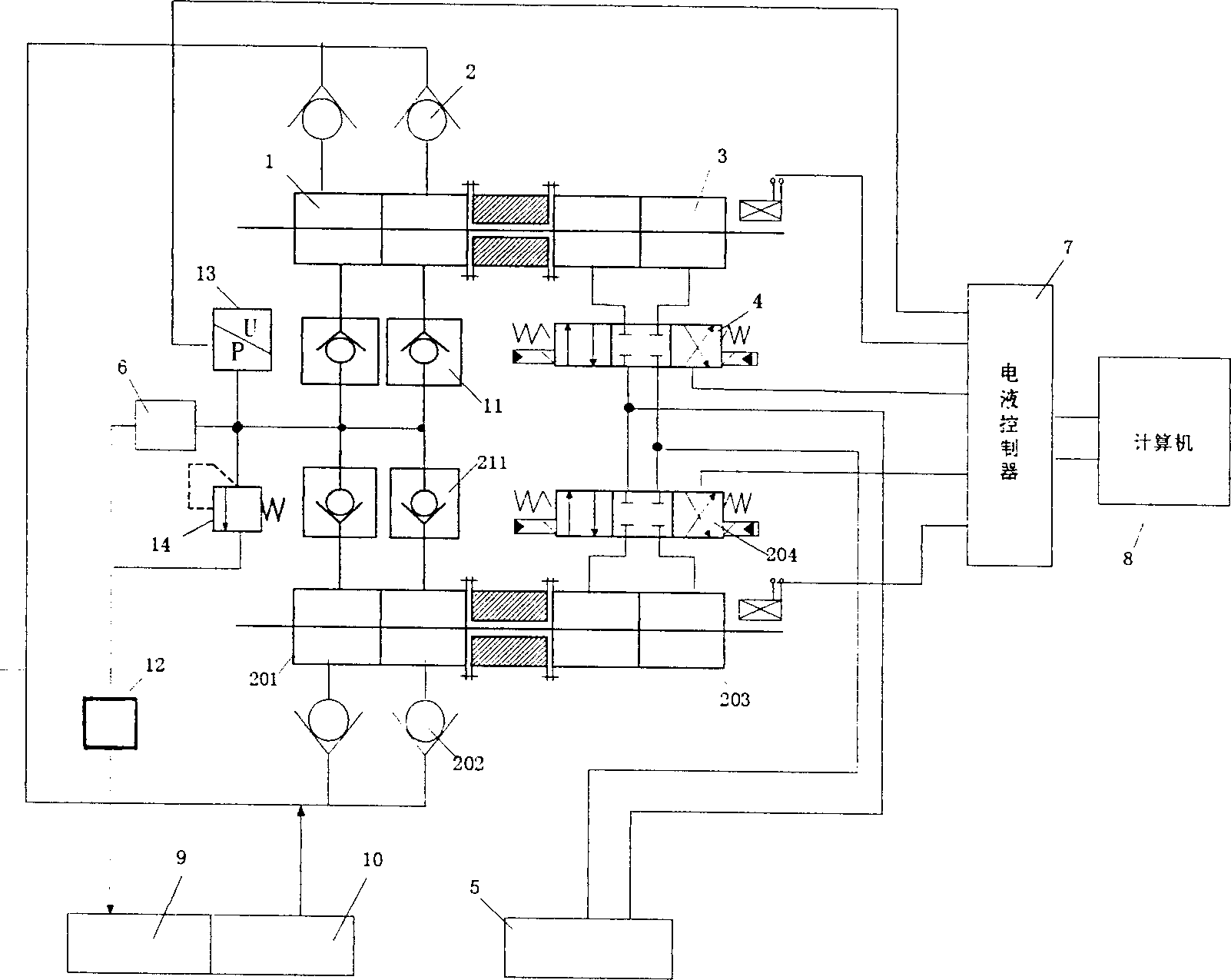

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] exist figure 2 Among them, the upper high-temperature pump group is composed of a high-temperature cylinder 1, two oil inlet check valves 2, two oil outlet check valves 11 and a normal temperature drive cylinder 3. The two oil inlet units connected to the high-temperature cylinder 1 The direction valve 2 is connected to the oil supply tank 10 through a pipeline, and the two oil outlet check valves 11 connected to the high temperature cylinder 1 are connected to the oil return tank 9 through an output pipeline, and the test piece 6, The measuring point of the pressure sensor 13 and the contact point of the overflow valve 14, the sealing ring used in the high temperature cylinder 1 is made of high temperature resistant rubber made of fluoroplastic; the normal temperature drive cylinder 3 is connected to the proportional reversing valve through the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com