Rotary compressor with permanent magnet motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

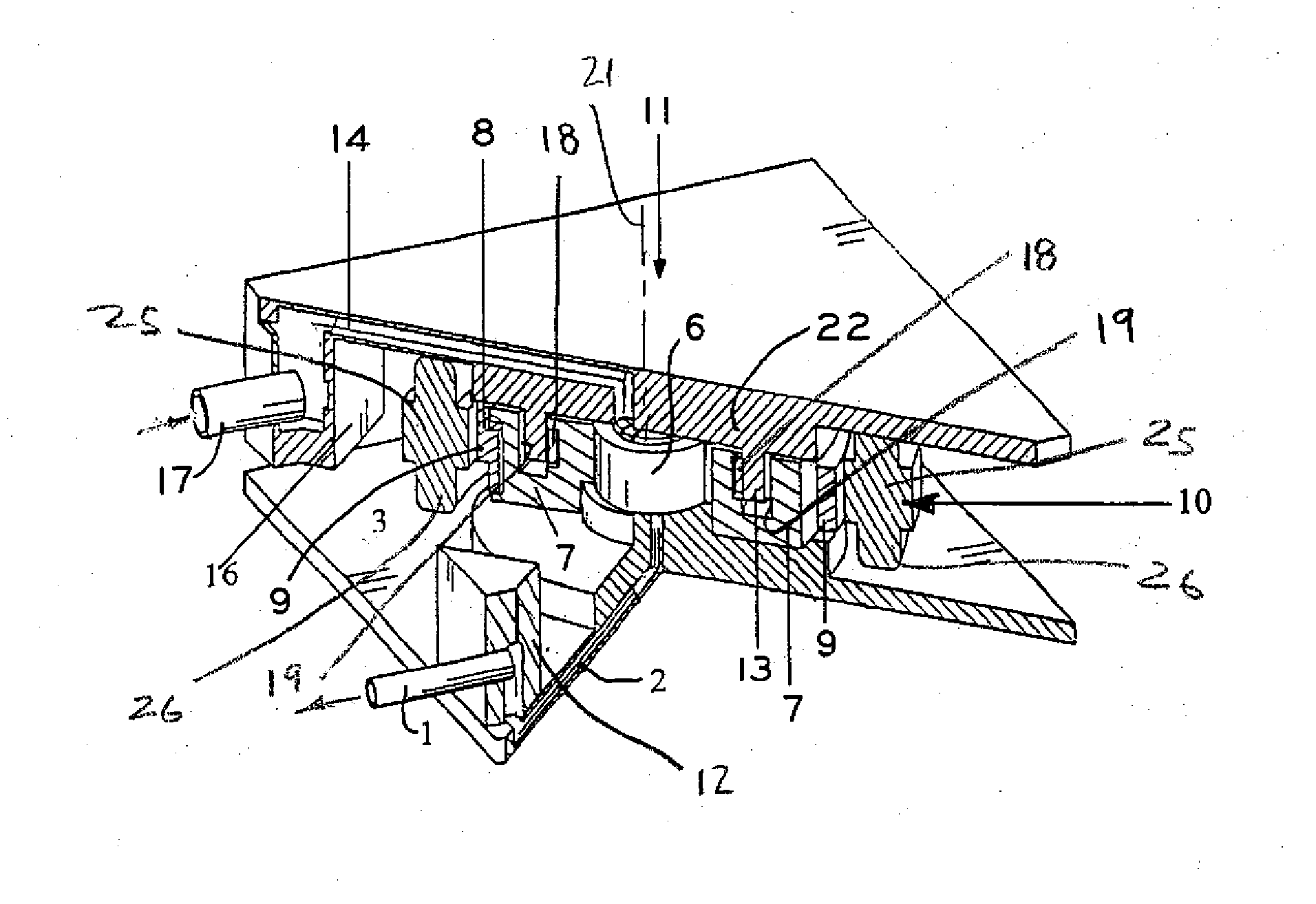

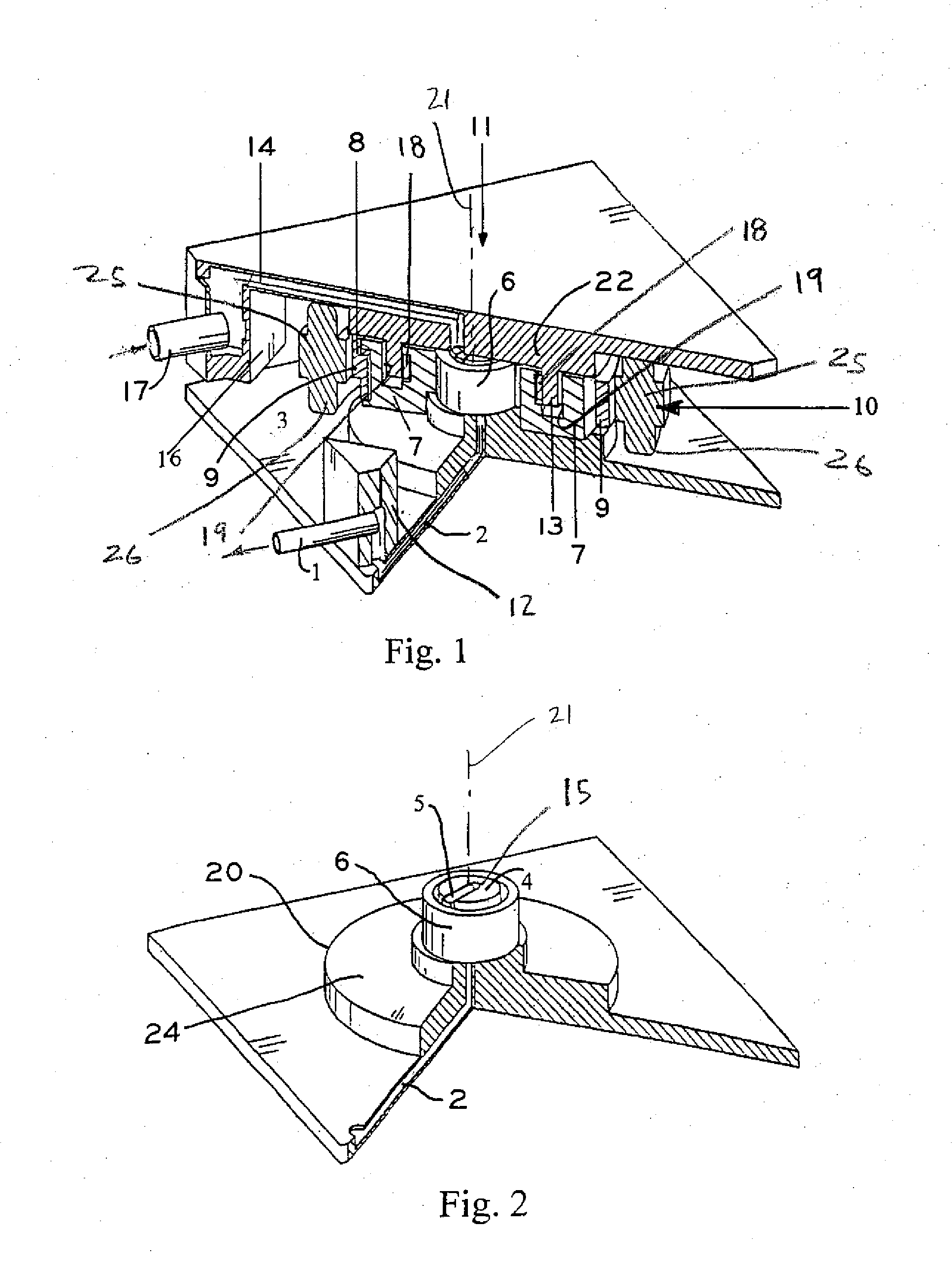

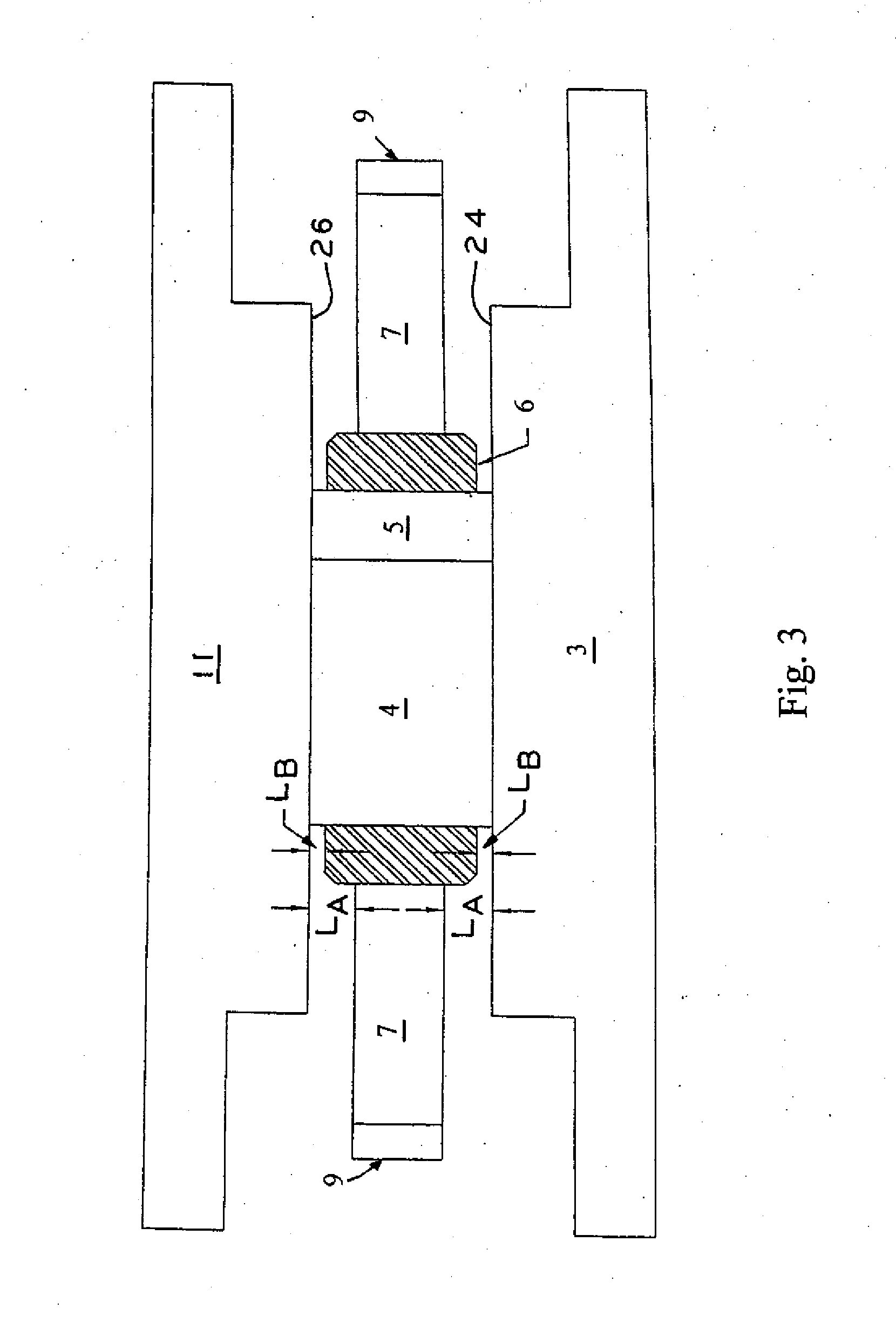

[0017] Refrigeration circuits typically comprise, in serial order, a compressor, a condenser, a throttling valve, and an evaporator. Referring to the exemplary rotary compressor illustrated in FIG. 1, refrigerant, such as R245fa, for example, enters the rotary compressor through suction inlet 17. The refrigerant then flows through distributor 16, and passage 14 in top plate 11 where it is drawn into a chamber defined between post 4, vane 5 and roller 6 of a compression, or pump, mechanism. As described in further detail below, roller 6 is positioned eccentric with respect to post 4 such that, when roller 6 is orbited with respect to post 4 by rotor 7, the refrigerant in the chamber is compressed to a discharge pressure. The refrigerant is then discharged from the pump mechanism through a discharge valve (not illustrated) into passage 2 in bottom plate 3 and exits the compressor through manifold 12 and outlet 1. In some embodiments, either the low pressure flow passage 14 or the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com