Sliding component and compressor

A sliding part and compressor technology, applied in the field of compressors, can solve the problems of deterioration of sliding environment and increase of compression load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

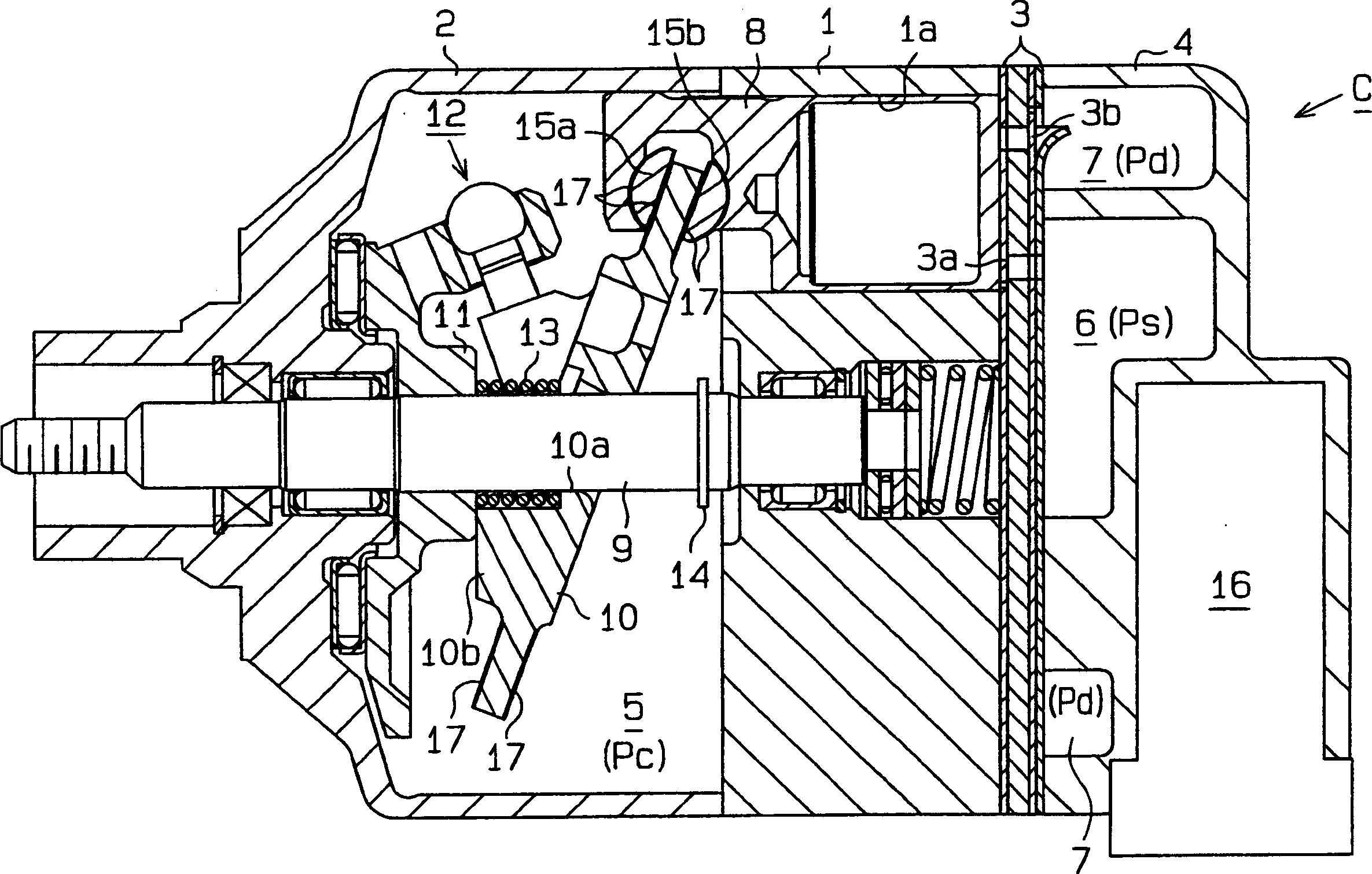

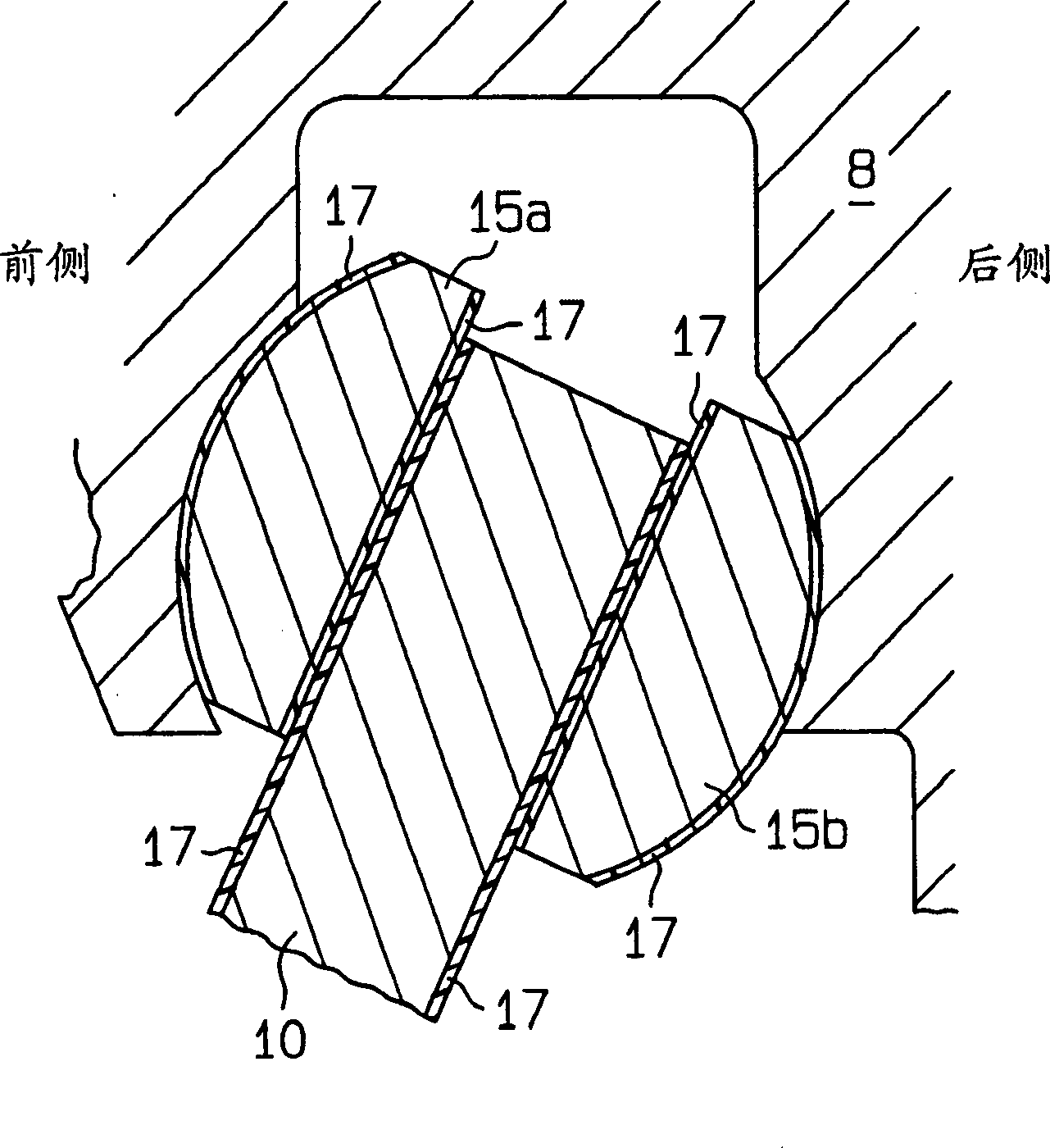

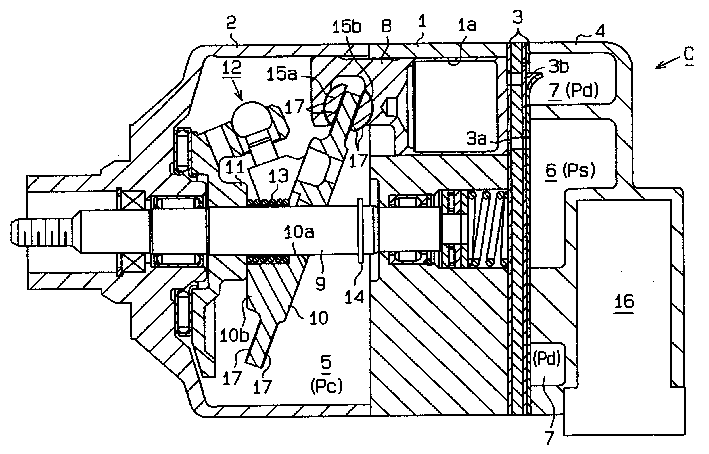

[0015] Below, will refer to figure 1 and 2 The variable displacement swash plate compressor of the present invention will be described.

[0016] Such as figure 1 As shown, the compressor C includes a cylinder 1 , a front housing element 2 connected to the front end of the cylinder 1 , and a rear housing element 4 connected to the rear end of the cylinder 1 through a valve plate assembly 3 . The cylinder block 1 , the valve plate assembly 3 and the two casing elements 2 and 4 are connected to each other by some through bolts (not shown), thereby constituting the casing of the compressor C. figure 1 The left side in is the front side of compressor C.

[0017] A crank chamber 5, a suction chamber 6 and a discharge chamber 7 are defined within the compressor housing. A number of cylinder holes 1a (only one is shown) are formed in the cylinder block 1, and a single-headed piston 8 is mounted in each cylinder hole 1a for reciprocating movement. The suction chamber 6 and the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com