Compressor

A technology for compressors and components, applied in the field of compressors, can solve the problems of increased wear depth of sliding films and shedding of solid lubricants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Several embodiments of the invention will now be described with reference to the accompanying drawings. Similar or identical reference numerals denote similar or identical components in the drawings.

[0053] will refer to Figures 1 to 16 The first embodiment of the present invention is described.

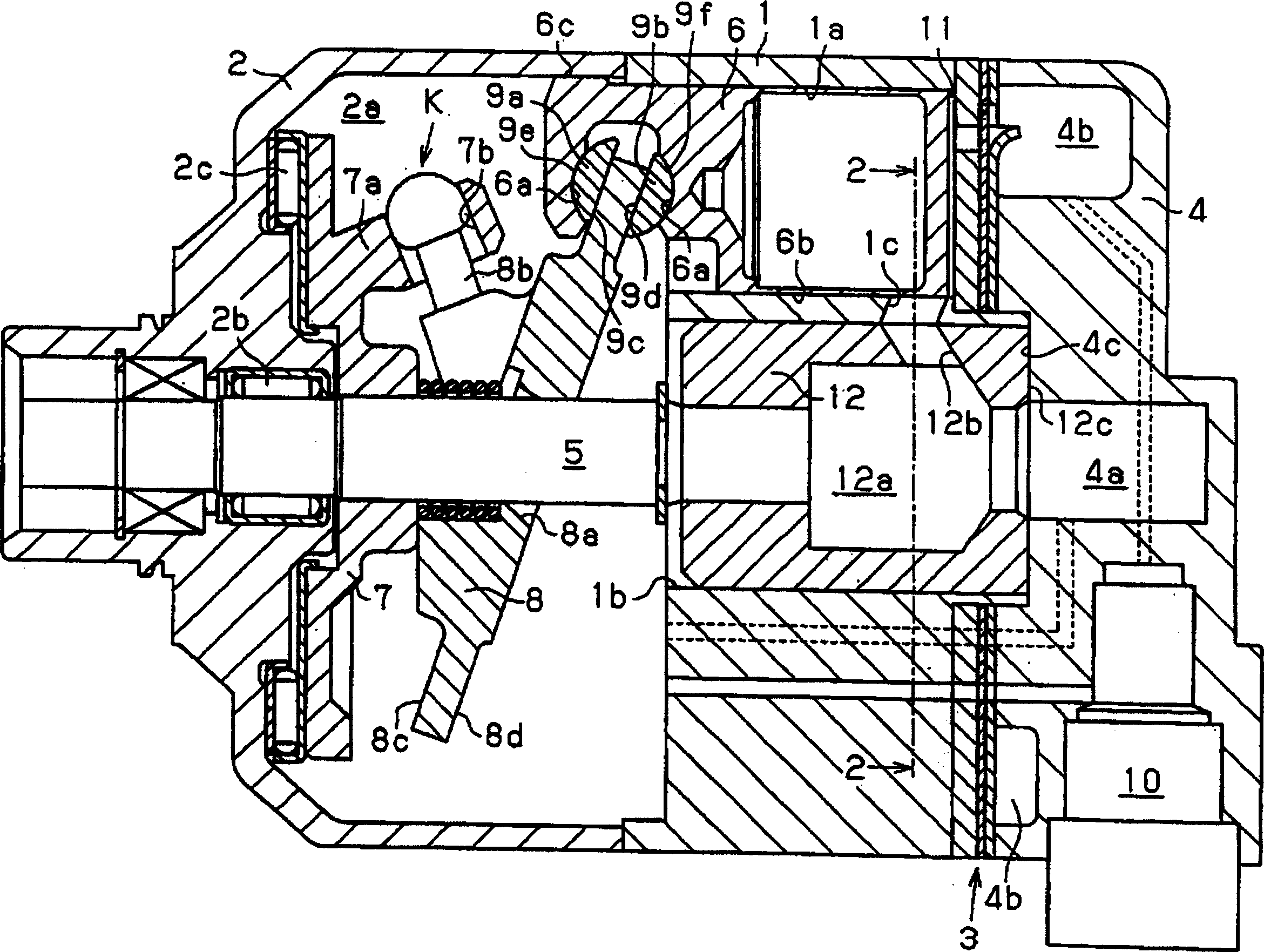

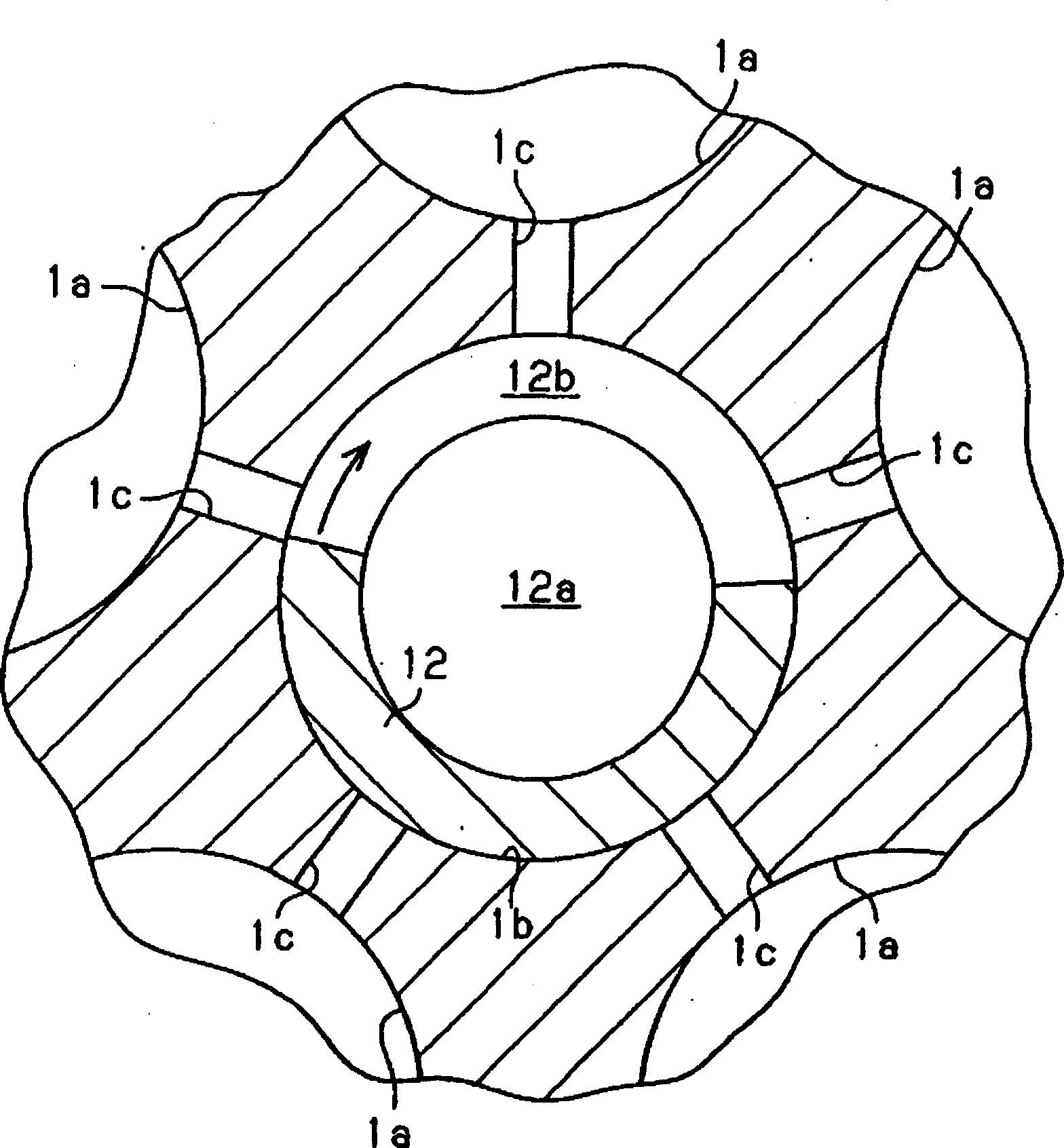

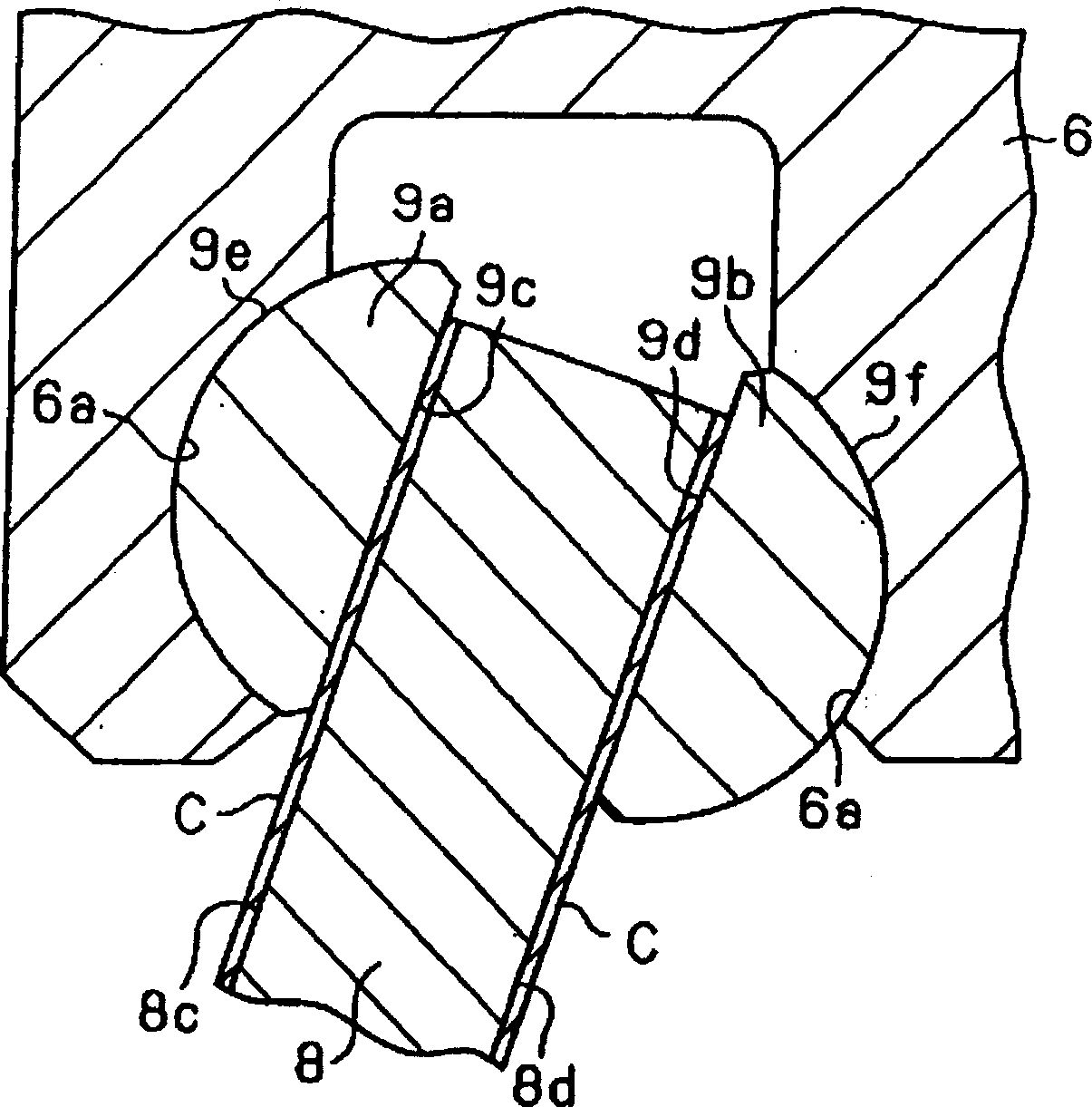

[0054] Such as figure 1As shown, the variable displacement swash plate compressor includes a cylinder block 1 made of an aluminum-based alloy, a front housing 2 made of an aluminum-based alloy and fixed to the front end of the cylinder block 1, and a cylinder block made of an aluminum-based alloy. The rear casing 4 is fixed to the rear end of the cylinder block 1 through the valve mechanism 3, and the valve mechanism 3 includes a valve plate, an exhaust valve and a baffle. A crank chamber 2 a is defined between the cylinder block 1 and the front housing 2 . An air intake chamber 4 a and an exhaust chamber 4 b are defined in the rear case 4 . In this embodiment, the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com