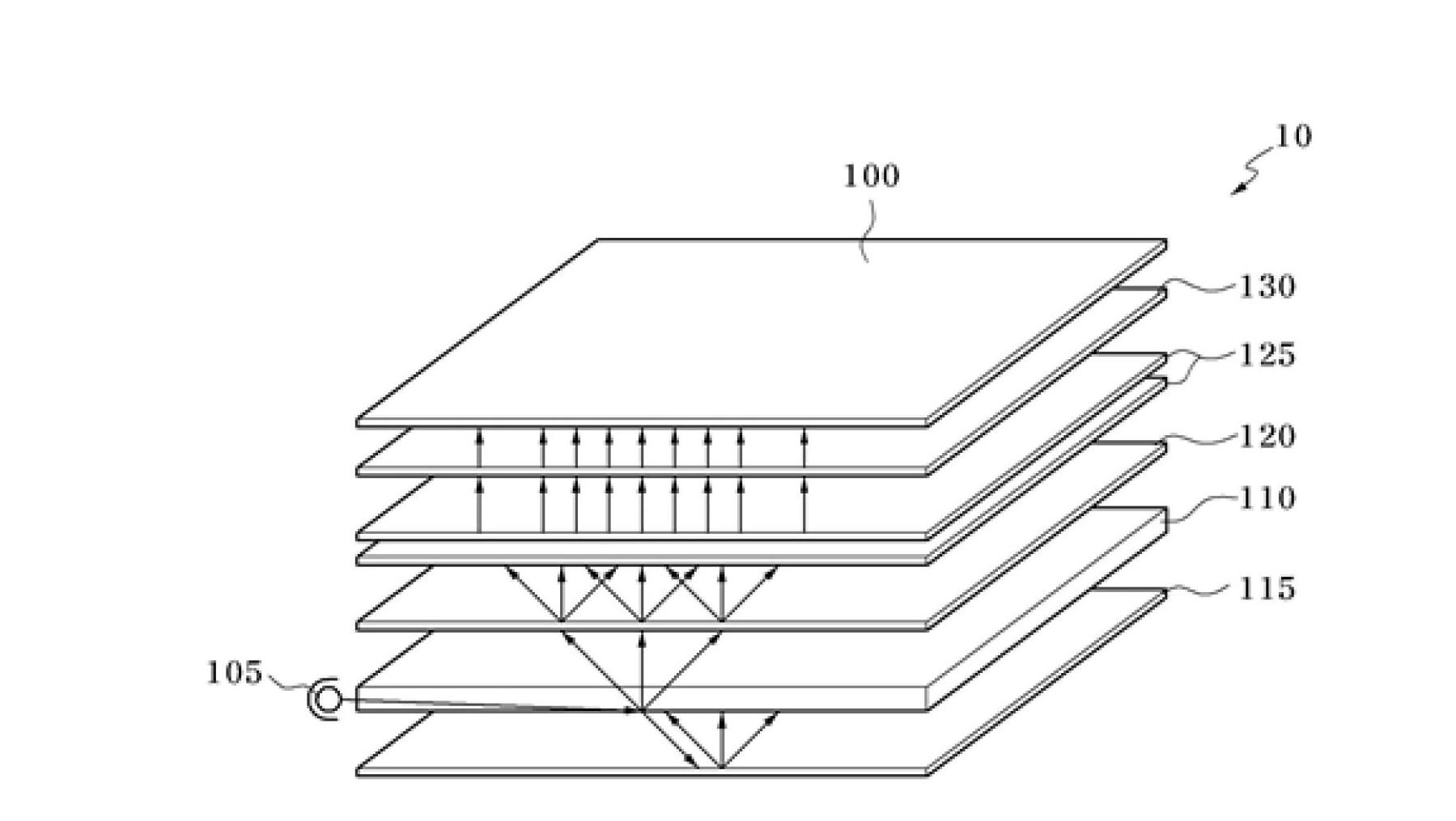

Pattern light guide plate, method for manufacturing same, and backlight unit of a liquid crystal display using same

A technology of light guide plate and patterning, applied in the direction of optical components, light guides, optics, etc., can solve problems such as low productivity, increased manufacturing cost, viewing angle, black area and other quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

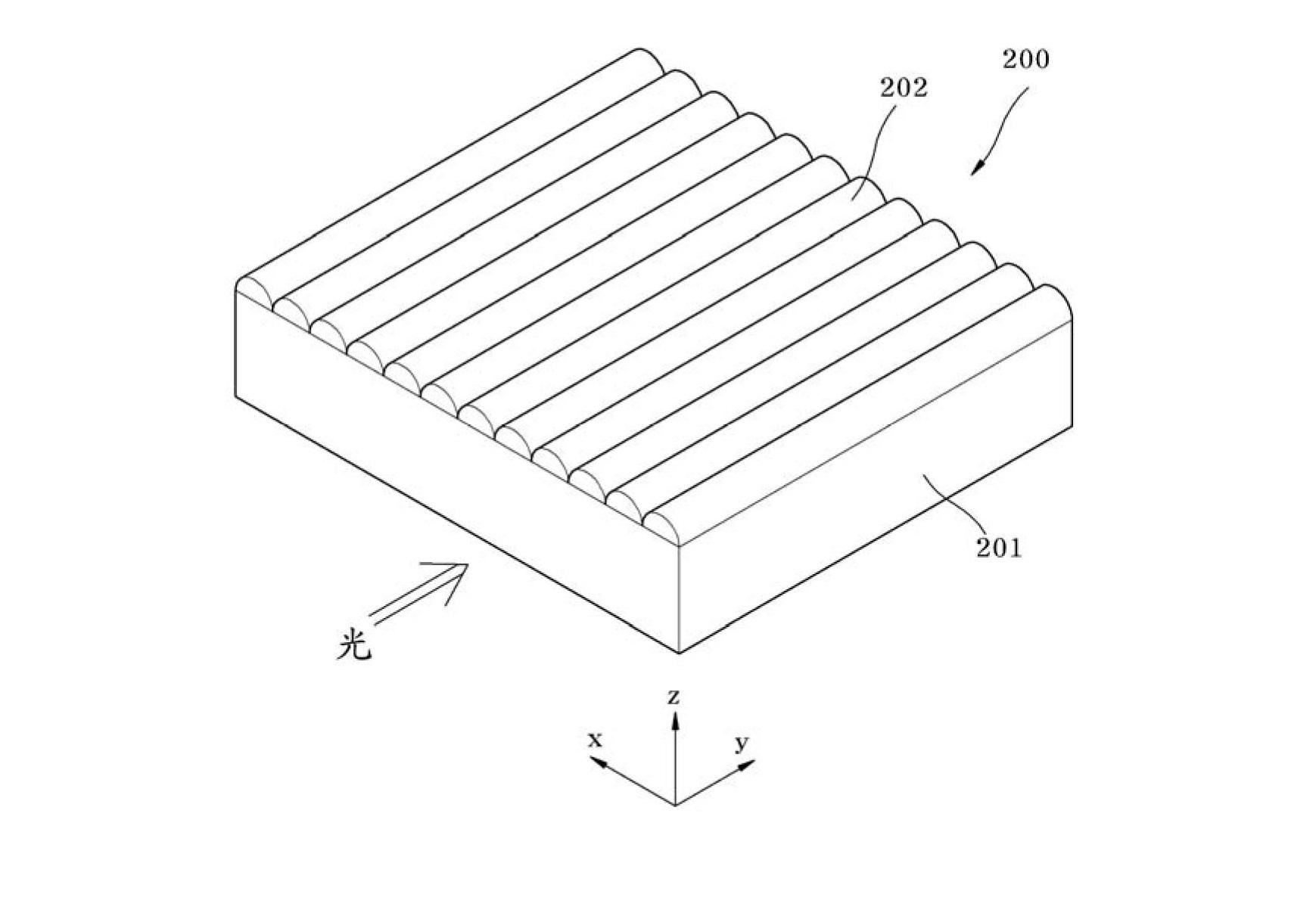

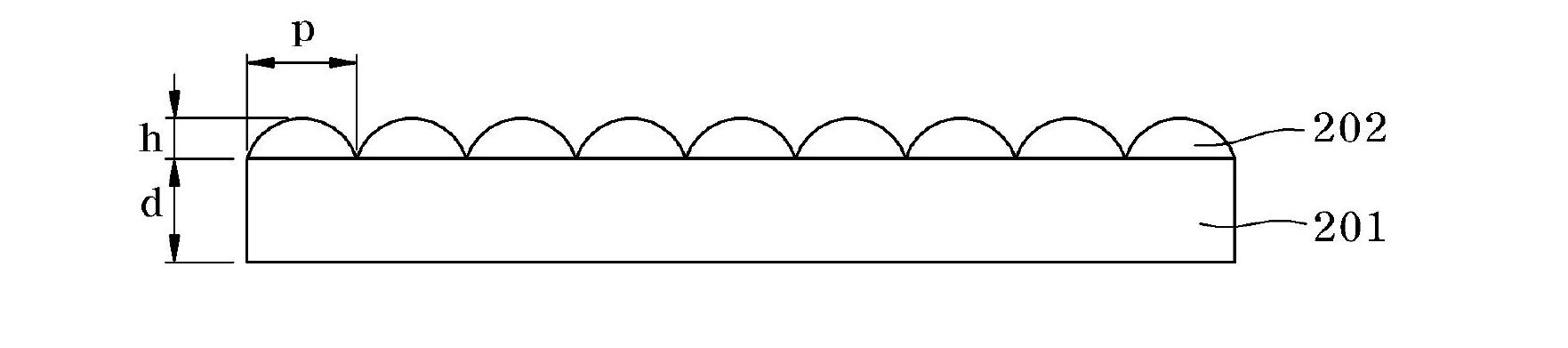

Embodiment 1

[0074] 7.5 parts by weight of acrylic acid crosslinked particles with an average particle size of 30 μm ( Sekisui Co., Ltd.) added to 100 parts by weight of polymethylmethacrylate (PMMA) resin ( Sumitomo Co., Ltd.), followed by extrusion under clean room conditions to prepare pellets. The pellets were melted through a first extruder with a diameter of 50 mm, and the PMMA resin was melted through a second extruder with a diameter of 150 mm ( Sumitomo Co., Ltd.) to prepare a 6 mm thick bilayer film comprising a substrate layer and a surface layer. At this time, the extrusion ratio of the first extruder and the second extruder was set to 1:100. In addition, the ratio of the thickness of the surface layer to the thickness of the base layer was set to 1:100. After passing through a T-die, the double-layer resin film melted by the extruder is cooled by an embossing roller with engraved lenticular patterns to form a lenticular pattern on the film, thereby making a patterned lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com