Gear shift controlling method and system for automatic changing speed device

A technology of automatic transmission and shift control, applied in the direction of engine control, transmission control, and components with teeth, etc., can solve the problems of manual movement, foot brake decay, difficult engine braking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

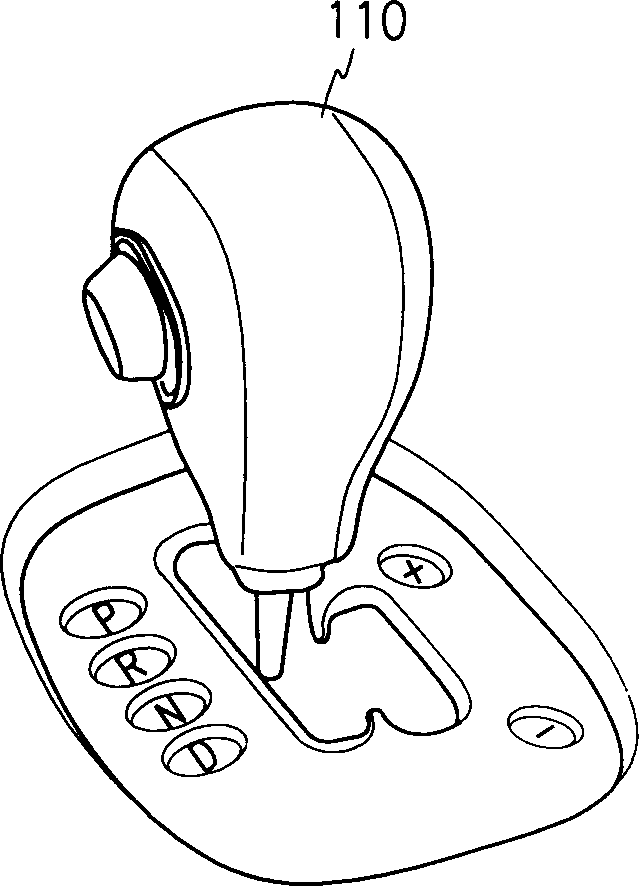

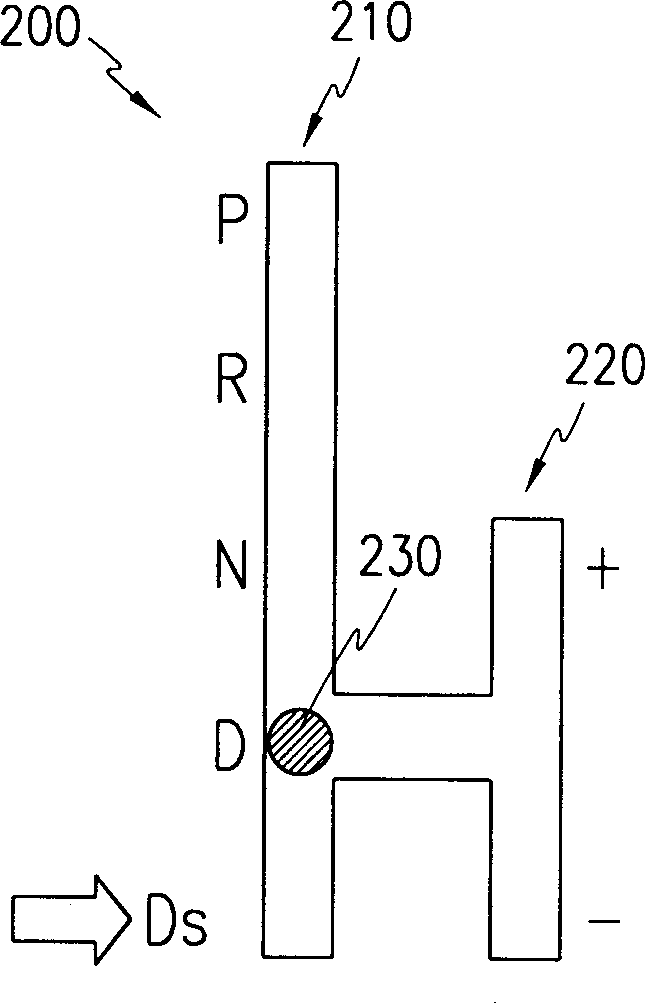

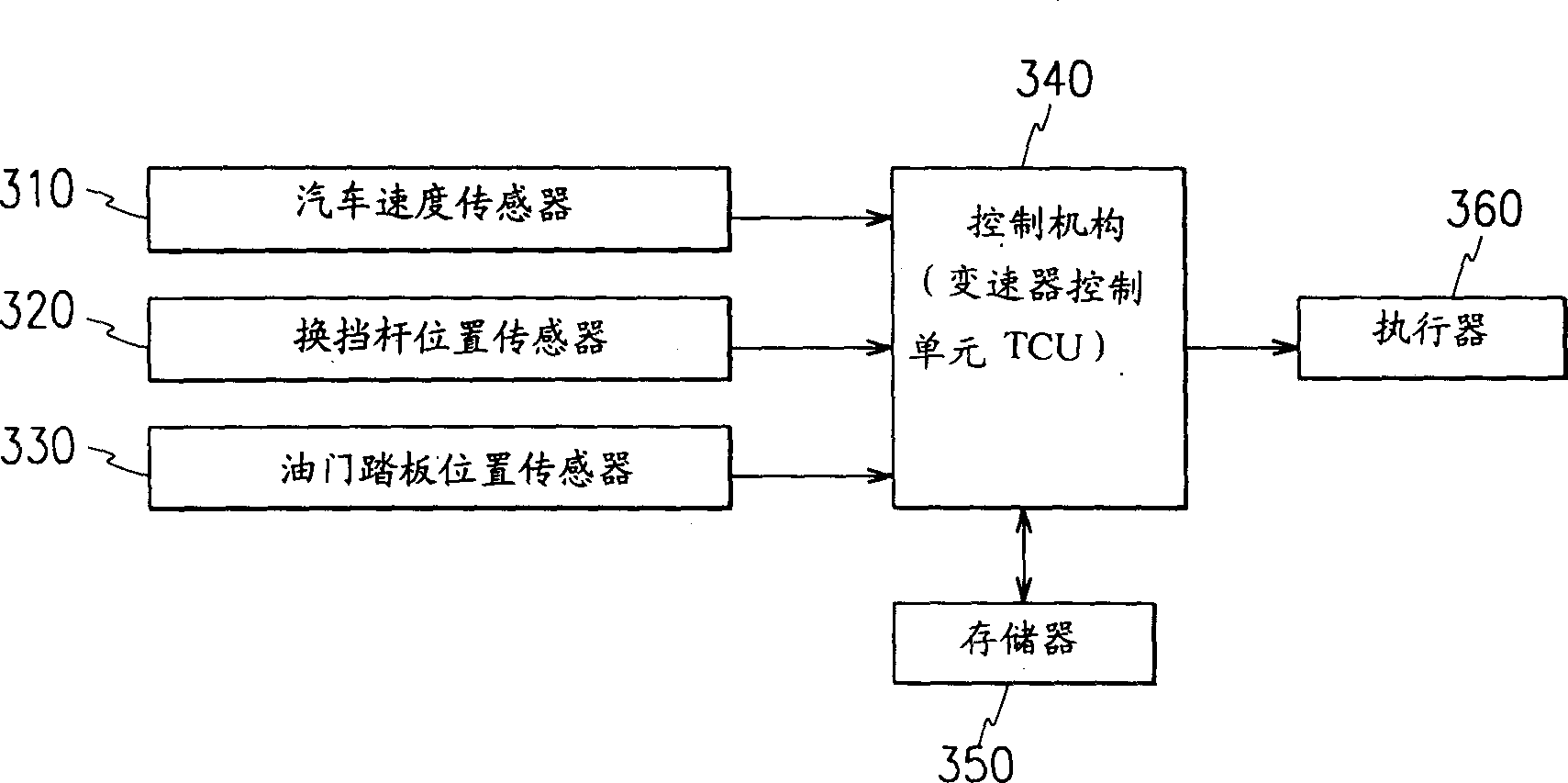

[0034] Such as figure 2 with 3 As shown, the gear shift control system described in the preferred embodiment of the present invention includes a gear shift accessory 200, a shift lever position sensor 320, an accelerator pedal position sensor 330, a control mechanism (or speed change control unit) 340, a memory 350 and a brake 360 .

[0035] The shift accessory 200 includes an automatic shift mode gear 210 and a manual shift mode gear 220 . The automatic shift mode gear 210 includes a park gear P, a reverse gear R, a neutral gear N, a forward gear D and an engine braking gear Ds, and the manual shift mode gear 220 includes a manual upshift (+) and a manual downshift (-). Preferably, the engine brake range Ds is below the drive range D, and if the shift lever 230 is in the engine brake range Ds, a downshift is performed to use the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com