Dynamically positioned semi-submersible drilling vessel with slender horizontal braces

A technology of horizontal tie rods and tie rods, which is applied in the direction of ship hulls, motor vehicles, ship construction, etc., and can solve the problems of affecting the weight of the ship, unfavorable, and increasing the area of the ship's water plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

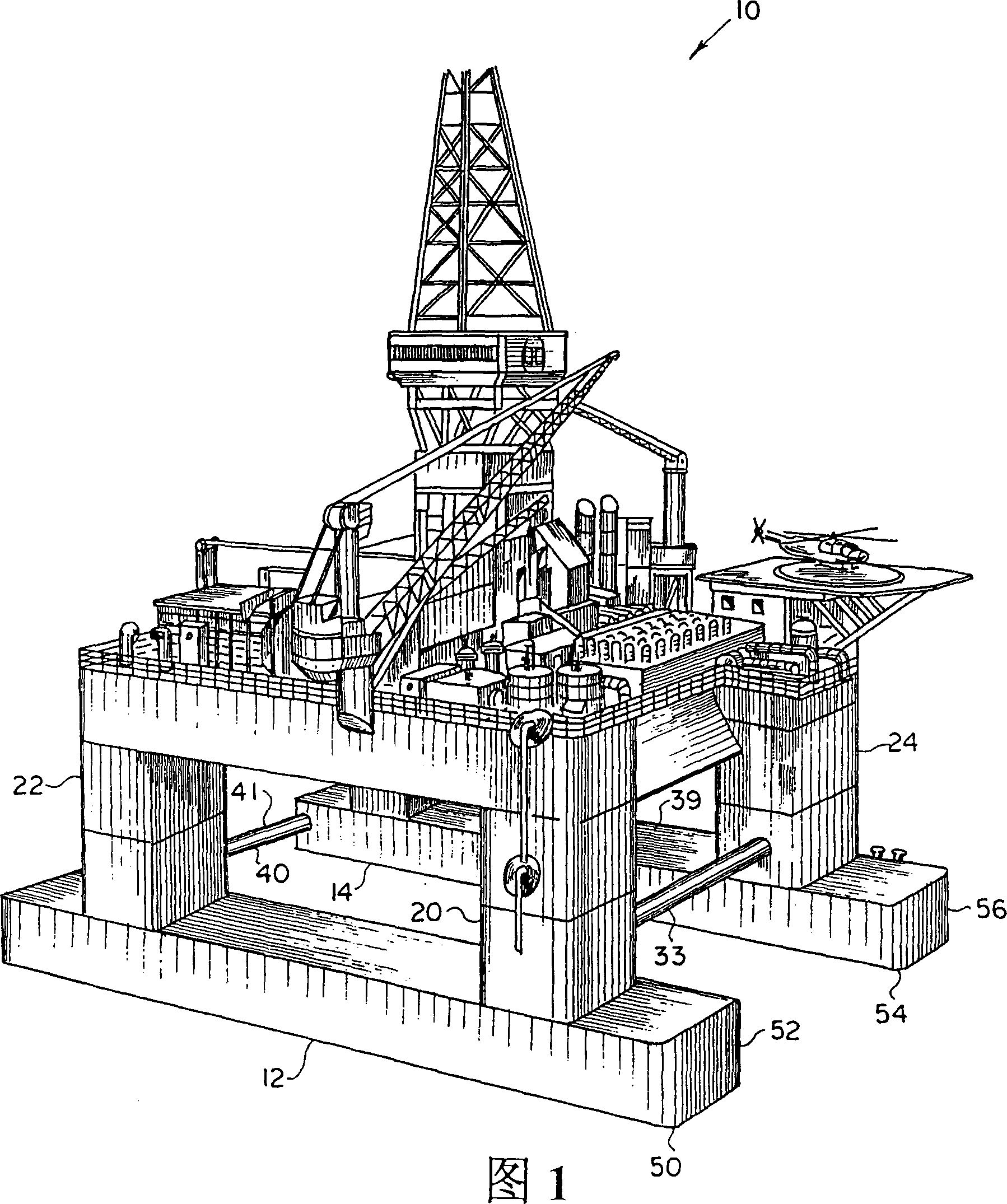

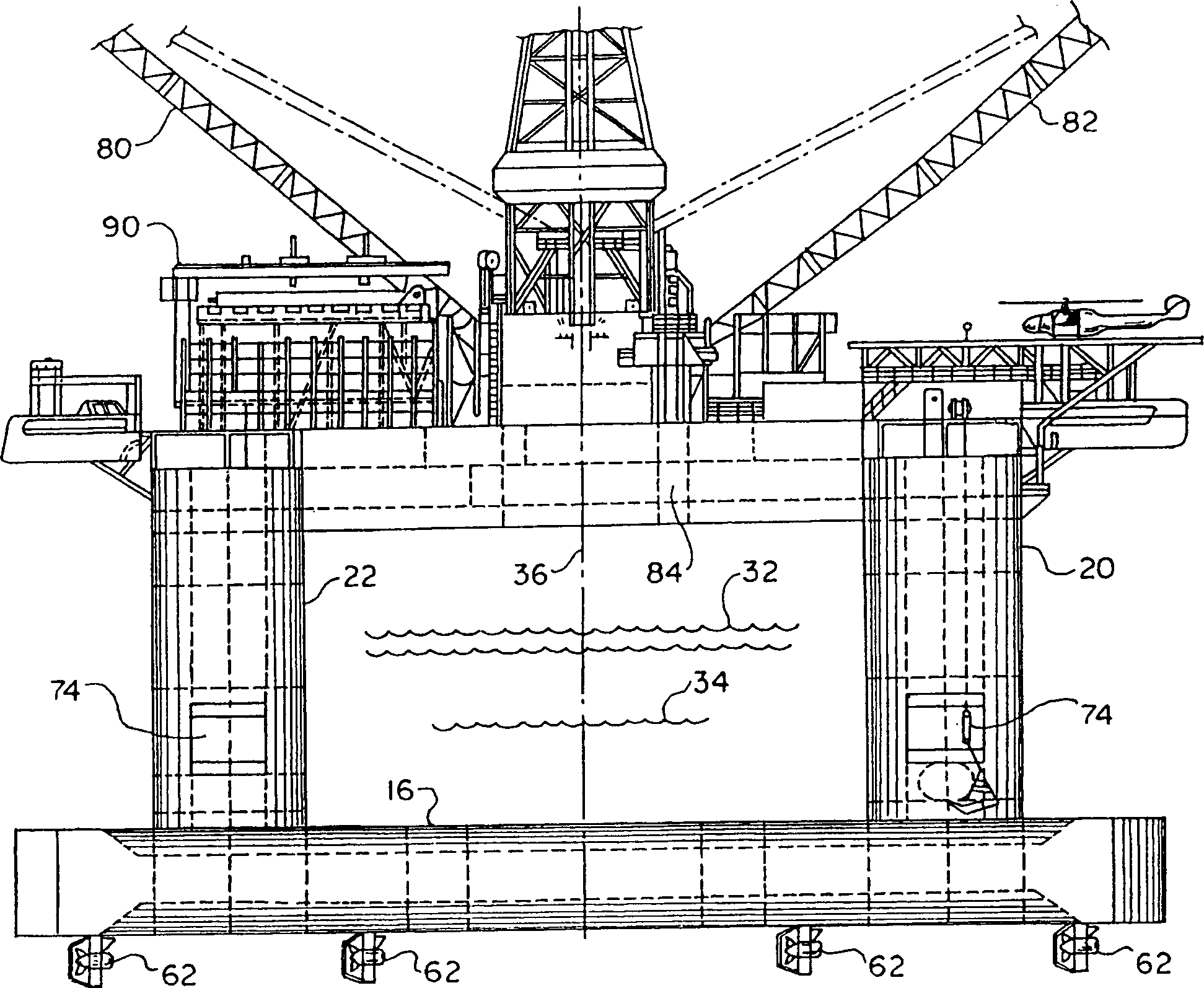

[0030] Referring now to the accompanying drawings in detail, numeral 10 denotes a semi-submersible vessel of the present invention. As will be described in more detail below, the vessel includes a pair of buoyant or submerged tanks 12, 14, wherein the submerged tanks are divided into a plurality of watertight compartments for containing ballast and allowing access to the thruster assemblies . Secured to the upper portions 16 and 18 of the diving tanks 12 , 14 respectively are columns or caissons 20 , 22 , 24 and 26 extending in a direction transverse to the vertical axis of the diving tanks 12 , 14 .

[0031] The upper part of the columns 20, 22, 24 and 26 is supported by a platform 30 for supporting mineral exploration and production operations. Such as figure 2 As shown, portions of columns 20-26 and submersible tanks 12 and 14 are submerged to an operating draft 32, while upper portions of columns 20-26 and platform 30 are raised above the maximum expected water wave heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com