Magnetic tape separate winder

A winding device and magnetic tape technology, which is applied in the direction of carrier storage device, packaging, magazine/cassette tape manufacturing equipment, etc., can solve the problems of entanglement in products, unable to manage winding length, etc., and achieve the effect of correct length management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the tape rewinding device of the present invention will be described in detail with reference to the accompanying drawings.

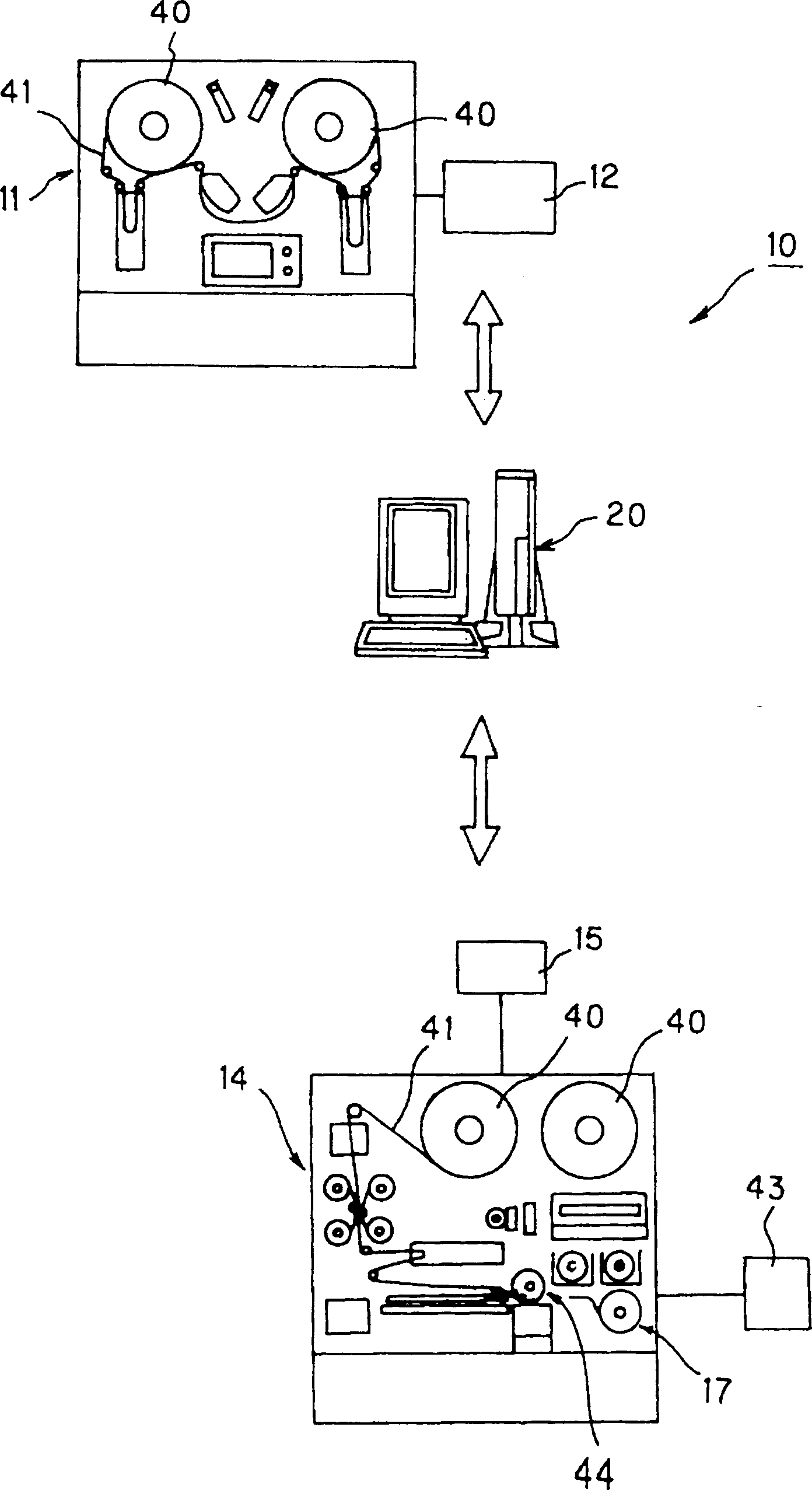

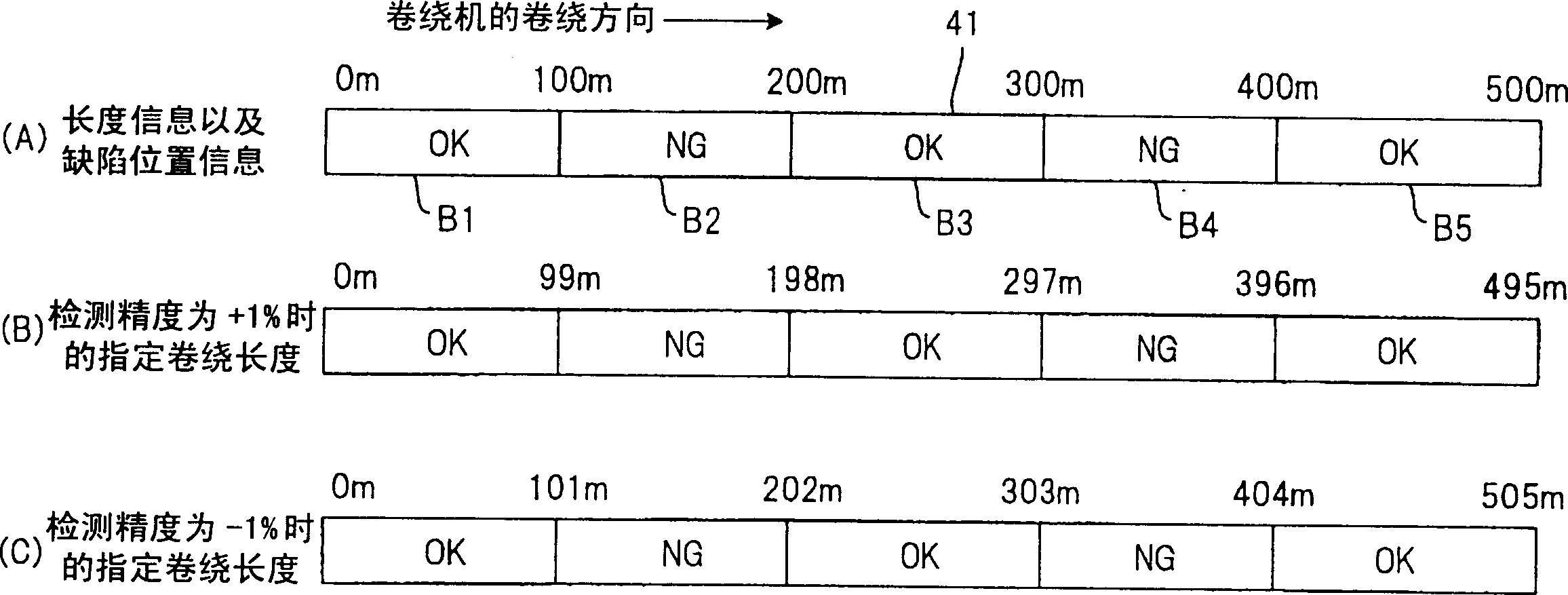

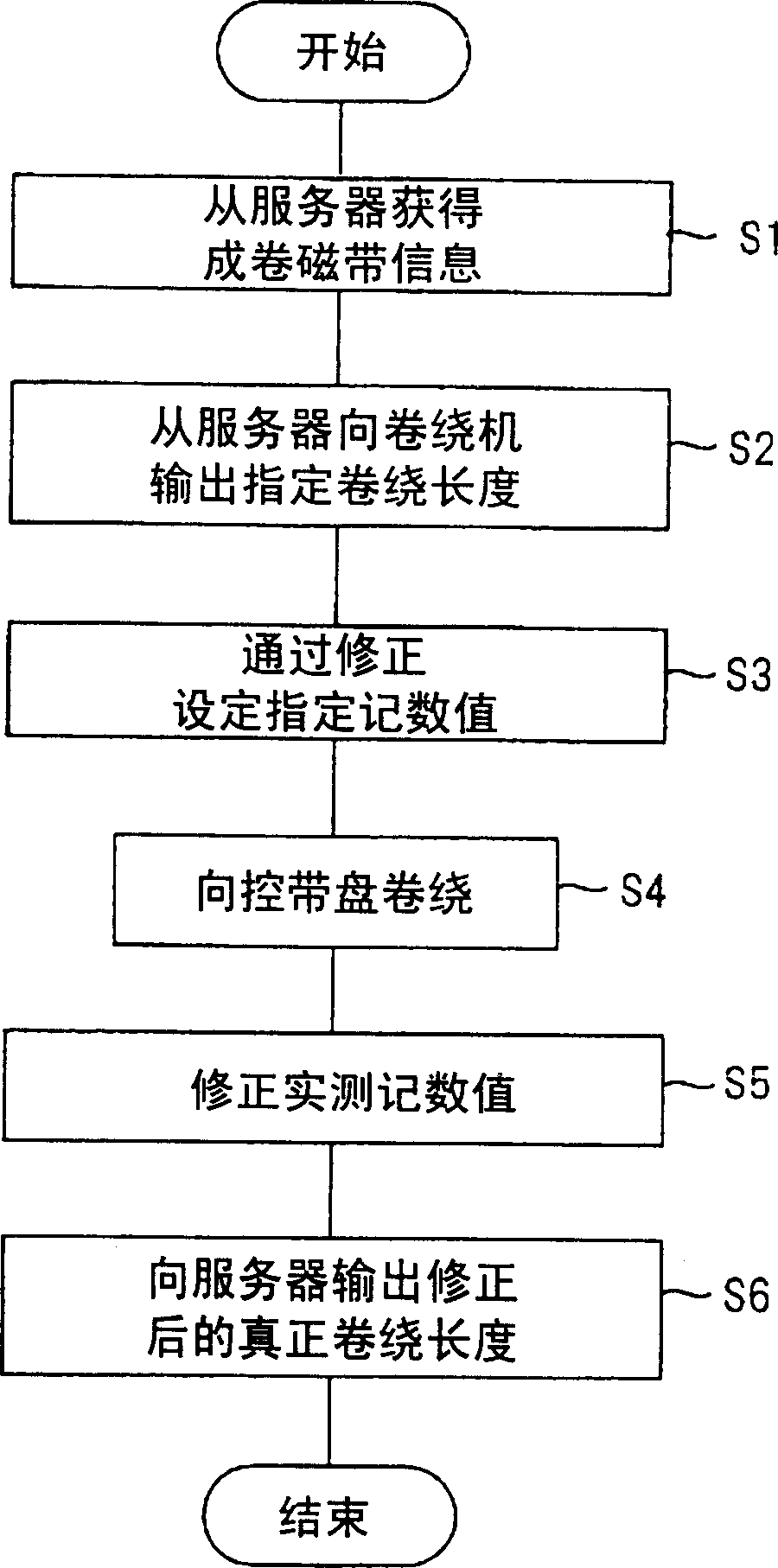

[0018] figure 1 Shown is the tape reeling device of the present invention. figure 2 is a diagram showing length management information and defect position information related to the present invention, image 3 It is a flow chart showing the volume separation process of the tape volume separation device of the present invention.

[0019] like figure 1 As shown, the tape rewinding device 10 of the present invention has: a server 20 that previously memorizes defect position information indicating the position of a defective portion of the magnetic tape 41 wound on the tape 40, and which is also an overall control device of the reeling device 10, and a server 20 based on the memory In the defect position information of the server 20, only the tape 41 drawn out from the roll tape 40 is wound on the reel 44 by a predeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com