Method for detecting deformation of underwater engineering structure based on fibre-optic gyro technique and its device

A technology for technical inspection and underwater engineering, which is applied to devices using optical methods, measuring devices, and optical devices. effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

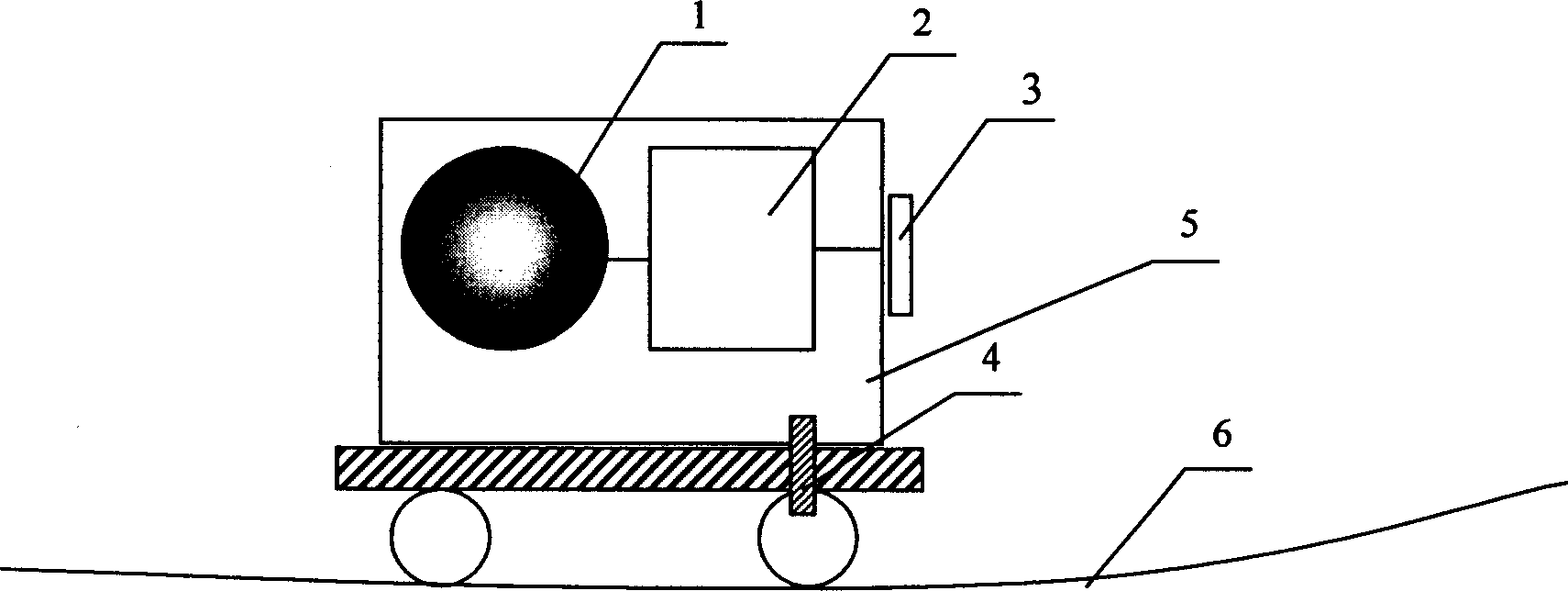

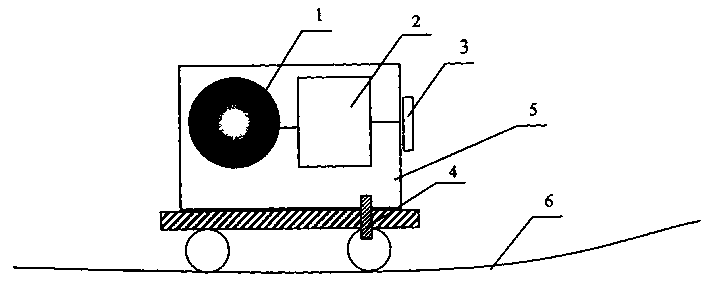

[0017] The basic composition of the device for detecting deformation of underwater engineering structures based on fiber optic gyroscope technology is as follows: figure 1 shown. The device includes a fiber optic gyroscope 1 , a signal receiving and storing unit 2 , a computer interface 3 , a linear velocity sensor 4 and a casing 5 . The fiber optic gyroscope 1, the signal receiving storage unit 2, the computer interface 3, and the linear velocity sensor 4 are all installed in a waterproof airtight casing 5, and the casing 5 can move along the measured object 6 under the drive of external force, and the measurement data is passed through the computer interface 3 sent to a computer for data processing. The shell 5 has good sealing, waterproof and anti-interference performance, and can adapt to the harsh underwater environment.

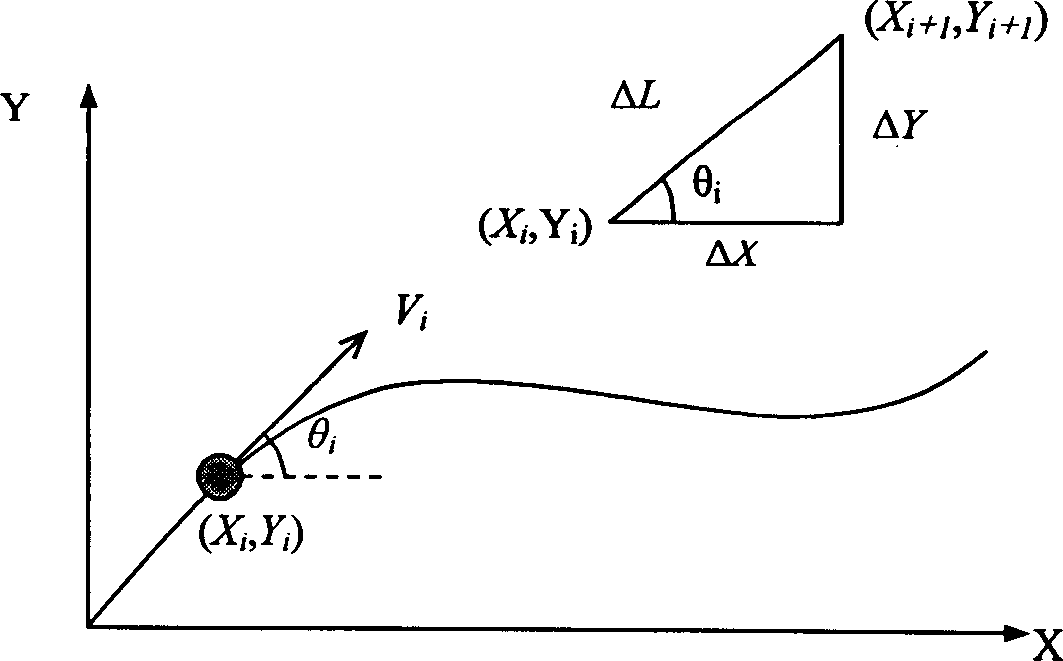

[0018] Determine the parameters such as the inclination angle of the starting point before the measurement. During the measurement, the device needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com