Roller support device or long-distance heavy-load drag chain idle

A support device and long-distance technology, applied in the field of idler support device and rolling support device, can solve problems such as the adverse effect of moving precision trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

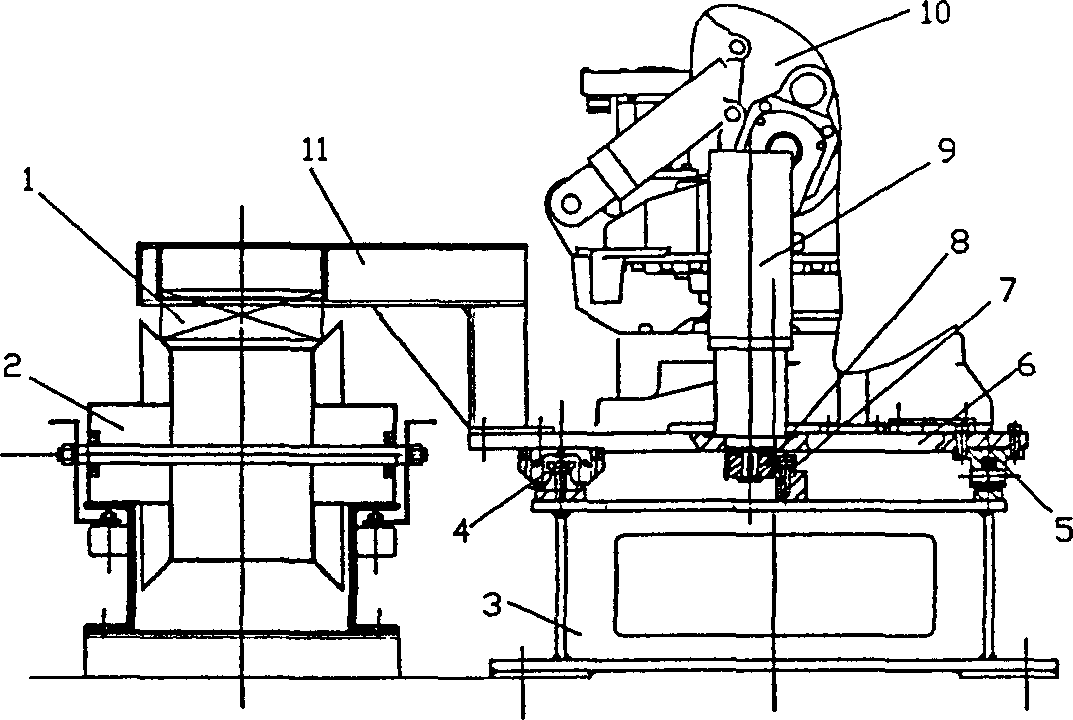

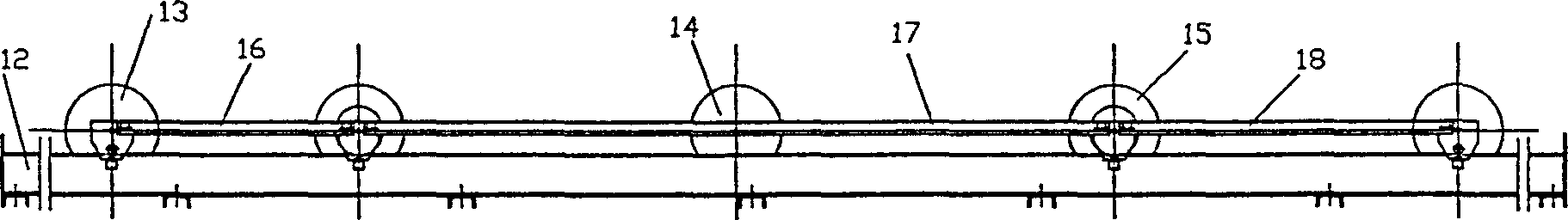

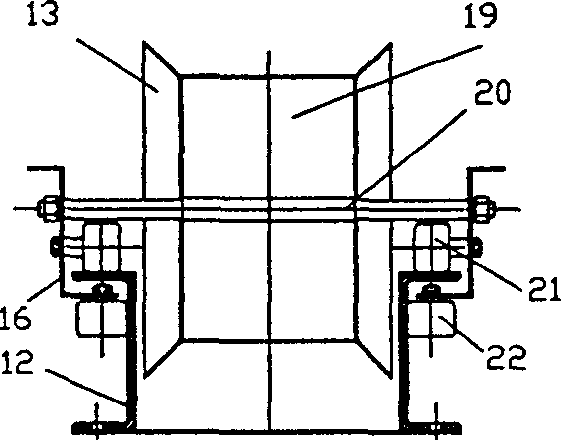

[0018] like Figure 1 to Figure 5 As shown, the present invention mainly includes: heavy-duty drag chain 1, idler support system 2, frame 3, linear rolling guide rail pair 4, roller guide rail pair 5, mobile trolley 6, rack 7, gear 8, drive reduction motor 9 , robot 10, towline connection frame 11, the connection method is: one end of the heavy-duty towline 1 is fixed on the foundation in the center of the roller support system with screws, after bypassing several rollers in the roller support system 2, the heavy-duty towline The other end of the chain 1 is fastened to the towline connection frame 11 with screws. At the same time, the steel wire rope with the same length as the heavy-duty towline 1 is bypassed by the rest of the rollers and connected to the end of the heavy-duty towline. The roller support system 2 is arranged on One side of the frame 3 is fixed on the foundation with screws, and the robot 10 is fixed on the bottom plate of the mobile trolley 6 with screws. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com