Automatically starting paper cutter

An automatic start and paper shredding technology, which is applied in the direction of grain processing, etc., can solve the problems of no space, automatic start failure, insufficient upward range of shrapnel 14, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

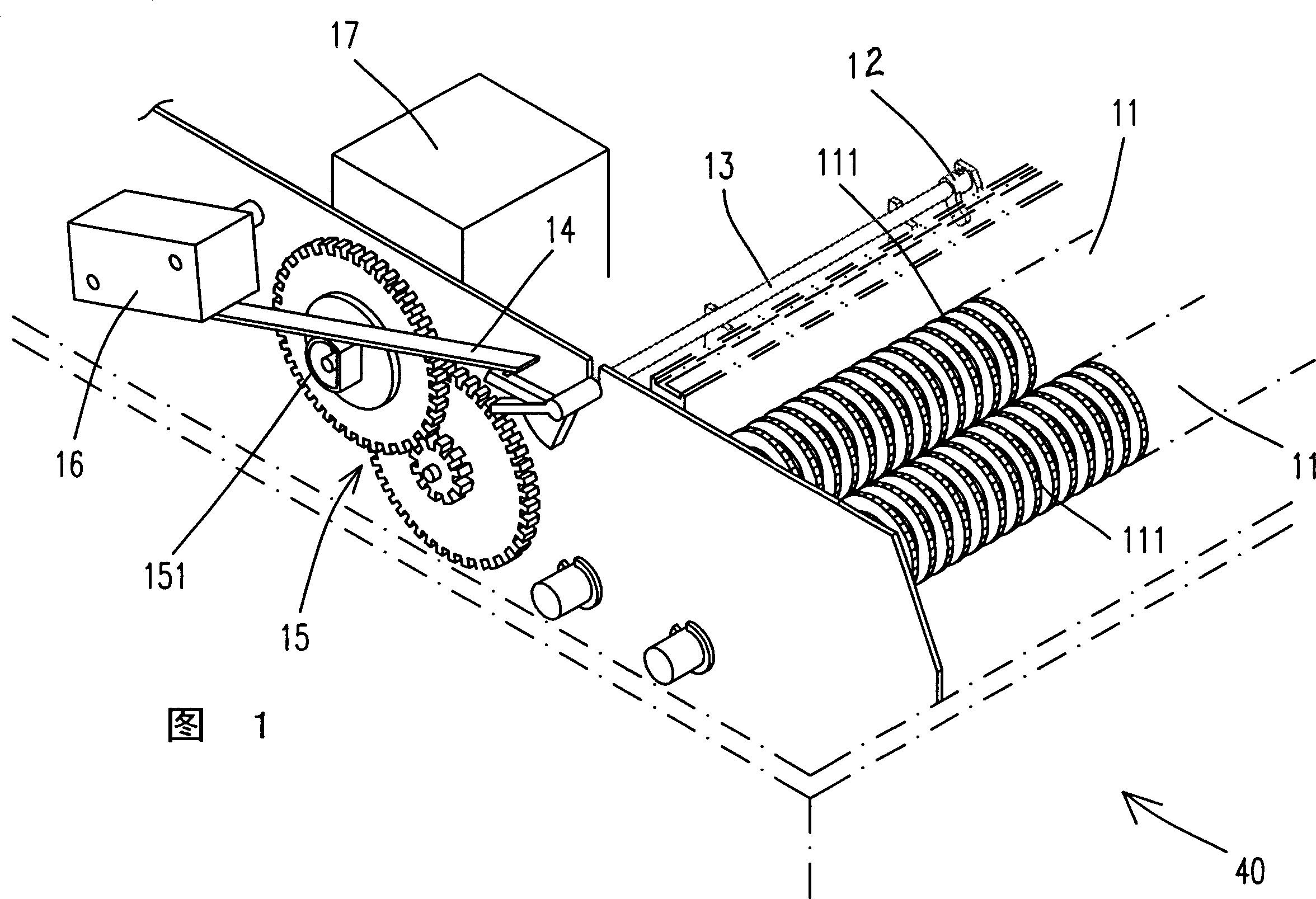

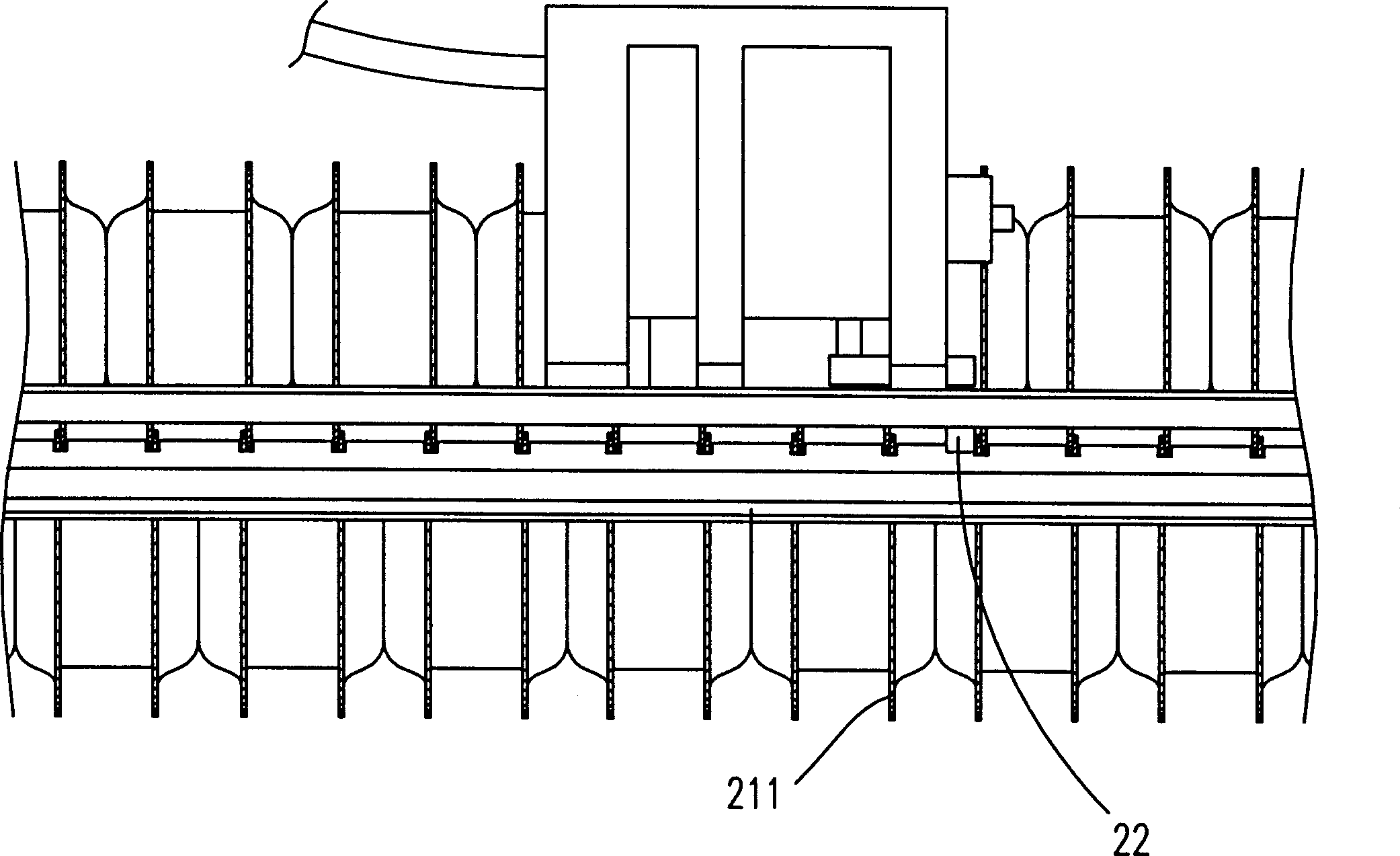

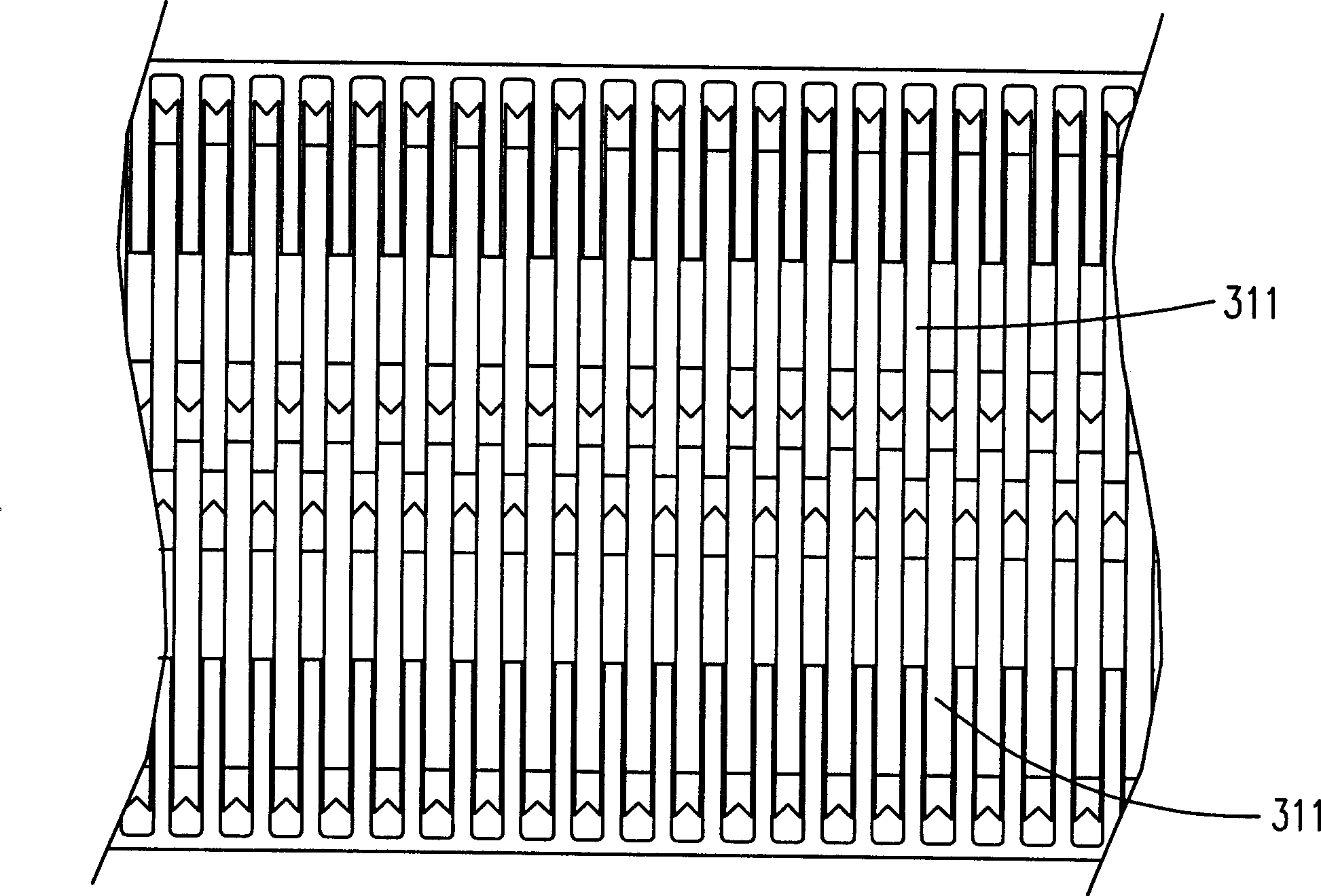

[0016] Please refer to Fig. 4, it is a schematic view of the structure of a preferred embodiment of the paper shredding device of the present invention, because the present invention is aimed at the improvement of the automatic start and delay structure part, so it is suitable for conventional structures (such as image 3 ) is not much different from the paper shredding mechanism (consisting of the first shaft, the second shaft, multiple cutting blades, multiple gap paper guides) and the power source completed by the motor and other components are not disclosed in the figure middle. As can be clearly seen from the figure, the trigger of the present embodiment is completed by a lug 401 fixed on the connecting rod 40 and is located at the inlet end of the shredded paper passage 41, which can overcome the conventional image 3 There is no problem that there is space for the actuator to be arranged between the middle blades 311 . The protruding piece 401 is resisted by the paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com