High fine centrifugal oil purifying device

A centrifuge and centrifugal technology, applied in the fields of petroleum, chemical industry, metallurgy, aerospace, and aviation, can solve the problems of poor oil purification effect, cumbersome operation, time-consuming and laborious, etc., achieve high oil purification quality, prolong service life, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

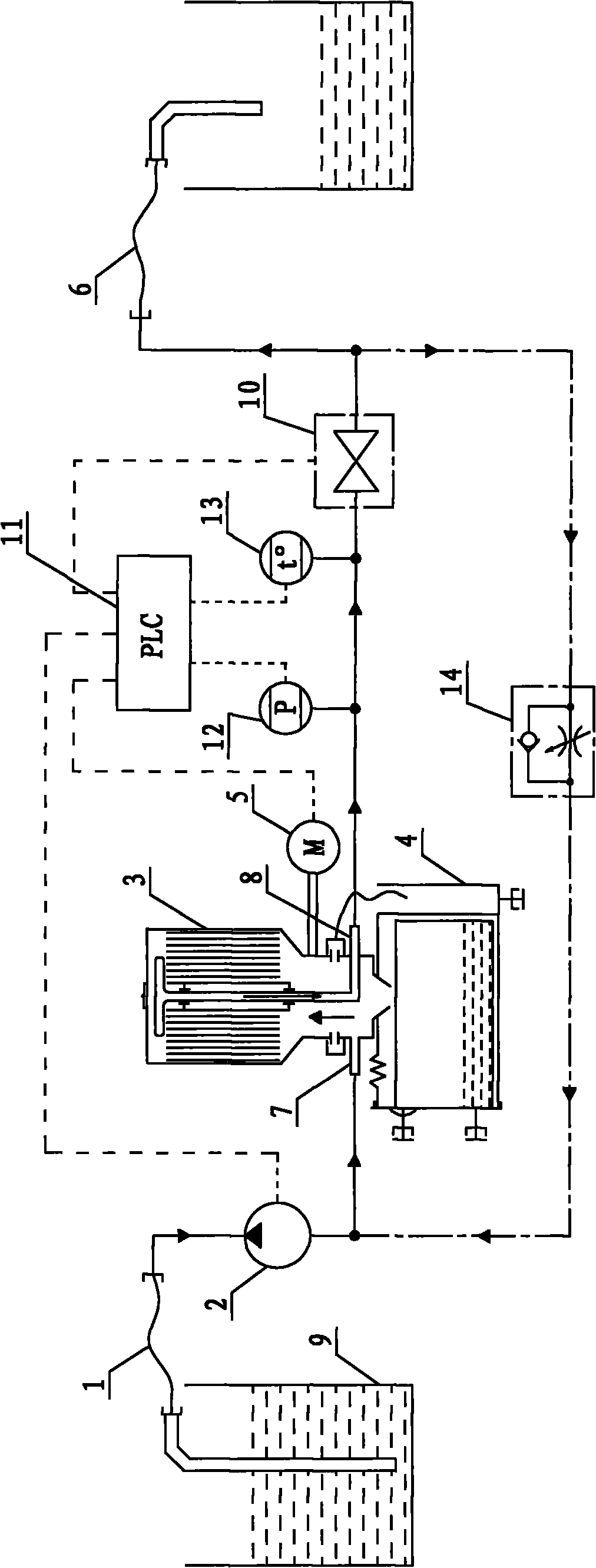

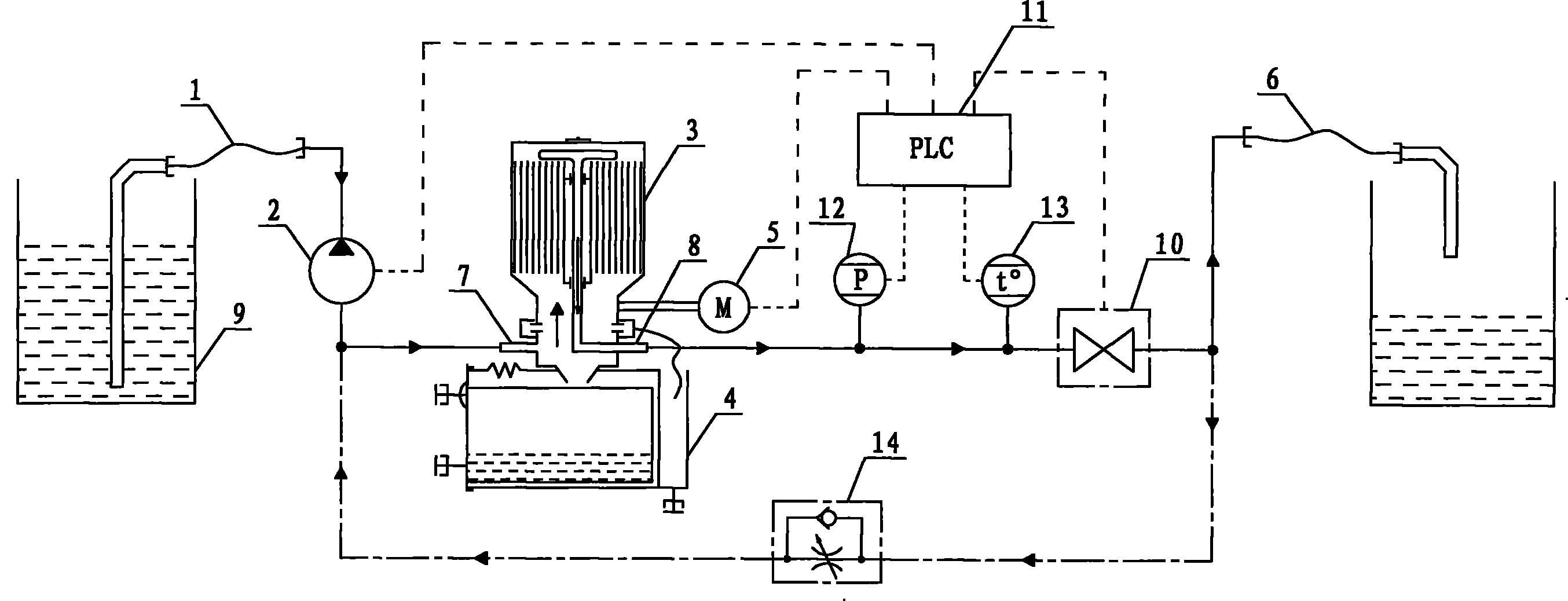

[0024] Such as figure 1 As shown, a high-precision centrifugal oil purifier includes an intake hose 1 , a gear pump 2 , a centrifuge 3 , a sewage tank 4 , a motor 5 and an oil outlet pipe 6 . figure 1 The direction of the arrow in indicates the direction of oil flow.

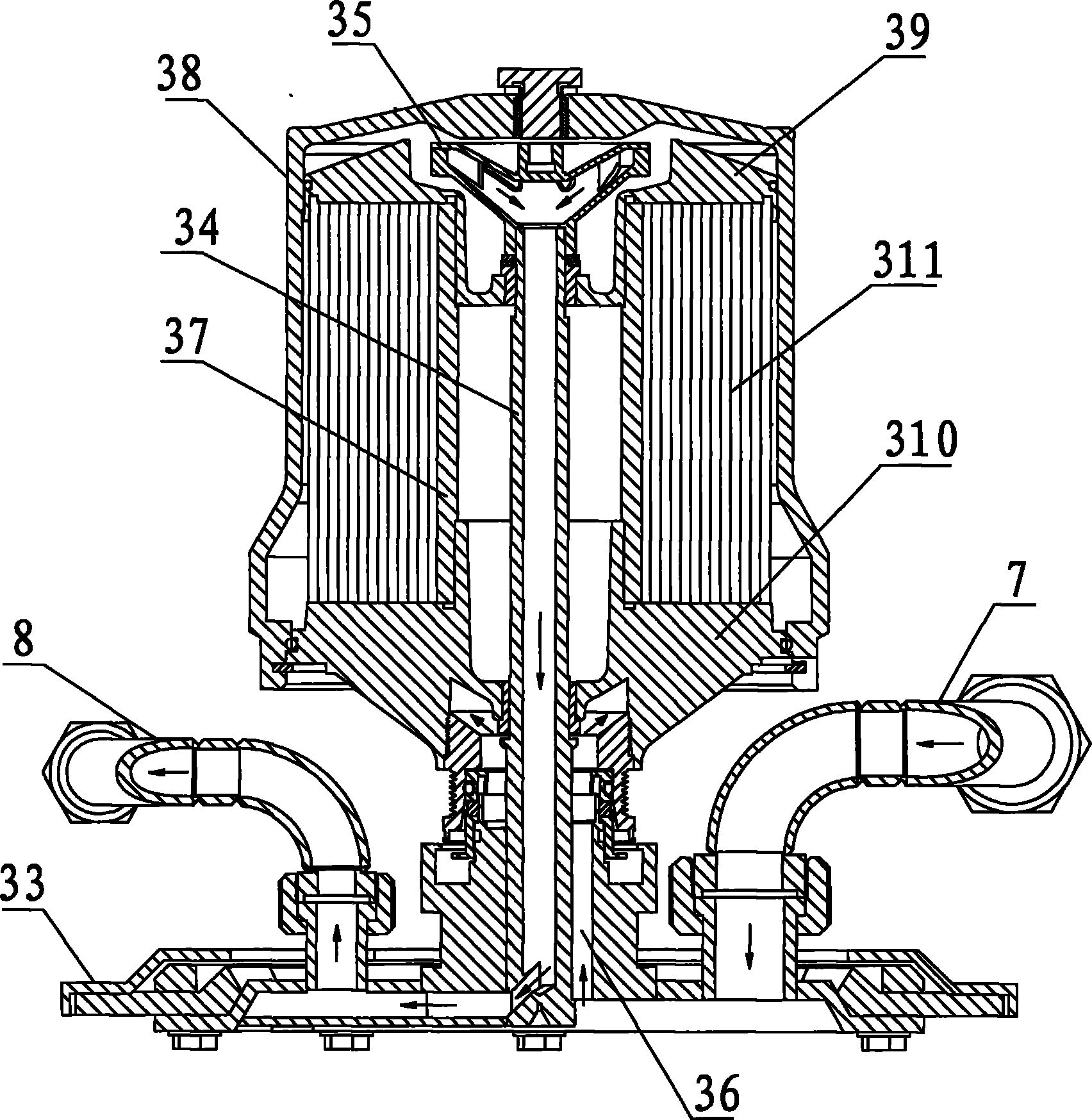

[0025] The centrifuge 3 has an input interface 7 for oil intake, a centrifugal device for filtering and purifying oil, and an output interface 8 for oil output. The intake hose 1 extends into the oil tank 9 to extract the oil to be purified, and the intake hose 1 passes through the The gear pump 2 is connected to the input interface 7 of the centrifuge 3 to form an oil inlet pipeline, the centrifugal device of the centrifuge 3 has a pipeline connected to the sewage tank 4, and the output interface 8 of the centrifuge 3 is connected to the oil outlet pipe 6 to form an oil outlet pipeline .

[0026] A flow valve 10 is installed on the oil outlet pipeline, and a PLC controller 11 is connected to the flow valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com