Dryer

A drying device and drying technology, which are applied in the drying of solid materials, non-progressive dryers, drying, etc., can solve the problems of inability to circulate drying and the drying process cannot be carried out smoothly, and achieve the effect of reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the invention

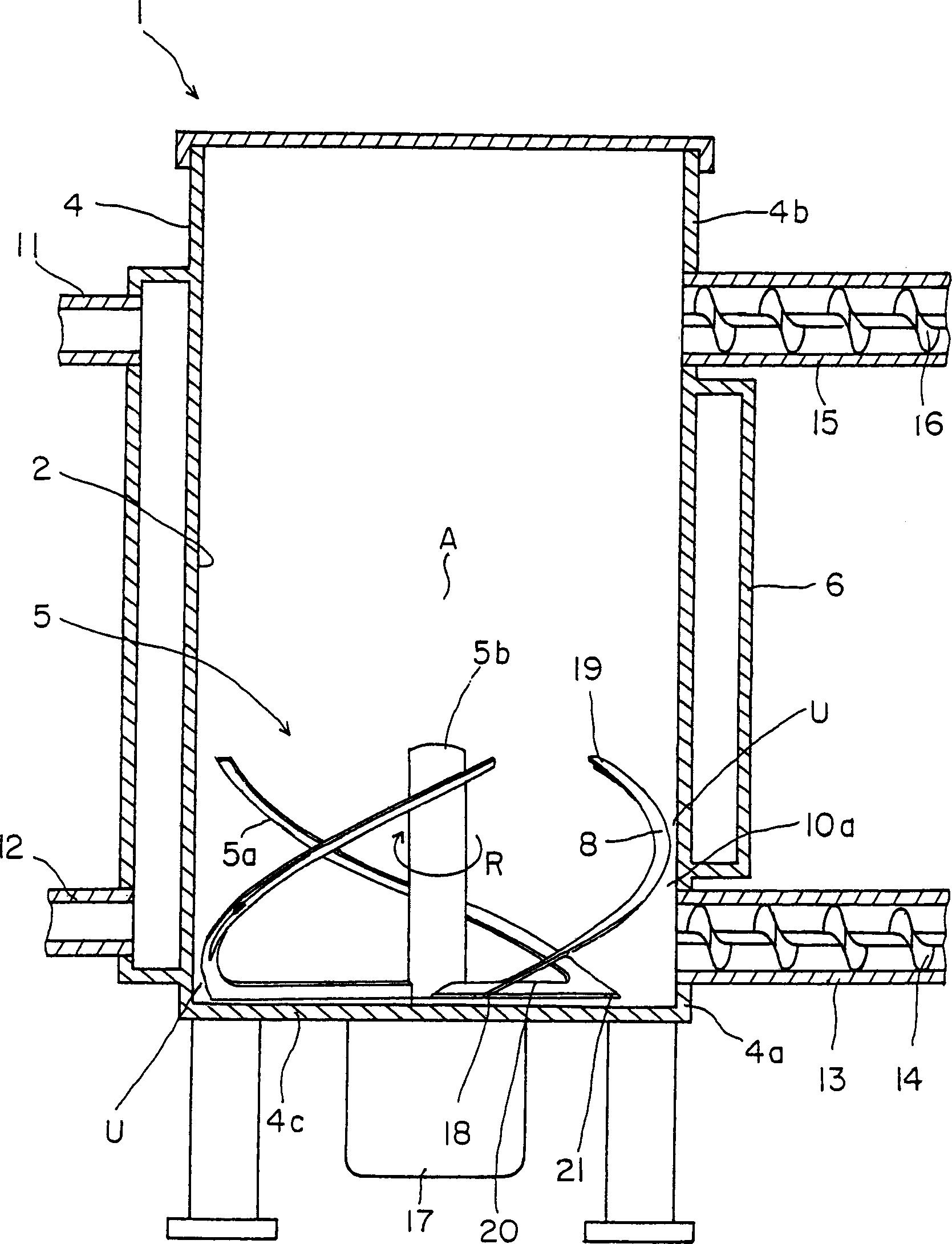

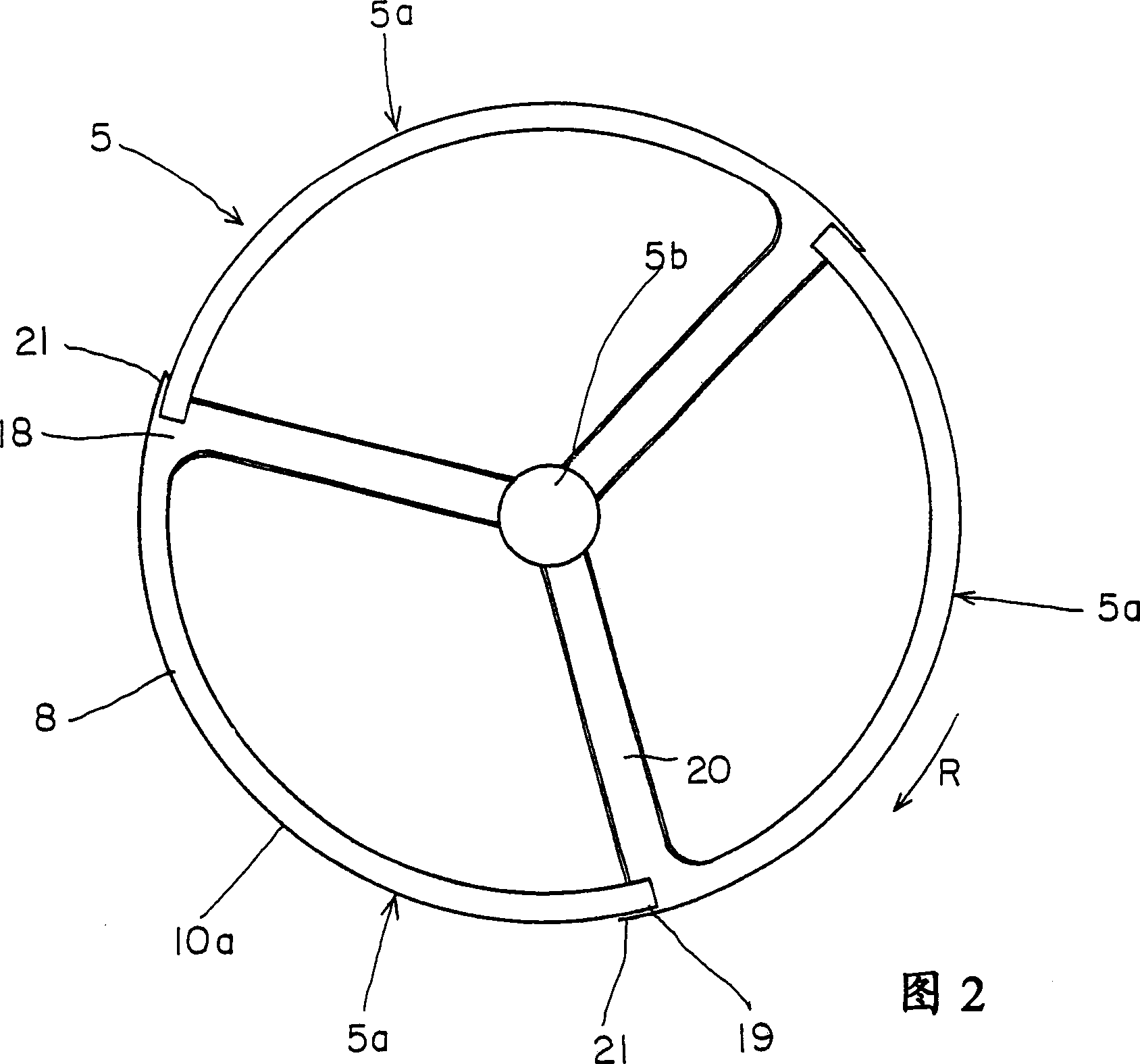

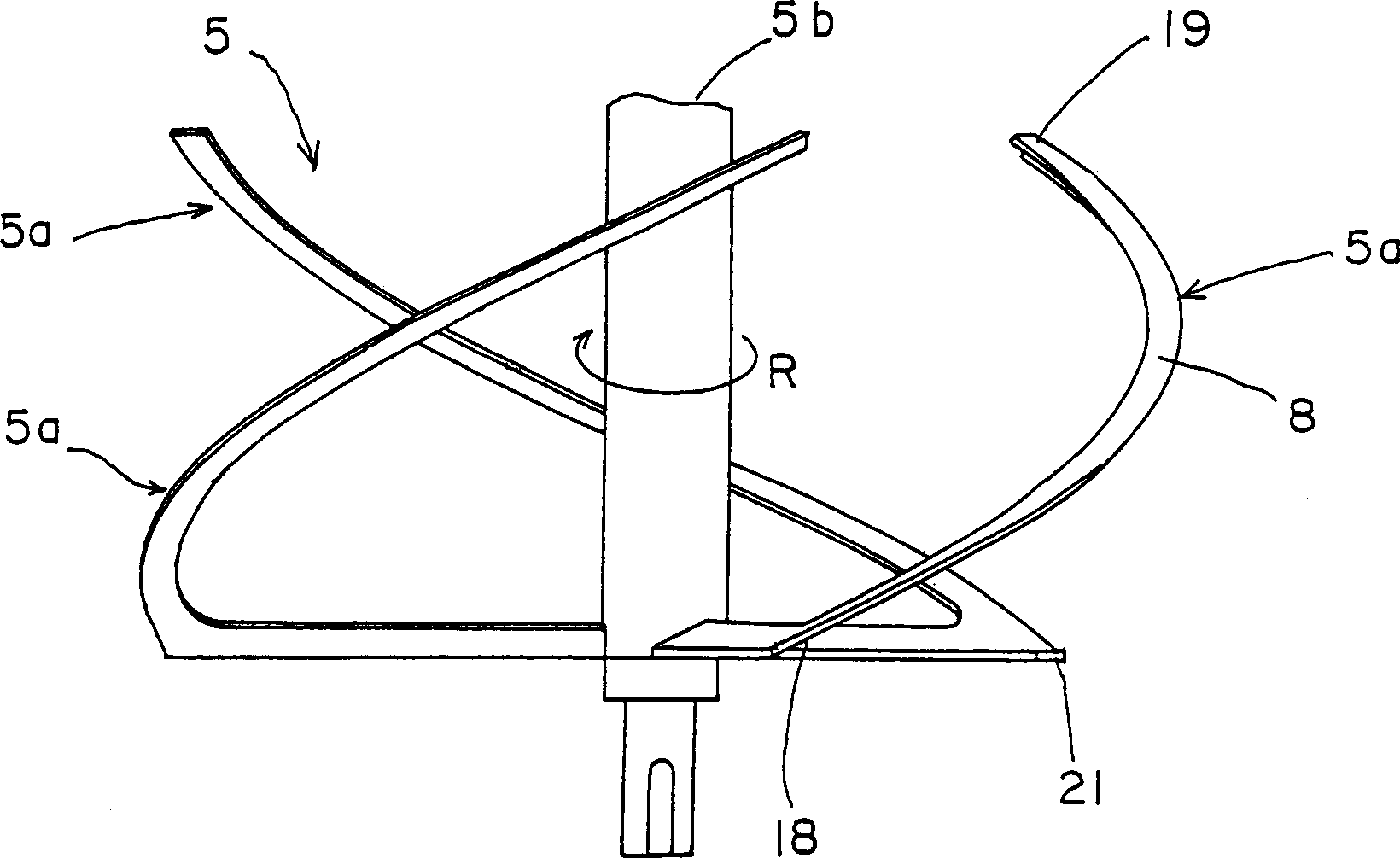

[0054] Embodiments of the present invention will be described in detail below with reference to the drawings. Figure 1 to Figure 8 It is the drying device 1 of the first embodiment. In the figure, 4 is a cylindrical drying tank, and its cylindrical inner wall is the heat transfer surface 2 of the drying device, and its function is to transfer the heat supplied by the heat transfer equipment to the object 3 to be dried. The above-mentioned heat transfer equipment refers to the jacket 6 located around the drying tank 4 and the boiler (not shown) connected to the jacket to send steam 7 to the jacket 6 . In addition, the jacket 6 is provided with a steam introduction part 11 for introducing the steam 7 into the jacket 6 and a steam discharge part 12 for discharging the steam 7 out of the jacket 6 .

[0055] The side wall at the bottom 4a of the above-mentioned drying tank 4 is connected with a dried material supply pipe 13, and the dried ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com