Apparatus for correcting paper-rolling and recording device with said apparatus

A technology for calibrating equipment and roll paper, applied in printing devices, winding strips, transportation and packaging, etc., can solve the problems of not being able to provide printing quality and not being able to perform correct printing work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

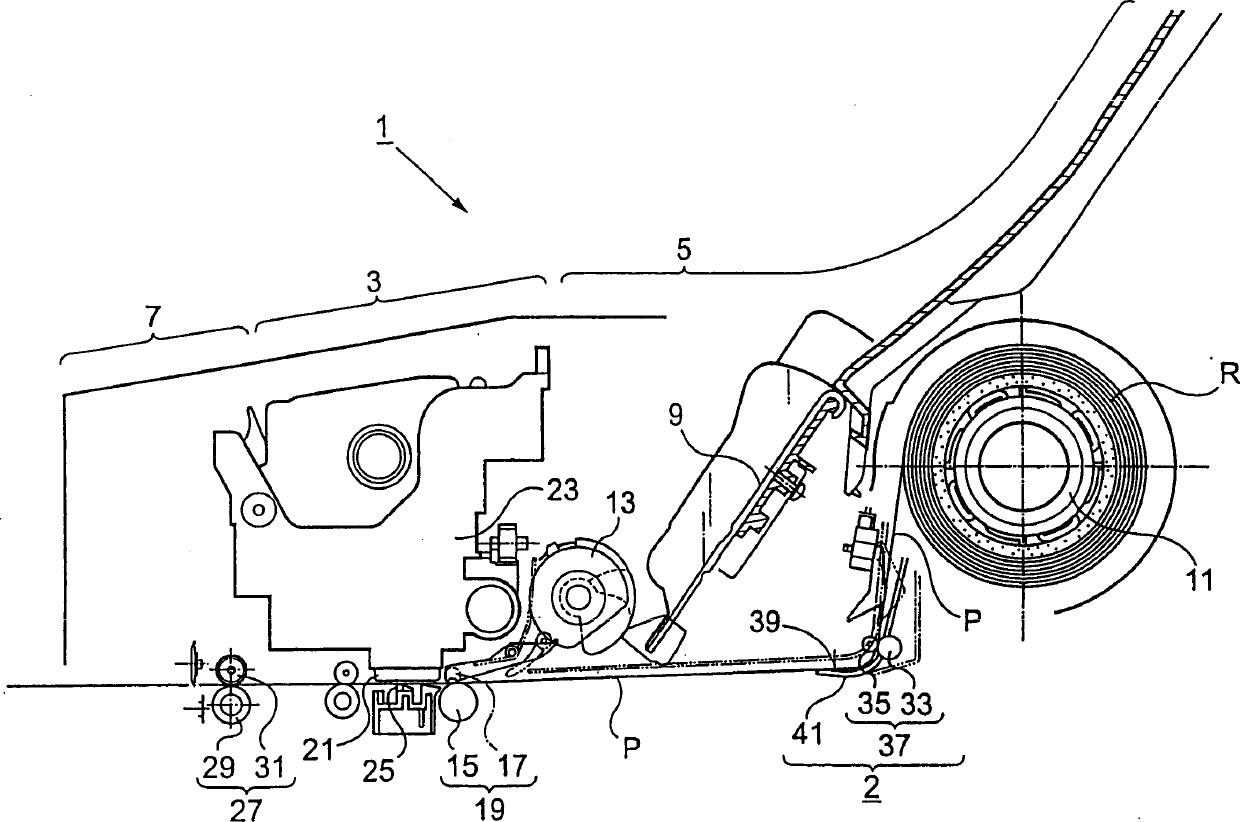

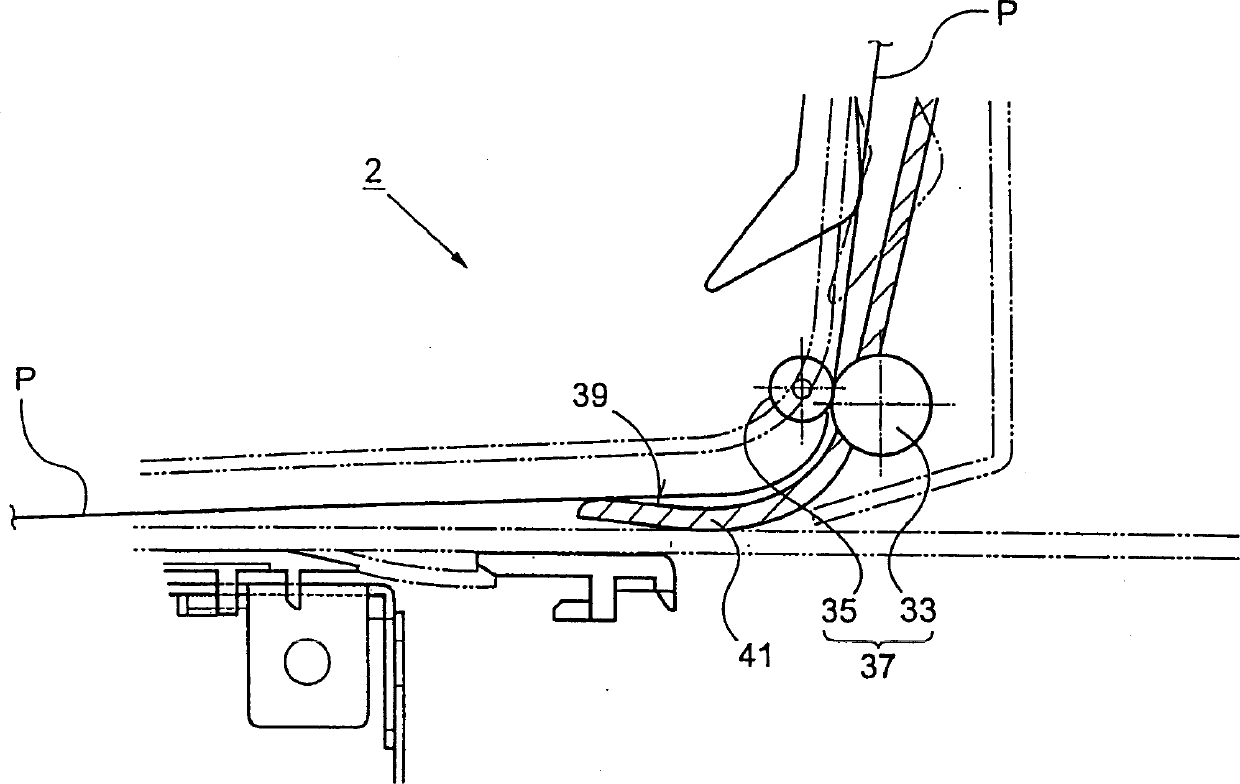

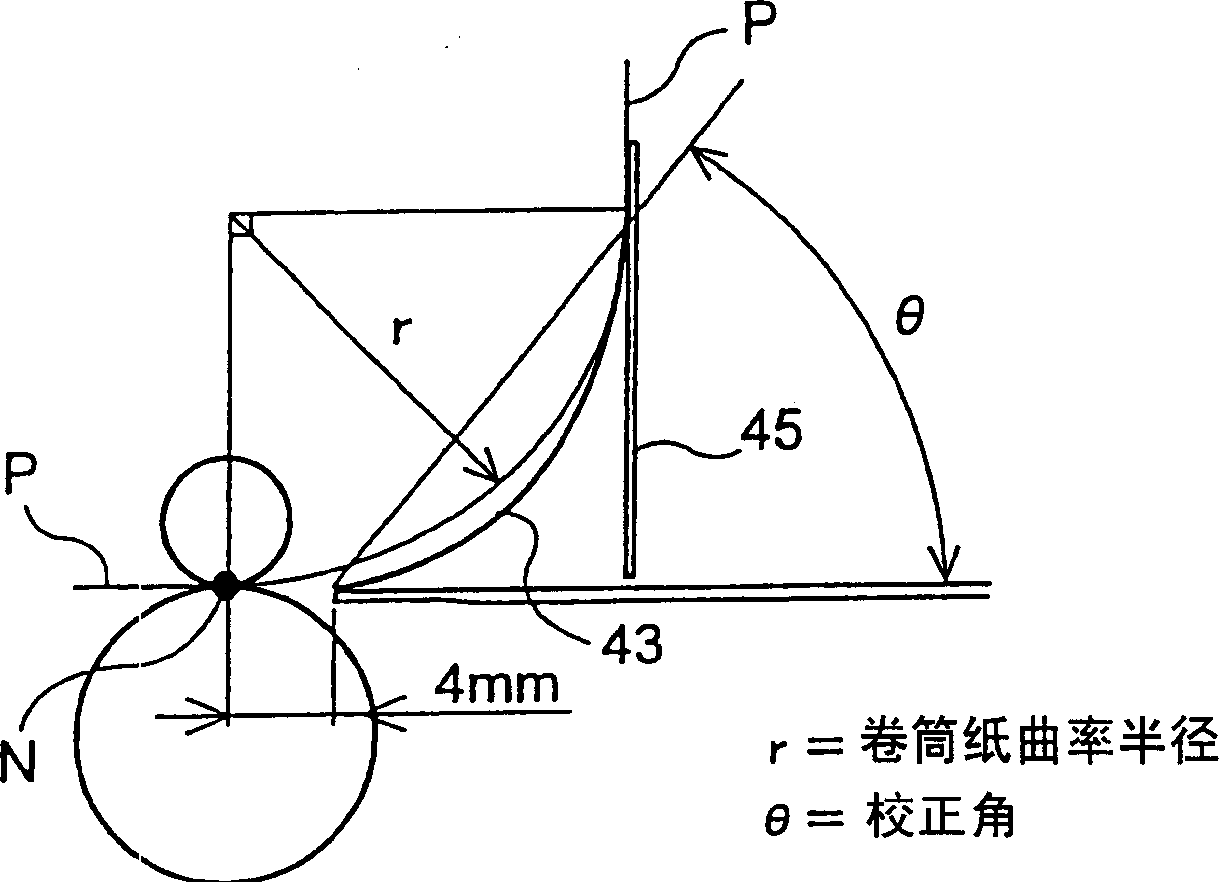

[0089] A first embodiment of the present invention will be described below with reference to the drawings. Fig. 1 is a schematic sectional side view of an inkjet printer (abbreviated as printer) 1 usable with cut sheets and roll papers, which is equipped with a roll paper curl correcting apparatus according to a first embodiment of the present invention.

[0090] The printer 1 includes a printer main unit 3 , a paper feeder 5 located behind the printer main unit 3 , and a paper discharge portion 7 formed in front of the printer main unit 3 .

[0091] The sheet feeder 5 is provided with a hopper (feed tray) 9 in which many single sheets are piled up on each other, and a sheet feed roller 13 for feeding one sheet at a time is located just downstream of the hopper 9 . On the other hand, the roll paper supply unit 11 for holding the paper roll R of the roll paper P is located behind the hopper 9 and forms a passage in which the roll paper P fed from the paper roll R passes through...

no. 3 example

[0103] Next, a third embodiment of the present invention is discussed in the following order with reference to FIGS. 8-23C:

[0104] 1. The structure of inkjet printer

[0105] 2. The structure and function of web curl correction equipment

[0106] 3. Structure and function of power transmission unit

[0107] (1. Structure of inkjet printer)

[0108]The structure of an inkjet printer (printer for short) 1 according to a third embodiment of the present invention will be generally discussed with reference to FIGS. 8-10. 8 is an external perspective view of the printer 1 (with the cover removed), FIG. 9 is a schematic sectional side view of the printer 1 , and FIG. 10 is a block diagram of a control system of the printer 1 .

[0109] In FIGS. 8 and 9, the printer 1 includes a paper feeder 5 located at the rear of the printer (left part of FIGS. 8 and 9). The paper feeder 5 conveys printing paper as a recording material (cut sheets, roll paper, cardboard, etc., hereinafter col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com