Rice seedling raising bed soil, application and seedling raising method

A technology for raising seedbed soil and rice seedlings, which is applied in the agricultural field, can solve the problems of complicated configuration steps, unusable configuration of seedbed soil, and increased production costs, so as to reduce the occurrence of weed damage in seedbeds, reduce the amount of soil used in seedbeds, and reduce production. risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

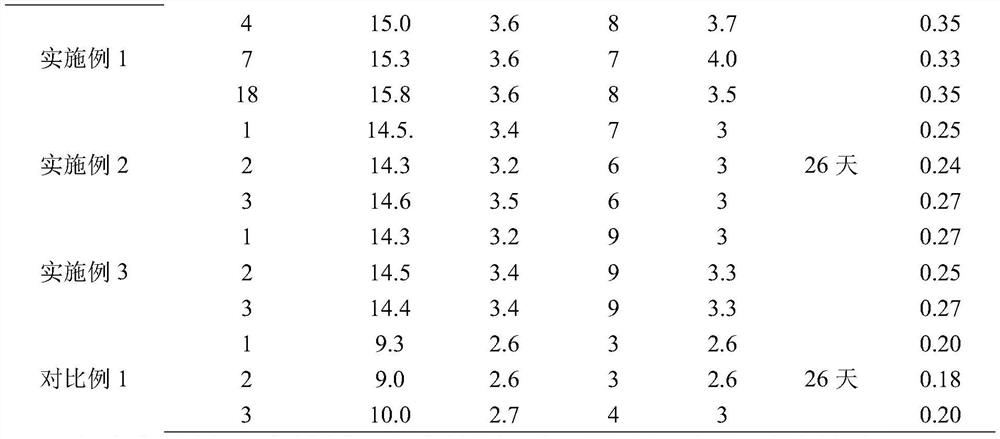

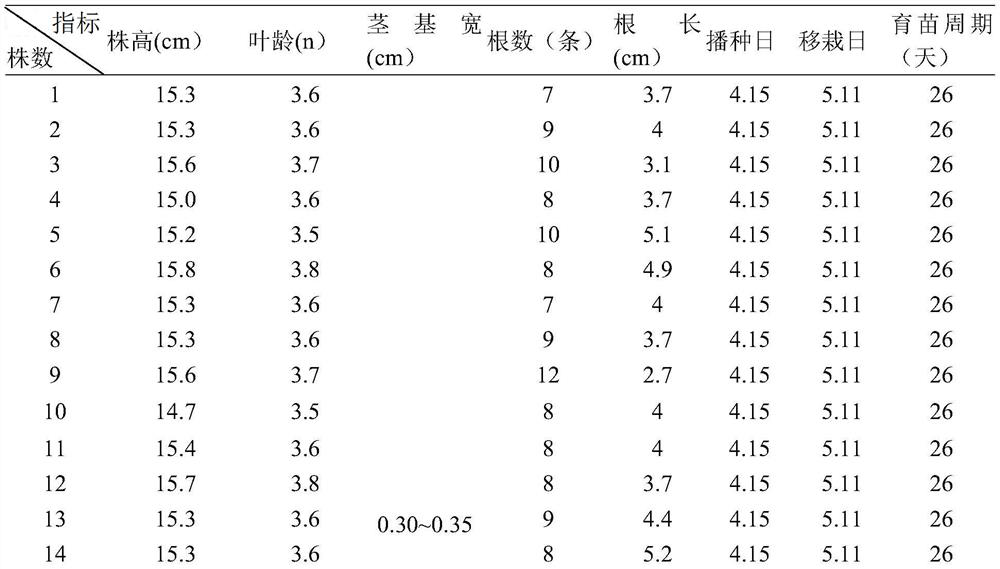

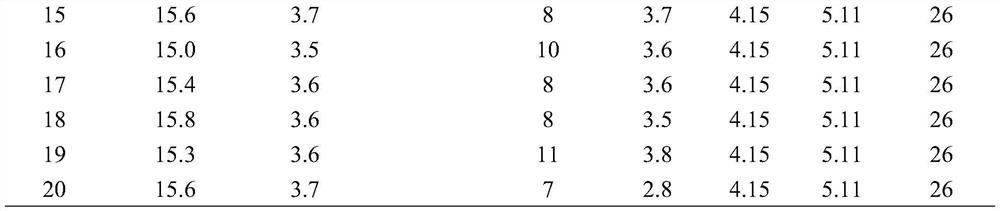

Embodiment 1

[0044] 1.1 Preparation of carbonized straw

[0045] The rice husk was calcined at 200° C. for 180 min to obtain carbonized straw.

[0046] 1.2 Configure rice seedling bed soil

[0047] Take 250 kg of paddy field soil, 250 kg of a mixture of carbonized straw and rice husk, wherein the volume of carbonized straw and rice husk is equal, mix to obtain 500 kg of rice seedling bed soil mixed with carbonized straw and rice husk, and then add urea 0.16 kg, hydrogen phosphate Diammonium 0.4kg, potassium sulfate 0.4kg, 20g carbendazim (purity quantity) and 20g thiram (purity quantity), mix well.

[0048] 1.3 Configure pH buffer solution (solution A)

[0049] Weigh Na 2 HPO 4 Added into water with pH=7.0, fully dissolved to obtain 0.2mol / L Na 2 HPO 4 solution. Weigh citric acid and add it into water with pH=7.0, fully dissolve to obtain 0.1 mol / L citric acid solution. According to Na 2 HPO 4 The volume ratio of the solution to the citric acid solution is 51.5:48.5, and the acid s...

Embodiment 2

[0070] The difference between this example and Example 1 is that the seedling bed soil does not contain any carbonized straw, and the amount of rice husk is 250m 3 .

Embodiment 3

[0072] The difference between this example and Example 1 is that the seedling bed soil does not contain any rice husks, and the amount of carbonized straw is 250m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com