Flow regulating method and apparatus for gas

A flow adjustment device and flow adjustment technology, which are applied in the directions of flow control without auxiliary power, valve device, combustion method, etc., can solve the problems that the cross-sectional area cannot be changed, the flow rate is changed, and the flame length is changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

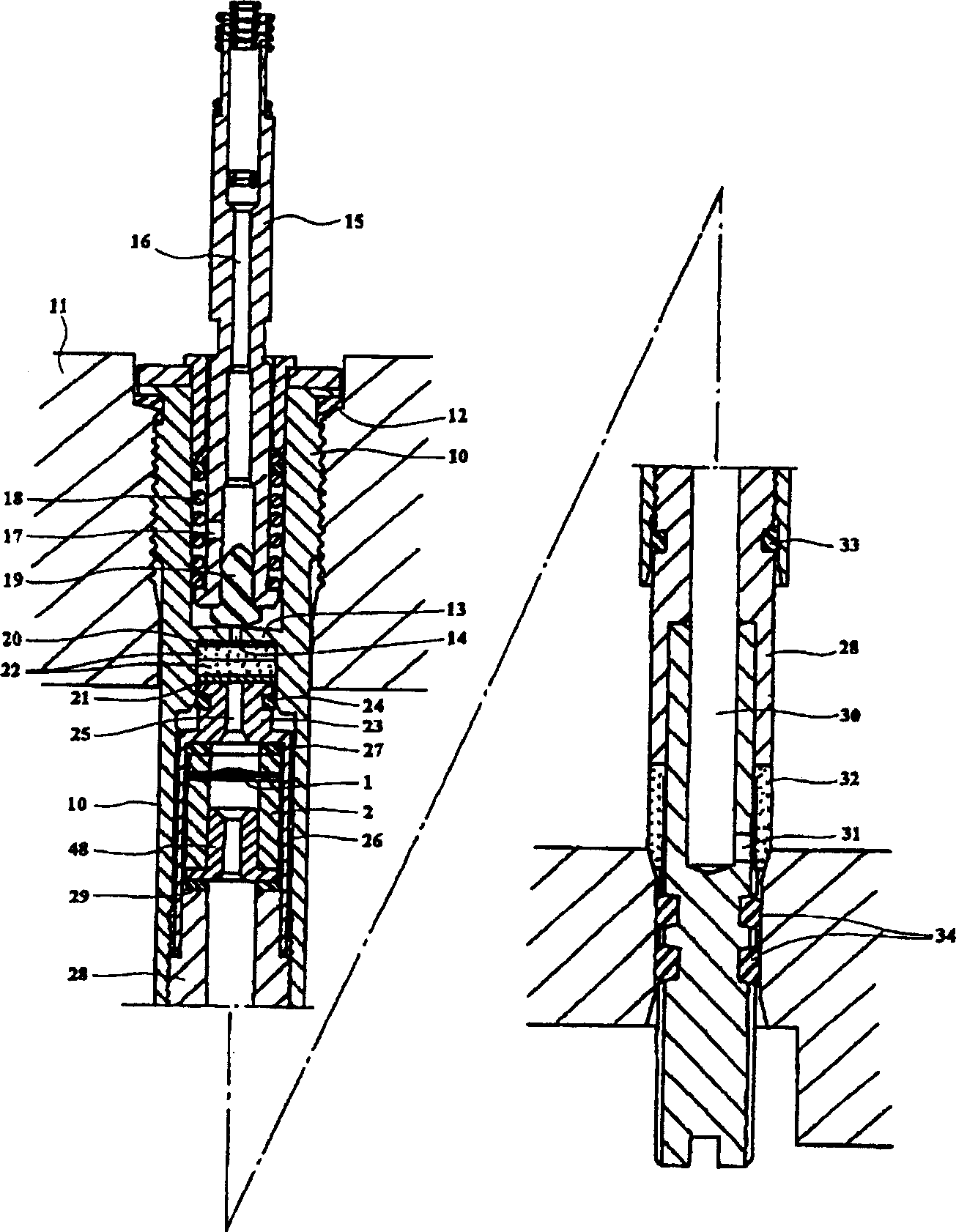

[0023] refer to image 3 , (10) is a fixed cylinder, which is fixedly installed on the upper wall of the storage container (11) with liquid storage gas with O-ring (12) to maintain airtightness. The fixed cylinder (10) constitutes the main component of the flow regulating device, and is composed of a cylinder that penetrates up and down, and is divided into upper and lower chambers by a partition (13) located in the roughly central part. The through hole (14) of perforation on the center communicates with the upper and lower chambers. Utilize the partition wall (13) to insert the combustion nozzle (15) in the upper chamber. At the center of the combustion nozzle (15), a gas ejection passage (16) is arranged axially through and communicated with the upper chamber through the horizontal hole (17). The fuel gas ejected from the upper end of the combustion nozzle (15) is ignited by an ignition spark formed by an appropriate ignition device such as an electric spark, a piezoelect...

Embodiment 2

[0031] Figure 5 Example 2 is shown. Embodiment 2 is that the rotation of the flow regulator of the press-molded flat sheet is performed from above the storage container, which is different from Embodiment 1 in which the flow regulation is performed from the bottom of the container. However, in addition to the difference in such flow regulating devices, other places, especially the two-stage flow regulation consisting of a primary regulation with a diaphragm and a secondary regulation with compression of a molded flat sheet, are characteristic of the invention of the present application. Method and structure are identical with embodiment 1. refer to Figure 5 , the inside of the fixed cylinder (10) fixed on the upper wall of the storage container (11) is divided into upper and lower chambers with a partition (13), and the upper chamber is equipped with a wall adjacent to the partition (13) and clamped in The molded flat sheet (22) between the grooved gasket (21) and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com