Printed circuit board assembly

A technology of printed circuit boards and components, applied in the direction of electrical components, electrical equipment structural parts, card reinforcement boards, etc., can solve the problems of limited quantity, unable to provide sufficient support for PCB, unable to provide separation and calibration, etc., to achieve the promotion ability , the effect of maintaining mechanical alignment and structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] This invention relates to printed circuit board assemblies. The following description is presented to enable one of ordinary skill in the art to make and use the invention, and is provided in the context of a patent application and its requirements. Various modifications to the preferred embodiments and the general principles and features described herein will be apparent to those skilled in the art. Therefore, the present invention is not intended to be limited to the illustrated embodiments, but is to be accorded the widest scope consistent with the principles and features described hereinafter.

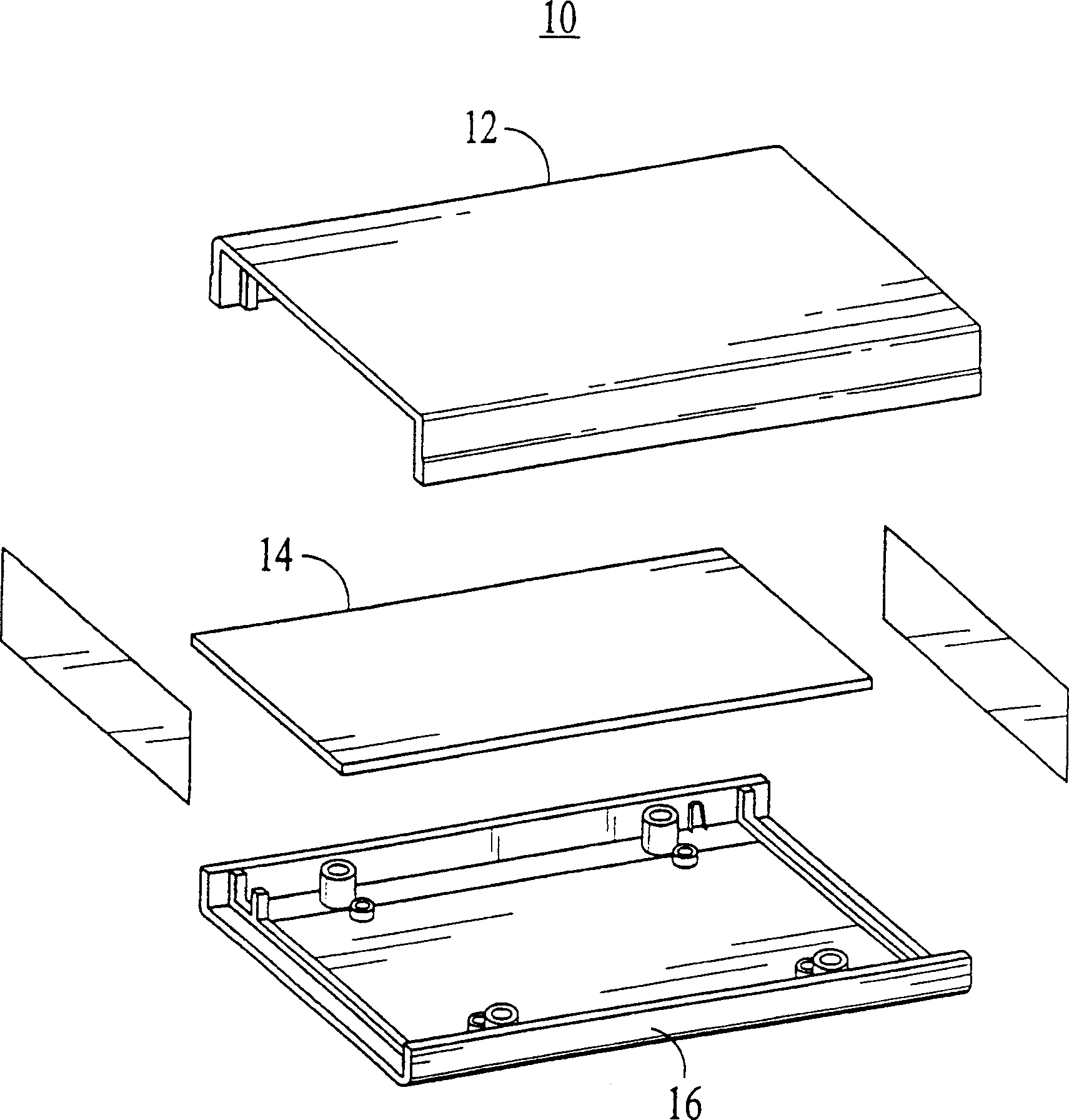

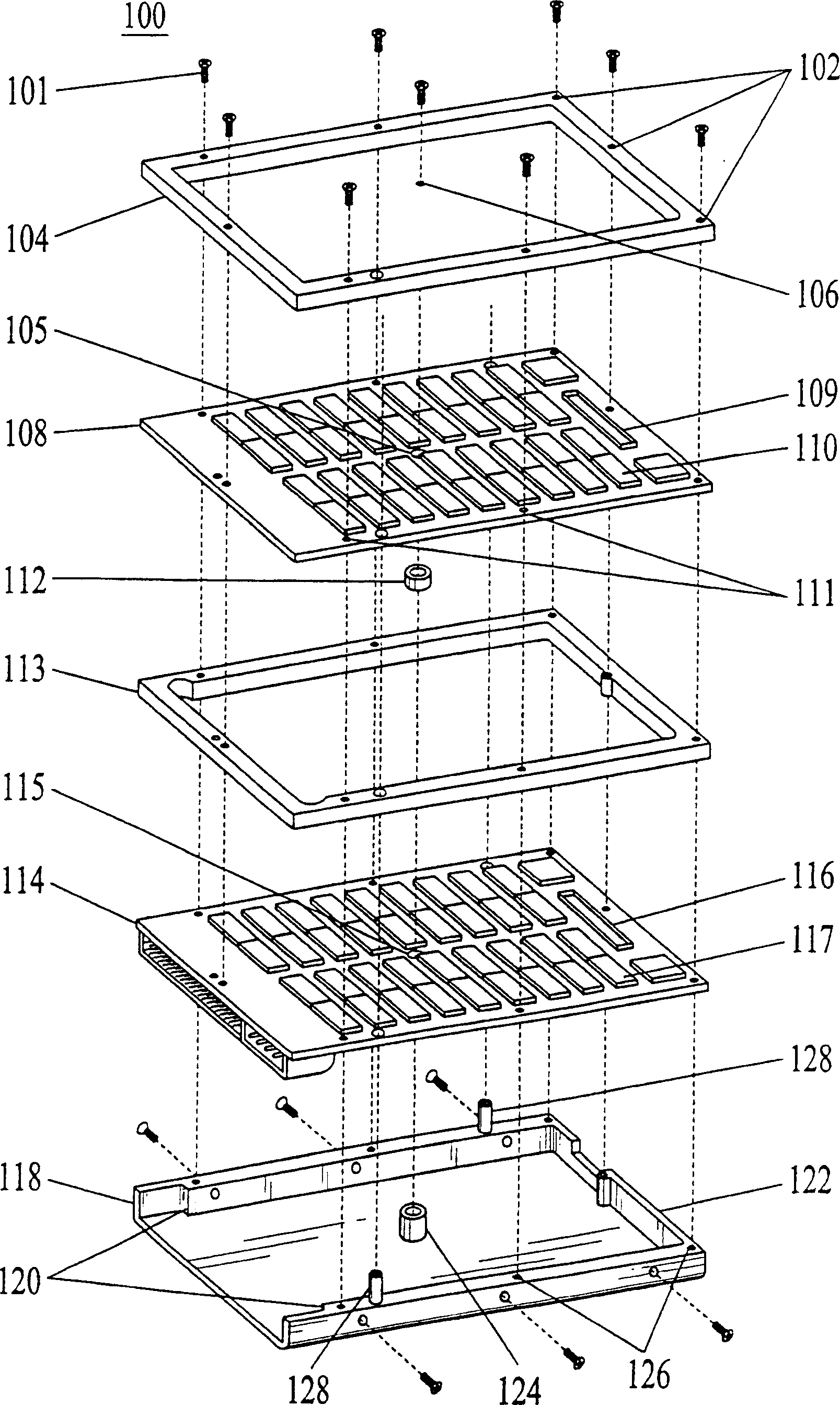

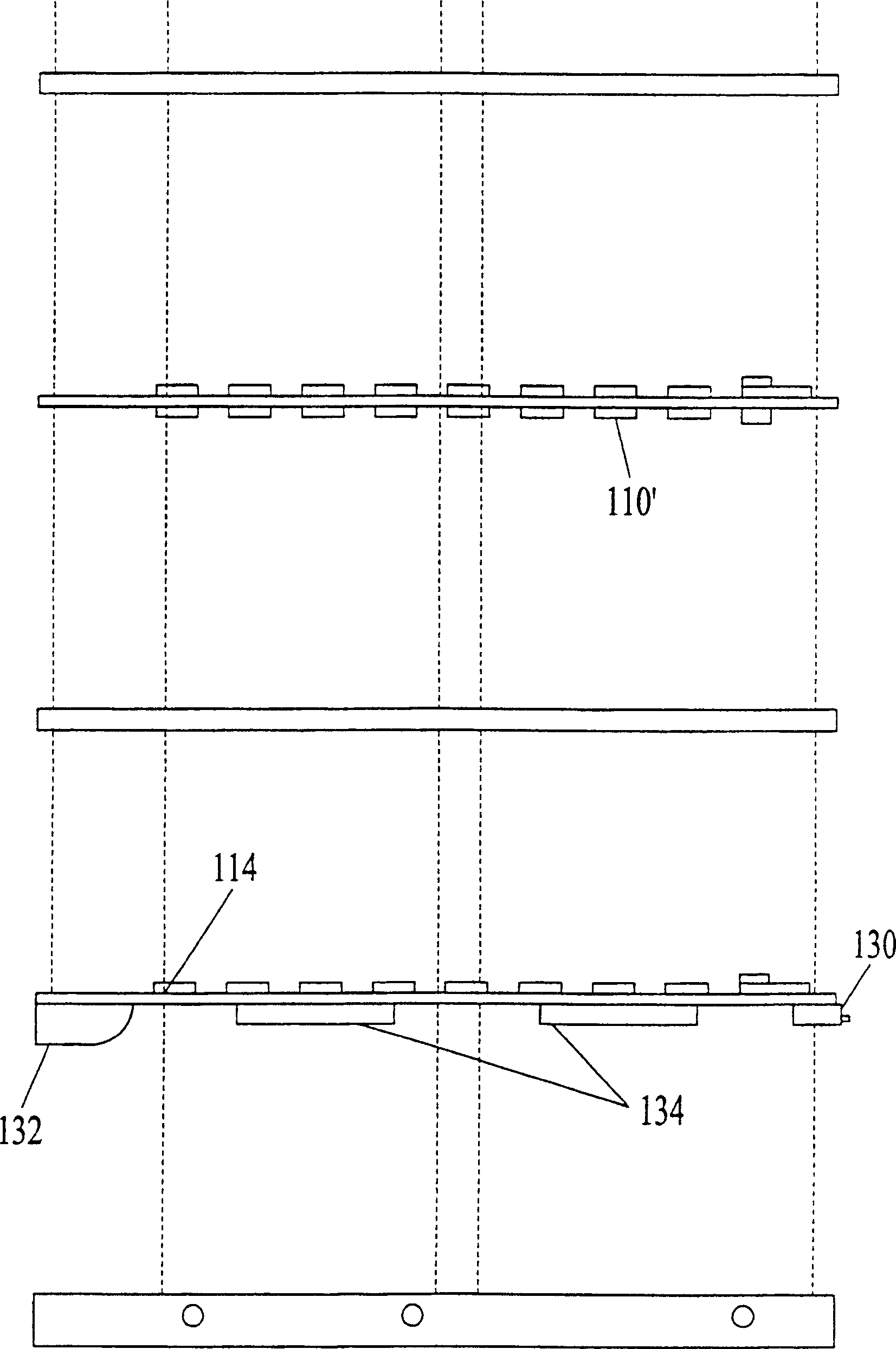

[0016] The device according to the invention is presented in the form of a preferred embodiment. The preferred embodiment of the present invention is an improved printed circuit board assembly. The printed circuit board assembly according to the invention incorporates a printed circuit board extending over the entire base area. By extending the printed circuit boards acro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com