Similar material for small and medium solid-fluid coupled model test and preparation method thereof

A technology of coupled models and similar materials, applied in the field of material science, can solve the problems of lack of representation, insignificant actual effect, and failure to reflect the actual situation of rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

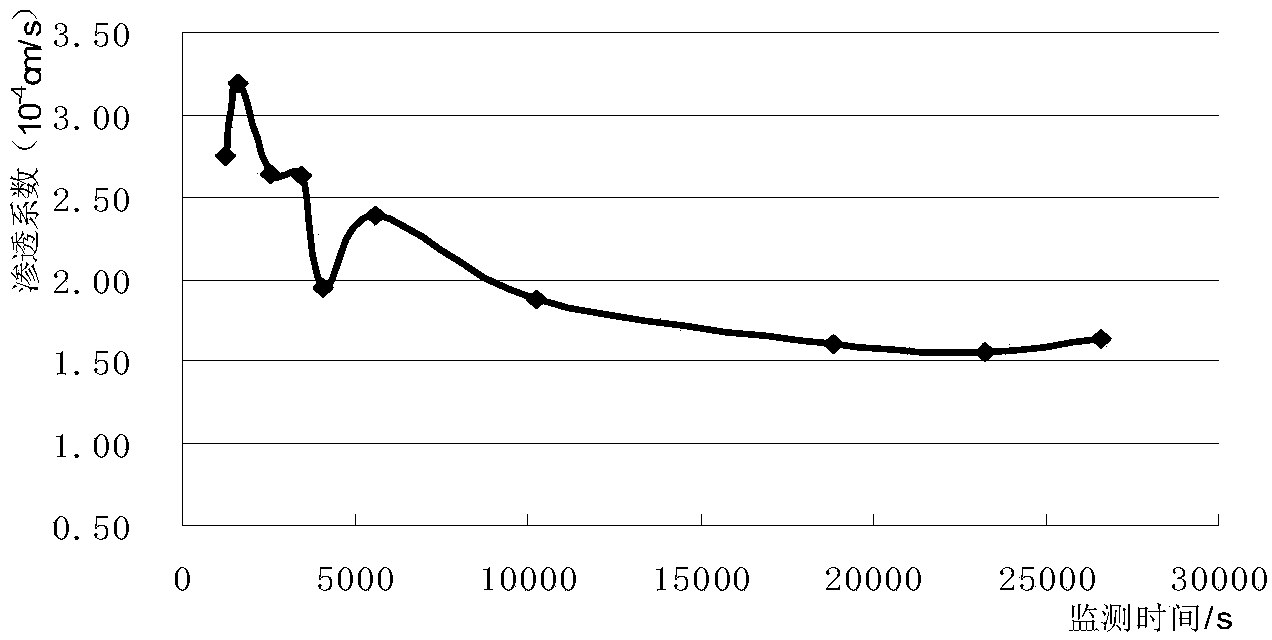

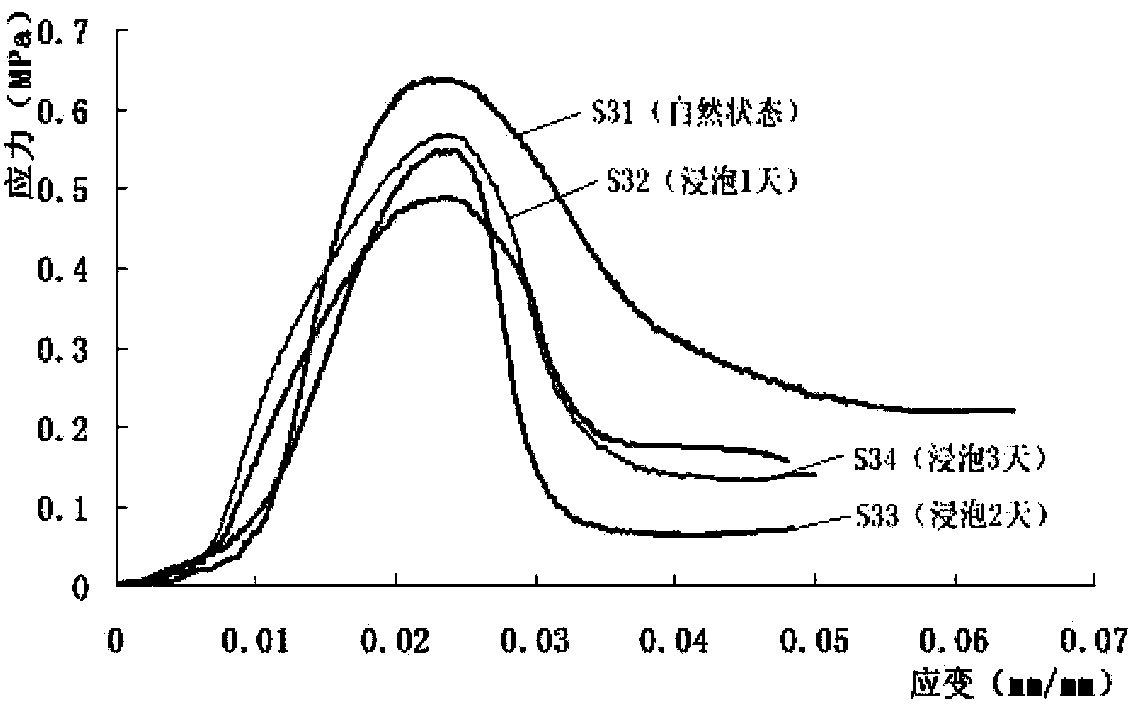

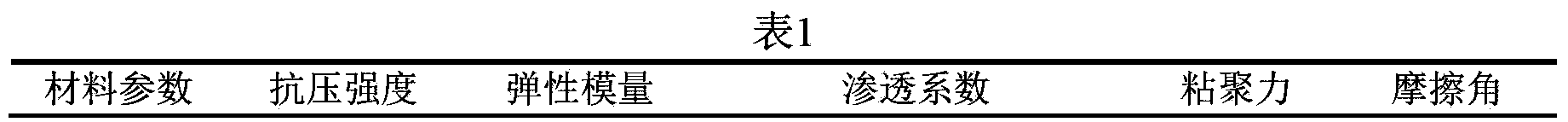

[0056] Take sand, cement, kaolin, vaseline and water in proportion, the total weight is 1000 grams, and the weights of each component are respectively: 750 grams of sand, 60 grams of cement, 65 grams of kaolin, 70 grams of vaseline, and 55 grams of water;

[0057] Experimental results: the uniaxial compressive strength is 0.6Mpa, and the permeability coefficient is 3.87×10 -6cm / s; the modulus of elasticity is 178Mpa, the cohesive force is 76Kpa, and the friction angle is 45 degrees.

Embodiment 2

[0059] Take sand, cement, kaolin, vaseline and water in proportion, the total weight is 1000 grams, and the weights of each component are respectively: 792 grams of sand, 50 grams of cement, 55 grams of kaolin, 55 grams of vaseline, and 48 grams of water;

[0060] Experimental results: the uniaxial compressive strength is 0.5Mpa, and the permeability coefficient is 9.37×10 -5 cm / s; the modulus of elasticity is 144Mpa, the cohesive force is 67Kpa, and the friction angle is 40 degrees.

Embodiment 3

[0062] Take sand, cement, kaolin, vaseline and water in proportion, the total weight is 1000 grams, and the weights of each component are respectively: 717 grams of sand, 81 grams of cement, 110 grams of kaolin, 44 grams of vaseline, and 48 grams of water;

[0063] Experimental results: the uniaxial compressive strength is 0.4Mpa, and the permeability coefficient is 8.54×10 -6 cm / s; the modulus of elasticity is 130Mpa, the cohesive force is 56Kpa, and the friction angle is 34 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Uniaxial compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com