Preparation method of vacuum pressurized impregnating epoxy resin

A technology of vacuum pressure impregnation and epoxy resin, which is applied in the direction of chemical instruments and methods, plastic/resin/wax insulators, surface etching compositions, etc., and can solve problems such as toxicity to the human body and the environment, insulation damage, and restricted use. Achieve the effects of improving processability, reducing viscosity, and perfecting cross-linked structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: method (2)

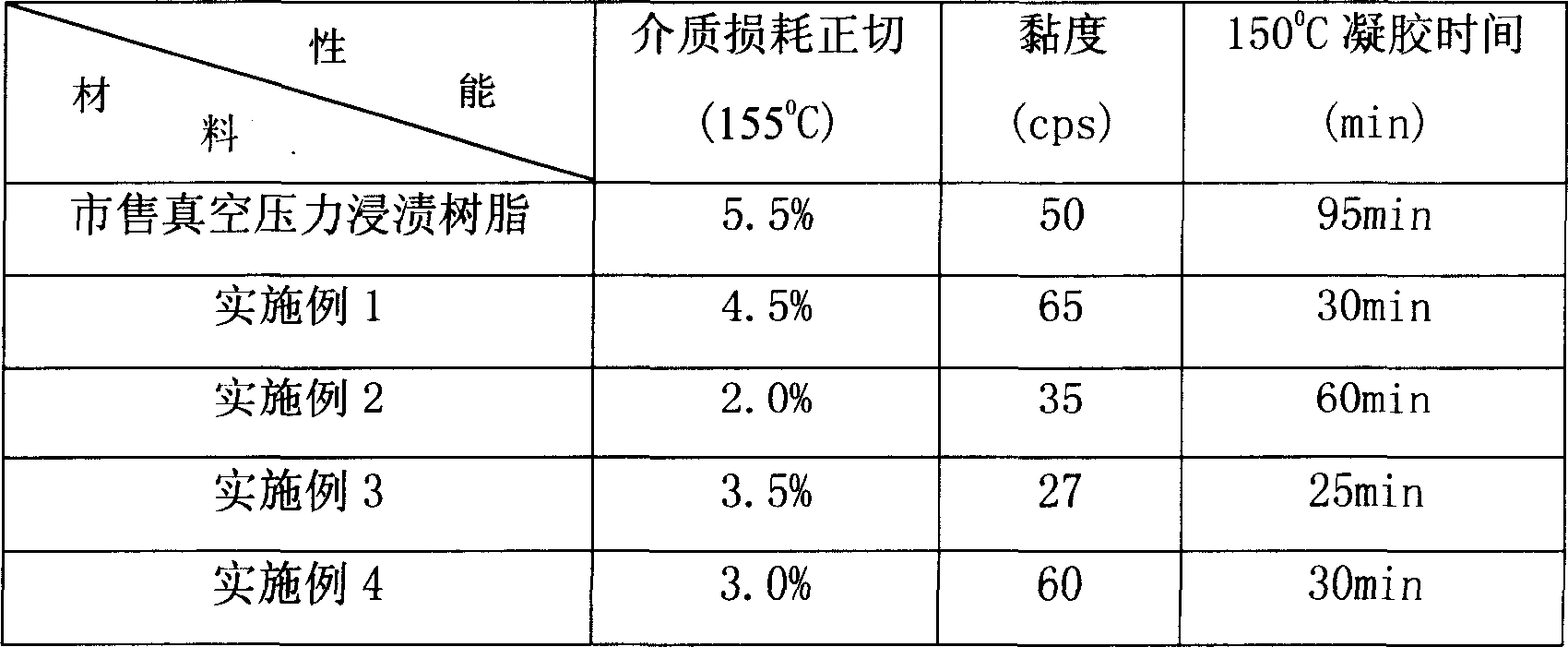

[0019] 25g bisphenol A epoxy resin (brand name DER331, DOW Chemicals) and 25g cycloaliphatic epoxy resin (brand name EXL4201, Union Carbide Corporation) mixture are heated to 90 ℃ and stir evenly, add 1.0g maleic anhydride and 0.002g of Benzyldimethylamine, keep the reaction at 90°C for 3 hours, cool down to 60°C, add 10g of vinyltriethoxysilane, 0.05g of aluminum acetylacetonate and 0.025g of p-benzoquinone, stir and mix evenly, and then Cool to room temperature, add 50g of methyl hexahydrophthalic anhydride and mix evenly to obtain 110g of epoxy vacuum pressure impregnation resin, the properties of the cured product are shown in Table 1.

Embodiment 2

[0020] Embodiment 2: method (1)

[0021] Add 0.025g aluminum acetylacetonate and 0.0025g p-benzoquinone to 25g cycloaliphatic epoxy resin (brand name EXL4221, Union Carbide Corporation), heat to 60°C to dissolve completely, cool to 25°C, add 3.75g γ-glycidyl ether oxypropyl Diethoxymethyldiethoxysilane and 25g of methylhexahydrophthalic anhydride were thoroughly mixed to obtain 53.8g of epoxy vacuum pressure impregnation resin. The properties of the cured product are shown in Table 1.

Embodiment 3

[0022] Embodiment 3: method (1)

[0023] Add 0.005g chromium acetylacetonate and 0.0005g tert-butyl hydroquinone to 14g cycloaliphatic epoxy resin (brand name EXL4201, Union Carbide Corporation), heat to 60°C to dissolve completely, cool to 25°C, add 6g γ-glycidol Etheroxypropyltrimethoxysilane and 18g of methyltetrahydrophthalic anhydride were thoroughly mixed to obtain 38g of epoxy vacuum pressure impregnation resin. The properties of the cured product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com