Automatic prestressing extension devices

A tensioning device and prestressing technology, applied in the direction of control without feedback, construction, building structure, etc., can solve the problems of difficult to accurately control the tensioning force, large control error of pressurization operation, etc., to ensure the design intent, improve the Safety, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

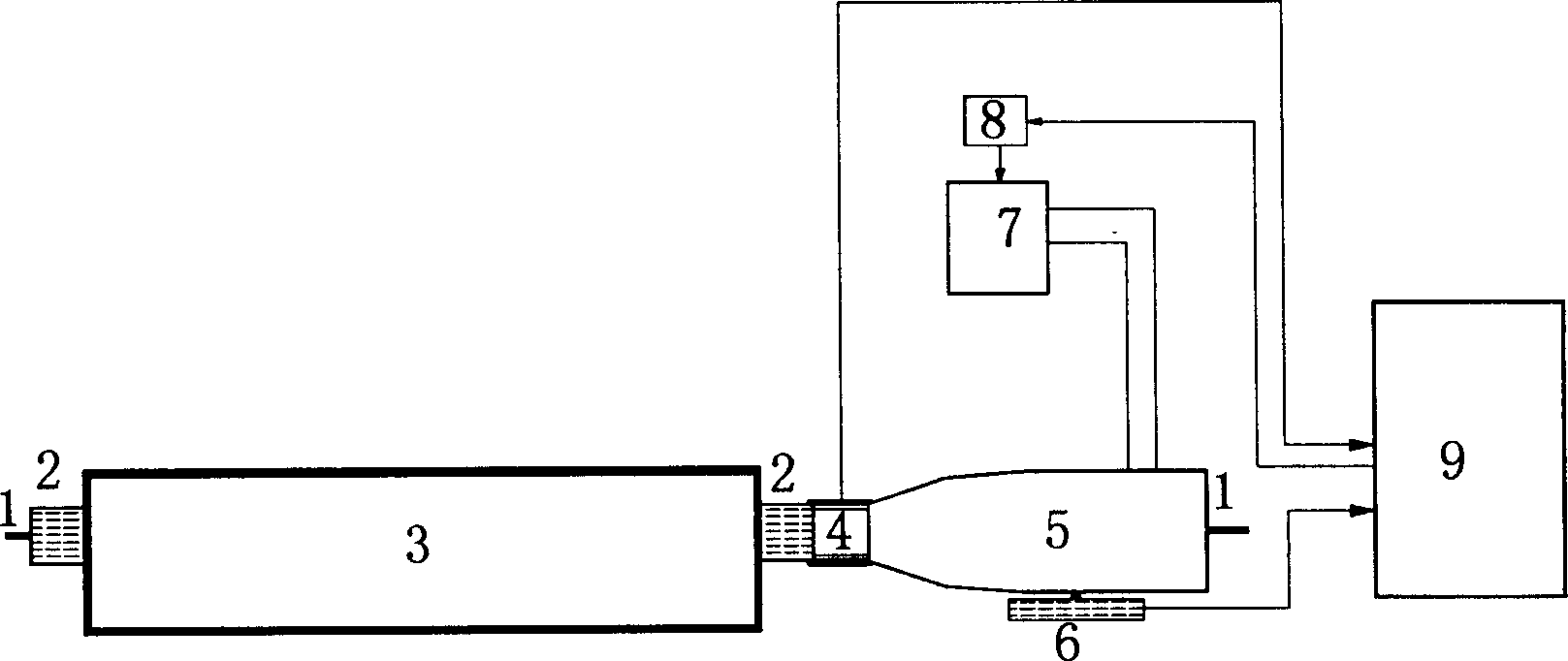

[0013] Fully automatic prestressed tensioning device, including the tensioning jack 5 driven by the oil pump 7, the force sensor 4, the displacement sensor 6 and the control assembly 9 of the tensioning device. Solenoid valve 8 controlled by the assembly.

[0014] The displacement sensor 6 is fixed below the jack 5, and its electrical signal output end is connected with the signal input end of the control assembly with a wire; the electrical signal output end of the force sensor 4 is also connected with the signal input end of the control assembly through a wire.

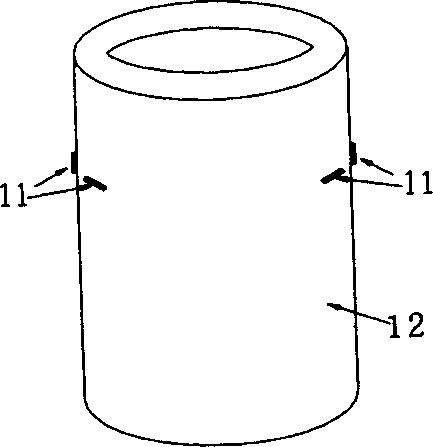

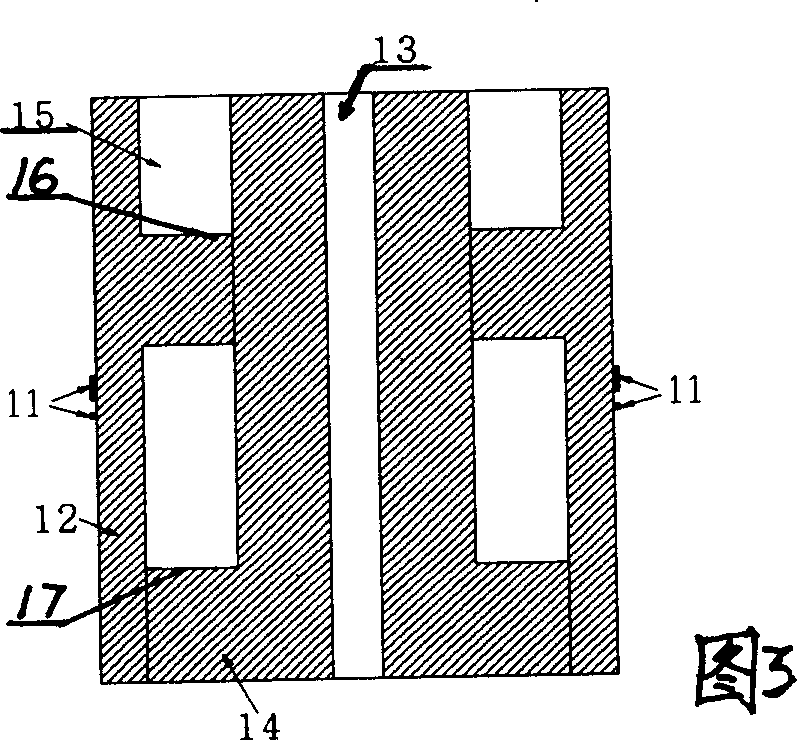

[0015] A force sensor having the following structure can be used. The force sensor 4 is composed of a force-sensing elastic member 12 with a strain gauge 11 fixed on its outer surface, and a plug 14 located in the force-sensing elastic member on which a prestressed tendon hole 13 is formed. There are eight strain gauges fixed on the force sensor, and the eight strain gauges are bridge-connected. The inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com