Pipe adapter of composite polymer strengthen by perforated steel skeleton

A technology of reinforced composite and pipe joints, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as lack, and achieve high stress resistance, wide application range, and strong environmental stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

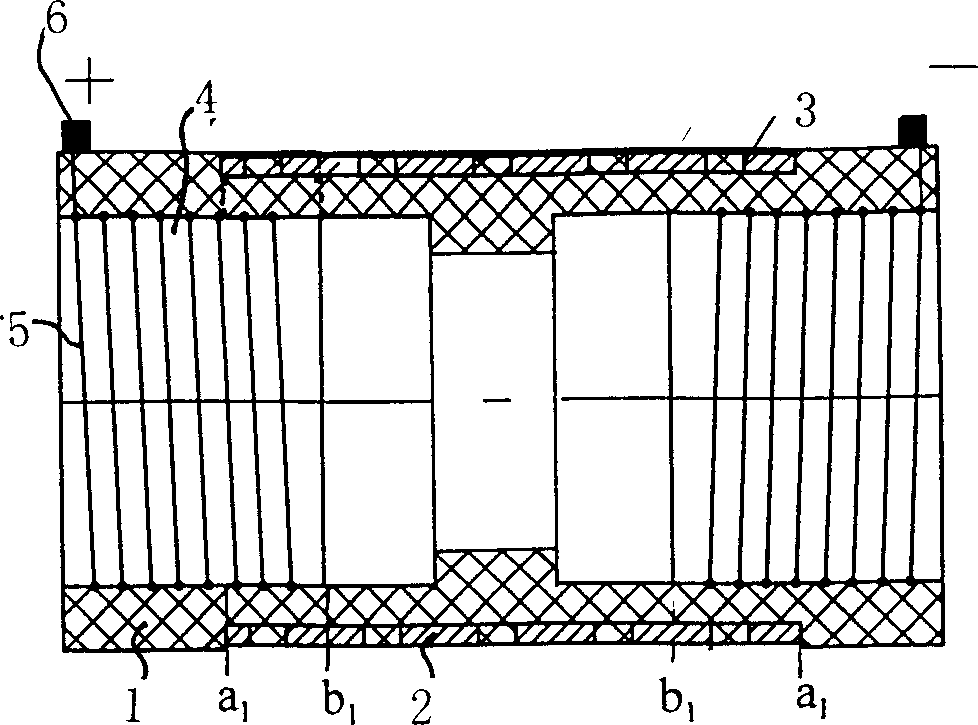

[0032] figure 1 A structural schematic section of Embodiment 1 of the present invention is given. In the outer wall of the two-way polymer continuous pipe body 1, there is a perforated steel skeleton 2 formed by welding composite steel plates with holes. There is a steel skeleton protection layer 3 on the outside of the steel skeleton. Spiral ring-shaped electric heating wires 5 are distributed circumferentially at 4 sockets at both ends of the pipe body, and positive and negative terminals 6 connected with the electric heating wires are installed on the outer wall of the pipe body. The overlapping part of the projection of the steel skeleton on the axis of the pipe body and the projection of the electric heating wire arranged in a spiral ring on the axis (as shown in the figure a 1 , b 1 ) steel frame opening area is 50% of the developed surface area of the steel frame.

Embodiment 2

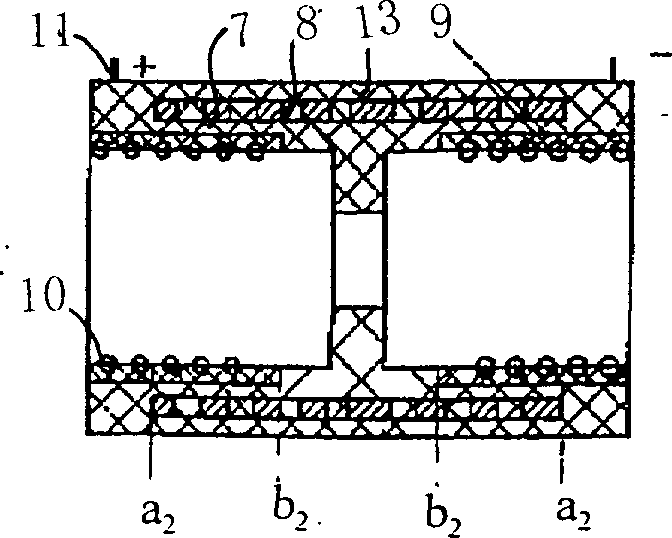

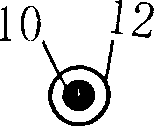

[0034] figure 2 , image 3 A schematic structural diagram of Embodiment 2 of the present invention is given. There is a perforated steel skeleton 8 compounded therein in the two-way polymer continuous pipe body 7 . The inner wall of the socket at both ends of the pipe body has a polymer material layer 9 different from the material of the pipe body, a spiral ring-shaped electric heating wire 10 distributed circumferentially on the polymer material layer, and positive and negative terminals 11 installed on the outer periphery of the pipe body . The part of the steel skeleton on the axis of the pipe body that coincides with the projection of the electric heating wire on the axis (as shown in Figure a 2 , b 2 ) opening area is 30% of the expanded area of the steel skeleton. Electric heating wire 10 such as image 3 Its periphery is shown covered with an adhesive layer 12 . The steel frame used in the present embodiment can be selected the steel frame that is welded by th...

Embodiment 3

[0036] Figure 7 Figure 3 of Embodiment 3 of the present invention is given. A perforated steel framework 15 similar in shape to the three-way polymer continuous pipe body 14 is compounded. The inner wall of the socket socket is respectively provided with helically wound electric heating wires 16, 17 and connected with positive and negative poles 18, 19 respectively. The opening area of the part where the upper or lower part of the steel skeleton coincides with the projection of the electric heating wire on the axis of the pipe body (a in the figure) 3 , b 3 、a 4 , b 4 ) is 95% of the expanded area of the steel skeleton.

[0037] This embodiment 3 can be selected as Figure 8 Shown is an investment cast steel skeleton with unequally spaced holes and hole diameters.

[0038] Fig. 9 is a schematic diagram of a 90° elbow steel skeleton structure. The opening area at its two straight ends is between 30% and 95% of the developed area of this section, and the open area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com