Multiple transmission pair stepless speed variation transmission device

A variable speed transmission, vice stepless technology, applied in the field of transmission, can solve the problems of limited torque range, unsuitable for large torque transmission, difficult to apply, etc., to achieve the effect of increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

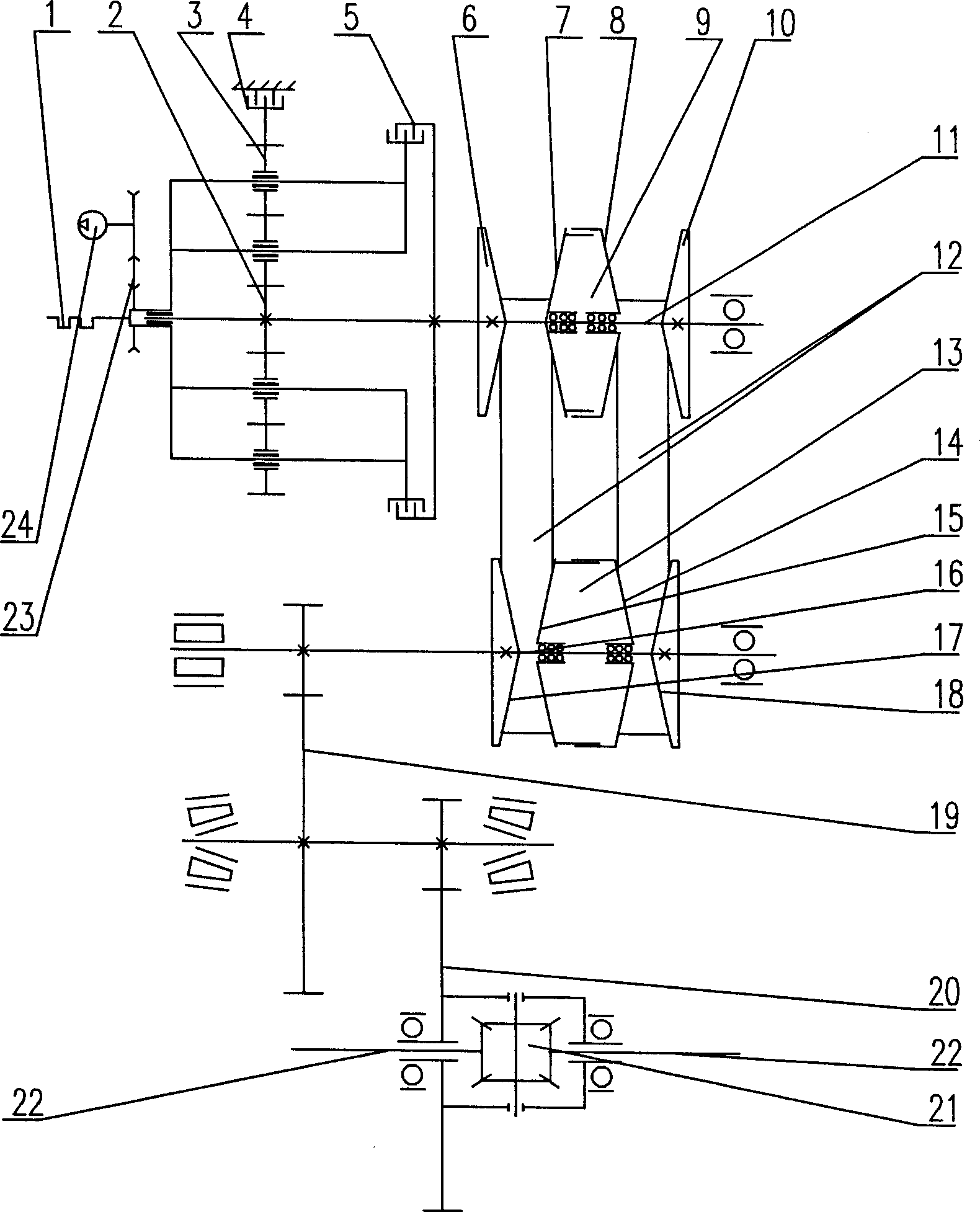

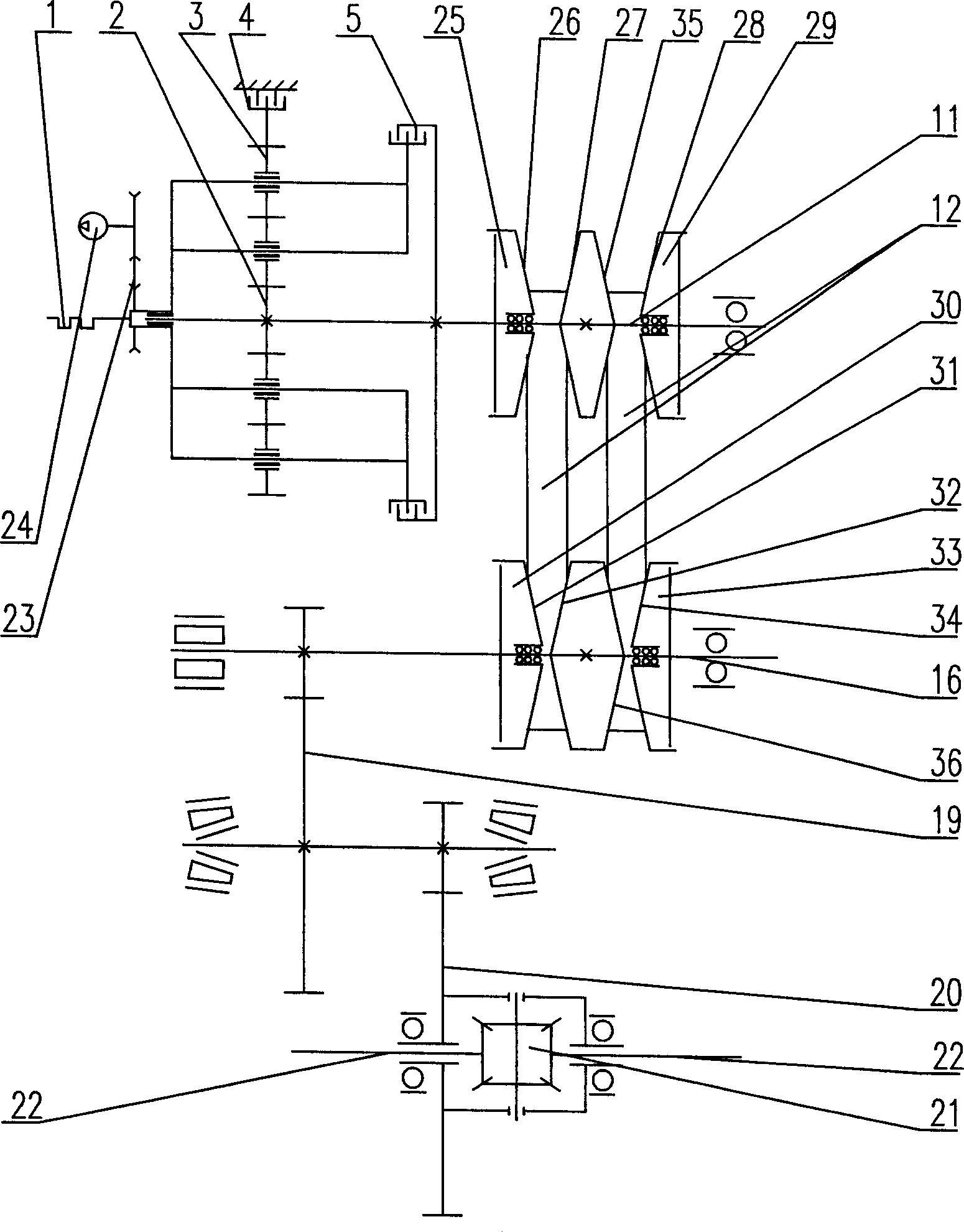

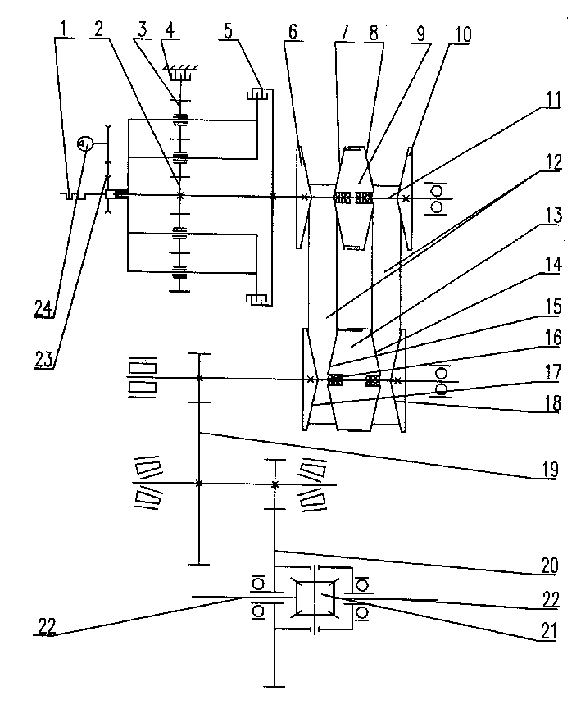

[0013] The present invention will be further described in conjunction with the embodiment that accompanying drawing provides, as appended figure 1 As shown: the engine output shaft 1 is linked with the forward gear clutch provided in the gearbox, and the power is transmitted to the oil pump 24 through the sprocket transmission pair 23, the forward gear clutch hub is linked with the gearbox main shaft 11 and the active cone-disk part, and the active cone The disk part includes two fixed cones 6, 10 arranged on both sides and two moving cones 7, 8 arranged in opposite directions. The fixed cone 6 is integrated with the gearbox main shaft 11, and the fixed cone 10 and The gearbox main shaft 11 is keyed and fixed with nuts, and the moving cones 7, 8 are keyed with the main shaft 11 and can move axially along the main shaft 11. A pressure cylinder 9 is arranged in the middle of the moving cone. Equally driven cone part also comprises the fixed cone 17,18 that is arranged on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com