Defrosting device for evaporator of electric refrigerator

A technology for evaporators and refrigerators, applied in defrosting, household refrigeration equipment, damage protection, etc., can solve the problems of blocked drainage pipe 26, increased cost, and reduced defrosting effect, so as to reduce the number of parts and reduce heat loss , Good defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

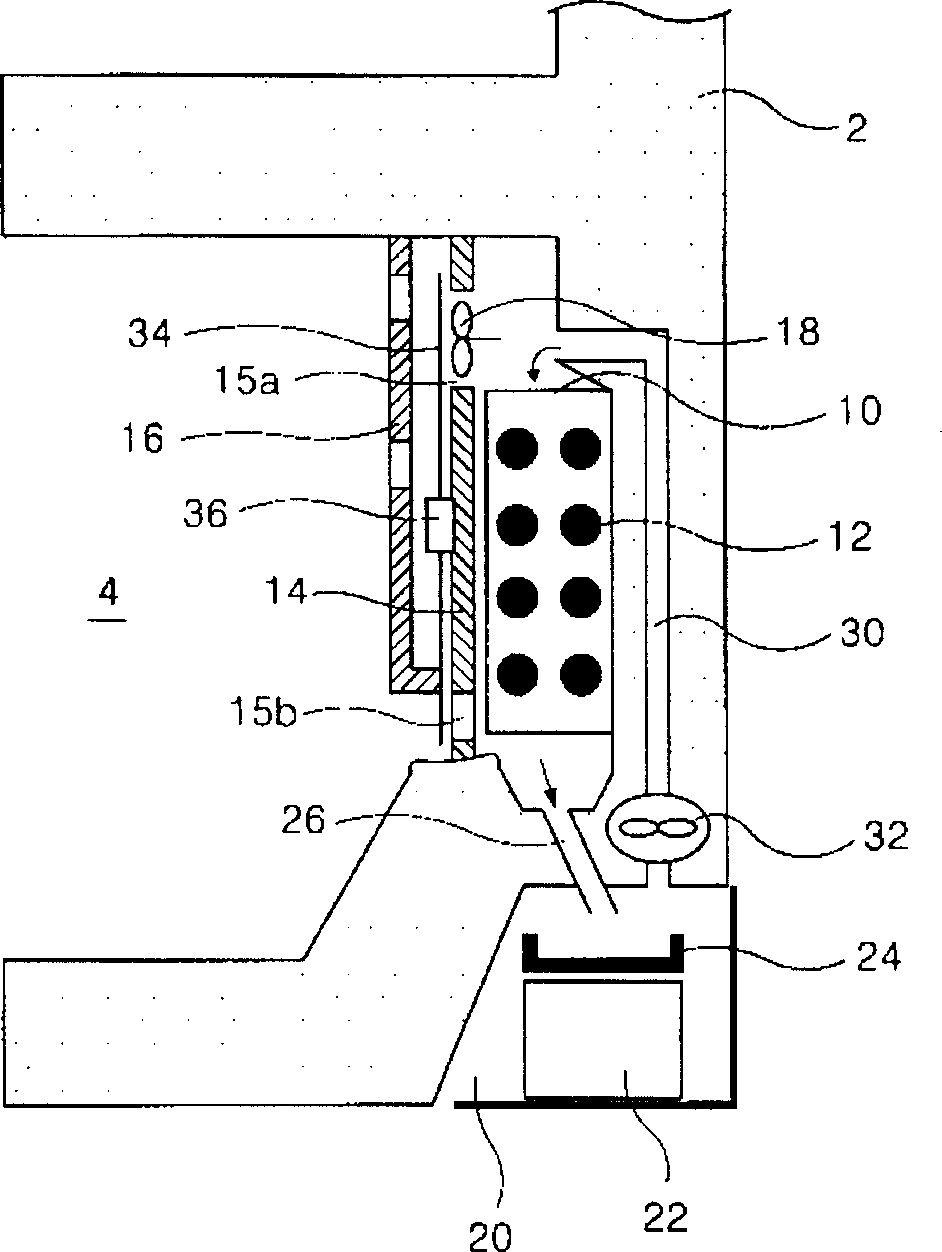

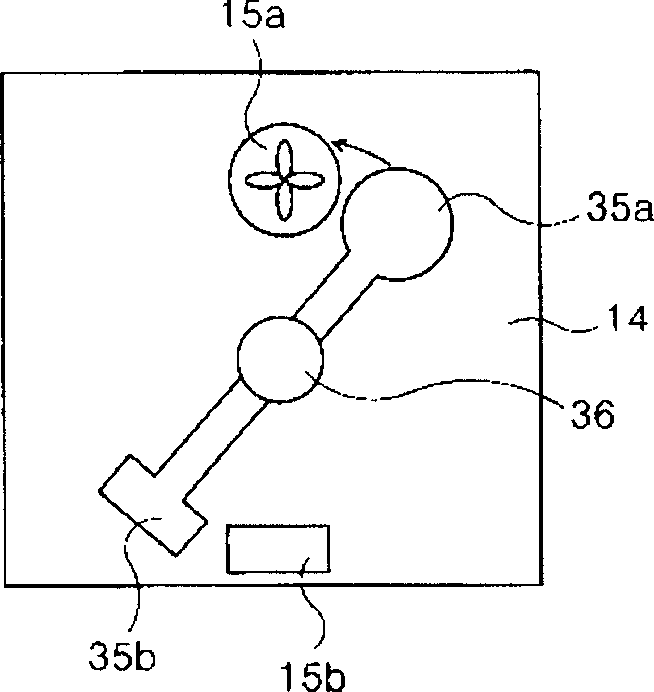

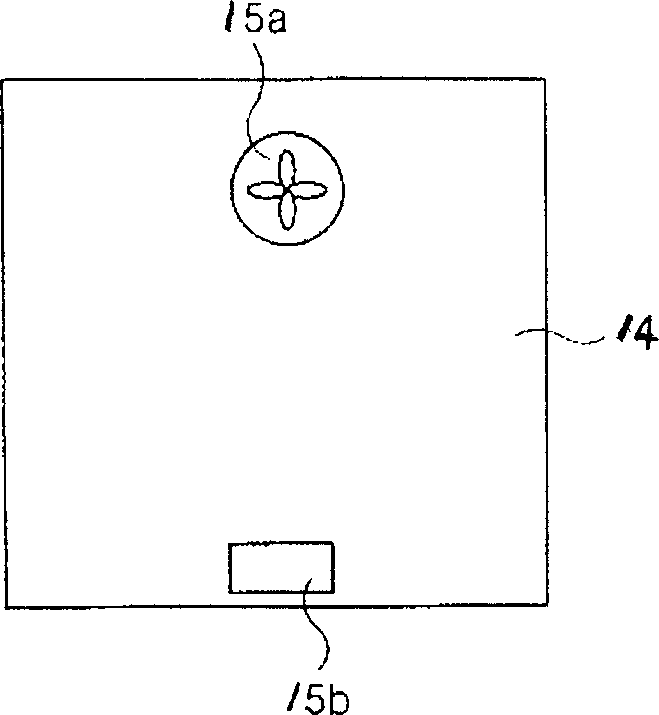

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings: image 3 , 4 As shown, there is a storage room 4 in the refrigerator casing 2 . The storage room 4 is maintained at a constant temperature by cold air generated in the refrigeration cycle.

[0014] The partition plate 14 and the fence 16 separate the storage room 4 from the evaporator 10, and the evaporator 10 at the rear end of the storage room 4 is bent at a certain interval to form a refrigerant pipeline 12 with a refrigerant flow inside. The upper end of the partition plate 14 has an output port 15a for outputting cold air to the storage chamber 4, and the lower end has an air inlet 15b for returning cold air to the lower end of the evaporator 10.

[0015] The lower side of the refrigerator box 2 is a machine room 20 . Parts such as compressor 22, condenser (not shown in the figure) and frost water basin 24 necessary for refrigerator operation are house...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com