Manual rotary devices of sewing machines

A technology of rotating device and sewing machine, which is applied in the direction of sewing machine protection device, sewing machine control device, sewing machine components, etc., which can solve the problems of difficult manual operation and fastening state, and achieve good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

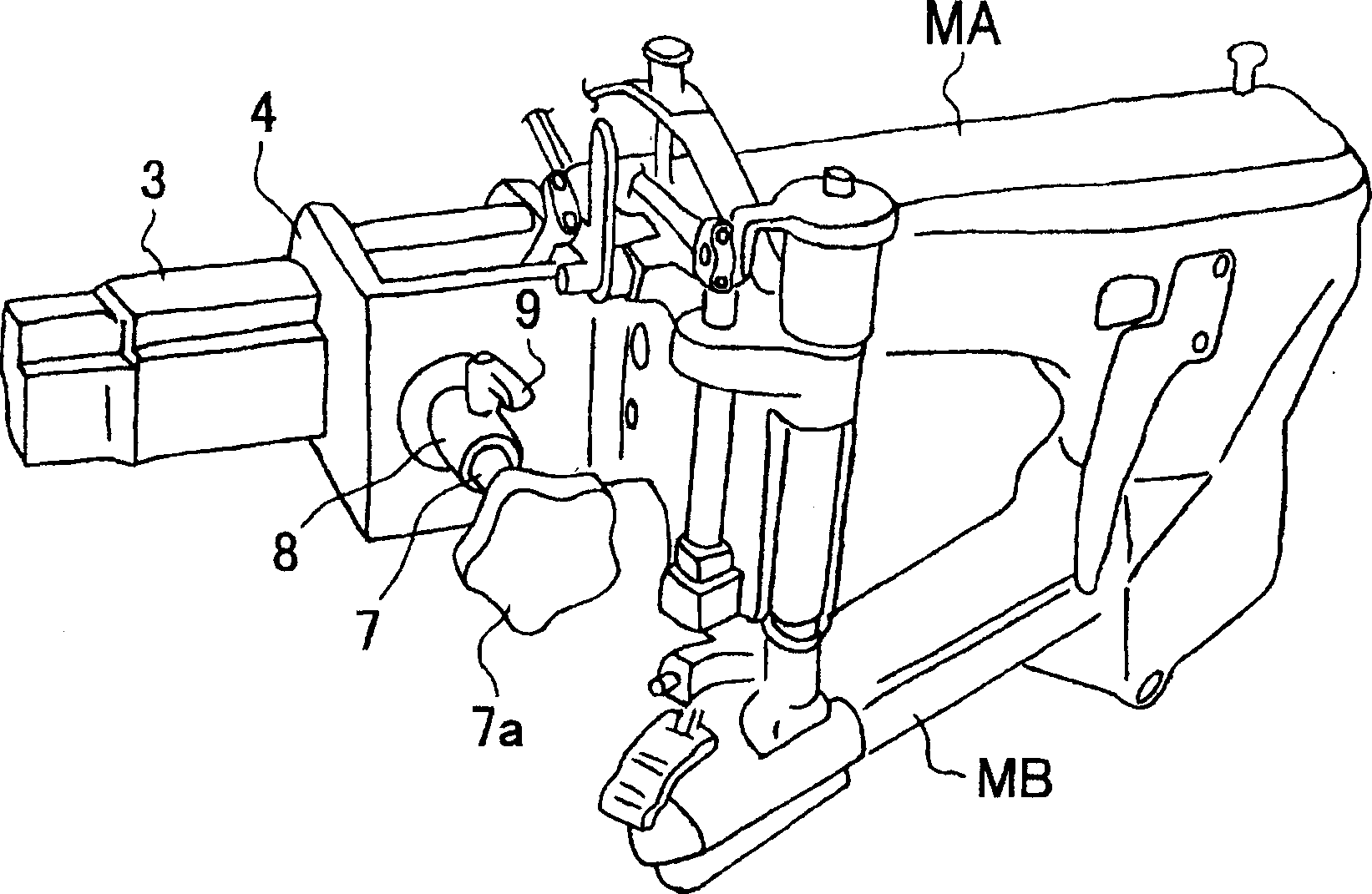

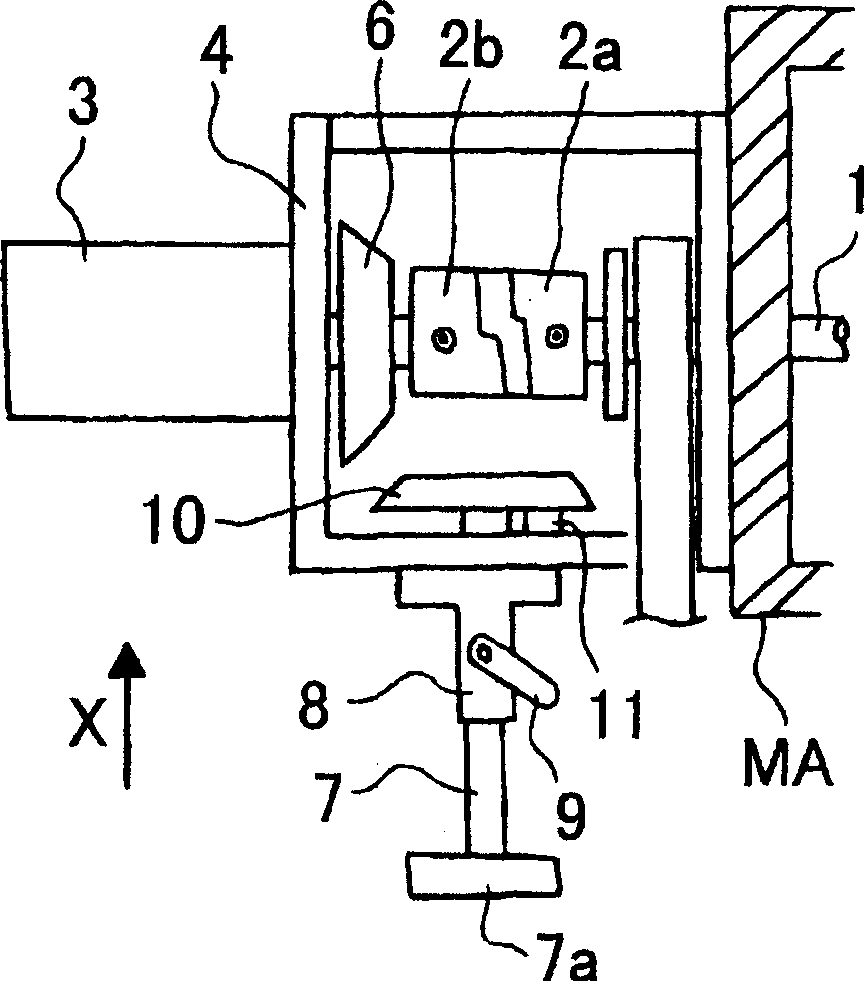

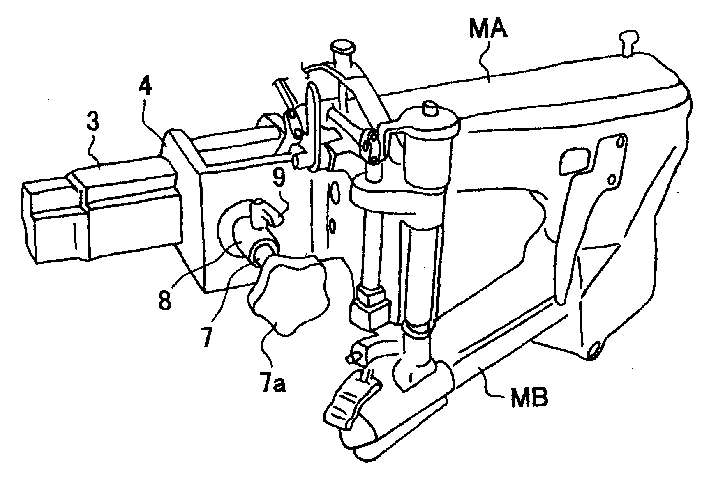

[0010] Embodiments of the present invention will be described below using the drawings. The sewing machine arm MA extends in a direction intersecting the longitudinal direction of the sewing machine head MB, and the operator stands on the right side of the continuation of both, and performs sewing work facing the longitudinal direction of the sewing machine head MB. The upper shaft 1 is fitted in the sewing machine arm MA, and is connected to a lower shaft (not shown) included in the sewing machine head MB via a link or the like. The upper shaft 1 is connected to the sewing machine motor 3 through couplings 2a, 2b. The sewing machine motor 3 is fixed to a bracket 4 attached to the sewing machine arm MA, and is located outside the sewing machine arm MA. The output shaft 5 of the sewing machine motor 3 has a bevel gear 6 (clutch plate).

[0011] A bearing 8 for supporting the manual pulley shaft 7 is provided on the front surface of the bracket 4 . The manual pulley shaft 7 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com