Flue diluted and mixed turbulent flow stepped sampler

A technique of hierarchical sampling and turbulent flow, applied in the direction of sampling devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

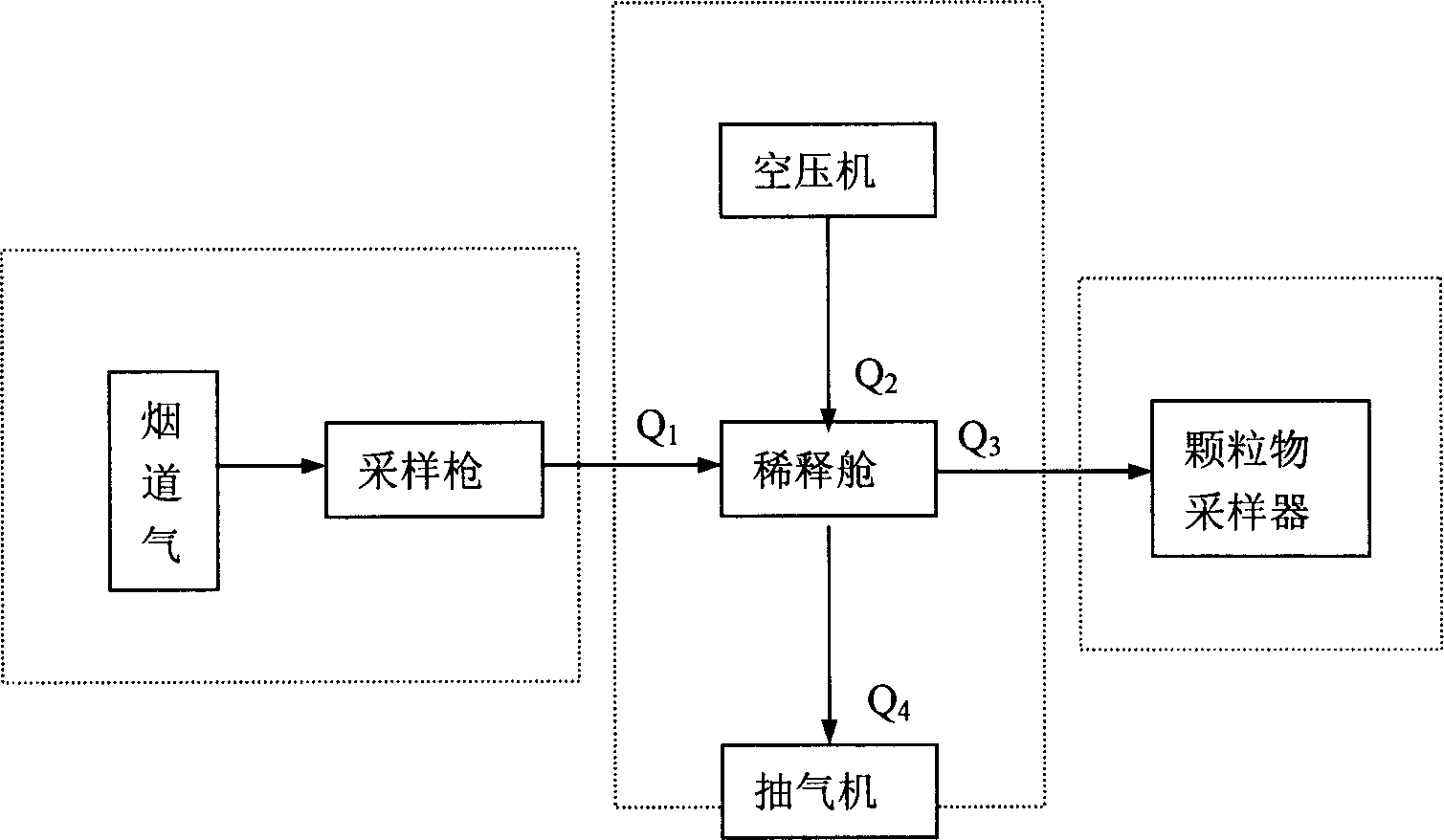

Method used

Image

Examples

Embodiment

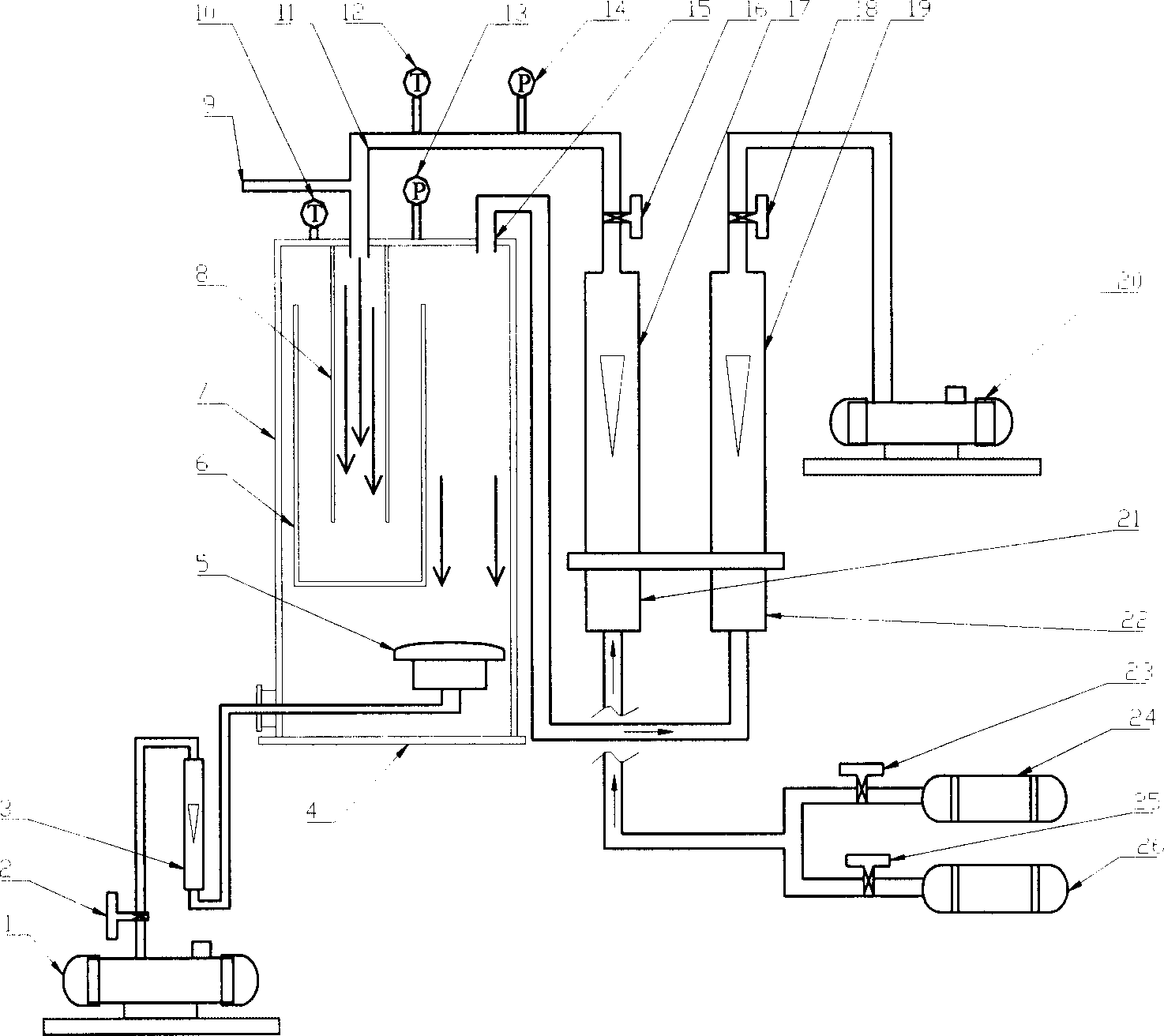

[0036] Specific sampling steps:

[0037] (1) Close the flue gas inlet valve 9, start the air compressors 24 and 26, adjust the compressor air valves 23, 25 and 16, so that a certain flow of dry and clean compressed air enters the dilution cabin, and record the incoming air flow Q 2 .

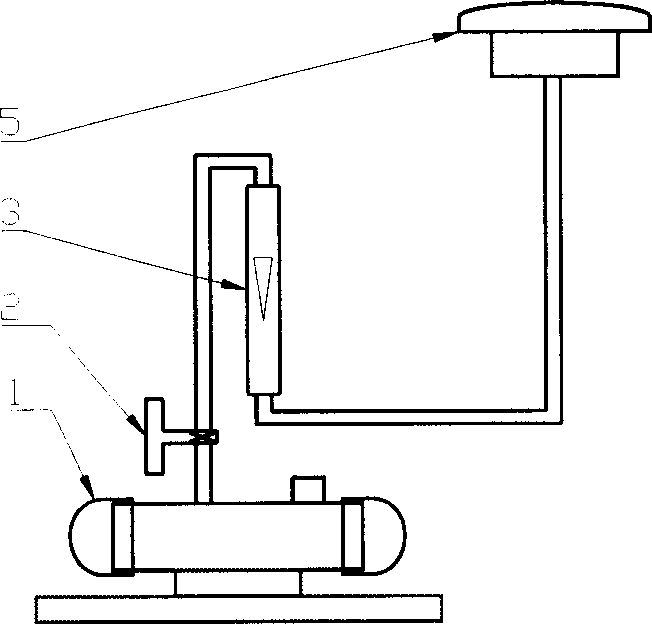

[0038] (2) Start the sampling vacuum pump 1 and adjust the exhaust valve 2 to adjust the flow meter 3 to a predetermined flow value. The sampling membrane with the cutting head installed is used for sampling at this flow rate.

[0039](3) Start the exhaust vacuum pump 20, adjust the exhaust valve 18, adjust the pressure gauge 13 on the dilution chamber loam cake to zero, and record the flow of the flowmeter (15).

[0040] (4) Open the flue gas inlet valve (9), mainly adjust the valve (18) and adjust other valves, so that the flue gas enters the dilution chamber according to a certain flow rate, and makes the pressure gauge 13 be zero. At this time, the air intake and exhaust of the dilution ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com