Stainless sheet honeycomb panel and method for mfg. thereof

A stainless steel plate, honeycomb structure technology, applied in chemical instruments and methods, manufacturing tools, building structures, etc., can solve problems such as flake peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention, that is, a stainless steel honeycomb structure panel and its manufacturing method and device, will be described in detail below with reference to the accompanying drawings.

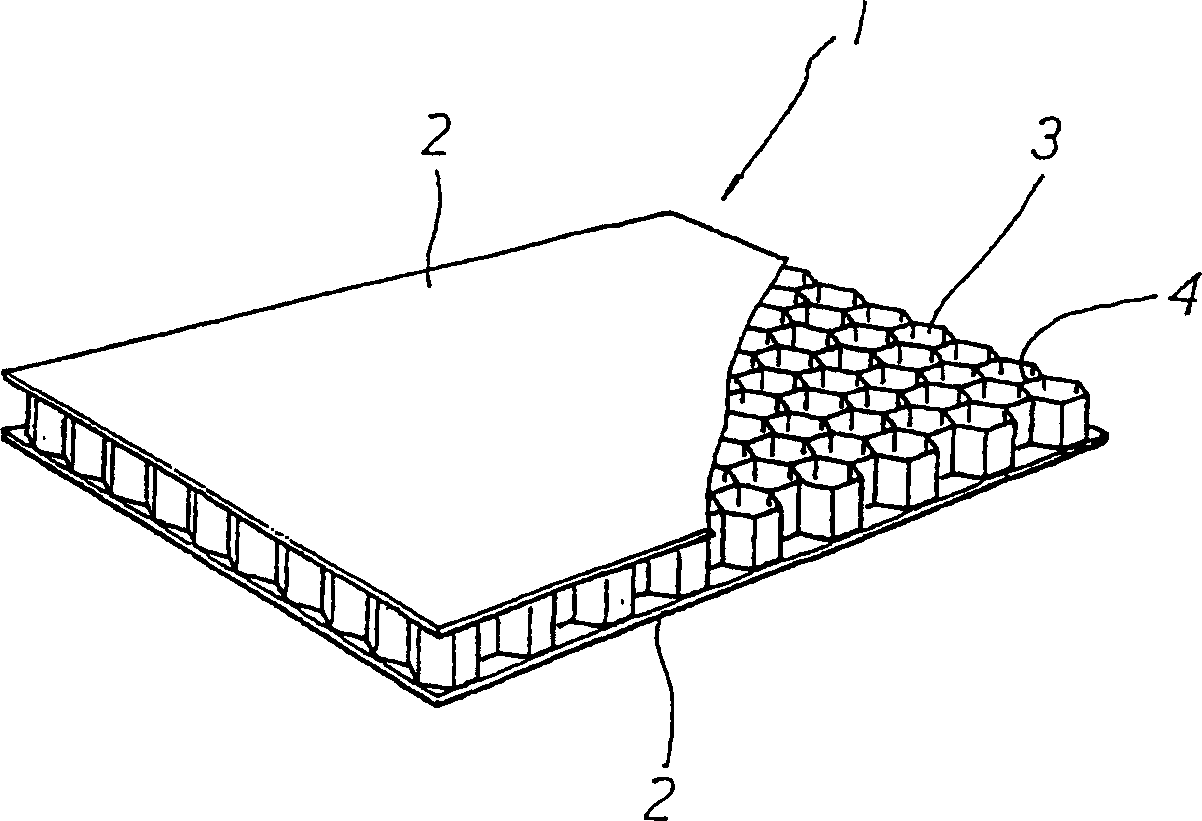

[0015] In the manufacture of the stainless steel honeycomb plate of the present invention, as figure 1 As shown, two stainless steel plates (2, 2') are placed opposite and a stainless steel honeycomb 3 is inserted between the two stainless steel plates (2, 2'), and in this way a stainless steel honeycomb structure plate 1 is formed.

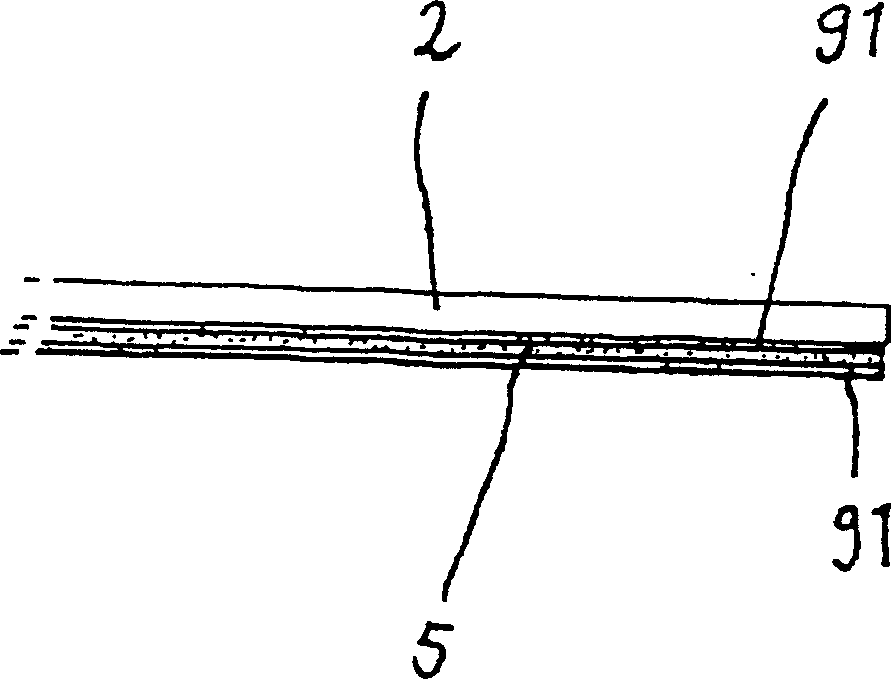

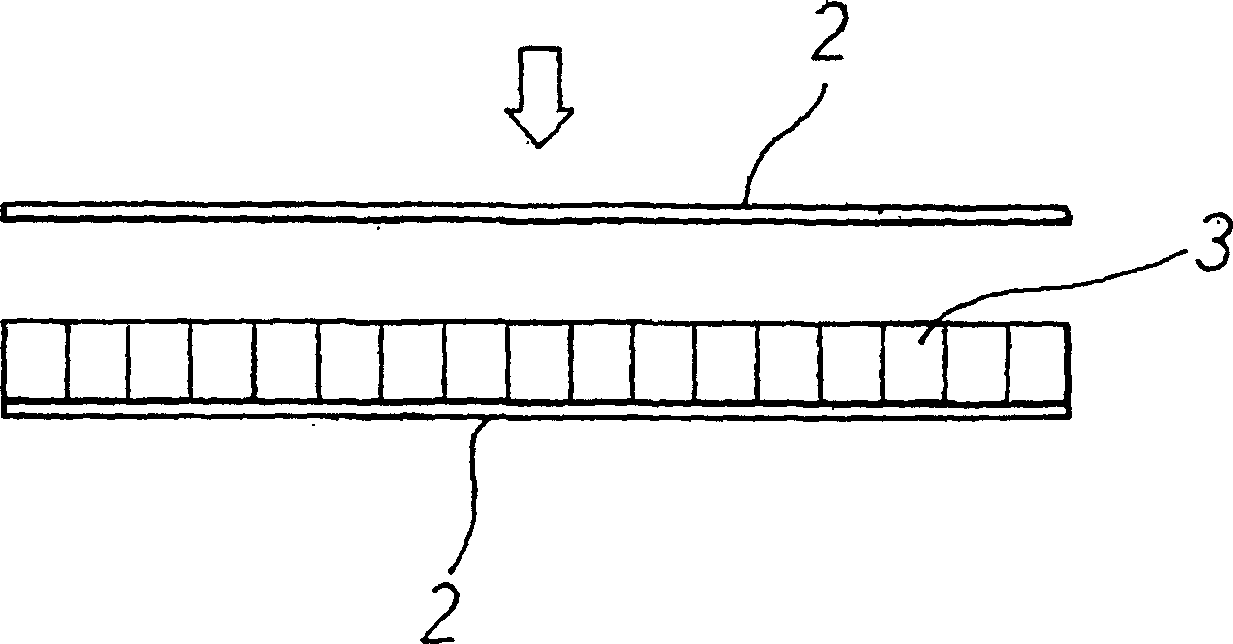

[0016] Such as figure 2 As shown, the solder 5 coated with flux 91 (a solvent) on both sides is placed between the stainless steel honeycomb 3 and the stainless steel plate 2 , and the stainless steel honeycomb 3 is also coated with flux 91 . Refer below image 3 , the bottom of the stainless steel plate 2 has solder 5 coated with flux 91 on both sides, and the top of the other stainless steel plate 2' has another so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com