Equipment for identifying working height of device conveying system and its method

A conveying system and working height technology, applied in the field of working height devices, can solve the problems of prone to errors, reduced overall test work efficiency, and more time for working height setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The examples shown in the drawings will be described in detail as preferred embodiments of the present invention. The same or similar parts in each drawing use the same reference numerals as much as possible.

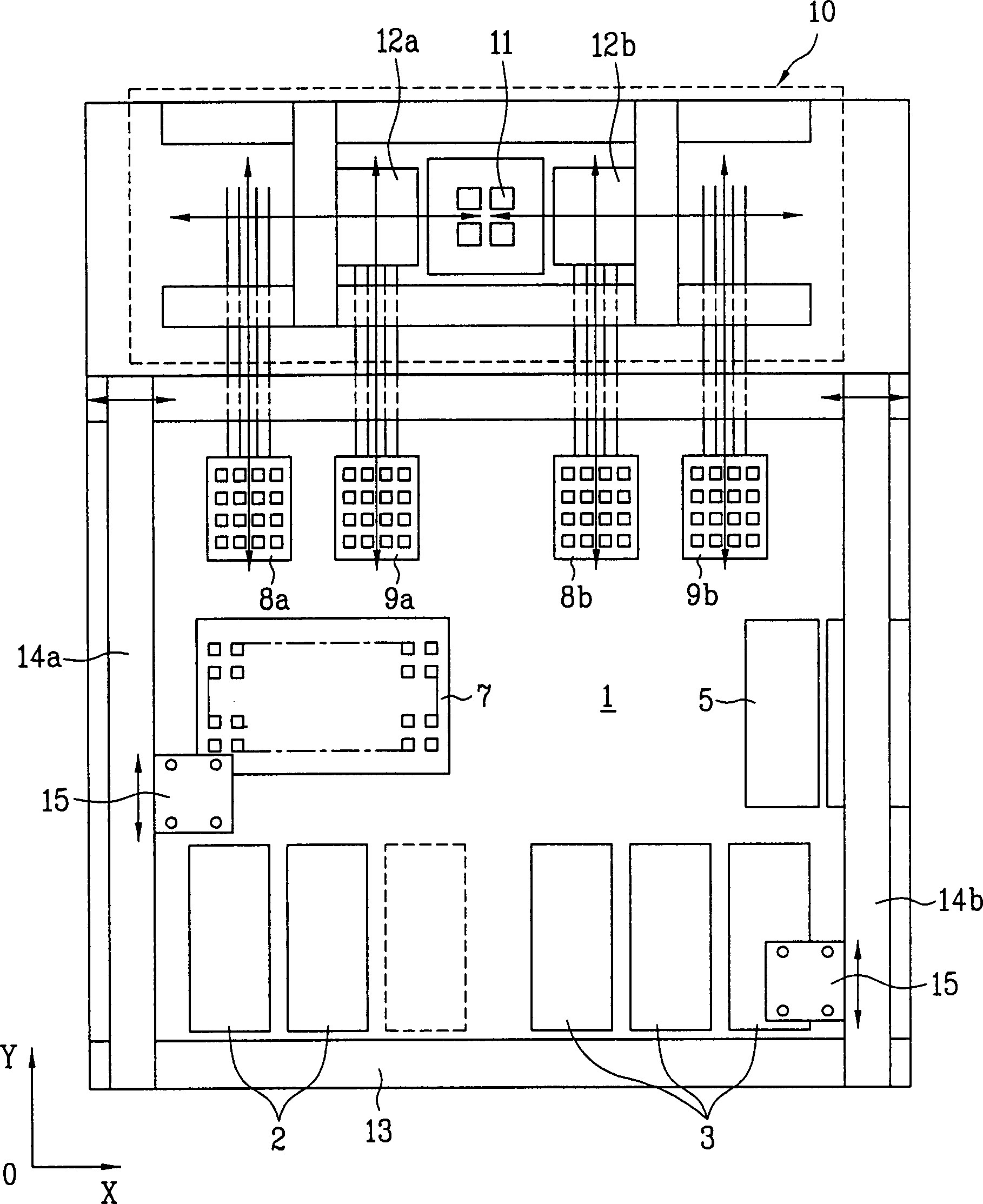

[0029] figure 2 Shown is a top view of a device transport system in a handler with a device for identifying working heights according to the invention.

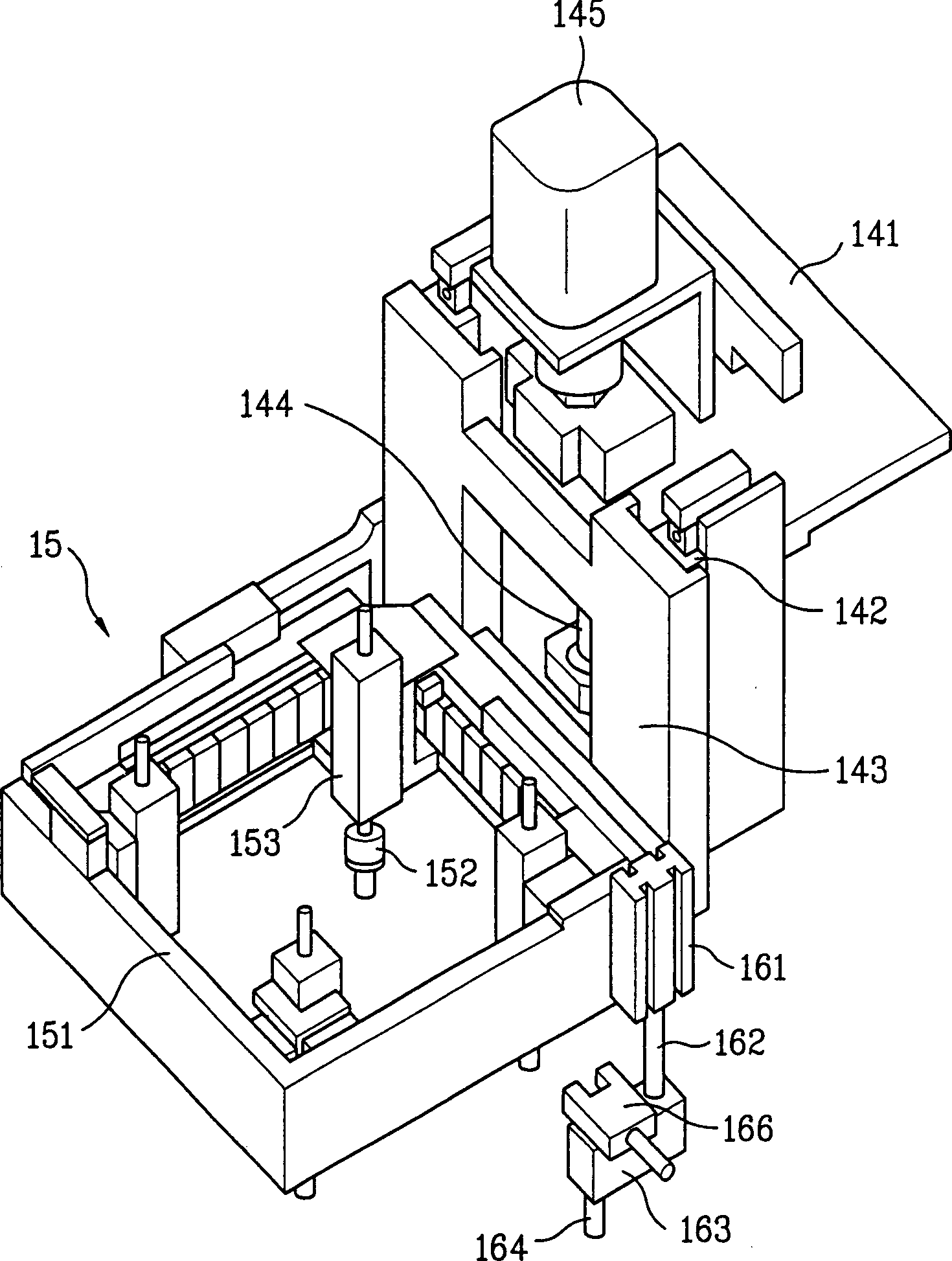

[0030] see figure 2 , on one side of a moving block 141, a support block 143 is installed, which can move along the movable frame 14a (see FIG. 1) of the processing machine, and move up and down by a guide such as a linear motion guide rail 142. On the support block 143 is mounted a device transfer unit 15 for picking up semiconductor devices.

[0031] With the help of a ball screw 144 vertically installed on the moving block 141 and a vertical axis servo motor 145 driving the ball screw 144 , the support block 143 can move up and down along the linear motion guide rail 142 .

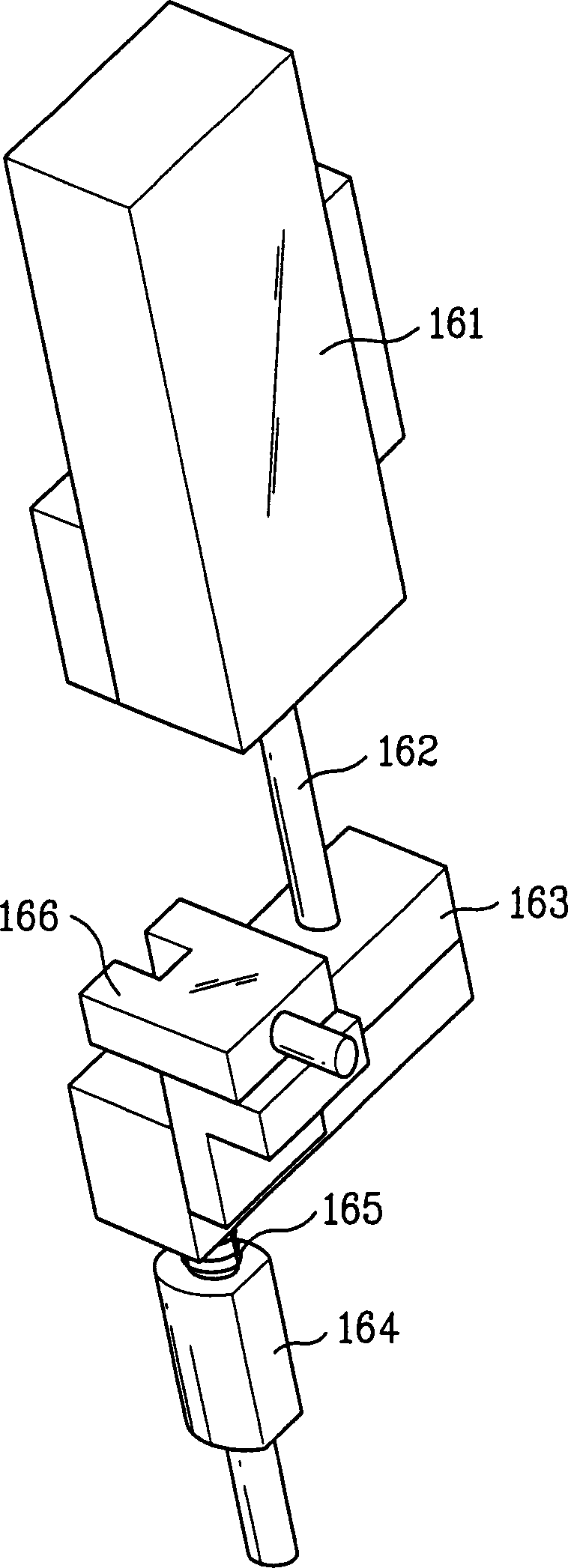

[0032] The device transfer uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com