Acoustic board

A technology of sound-absorbing panels and bottom plates, which is applied in the direction of sound insulation, sound-emitting devices, instruments, etc., can solve the problems of increasing losses, achieve the effects of preventing the spread of flames, improving sound-absorbing effects, and strong bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A detailed description of the present invention will be provided below with reference to the accompanying drawings.

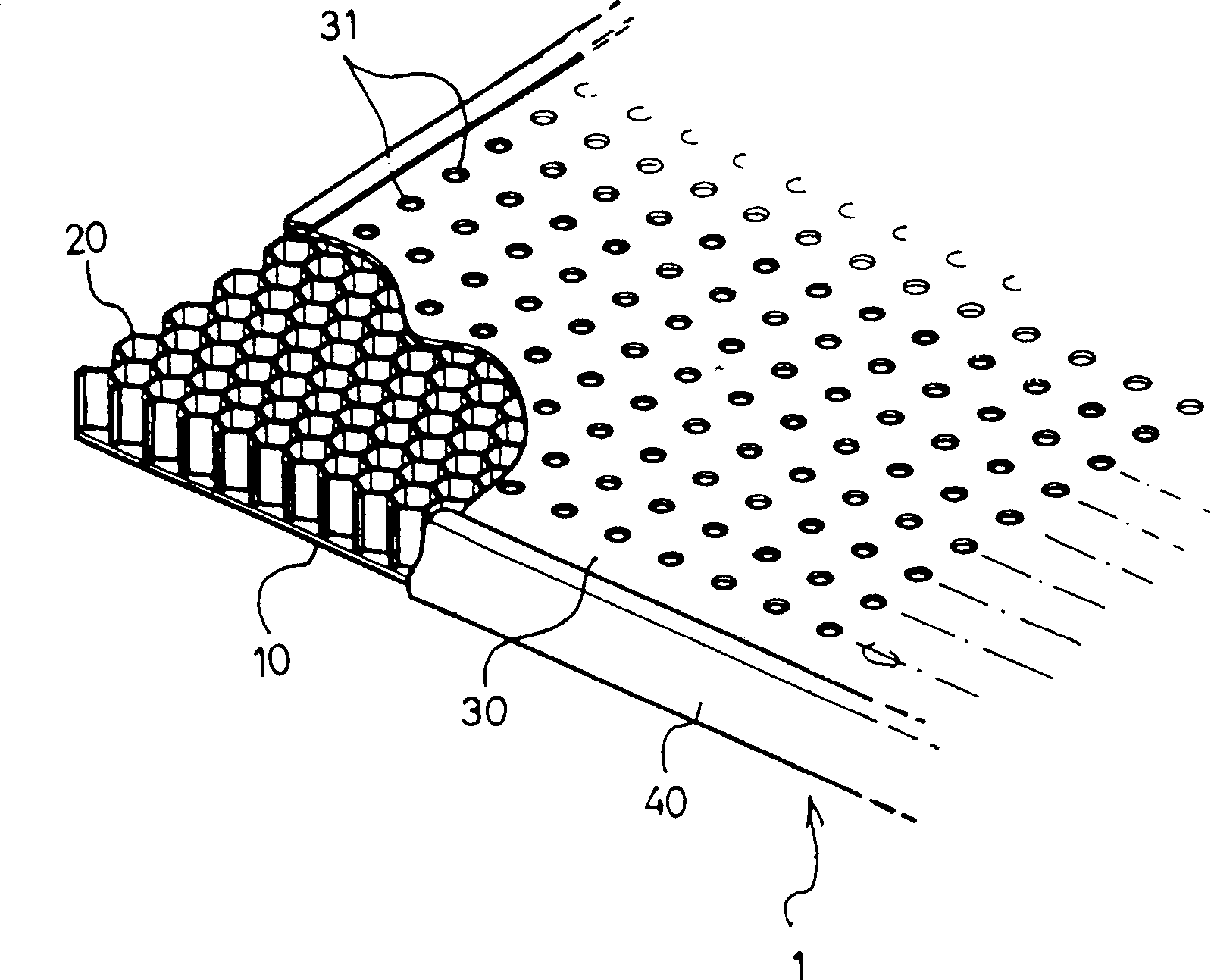

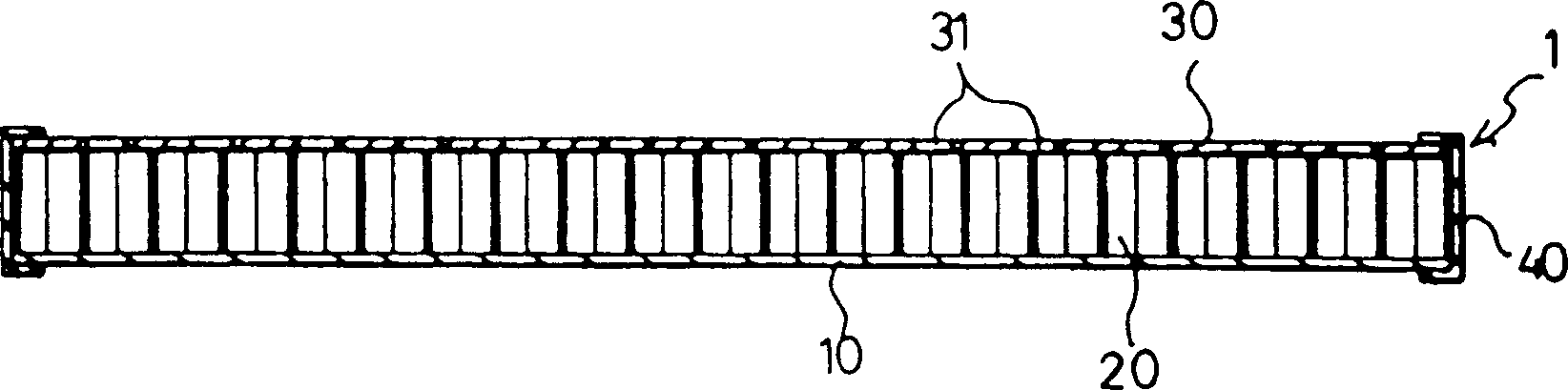

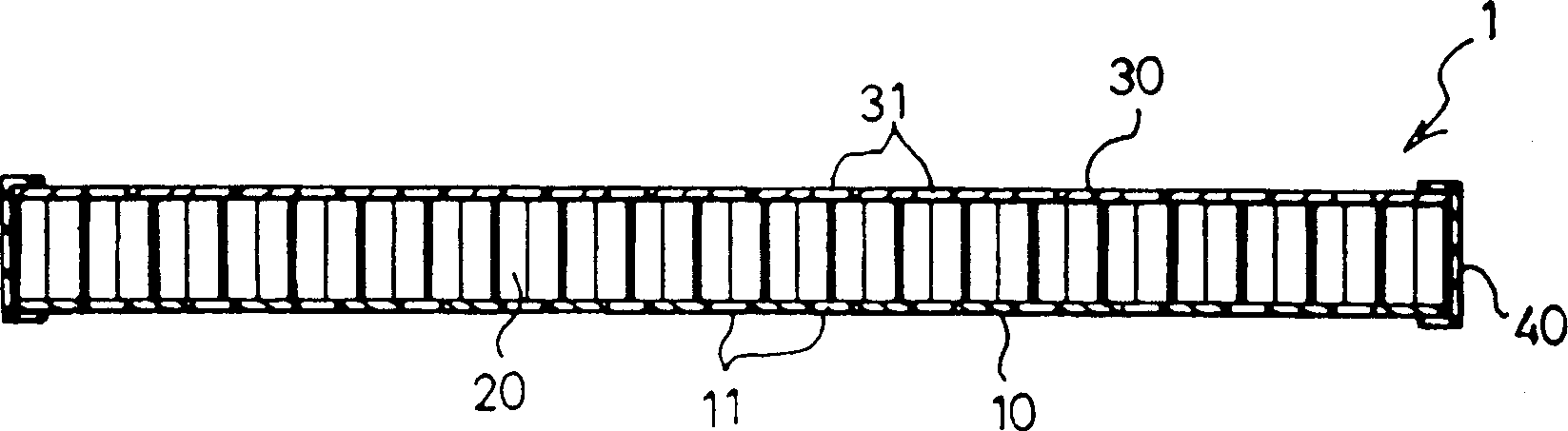

[0027] The sound-absorbing panel 1 according to the present invention includes: a floor element 10 having a predetermined size; an intermediate layer 20 having a honeycomb structure with a predetermined thickness, which is composed of a plurality of cells having a honeycomb shape and mounted on the floor element 10; The porous plate member 30 has a plurality of holes 31 and is mounted on the middle layer 20 of the honeycomb structure; the side plate member 40 closes the sides of the bottom plate member 10 and the porous plate member 30.

[0028] The intermediate layer 20 of the honeycomb structure is fixed to the porous plate member 30 and the bottom plate member 10 with an adhesive.

[0029] Such as figure 1 with 2 As shown, around the four sides of the honeycomb structure layer 20 in the middle, the upper part of the side plate element 40 is fixed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com